fuel filter RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 186 of 204

13B-186V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

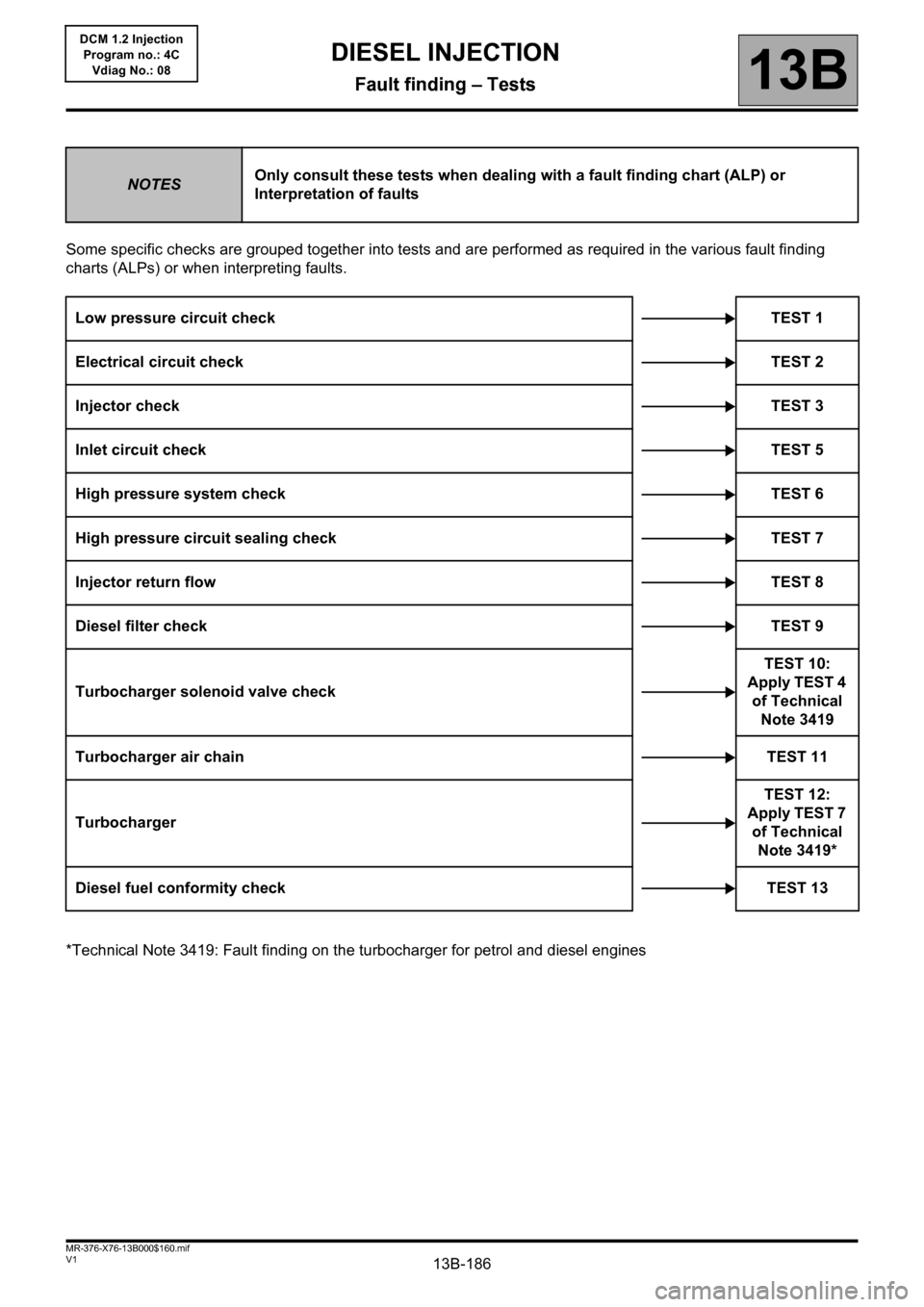

Some specific checks are grouped together into tests and are performed as required in the various fault finding

charts (ALPs) or when interpreting faults.

*Technical Note 3419: Fault finding on the turbocharger for petrol and diesel engines

NOTESOnly consult these tests when dealing with a fault finding chart (ALP) or

Interpretation of faults

Low pressure circuit checkTEST 1

Electrical circuit checkTEST 2

Injector checkTEST 3

Inlet circuit checkTEST 5

High pressure system check TEST 6

High pressure circuit sealing check TEST 7

Injector return flowTEST 8

Diesel filter checkTEST 9

Turbocharger solenoid valve checkTEST 10:

Apply TEST 4

of Technical

Note 3419

Turbocharger air chainTEST 11

TurbochargerTEST 12:

Apply TEST 7

of Technical

Note 3419*

Diesel fuel conformity check TEST 13

DIESEL INJECTION

Fault finding – Tests

Page 187 of 204

13B-187V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

TEST 1 Low pressure circuit check

Check the conformity of the low pressure circuit

connections

Are the low pressure circuit connections correct? Carry out the necessary repairs.

