ESP RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 74 of 204

13B-74

AFTER

REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

DF052

PRESENT

OR

STOREDINJECTORS CONTROL CIRCUIT

CC.1: Short circuit to + 12 V

CC.0: Short circuit to earth

NOTESPriorities when dealing with a number of faults:

In the event of a combination of faults DF052,

– DF026 Cylinder 1 injector circuit control,

– DF027 Cylinder 2 injector circuit control,

– DF028 Cylinder 3 injector circuit control, and

– DF029 Cylinder 4 injector circuit control.

The fault finding procedure remains the same for DF026 to DF027 which is used to

identify the faulty injector.

Special notes:

When the fault appears, there is engine noise, unstable engine speed, reduced engine

performance and the level 2 warning light comes on.

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Switch off the ignition.

Check the condition and connection of the injector connectors, component codes 193, 194, 195 and 196.

Check the connection and condition of the injection computer connector, component code 120.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise

replace the wiring.

Switch off the ignition.

Disconnect the injectors (or the injector identified by DF026, DF027, DF028 and DF029) and switch on the ignition

again.

Using the diagnostic tool, check for changes to DF052.

Is DF052 present or stored?

DCM1.2_V08_DF052

Page 79 of 204

13B-79

AFTER

REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

DF056

PRESENT

OR

STOREDAIR FLOW SENSOR CIRCUIT1.DEF: Permanent low level

2.DEF: Permanent high level

3.DEF: At maximum limit

4.DEF: At minimum limit

NOTESPriorities when dealing with a number of faults:

– DF089 Inlet manifold pressure sensor circuit.

Special notes:

If fault DF056 is present: air flow regulation stops and the EGR valve is closed.

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Check the condition of the air filter, replace the air filter if necessary (see MR388 (Logan/Sandero), MR423 (Thalia

2 / Symbol 2) or MR451 (Duster), Mechanical, 12A Fuel mixture, Air filter: Removal – Refitting).

Check that the inlet manifold is not obstructed (clogged).

Run TEST 5 Inlet circuit check.

Run TEST 11 Air line at the turbocharger

Check the connection and condition of the air flowmeter connector, component code 799.

Check the condition of the injection computer connector, component code 120.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise

replace the wiring.

Check for + 12 V after ignition feed on connection 3FB (or 3FBA) of the connector of the air flowmeter,

component code 799.

Check for + 5 V on connection 3KJ of the connector of the air flowmeter, component code 799.

Check the earth on connection NH on the connector of the air flowmeter, component code 799.

If the connection(s) are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or

Technical Note 9804A (Dacia), Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

DCM1.2_V08_DF056

Page 86 of 204

13B-86

AFTER

REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

DF089

PRESENT

OR

STOREDINLET MANIFOLD PRESSURE SENSOR CIRCUIT1.DEF: Permanent low level

2.DEF: Permanent high level

3.DEF: Below minimum threshold

4.DEF: Above maximum threshold

5.DEF: Inconsistency

6.DEF: At maximum stop

7.DEF: At minimum stop

NOTESPriority when dealing with a number of faults:

– DF113 Sensor supply voltage.

Special notes:

If fault DF089 is present, the engine speed is maintained at 1000 rpm, engine

performance is reduced to 75% and the level 1 warning light comes on.

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

1.DEF

2.DEF

3.DEF

4.DEF

NOTESNone.

Check the condition and connection of the turbocharging pressure sensor connector, component code 1071.

Check the condition of the injection computer connector, component code 120.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise

replace the wiring.

Check for + 5 V on connection 3LQ of the turbocharging pressure sensor, component code 1071.

Check for earth on connection 3LN on the turbocharging pressure sensor, component code 1071.

If the connection(s) are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or

Technical Note 9804A (Dacia), Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

DCM1.2_V08_DF089

Page 96 of 204

13B-96

AFTER

REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

DF121

PRESENT

OR

STOREDACCELEROMETER CIRCUIT

1.DEF: No signal

NOTESPriorities when dealing with a number of faults:

– DF001 Coolant temperature sensor circuit,

– DF002 Air temperature sensor circuit,

– DF003 Atmospheric pressure sensor circuit,

– DF098 Fuel temperature sensor circuit,

A fault on one of these sensors could lead to incorrect fault finding on the

accelerometer.

