df016 RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 16 of 204

13B-16V1 MR-376-X76-13B000$030.mif

DIESEL INJECTION

Fault finding – System operation13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

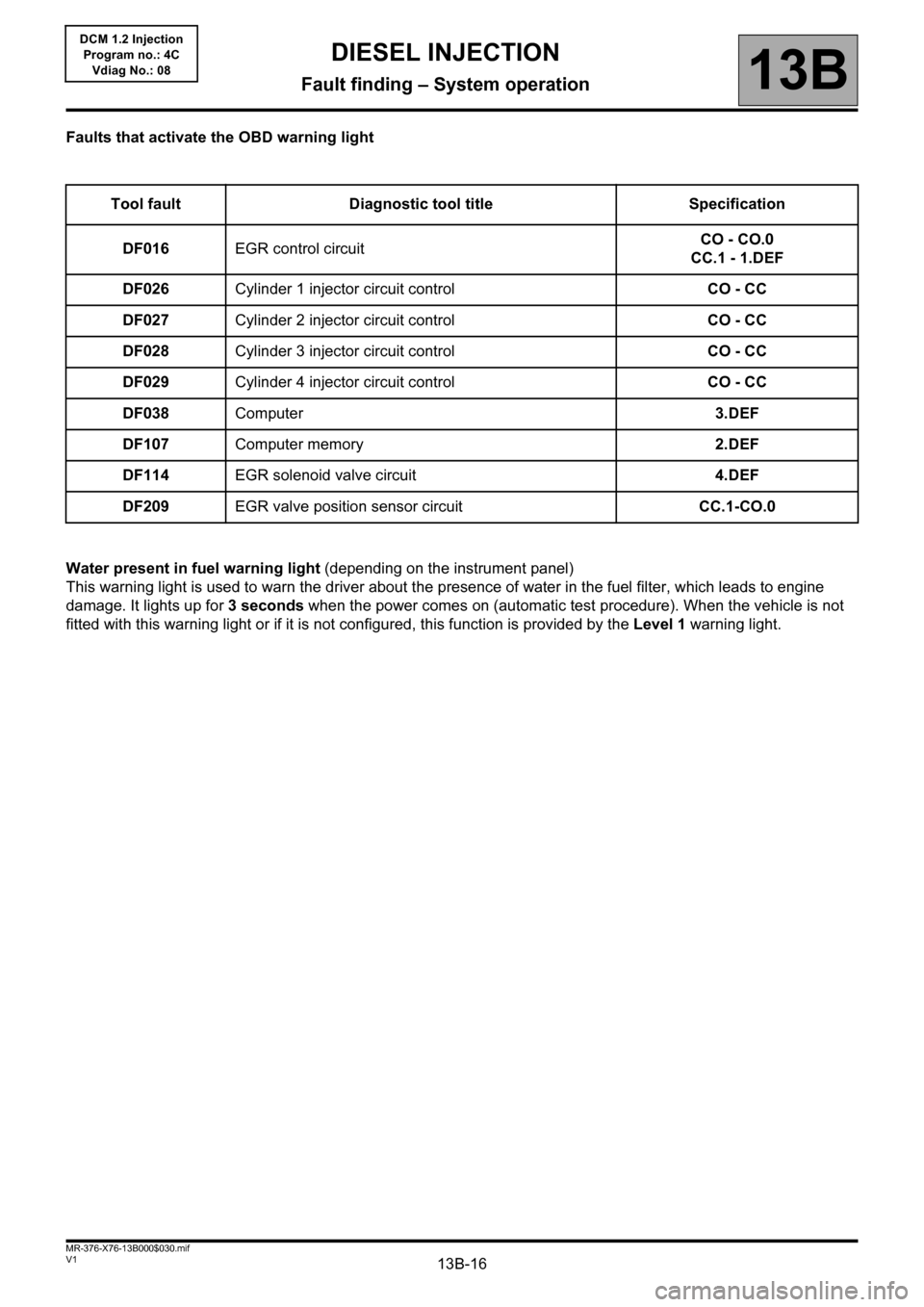

Faults that activate the OBD warning light

Water present in fuel warning light (depending on the instrument panel)

This warning light is used to warn the driver about the presence of water in the fuel filter, which leads to engine

damage. It lights up for 3 seconds when the power comes on (automatic test procedure). When the vehicle is not

fitted with this warning light or if it is not configured, this function is provided by the Level 1 warning light. Tool fault Diagnostic tool title Specification

DF016EGR control circuitCO - CO.0

CC.1 - 1.DEF

DF026Cylinder 1 injector circuit controlCO - CC

DF027Cylinder 2 injector circuit controlCO - CC

DF028Cylinder 3 injector circuit controlCO - CC

DF029Cylinder 4 injector circuit controlCO - CC

DF038Computer3.DEF

DF107Computer memory2.DEF

DF114EGR solenoid valve circuit4.DEF

DF209EGR valve position sensor circuitCC.1-CO.0

Page 22 of 204

13B-22V1 MR-376-X76-13B000$060.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