Check the condition of the priming bulb, and that it is

working properly.

Look for leaks at the unions.

Are there leaks from the hoses and unions? Carry out the necessary repairs

Check that there are no air bubbles in the diesel fuel. Bleed the low-pressure circuit.

Place a container under the filter.

– Disconnect the return hose from the filter

and plug the filter.

– Pump using the priming bulb until there is no

air left.

– Reconnect the return hose immediately. Check if there are air bubbles in the low pressure

circuit.

Low pressure circuit correct.

NO

YES

YES

NO

YES

NO

DCM1.2_V08_TEST01

Page 189 of 204

13B-189V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

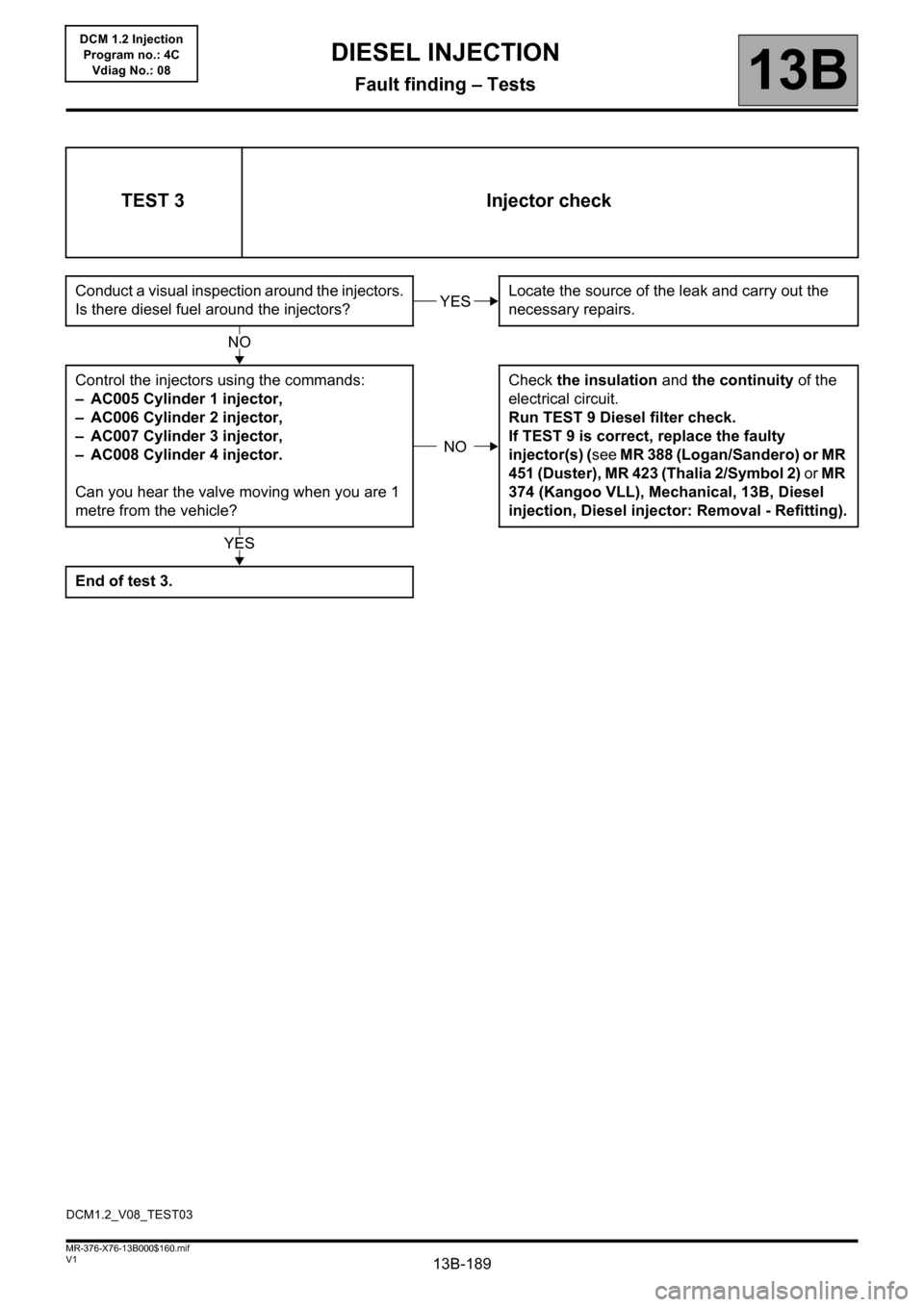

TEST 3 Injector check

Conduct a visual inspection around the injectors.