Conditions for applying the fault finding procedure to a stored fault:

The fault is considered present when the engine is running.

Special notes:

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Check the conformity of the injectorsfitted to the vehicle in relation to the type of vehicle and engine number (low,

high or very high injector pressure).

Check the connection and condition of the accelerometer connector, component code 146.

Check the connection and condition of the injection computer connector, component code 120 and the shielding

of the sensor on connection TB1.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise

replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connections:

●3DQ between components 120 and 146,

●3S between components 120 and 146.

If the connection(s) are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or

Technical Note 9804A (Dacia), Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

DCM1.2_V08_DF121

Page 104 of 204

13B-104

AFTER

REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

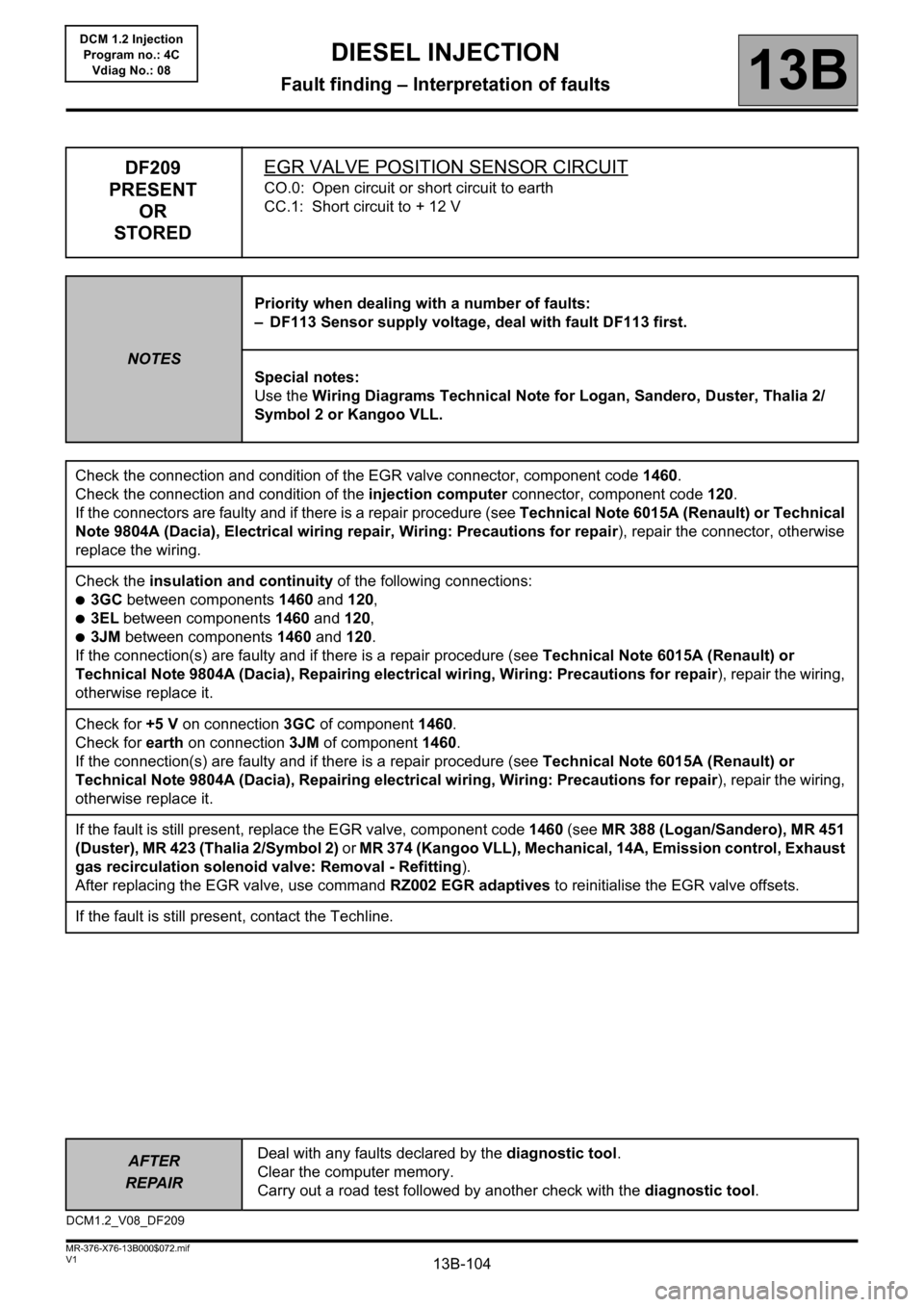

DF209

PRESENT

OR

STOREDEGR VALVE POSITION SENSOR CIRCUIT

CO.0: Open circuit or short circuit to earth

CC.1: Short circuit to + 12 V

NOTESPriority when dealing with a number of faults:

– DF113 Sensor supply voltage, deal with fault DF113 first.

