engine RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection Owners Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 131 of 204

13B-131V1 MR-376-X76-13B000$080.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

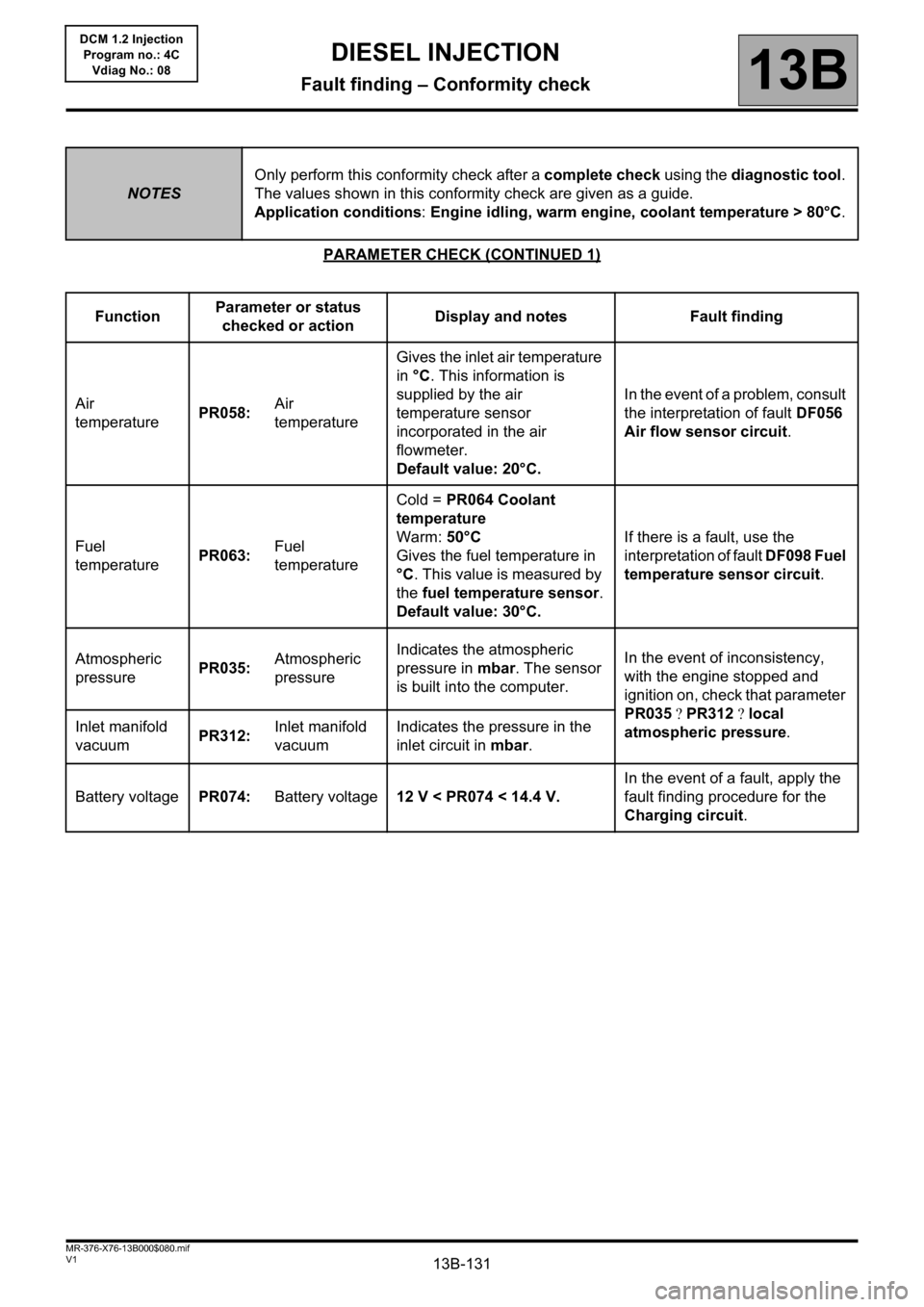

PARAMETER CHECK (CONTINUED 1)

NOTESOnly perform this conformity check after a complete check using the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine idling, warm engine, coolant temperature > 80°C.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

Air

temperaturePR058:Air

temperatureGives the inlet air temperature

in °C. This information is

supplied by the air

temperature sensor

incorporated in the air

flowmeter.

Default value: 20°C.In the event of a problem, consult

the interpretation of fault DF056

Air flow sensor circuit.

Fuel

temperaturePR063:Fuel

temperatureCold = PR064 Coolant

temperature

Warm: 50°C

Gives the fuel temperature in

°C. This value is measured by

the fuel temperature sensor.

Default value: 30°C.If there is a fault, use the

interpretation of fault DF098 Fuel

temperature sensor circuit.

Atmospheric

pressurePR035:Atmospheric

pressureIndicates the atmospheric

pressure in mbar. The sensor

is built into the computer. In the event of inconsistency,

with the engine stopped and

ignition on, check that parameter

PR035PR312local

atmospheric pressure. Inlet manifold

vacuumPR312:Inlet manifold

vacuumIndicates the pressure in the

inlet circuit in mbar.

Battery voltagePR074:Battery voltage12 V < PR074 < 14.4 V.In the event of a fault, apply the

fault finding procedure for the

Charging circuit.