Is there diesel fuel around the injectors?Locate the source of the leak and carry out the

necessary repairs.

Control the injectors using the commands:

– AC005 Cylinder 1 injector,

– AC006 Cylinder 2 injector,

– AC007 Cylinder 3 injector,

– AC008 Cylinder 4 injector.

Can you hear the valve moving when you are 1

metre from the vehicle?Check the insulation and the continuity of the

electrical circuit.

Run TEST 9 Diesel filter check.

If TEST 9 is correct, replace the faulty

injector(s) (see MR 388 (Logan/Sandero) or MR

451 (Duster), MR 423 (Thalia 2/Symbol 2) or MR

374 (Kangoo VLL), Mechanical, 13B, Diesel

injection, Diesel injector: Removal - Refitting).

End of test 3.YES

NO

NO

YES

DCM1.2_V08_TEST03

Page 190 of 204

13B-190V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

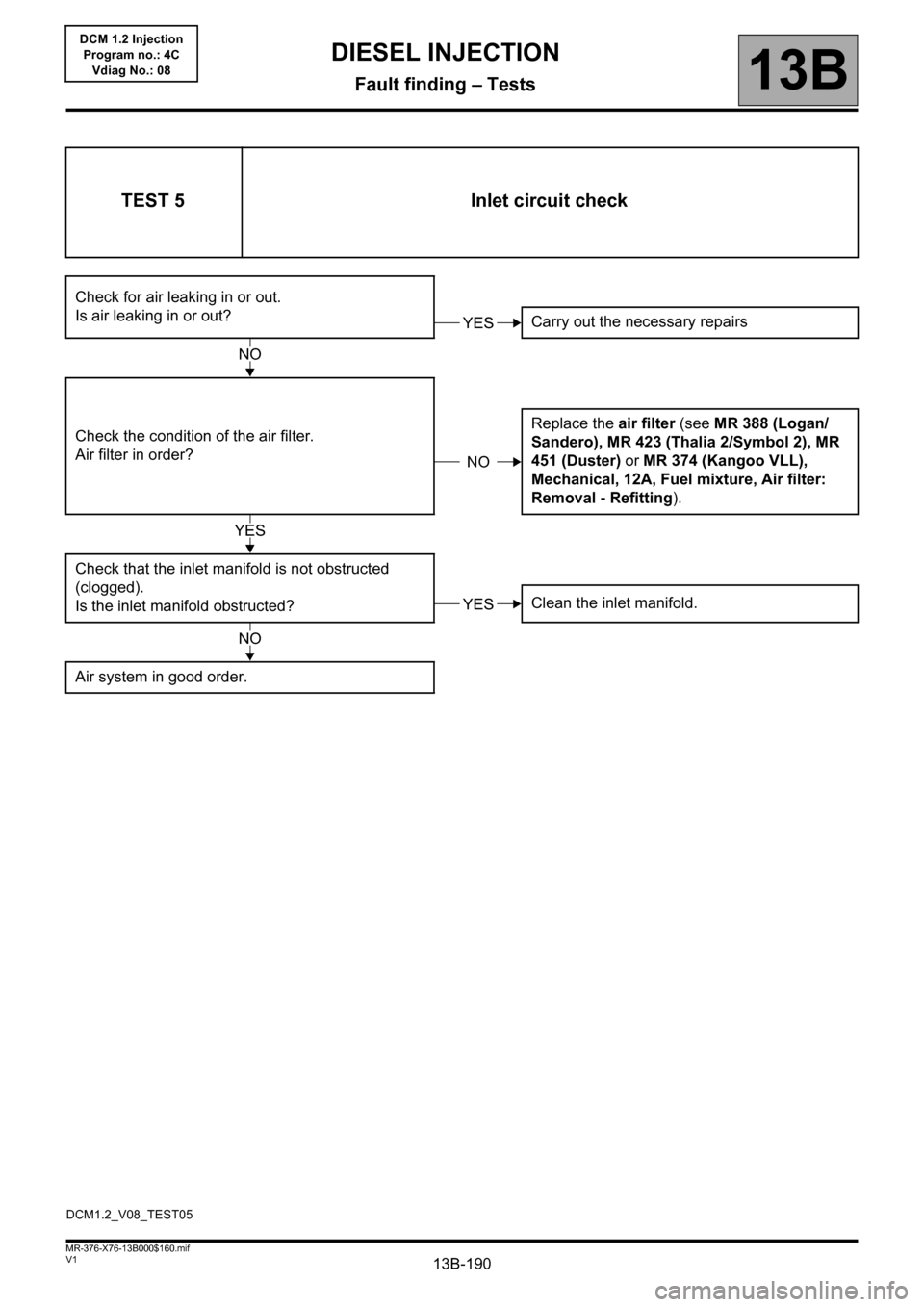

TEST 5 Inlet circuit check

Check for air leaking in or out.

Is air leaking in or out?

Carry out the necessary repairs

Check the condition of the air filter.

Air filter in order?Replace the air filter (see MR 388 (Logan/

Sandero), MR 423 (Thalia 2/Symbol 2), MR

451 (Duster) or MR 374 (Kangoo VLL),

Mechanical, 12A, Fuel mixture, Air filter:

Removal - Refitting).

Check that the inlet manifold is not obstructed

(clogged).

Is the inlet manifold obstructed?Clean the inlet manifold.

Air system in good order.