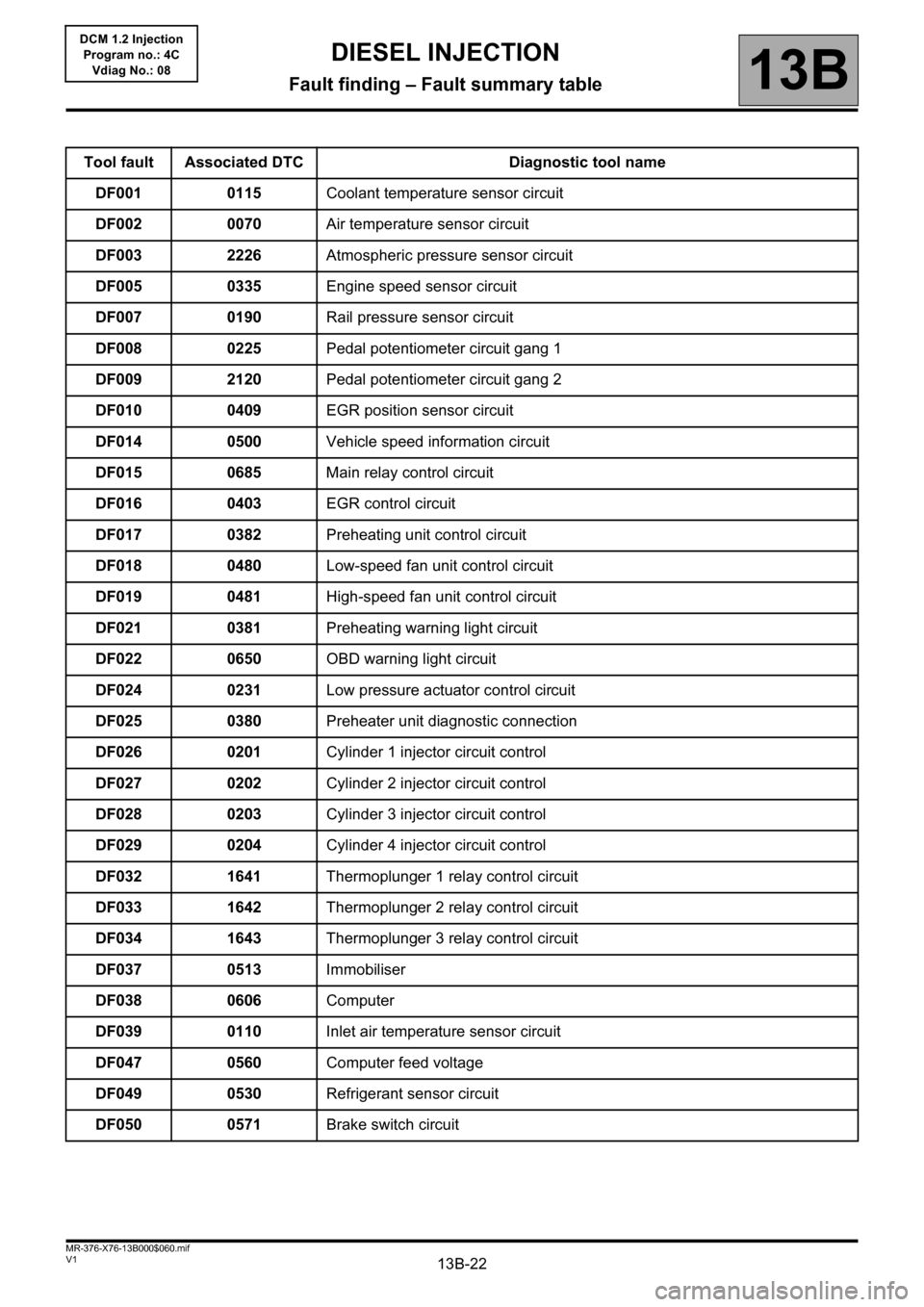

Tool fault Associated DTC Diagnostic tool name

DF001 0115Coolant temperature sensor circuit

DF002 0070Air temperature sensor circuit

DF003 2226Atmospheric pressure sensor circuit

DF005 0335Engine speed sensor circuit

DF007 0190Rail pressure sensor circuit

DF008 0225Pedal potentiometer circuit gang 1

DF009 2120Pedal potentiometer circuit gang 2

DF010 0409EGR position sensor circuit

DF014 0500Vehicle speed information circuit

DF015 0685Main relay control circuit

DF016 0403EGR control circuit

DF017 0382Preheating unit control circuit

DF018 0480Low-speed fan unit control circuit

DF019 0481High-speed fan unit control circuit

DF021 0381Preheating warning light circuit

DF022 0650OBD warning light circuit

DF024 0231Low pressure actuator control circuit

DF025 0380Preheater unit diagnostic connection

DF026 0201Cylinder 1 injector circuit control

DF027 0202Cylinder 2 injector circuit control

DF028 0203Cylinder 3 injector circuit control

DF029 0204Cylinder 4 injector circuit control

DF032 1641Thermoplunger 1 relay control circuit

DF033 1642Thermoplunger 2 relay control circuit

DF034 1643Thermoplunger 3 relay control circuit

DF037 0513Immobiliser

DF038 0606Computer

DF039 0110Inlet air temperature sensor circuit

DF047 0560Computer feed voltage

DF049 0530Refrigerant sensor circuit

DF050 0571Brake switch circuit

DIESEL INJECTION

Fault finding – Fault summary table

Page 42 of 204

13B-42