Page 132 of 204

13B-132V1 MR-376-X76-13B000$080.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

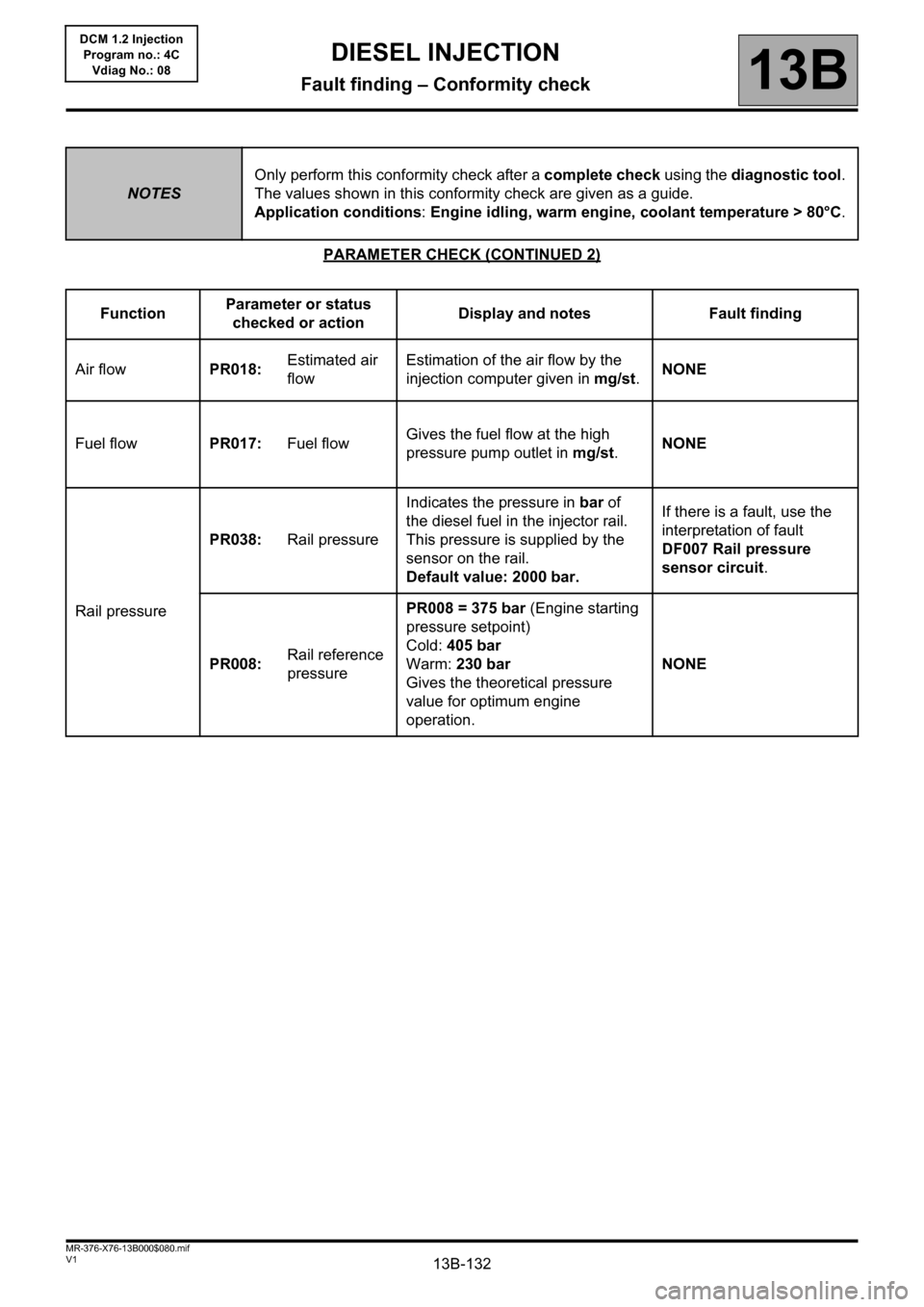

PARAMETER CHECK (CONTINUED 2)

NOTESOnly perform this conformity check after a complete check using the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine idling, warm engine, coolant temperature > 80°C.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

Air flowPR018:Estimated air

flowEstimation of the air flow by the

injection computer given in mg/st.NONE

Fuel flowPR017:Fuel flowGives the fuel flow at the high

pressure pump outlet in mg/st.NONE

Rail pressurePR038:Rail pressureIndicates the pressure in bar of

the diesel fuel in the injector rail.

This pressure is supplied by the

sensor on the rail.

Default value: 2000 bar.If there is a fault, use the

interpretation of fault

DF007 Rail pressure

sensor circuit.

PR008:Rail reference

pressurePR008 = 375 bar (Engine starting

pressure setpoint)

Cold: 405 bar

Warm: 230 bar

Gives the theoretical pressure

value for optimum engine

operation.NONE

Page 133 of 204

13B-133V1 MR-376-X76-13B000$080.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

