engine RENAULT KANGOO 2013 X61 / 2.G Petrol V42 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 279, PDF Size: 1.29 MB

Page 234 of 279

17B-234

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$160.mif

PETROL INJECTION

Fault finding – Fault Finding Chart17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

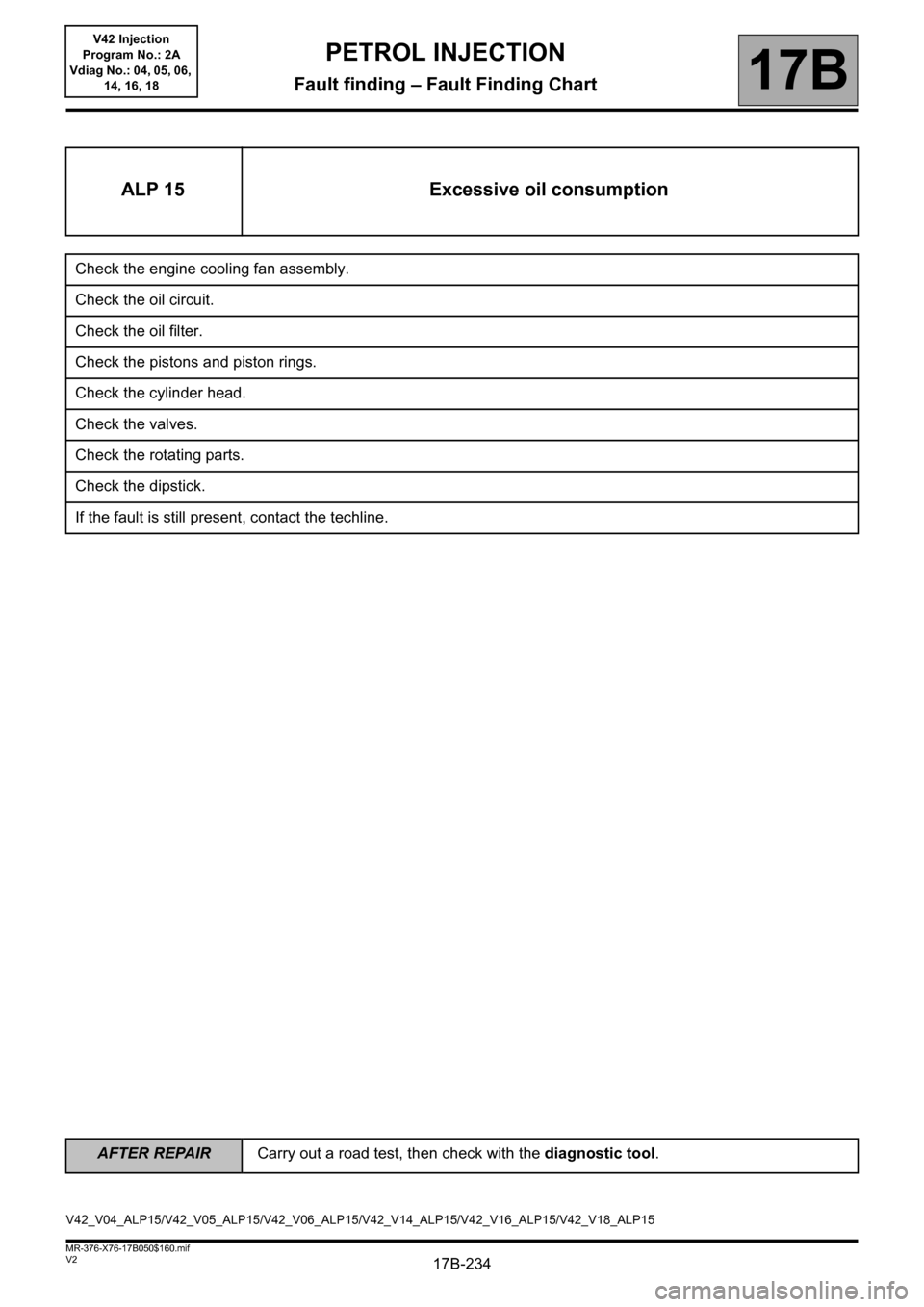

ALP 15 Excessive oil consumption

Check the engine cooling fan assembly.

Check the oil circuit.

Check the oil filter.

Check the pistons and piston rings.

Check the cylinder head.

Check the valves.

Check the rotating parts.

Check the dipstick.

If the fault is still present, contact the techline.