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

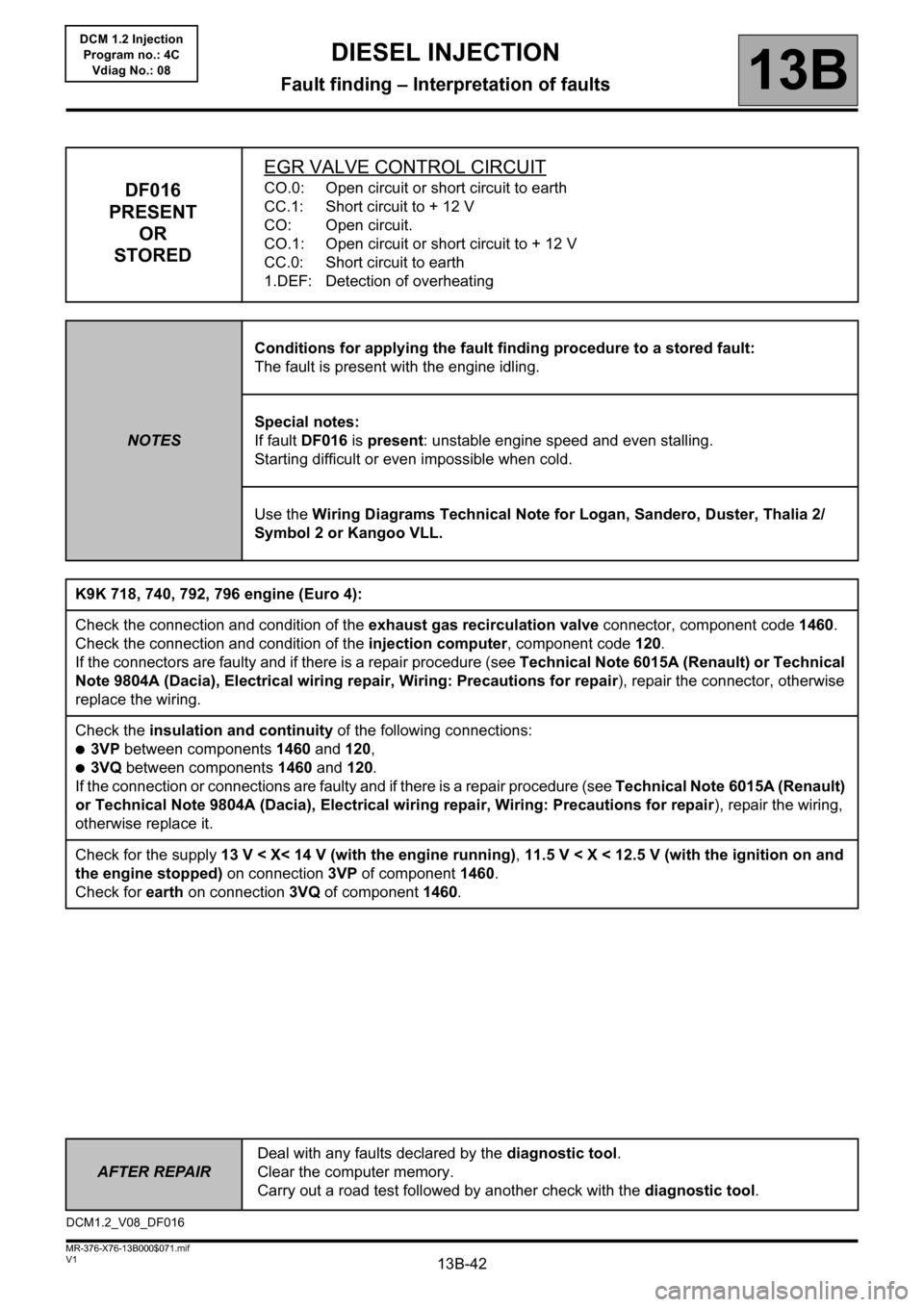

DF016

PRESENT

OR

STOREDEGR VALVE CONTROL CIRCUITCO.0: Open circuit or short circuit to earth

CC.1: Short circuit to + 12 V

CO: Open circuit.

CO.1: Open circuit or short circuit to + 12 V

CC.0: Short circuit to earth

1.DEF: Detection of overheating

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is present with the engine idling.

Special notes:

If fault DF016 is present: unstable engine speed and even stalling.

Starting difficult or even impossible when cold.

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

K9K 718, 740, 792, 796 engine (Euro 4):

Check the connection and condition of the exhaust gas recirculation valve connector, component code 1460.

Check the connection and condition of the injection computer, component code 120.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A (Renault) or Technical

Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise

replace the wiring.

Check the insulation and continuity of the following connections:

●3VP between components 1460 and 120,

●3VQ between components 1460 and 120.

If the connection or connections are faulty and if there is a repair procedure (see Technical Note 6015A (Renault)

or Technical Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

Check for the supply 13 V < X< 14 V (with the engine running), 11.5 V < X < 12.5 V (with the ignition on and

the engine stopped) on connection 3VP of component 1460.