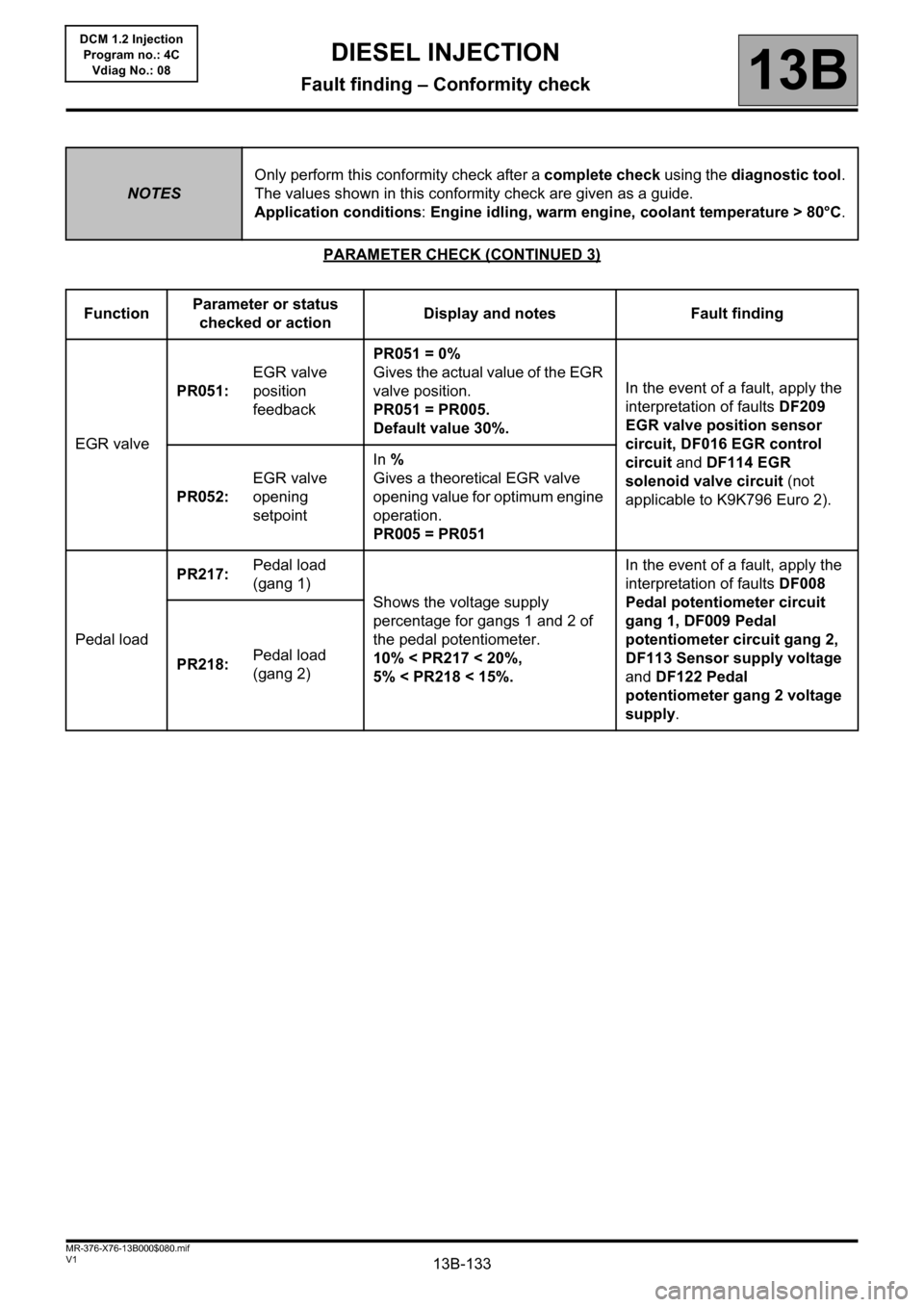

PARAMETER CHECK (CONTINUED 3)

NOTESOnly perform this conformity check after a complete check using the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine idling, warm engine, coolant temperature > 80°C.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

EGR valvePR051:EGR valve

position

feedbackPR051 = 0%

Gives the actual value of the EGR

valve position.

PR051 = PR005.

Default value 30%.In the event of a fault, apply the

interpretation of faults DF209

EGR valve position sensor

circuit, DF016 EGR control

circuit and DF114 EGR

solenoid valve circuit (not

applicable to K9K796 Euro 2). PR052:EGR valve

opening

setpointIn %

Gives a theoretical EGR valve

opening value for optimum engine

operation.

PR005 = PR051

Pedal loadPR217:Pedal load

(gang 1)

Shows the voltage supply

percentage for gangs 1 and 2 of

the pedal potentiometer.

10% < PR217 < 20%,

5% < PR218 < 15%.In the event of a fault, apply the

interpretation of faults DF008

Pedal potentiometer circuit

gang 1, DF009 Pedal

potentiometer circuit gang 2,

DF113 Sensor supply voltage

and DF122 Pedal

potentiometer gang 2 voltage

supply. PR218:Pedal load

(gang 2)

Page 134 of 204

13B-134V1 MR-376-X76-13B000$080.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

PARAMETER CHECK (CONTINUED 4)

NOTESOnly perform this conformity check after a complete check using the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine idling, warm engine, coolant temperature > 80°C.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

Sensor

voltagePR077:EGR valve

position

sensor voltage0.5 V < PR077 < 4.8 VIn the event of a fault, apply the

interpretation of fault DF209

EGR valve position sensor

circuit (not applicable to

K9K796 Euro 2).

PR344:Manifold

pressure

sensor voltageShows the voltage supplied by the

computer to feed the inlet pressure

sensor in volts.In the event of a fault, apply the

interpretation of fault DF089

Inlet manifold pressure

sensor circuit.

PR080:Rail pressure

sensor voltage0.5 V < PR080 < 4.5 V

Shows the voltage supplied by the

computer on the rail pressure

sensor in volts.

Default value: 4.5 V.In the event of a problem, apply

the interpretation of DF007 Rail

pressure sensor circuit.

PressurePR037:Refrigerant

pressure2 bar < PR037 < 27 bar

Shows the value of the refrigerant

fluid pressure in the system in bar.

Default value: 0 bar.In the event of a fault, apply the

interpretation of fault DF049

Refrigerant sensor circuit.

Air flowPR019:Linearised air

flowShows the linearised air flow in g/s.In the event of a fault, apply the

interpretation of fault DF056 Air

flow sensor circuit.