Special notes:

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Check the connection and condition of the EGR valve connector, component code 1460.

Check the connection and condition of the injection computer connector, component code 120.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise

replace the wiring.

Check the insulation and continuity of the following connections:

●3GC between components 1460 and 120,

●3EL between components 1460 and 120,

●3JM between components 1460 and 120.

If the connection(s) are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or

Technical Note 9804A (Dacia), Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

Check for +5 V on connection 3GC of component 1460.

Check for earth on connection 3JM of component 1460.

If the connection(s) are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or

Technical Note 9804A (Dacia), Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

If the fault is still present, replace the EGR valve, component code 1460 (see MR 388 (Logan/Sandero), MR 451

(Duster), MR 423 (Thalia 2/Symbol 2) or MR 374 (Kangoo VLL), Mechanical, 14A, Emission control, Exhaust

gas recirculation solenoid valve: Removal - Refitting).

After replacing the EGR valve, use command RZ002 EGR adaptives to reinitialise the EGR valve offsets.

If the fault is still present, contact the Techline.

DCM1.2_V08_DF209

Page 108 of 204

13B-108

AFTER

REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

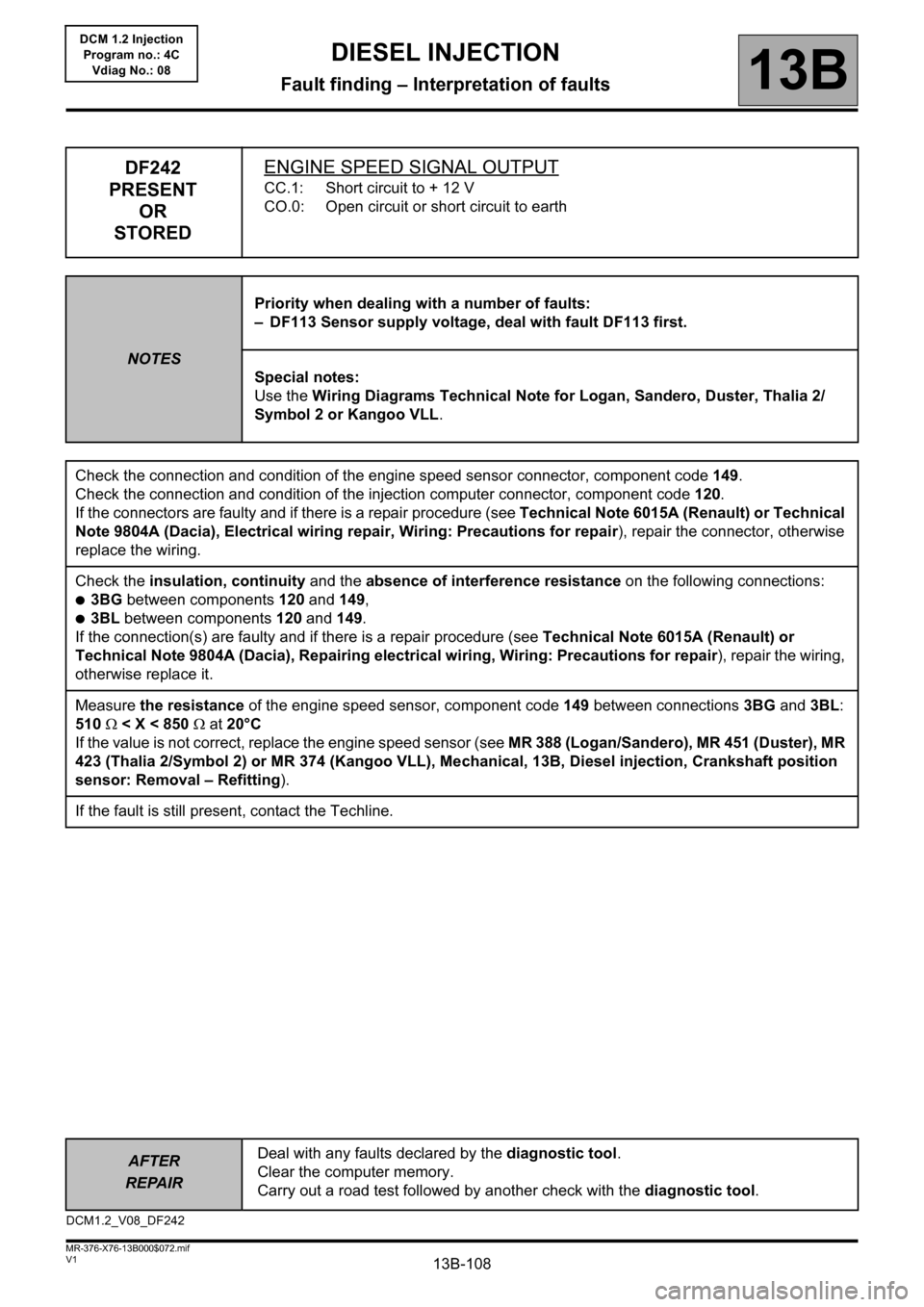

DF242

PRESENT

OR

STOREDENGINE SPEED SIGNAL OUTPUT

CC.1: Short circuit to + 12 V

CO.0: Open circuit or short circuit to earth

NOTESPriority when dealing with a number of faults:

– DF113 Sensor supply voltage, deal with fault DF113 first.

Special notes:

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Check the connection and condition of the engine speed sensor connector, component code 149.

Check the connection and condition of the injection computer connector, component code 120.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise

replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connections:

●3BG between components 120 and 149,

●3BL between components 120 and 149.

If the connection(s) are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or

Technical Note 9804A (Dacia), Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

Measure the resistance of the engine speed sensor, component code 149 between connections 3BG and 3BL:

510 < X < 850 at 20°C

If the value is not correct, replace the engine speed sensor (see MR 388 (Logan/Sandero), MR 451 (Duster), MR

423 (Thalia 2/Symbol 2) or MR 374 (Kangoo VLL), Mechanical, 13B, Diesel injection, Crankshaft position

sensor: Removal – Refitting).

If the fault is still present, contact the Techline.

DCM1.2_V08_DF242

Page 123 of 204

13B-123V1 MR-376-X76-13B000$080.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