Check for earth on connection 3VQ of component 1460.

DCM1.2_V08_DF016

Page 43 of 204

13B-43

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

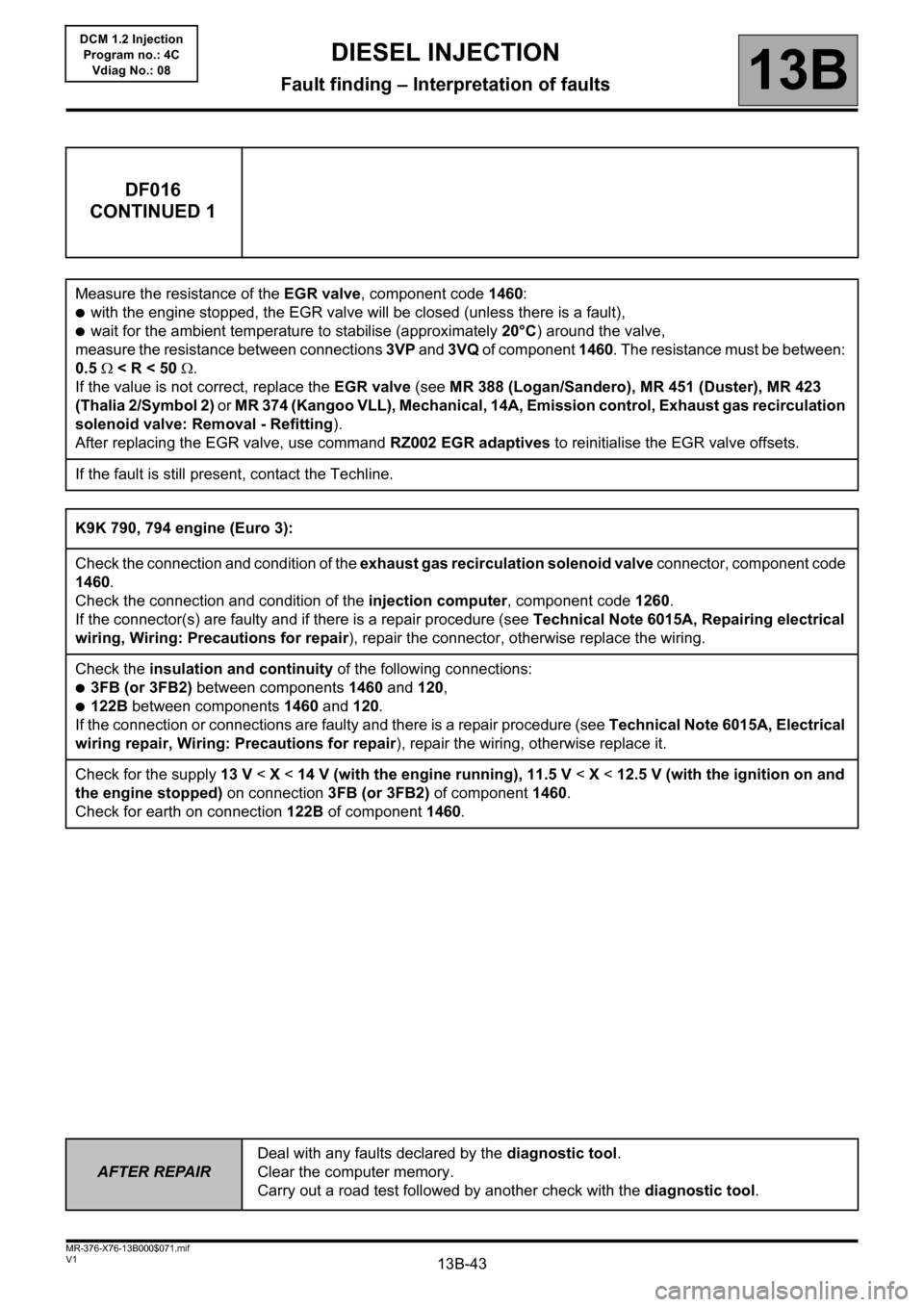

DF016

CONTINUED 1

Measure the resistance of the EGR valve, component code 1460:

●with the engine stopped, the EGR valve will be closed (unless there is a fault),

●wait for the ambient temperature to stabilise (approximately 20°C) around the valve,

measure the resistance between connections 3VP and 3VQ of component 1460. The resistance must be between:

0.5 < R < 50 .

If the value is not correct, replace the EGR valve (see MR 388 (Logan/Sandero), MR 451 (Duster), MR 423

(Thalia 2/Symbol 2) or MR 374 (Kangoo VLL), Mechanical, 14A, Emission control, Exhaust gas recirculation

solenoid valve: Removal - Refitting).

After replacing the EGR valve, use command RZ002 EGR adaptives to reinitialise the EGR valve offsets.

If the fault is still present, contact the Techline.

K9K 790, 794 engine (Euro 3):

Check the connection and condition of the exhaust gas recirculation solenoid valve connector, component code

1460.

Check the connection and condition of the injection computer, component code 1260.