Page 135 of 204

13B-135V1 MR-376-X76-13B000$090.mif

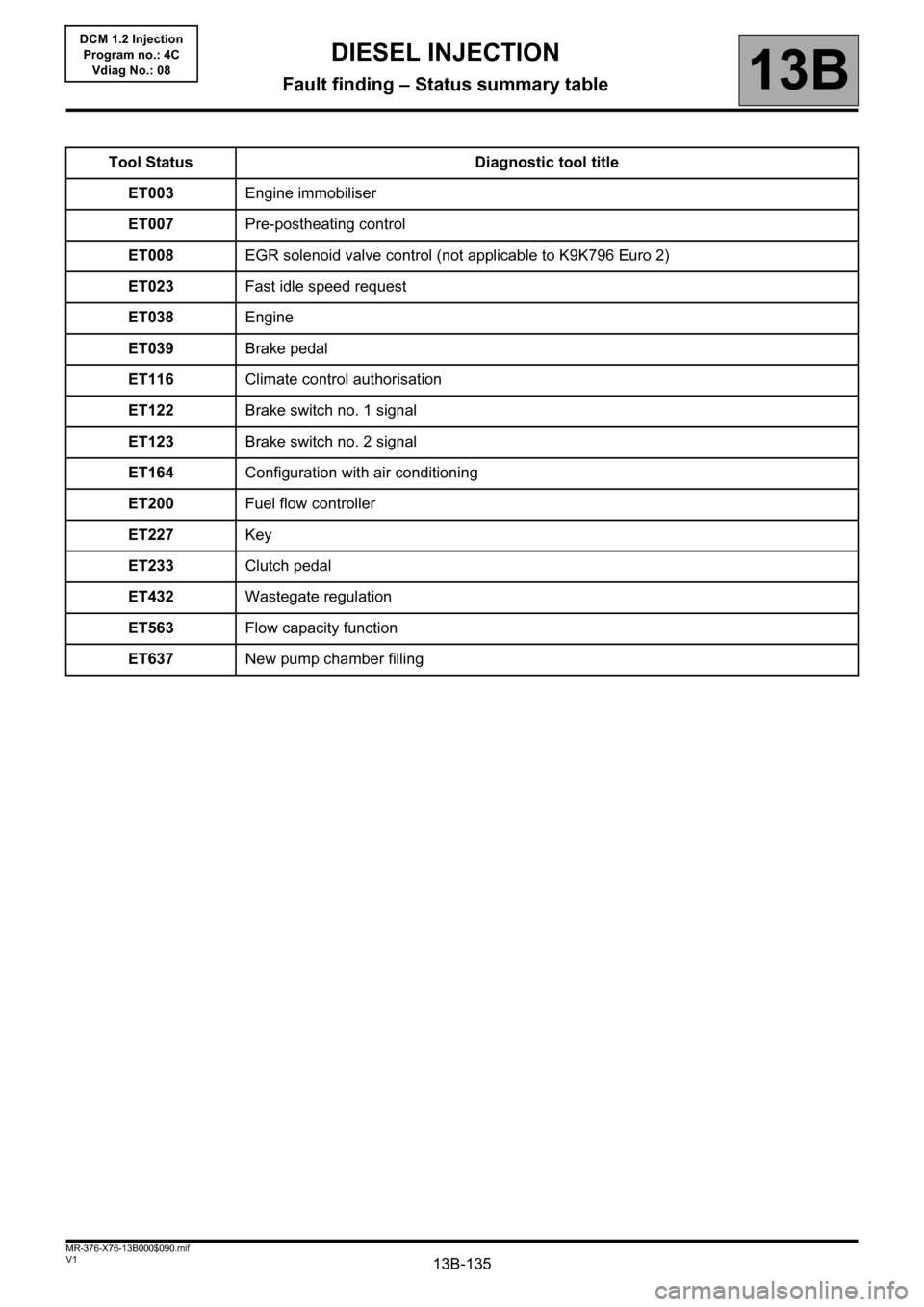

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

Tool Status Diagnostic tool title

ET003Engine immobiliser

ET007Pre-postheating control

ET008EGR solenoid valve control (not applicable to K9K796 Euro 2)

ET023Fast idle speed request

ET038Engine

ET039Brake pedal

ET116Climate control authorisation

ET122Brake switch no. 1 signal

ET123Brake switch no. 2 signal

ET164Configuration with air conditioning

ET200Fuel flow controller

ET227Key

ET233Clutch pedal

ET432Wastegate regulation

ET563Flow capacity function

ET637New pump chamber filling

DIESEL INJECTION

Fault finding – Status summary table

Page 136 of 204

13B-136

AFTER REPAIRDeal with any faults. Clear the faults from the computer memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