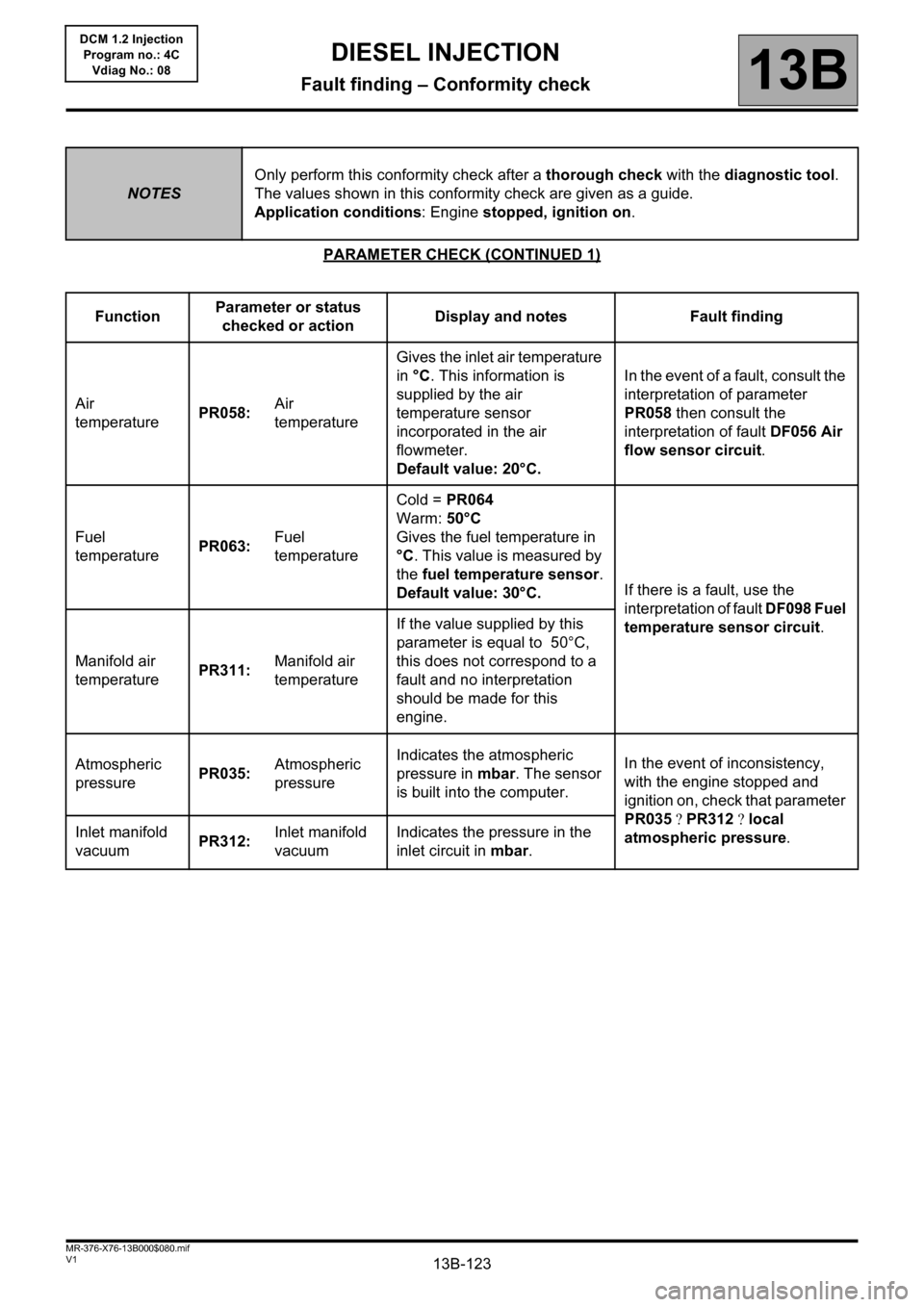

PARAMETER CHECK (CONTINUED 1)

NOTESOnly perform this conformity check after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine stopped, ignition on.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

Air

temperaturePR058:Air

temperatureGives the inlet air temperature

in °C. This information is

supplied by the air

temperature sensor

incorporated in the air

flowmeter.

Default value: 20°C.In the event of a fault, consult the

interpretation of parameter

PR058 then consult the

interpretation of fault DF056 Air

flow sensor circuit.

Fuel

temperaturePR063:Fuel

temperatureCold = PR064

Warm: 50°C

Gives the fuel temperature in

°C. This value is measured by

the fuel temperature sensor.

Default value: 30°C.If there is a fault, use the

interpretation of fault DF098 Fuel

temperature sensor circuit.

Manifold air

temperaturePR311:Manifold air

temperatureIf the value supplied by this

parameter is equal to 50°C,

this does not correspond to a

fault and no interpretation

should be made for this

engine.

Atmospheric

pressurePR035:Atmospheric

pressureIndicates the atmospheric

pressure in mbar. The sensor

is built into the computer. In the event of inconsistency,

with the engine stopped and

ignition on, check that parameter

PR035PR312local

atmospheric pressure. Inlet manifold

vacuumPR312:Inlet manifold

vacuumIndicates the pressure in the

inlet circuit in mbar.

Page 195 of 204

13B-195V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

TEST 8

CONTINUED 1

When all the preparations are complete, start the engine and leave it running:

For 30 seconds at idle speed for Euro 4 type engines: K9K 714 - 718 - 740 - 792 - 796.

Let it idle for 2 minutesfor the euro 3 type engines: K9K 790 - 794.

Note:

These time periods must be respected for the test results to be interpreted correctly.

–Run command AC029 High pressure circuit sealing check

.The engine will automatically carry out a cycle of four accelerations to increase the rail pressure and measure

the internal injector leaks under these conditions.

–When the cycle has finished, run command AC029 High pressure circuit sealing test a second time to

obtain the correct return volume reading for each injector.

Switch off the engine at the end of the cycle.