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

●3FB (or 3FB2) between components 1460 and 120,

●122B between components 1460 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check for the supply 13 V < X < 14 V (with the engine running), 11.5 V < X < 12.5 V (with the ignition on and

the engine stopped) on connection 3FB (or 3FB2) of component 1460.

Check for earth on connection122B of component1460.

Page 44 of 204

13B-44

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

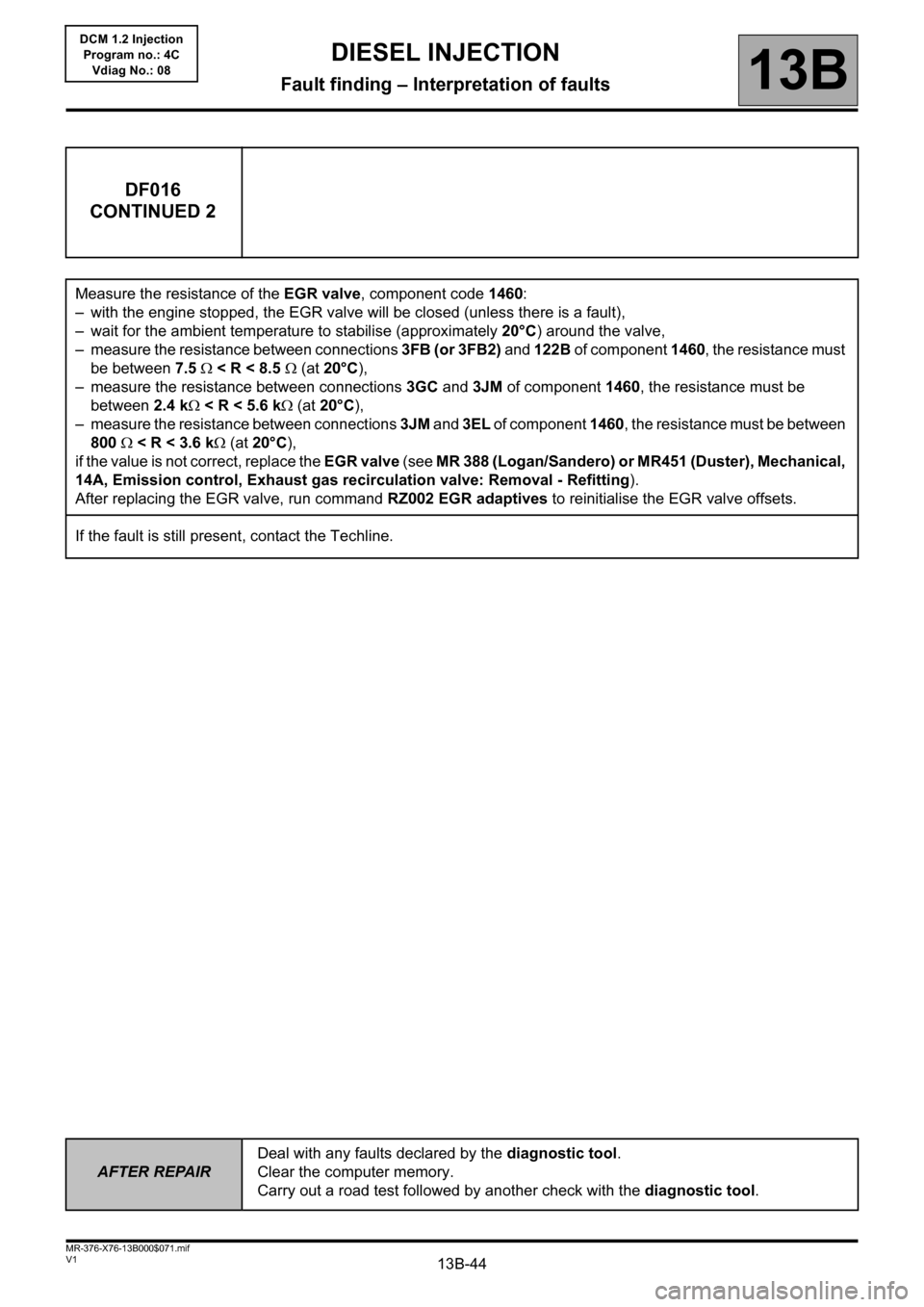

DF016

CONTINUED 2

Measure the resistance of the EGR valve, component code 1460:

– with the engine stopped, the EGR valve will be closed (unless there is a fault),

– wait for the ambient temperature to stabilise (approximately 20°C) around the valve,

– measure the resistance between connections 3FB (or 3FB2) and 122B of component 1460, the resistance must

be between 7.5 < R < 8.5 (at 20°C),

– measure the resistance between connections 3GC and 3JM of component 1460, the resistance must be

between 2.4 k < R < 5.6 k (at 20°C),

– measure the resistance between connections 3JM and 3EL of component 1460, the resistance must be between

800 < R < 3.6 k (at 20°C),

if the value is not correct, replace the EGR valve (see MR 388 (Logan/Sandero) or MR451 (Duster), Mechanical,

14A, Emission control, Exhaust gas recirculation valve: Removal - Refitting).

After replacing the EGR valve, run command RZ002 EGR adaptives to reinitialise the EGR valve offsets.