V1 MR-376-X76-13B000$100.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

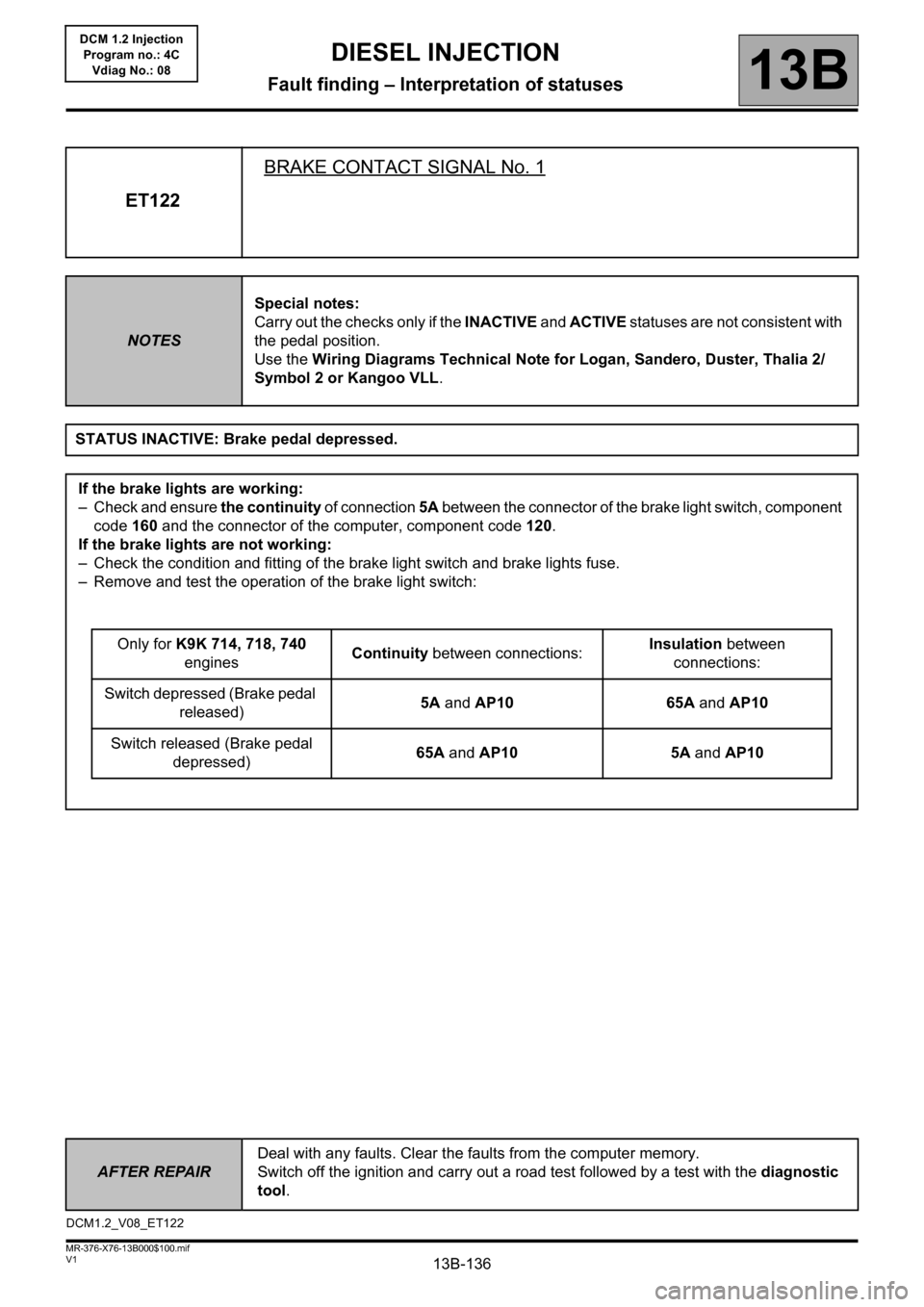

ET122BRAKE CONTACT SIGNAL No. 1

NOTESSpecial notes:

Carry out the checks only if the INACTIVE and ACTIVE statuses are not consistent with

the pedal position.

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

STATUS INACTIVE: Brake pedal depressed.

If the brake lights are working:

– Check and ensure the continuity of connection 5A between the connector of the brake light switch, component

code 160 and the connector of the computer, component code 120.

If the brake lights are not working:

– Check the condition and fitting of the brake light switch and brake lights fuse.

– Remove and test the operation of the brake light switch:

Only for K9K 714, 718, 740

enginesContinuity between connections:Insulation between

connections:

Switch depressed (Brake pedal

released)5A and AP10 65A and AP10

Switch released (Brake pedal

depressed)65A and AP10 5A and AP10

DCM1.2_V08_ET122

DIESEL INJECTION

Fault finding – Interpretation of statuses

Page 137 of 204

13B-137

AFTER REPAIRDeal with any faults. Clear the faults from the computer memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