YES

NO

NO

YES

YES

NO

DCM1.2_V08_TEST05

Page 192 of 204

13B-192V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

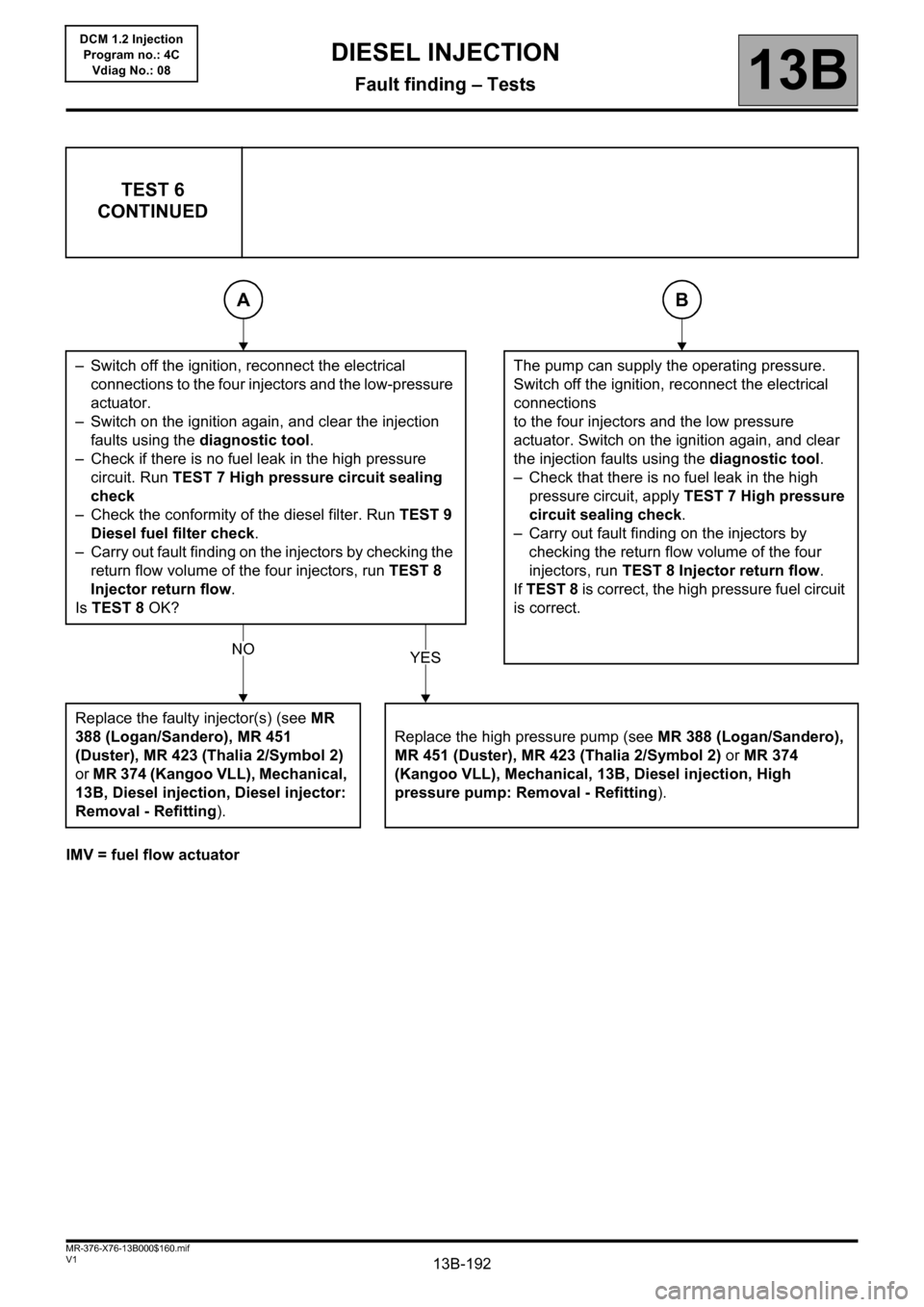

IMV = fuel flow actuator

TEST 6

CONTINUED

– Switch off the ignition, reconnect the electrical

connections to the four injectors and the low-pressure

actuator.

– Switch on the ignition again, and clear the injection

faults using the diagnostic tool.

– Check if there is no fuel leak in the high pressure

circuit. Run TEST 7 High pressure circuit sealing

check

– Check the conformity of the diesel filter. Run TEST 9

Diesel fuel filter check.

– Carry out fault finding on the injectors by checking the

return flow volume of the four injectors, run TEST 8

Injector return flow.

Is TEST 8 OK?The pump can supply the operating pressure.

Switch off the ignition, reconnect the electrical

connections

to the four injectors and the low pressure

actuator. Switch on the ignition again, and clear

the injection faults using the diagnostic tool.

– Check that there is no fuel leak in the high

pressure circuit, apply TEST 7 High pressure

circuit sealing check.

– Carry out fault finding on the injectors by

checking the return flow volume of the four

injectors, run TEST 8 Injector return flow.

If TEST 8 is correct, the high pressure fuel circuit

is correct.

Replace the faulty injector(s) (see MR

388 (Logan/Sandero), MR 451

(Duster), MR 423 (Thalia 2/Symbol 2)

or MR 374 (Kangoo VLL), Mechanical,

13B, Diesel injection, Diesel injector:

Removal - Refitting).Replace the high pressure pump (see MR 388 (Logan/Sandero),

MR 451 (Duster), MR 423 (Thalia 2/Symbol 2) or MR 374

(Kangoo VLL), Mechanical, 13B, Diesel injection, High

pressure pump: Removal - Refitting).