If the fault is still present, contact the Techline.

Page 125 of 204

13B-125V1 MR-376-X76-13B000$080.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

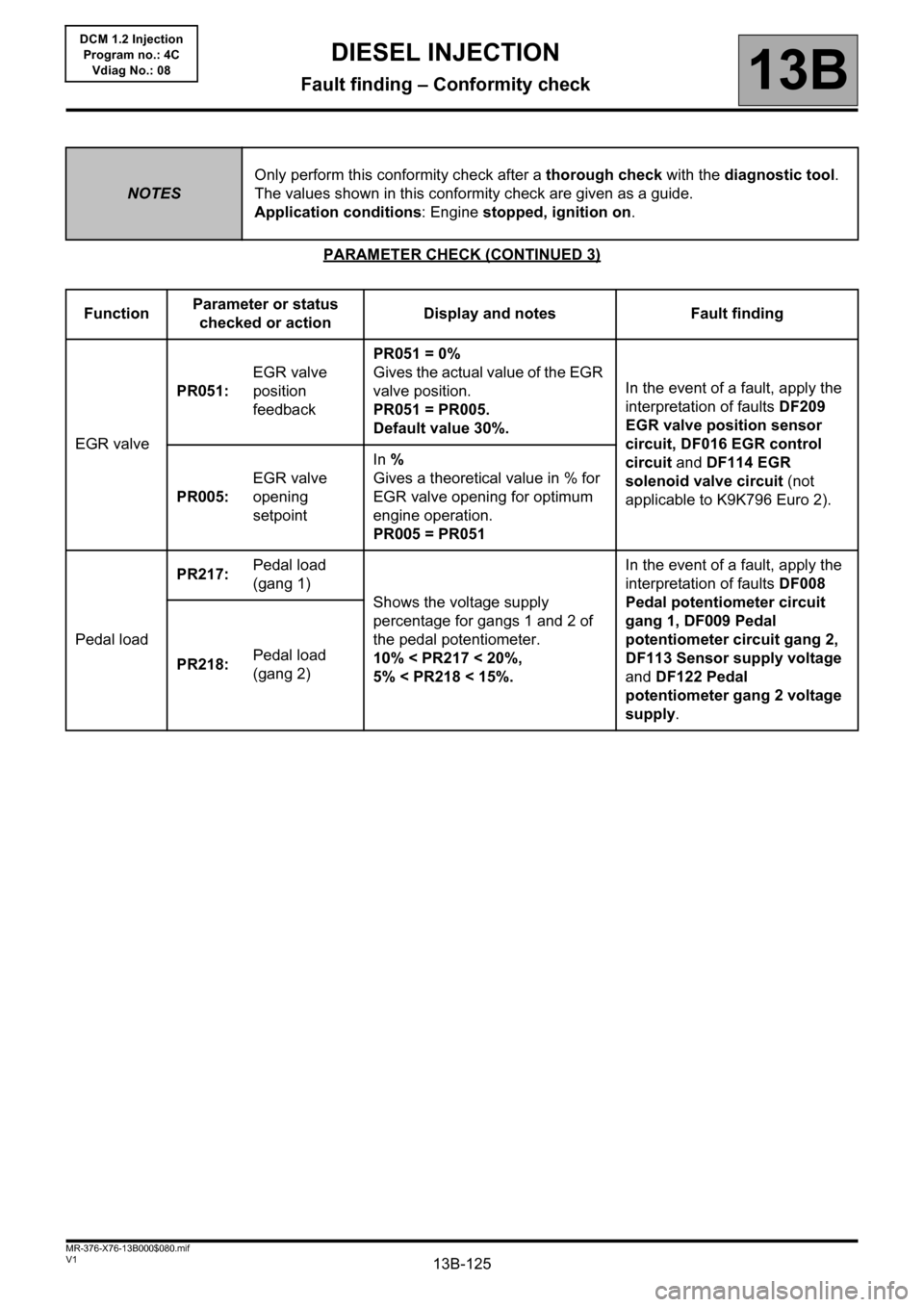

PARAMETER CHECK (CONTINUED 3)

NOTESOnly perform this conformity check after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine stopped, ignition on.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

EGR valvePR051:EGR valve

position

feedbackPR051 = 0%

Gives the actual value of the EGR

valve position.

PR051 = PR005.

Default value 30%.In the event of a fault, apply the

interpretation of faults DF209

EGR valve position sensor

circuit, DF016 EGR control

circuit and DF114 EGR

solenoid valve circuit (not

applicable to K9K796 Euro 2). PR005:EGR valve

opening

setpointIn %

Gives a theoretical value in % for

EGR valve opening for optimum

engine operation.

PR005 = PR051

Pedal loadPR217:Pedal load

(gang 1)

Shows the voltage supply

percentage for gangs 1 and 2 of

the pedal potentiometer.