V1 MR-376-X76-13B000$100.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

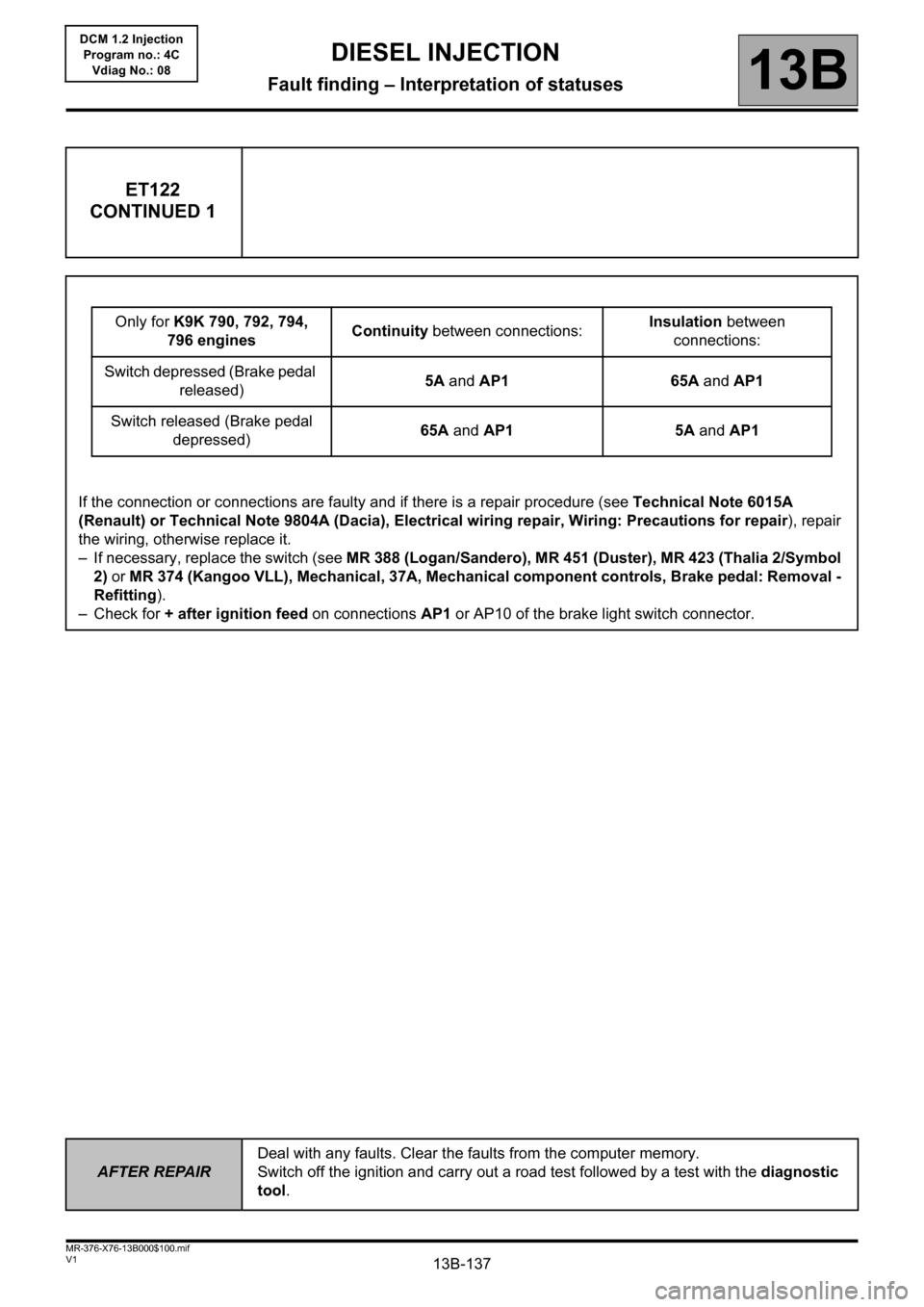

ET122

CONTINUED 1

Only for K9K 790, 792, 794,

796 enginesContinuity between connections:Insulation between

connections:

Switch depressed (Brake pedal

released)5A and AP1 65A and AP1

Switch released (Brake pedal

depressed)65A and AP1 5A and AP1

If the connection or connections are faulty and if there is a repair procedure (see Technical Note 6015A

(Renault) or Technical Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair

the wiring, otherwise replace it.

– If necessary, replace the switch (see MR 388 (Logan/Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol

2) or MR 374 (Kangoo VLL), Mechanical, 37A, Mechanical component controls, Brake pedal: Removal -

Refitting).

– Check for + after ignition feed on connections AP1 or AP10 of the brake light switch connector.

Page 138 of 204

13B-138

AFTER REPAIRDeal with any faults. Clear the faults from the computer memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

V1 MR-376-X76-13B000$100.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

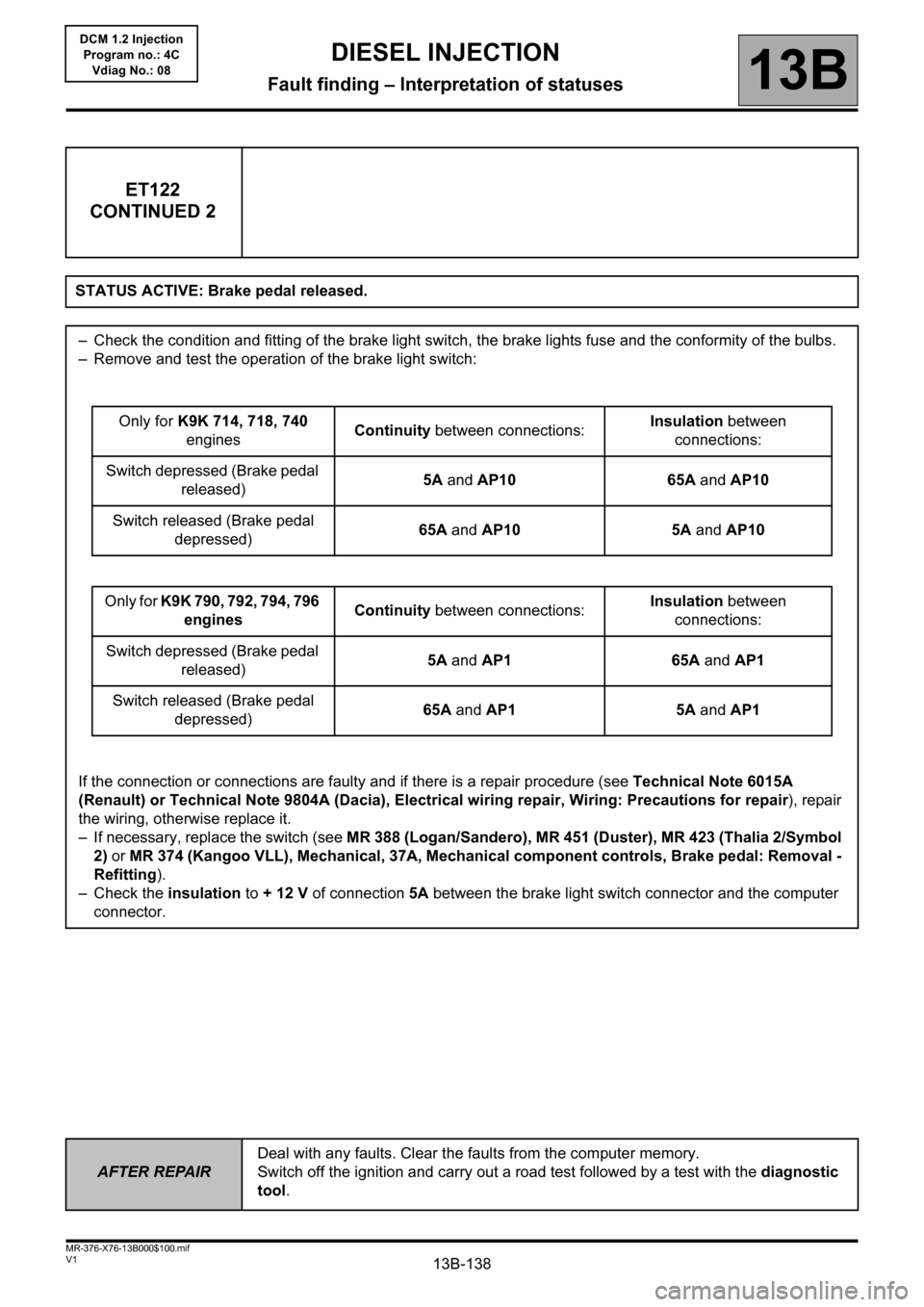

ET122

CONTINUED 2

STATUS ACTIVE: Brake pedal released.