AB

YESNO

Page 199 of 204

13B-199V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

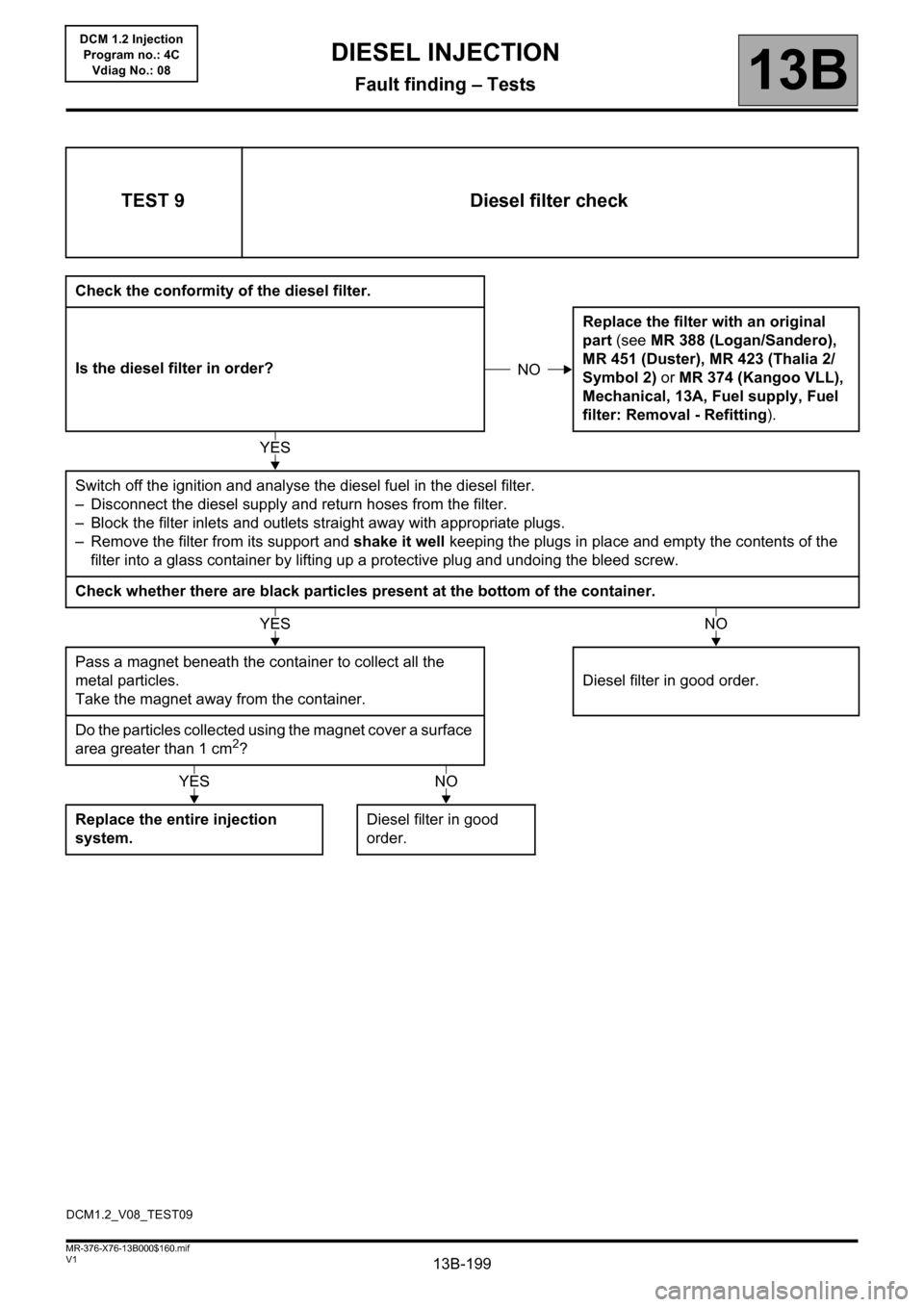

TEST 9 Diesel filter check

Check the conformity of the diesel filter.

Is the diesel filter in order?Replace the filter with an original

part (see MR 388 (Logan/Sandero),

MR 451 (Duster), MR 423 (Thalia 2/

Symbol 2) or MR 374 (Kangoo VLL),

Mechanical, 13A, Fuel supply, Fuel

filter: Removal - Refitting).

Switch off the ignition and analyse the diesel fuel in the diesel filter.

– Disconnect the diesel supply and return hoses from the filter.

– Block the filter inlets and outlets straight away with appropriate plugs.

– Remove the filter from its support and shake it well keeping the plugs in place and empty the contents of the

filter into a glass container by lifting up a protective plug and undoing the bleed screw.

Check whether there are black particles present at the bottom of the container.

Pass a magnet beneath the container to collect all the

metal particles.

Take the magnet away from the container.Diesel filter in good order.

Do the particles collected using the magnet cover a surface

area greater than 1 cm

2?

Replace the entire injection

system.Diesel filter in good

order.