10% < PR217 < 20%,

5% < PR218 < 15%.In the event of a fault, apply the

interpretation of faults DF008

Pedal potentiometer circuit

gang 1, DF009 Pedal

potentiometer circuit gang 2,

DF113 Sensor supply voltage

and DF122 Pedal

potentiometer gang 2 voltage

supply. PR218:Pedal load

(gang 2)

Page 128 of 204

13B-128V1 MR-376-X76-13B000$080.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

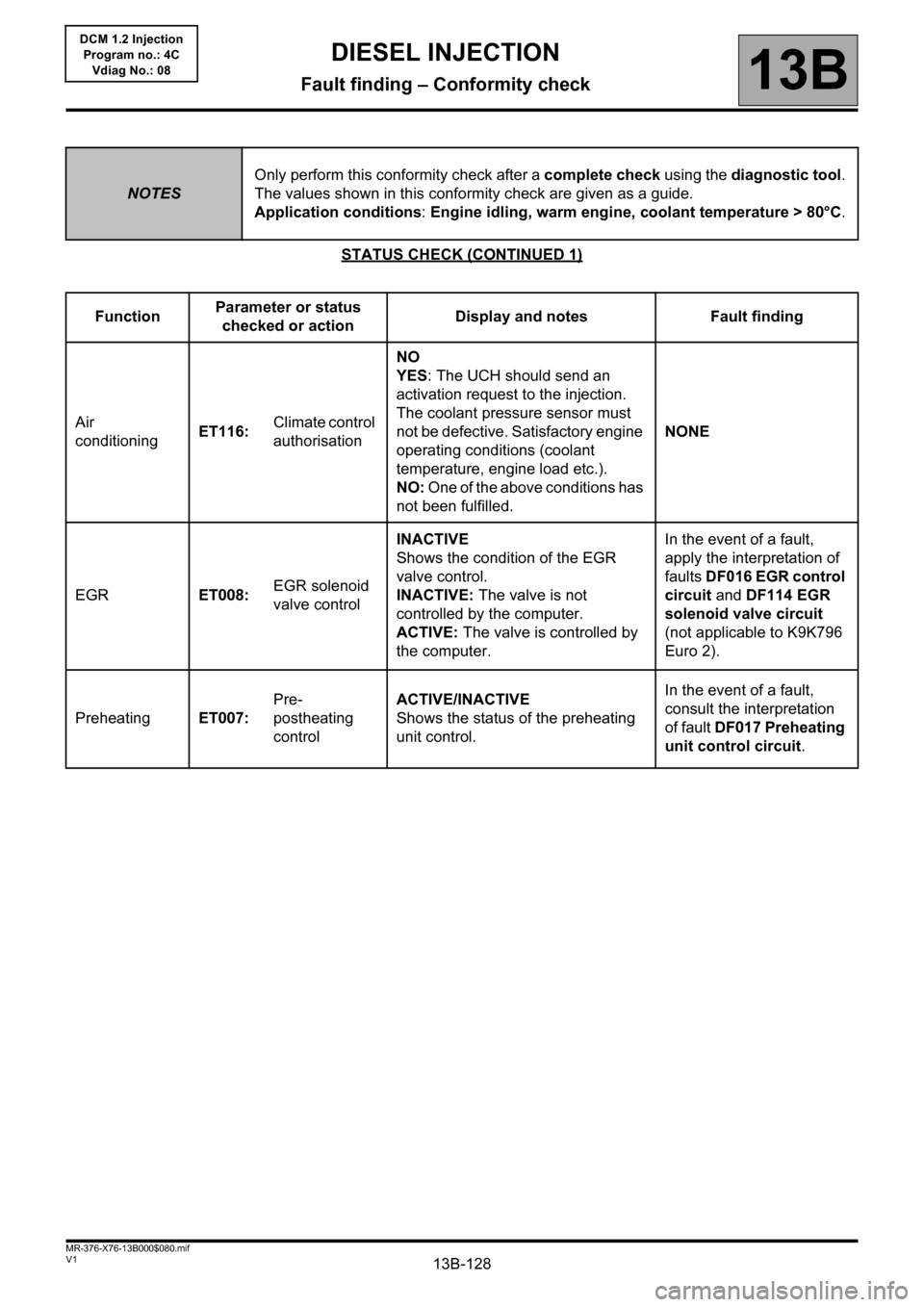

STATUS CHECK (CONTINUED 1)

NOTESOnly perform this conformity check after a complete check using the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine idling, warm engine, coolant temperature > 80°C.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

Air

conditioningET116:Climate control

authorisationNO

YES: The UCH should send an

activation request to the injection.

The coolant pressure sensor must

not be defective. Satisfactory engine

operating conditions (coolant

temperature, engine load etc.).

NO: One of the above conditions has

not been fulfilled.NONE

EGRET008:EGR solenoid

valve controlINACTIVE

Shows the condition of the EGR

valve control.

INACTIVE: The valve is not

controlled by the computer.

ACTIVE: The valve is controlled by

the computer.In the event of a fault,

apply the interpretation of

faults DF016 EGR control

circuit and DF114 EGR

solenoid valve circuit

(not applicable to K9K796

Euro 2).

PreheatingET007:Pre-

postheating

controlACTIVE/INACTIVE

Shows the status of the preheating

unit control.In the event of a fault,

consult the interpretation

of fault DF017 Preheating

unit control circuit.