– Check the condition and fitting of the brake light switch, the brake lights fuse and the conformity of the bulbs.

– Remove and test the operation of the brake light switch:

Only for K9K 714, 718, 740

enginesContinuity between connections:Insulation between

connections:

Switch depressed (Brake pedal

released)5A and AP10 65A and AP10

Switch released (Brake pedal

depressed)65A and AP10 5A and AP10

Only for K9K 790, 792, 794, 796

enginesContinuity between connections:Insulation between

connections:

Switch depressed (Brake pedal

released)5A and AP1 65A and AP1

Switch released (Brake pedal

depressed)65A and AP1 5A and AP1

If the connection or connections are faulty and if there is a repair procedure (see Technical Note 6015A

(Renault) or Technical Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair

the wiring, otherwise replace it.

– If necessary, replace the switch (see MR 388 (Logan/Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol

2) or MR 374 (Kangoo VLL), Mechanical, 37A, Mechanical component controls, Brake pedal: Removal -

Refitting).

– Check the insulation to + 12 V of connection 5A between the brake light switch connector and the computer

connector.

Page 139 of 204

13B-139

AFTER REPAIRDeal with any faults. Clear the faults from the computer memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

V1 MR-376-X76-13B000$100.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

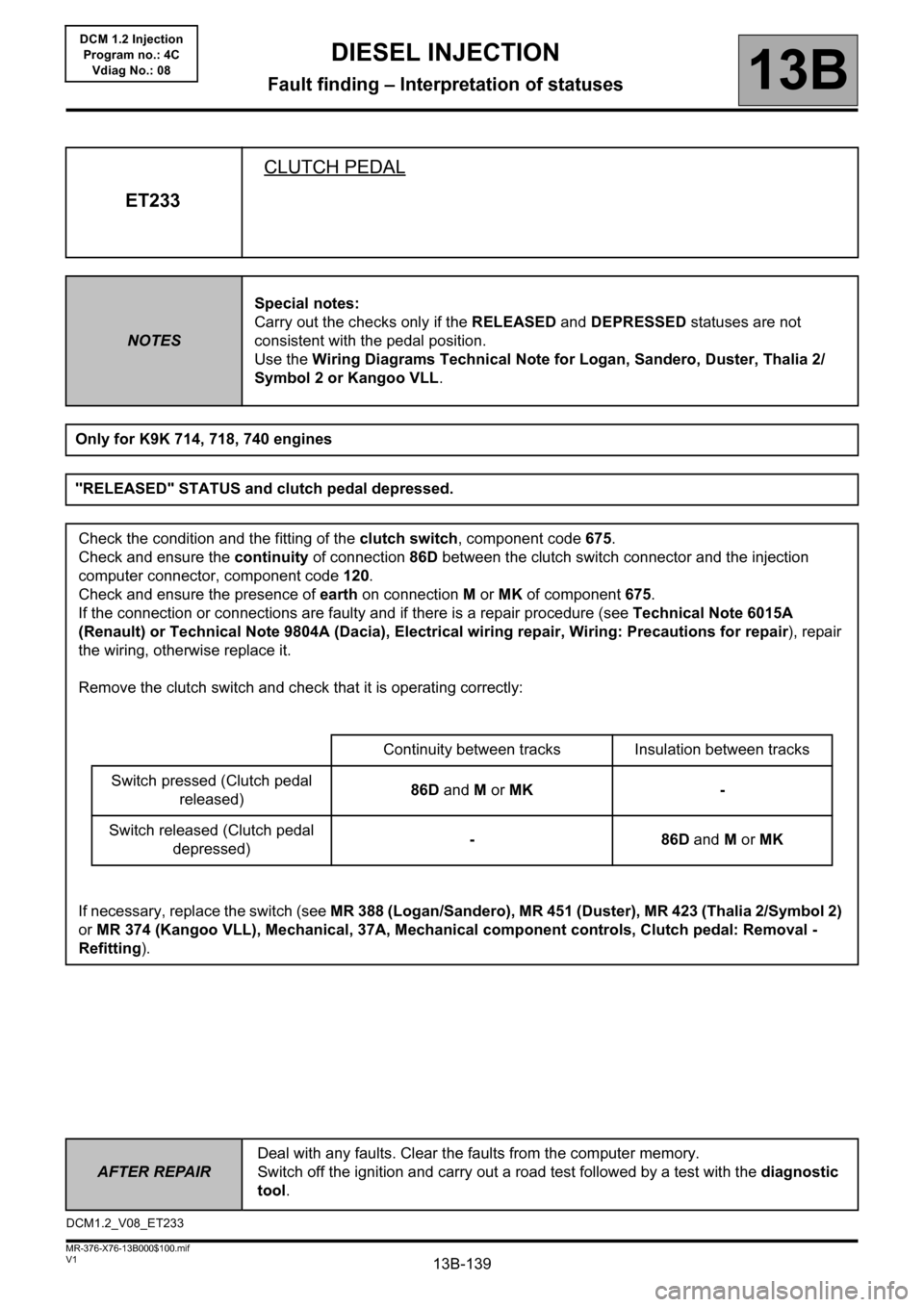

ET233CLUTCH PEDAL

NOTESSpecial notes:

Carry out the checks only if the RELEASED and DEPRESSED statuses are not

consistent with the pedal position.