NO

YES

YESNO

YESNO

DCM1.2_V08_TEST09

Page 200 of 204

13B-200V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

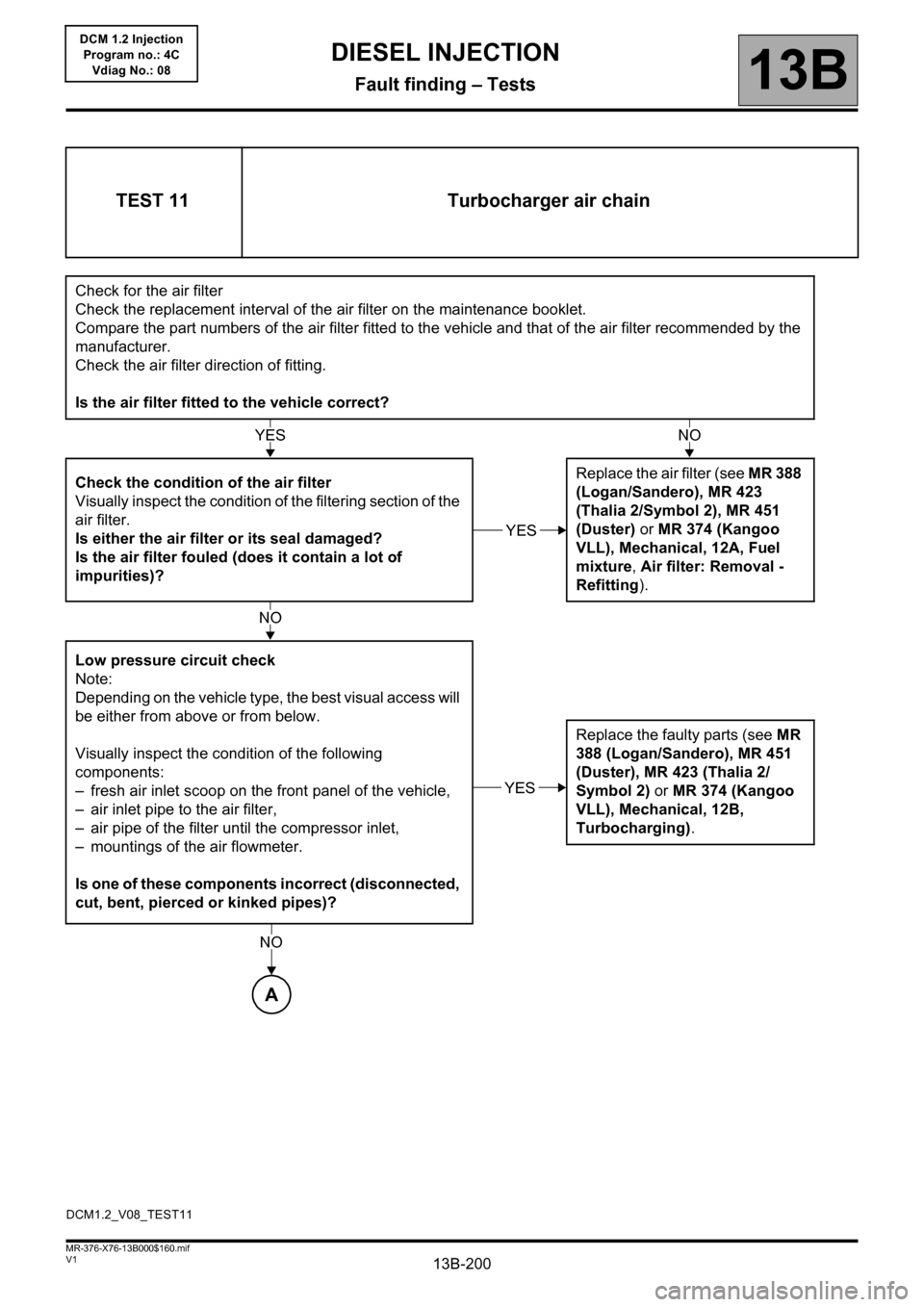

TEST 11 Turbocharger air chain

Check for the air filter

Check the replacement interval of the air filter on the maintenance booklet.

Compare the part numbers of the air filter fitted to the vehicle and that of the air filter recommended by the

manufacturer.

Check the air filter direction of fitting.

Is the air filter fitted to the vehicle correct?

Check the condition of the air filter

Visually inspect the condition of the filtering section of the

air filter.

Is either the air filter or its seal damaged?

Is the air filter fouled (does it contain a lot of

impurities)?Replace the air filter (see MR 388

(Logan/Sandero), MR 423

(Thalia 2/Symbol 2), MR 451

(Duster) or MR 374 (Kangoo

VLL), Mechanical, 12A, Fuel

mixture, Air filter: Removal -

Refitting).

Low pressure circuit check

Note:

Depending on the vehicle type, the best visual access will

be either from above or from below.

Visually inspect the condition of the following

components:

– fresh air inlet scoop on the front panel of the vehicle,

– air inlet pipe to the air filter,

– air pipe of the filter until the compressor inlet,

– mountings of the air flowmeter.

Is one of these components incorrect (disconnected,

cut, bent, pierced or kinked pipes)?Replace the faulty parts (see MR

388 (Logan/Sandero), MR 451

(Duster), MR 423 (Thalia 2/

Symbol 2) or MR 374 (Kangoo

VLL), Mechanical, 12B,

Turbocharging).