Page 133 of 204

13B-133V1 MR-376-X76-13B000$080.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

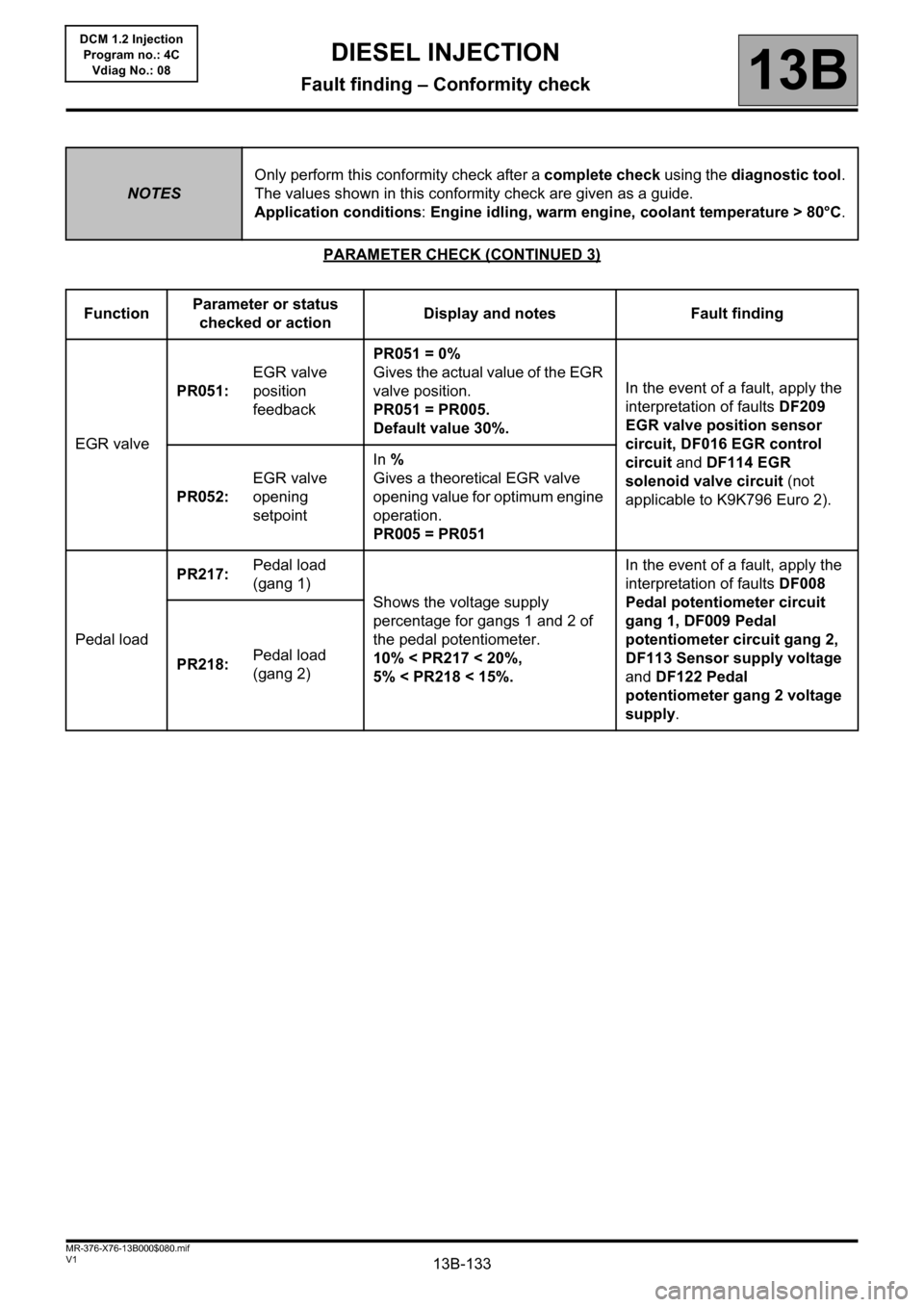

PARAMETER CHECK (CONTINUED 3)

NOTESOnly perform this conformity check after a complete check using the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine idling, warm engine, coolant temperature > 80°C.

FunctionParameter or status

checked or actionDisplay and notes Fault finding

EGR valvePR051:EGR valve

position

feedbackPR051 = 0%

Gives the actual value of the EGR

valve position.

PR051 = PR005.

Default value 30%.In the event of a fault, apply the

interpretation of faults DF209

EGR valve position sensor

circuit, DF016 EGR control

circuit and DF114 EGR

solenoid valve circuit (not

applicable to K9K796 Euro 2). PR052:EGR valve

opening

setpointIn %

Gives a theoretical EGR valve

opening value for optimum engine

operation.

PR005 = PR051

Pedal loadPR217:Pedal load

(gang 1)

Shows the voltage supply

percentage for gangs 1 and 2 of

the pedal potentiometer.

10% < PR217 < 20%,

5% < PR218 < 15%.In the event of a fault, apply the

interpretation of faults DF008

Pedal potentiometer circuit

gang 1, DF009 Pedal

potentiometer circuit gang 2,

DF113 Sensor supply voltage

and DF122 Pedal

potentiometer gang 2 voltage

supply. PR218:Pedal load

(gang 2)