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Only for K9K 714, 718, 740 engines

"RELEASED" STATUS and clutch pedal depressed.

Check the condition and the fitting of the clutch switch, component code 675.

Check and ensure the continuity of connection 86D between the clutch switch connector and the injection

computer connector, component code 120.

Check and ensure the presence of earth on connection M or MK of component 675.

If the connection or connections are faulty and if there is a repair procedure (see Technical Note 6015A

(Renault) or Technical Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair

the wiring, otherwise replace it.

Remove the clutch switch and check that it is operating correctly:

Continuity between tracks Insulation between tracks

Switch pressed (Clutch pedal

released)86D and M or MK -

Switch released (Clutch pedal

depressed)-86D and M or MK

If necessary, replace the switch (see MR 388 (Logan/Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol 2)

or MR 374 (Kangoo VLL), Mechanical, 37A, Mechanical component controls, Clutch pedal: Removal -

Refitting).

DCM1.2_V08_ET233

Page 141 of 204

13B-141V1 MR-376-X76-13B000$110.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

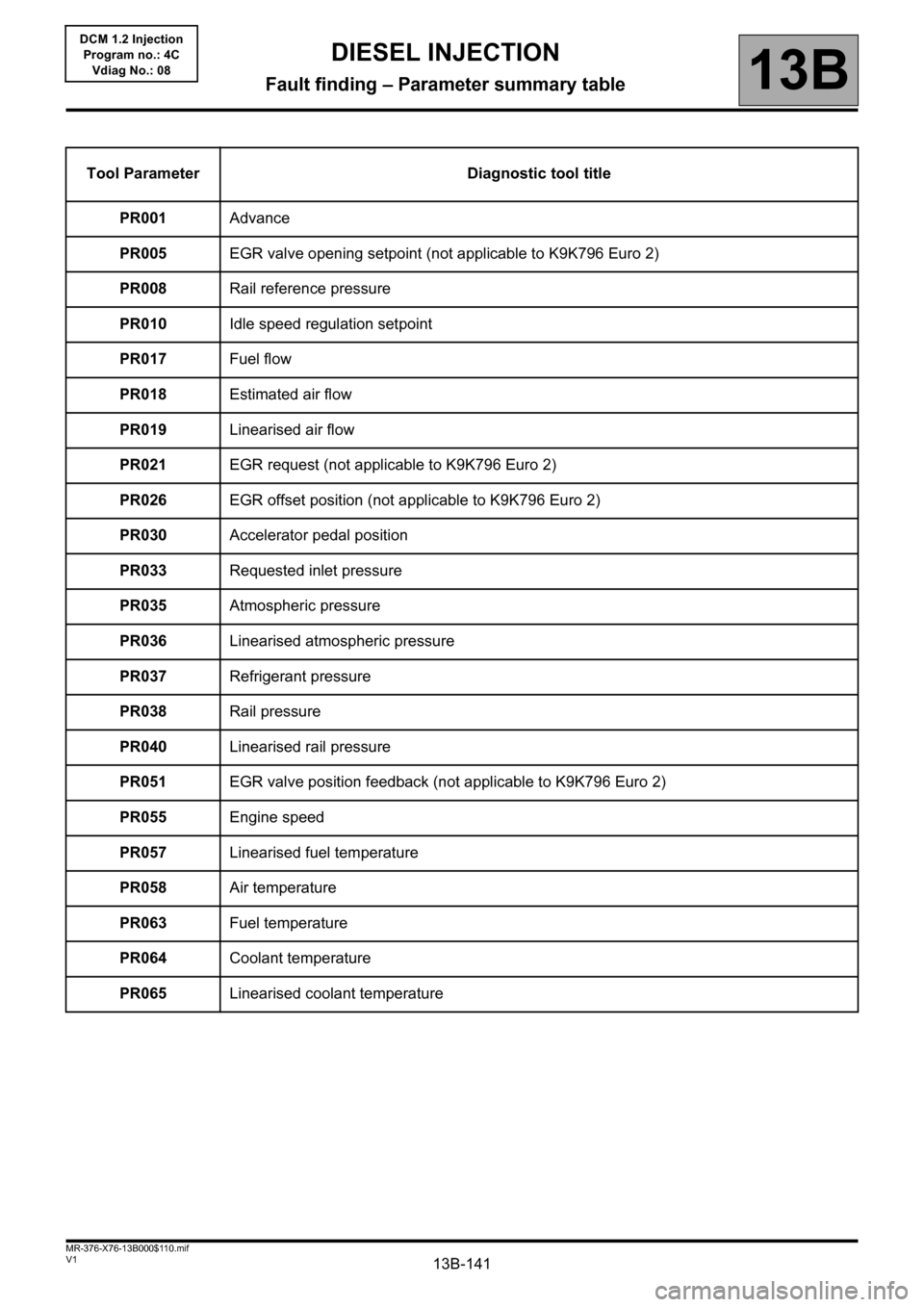

Tool Parameter Diagnostic tool title

PR001Advance

PR005EGR valve opening setpoint (not applicable to K9K796 Euro 2)

PR008Rail reference pressure

PR010Idle speed regulation setpoint

PR017Fuel flow

PR018Estimated air flow

PR019Linearised air flow

PR021EGR request (not applicable to K9K796 Euro 2)

PR026EGR offset position (not applicable to K9K796 Euro 2)

PR030Accelerator pedal position

PR033Requested inlet pressure

PR035Atmospheric pressure

PR036Linearised atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR040Linearised rail pressure

PR051EGR valve position feedback (not applicable to K9K796 Euro 2)

PR055Engine speed

PR057Linearised fuel temperature

PR058Air temperature

PR063Fuel temperature

PR064Coolant temperature

PR065Linearised coolant temperature

DIESEL INJECTION

Fault finding – Parameter summary table