YESNO

YES

NO

YES

A

NO

DCM1.2_V08_TEST11

Page 202 of 204

13B-202V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

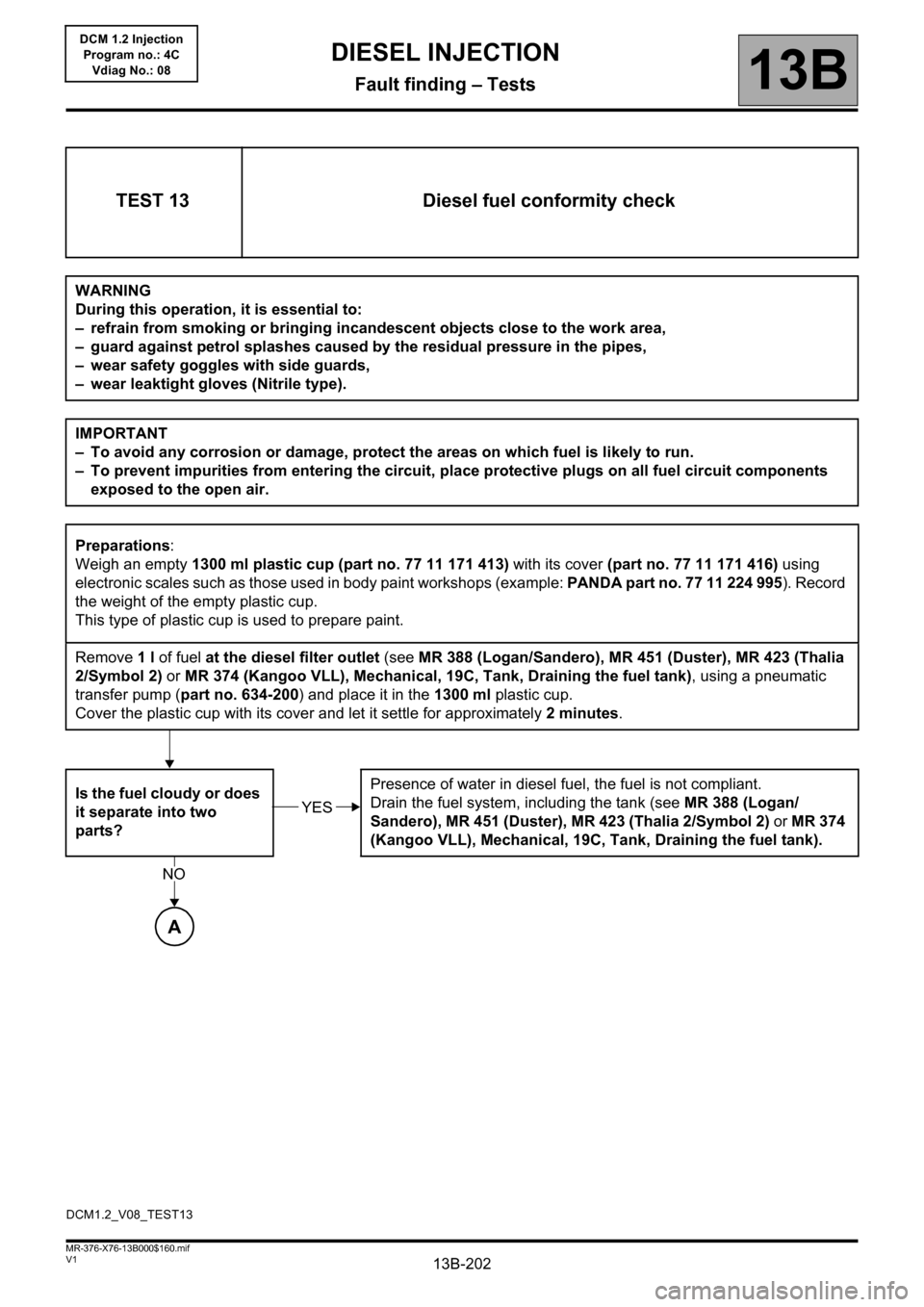

TEST 13 Diesel fuel conformity check

WARNING

During this operation, it is essential to:

– refrain from smoking or bringing incandescent objects close to the work area,

– guard against petrol splashes caused by the residual pressure in the pipes,

– wear safety goggles with side guards,

– wear leaktight gloves (Nitrile type).

IMPORTANT

– To avoid any corrosion or damage, protect the areas on which fuel is likely to run.

– To prevent impurities from entering the circuit, place protective plugs on all fuel circuit components

exposed to the open air.

Preparations:

Weigh an empty 1300 ml plastic cup (part no. 77 11 171 413) with its cover (part no. 77 11 171 416) using

electronic scales such as those used in body paint workshops (example: PANDA part no. 77 11 224 995). Record

the weight of the empty plastic cup.

This type of plastic cup is used to prepare paint.

Remove 1 l of fuel at the diesel filter outlet (see MR 388 (Logan/Sandero), MR 451 (Duster), MR 423 (Thalia

2/Symbol 2) or MR 374 (Kangoo VLL), Mechanical, 19C, Tank, Draining the fuel tank), using a pneumatic

transfer pump (part no. 634-200) and place it in the 1300 ml plastic cup.

Cover the plastic cup with its cover and let it settle for approximately 2 minutes.

Is the fuel cloudy or does

it separate into two

parts?Presence of water in diesel fuel, the fuel is not compliant.

Drain the fuel system, including the tank (see MR 388 (Logan/

Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol 2) or MR 374

(Kangoo VLL), Mechanical, 19C, Tank, Draining the fuel tank).

YES

A

NO

DCM1.2_V08_TEST13