V42_V04_ALP15/V42_V05_ALP15/V42_V06_ALP15/V42_V14_ALP15/V42_V16_ALP15/V42_V18_ALP15

Page 235 of 279

17B-235

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$160.mif

PETROL INJECTION

Fault finding – Fault Finding Chart17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

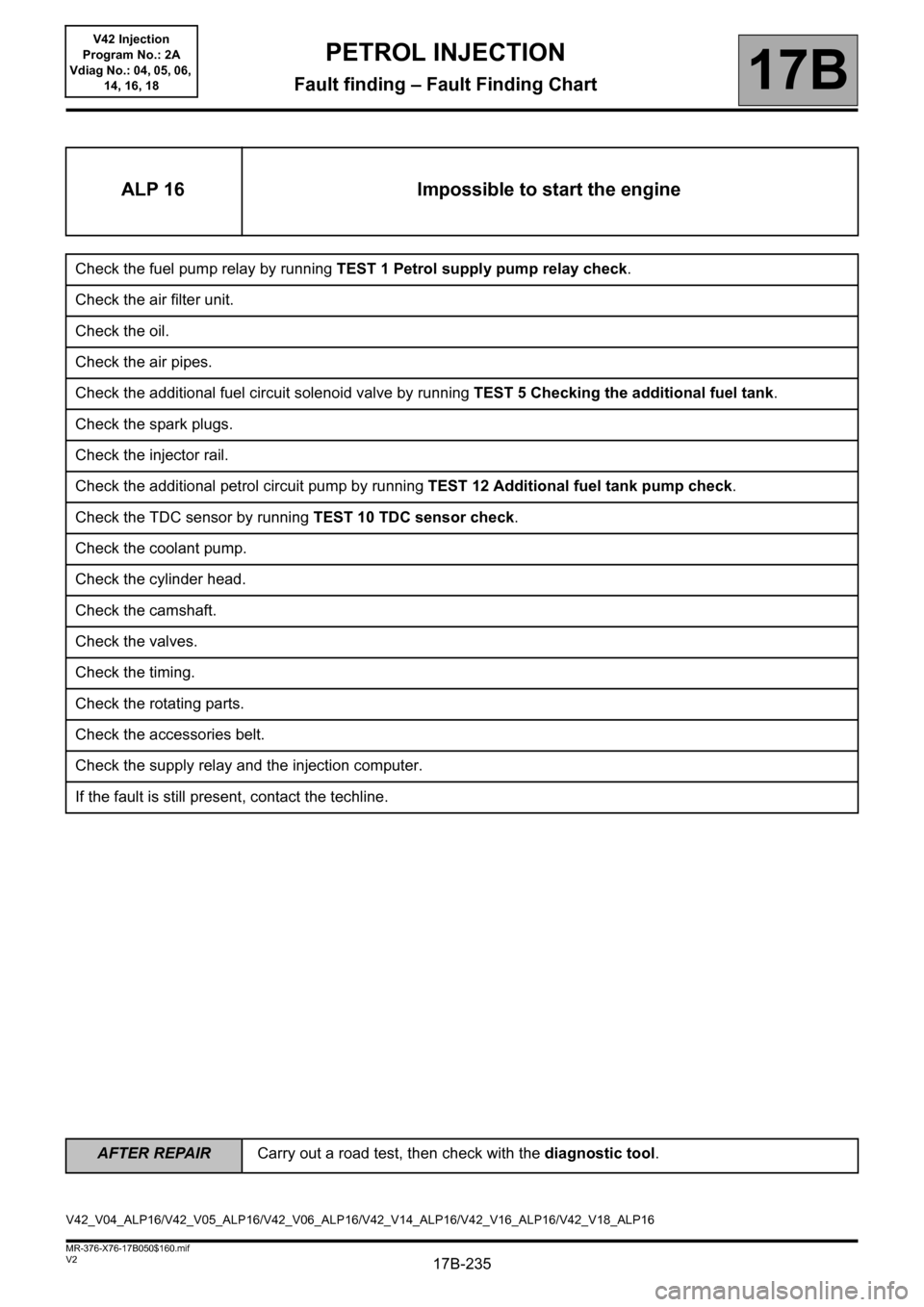

ALP 16 Impossible to start the engine

Check the fuel pump relay by running TEST 1 Petrol supply pump relay check.

Check the air filter unit.

Check the oil.

Check the air pipes.

Check the additional fuel circuit solenoid valve by running TEST 5 Checking the additional fuel tank.

Check the spark plugs.

Check the injector rail.

Check the additional petrol circuit pump by running TEST 12 Additional fuel tank pump check.

Check the TDC sensor by running TEST 10 TDC sensor check.

Check the coolant pump.

Check the cylinder head.

Check the camshaft.

Check the valves.

Check the timing.

Check the rotating parts.

Check the accessories belt.

Check the supply relay and the injection computer.

If the fault is still present, contact the techline.

V42_V04_ALP16/V42_V05_ALP16/V42_V06_ALP16/V42_V14_ALP16/V42_V16_ALP16/V42_V18_ALP16

Page 236 of 279

17B-236

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$160.mif

PETROL INJECTION

Fault finding – Fault Finding Chart17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

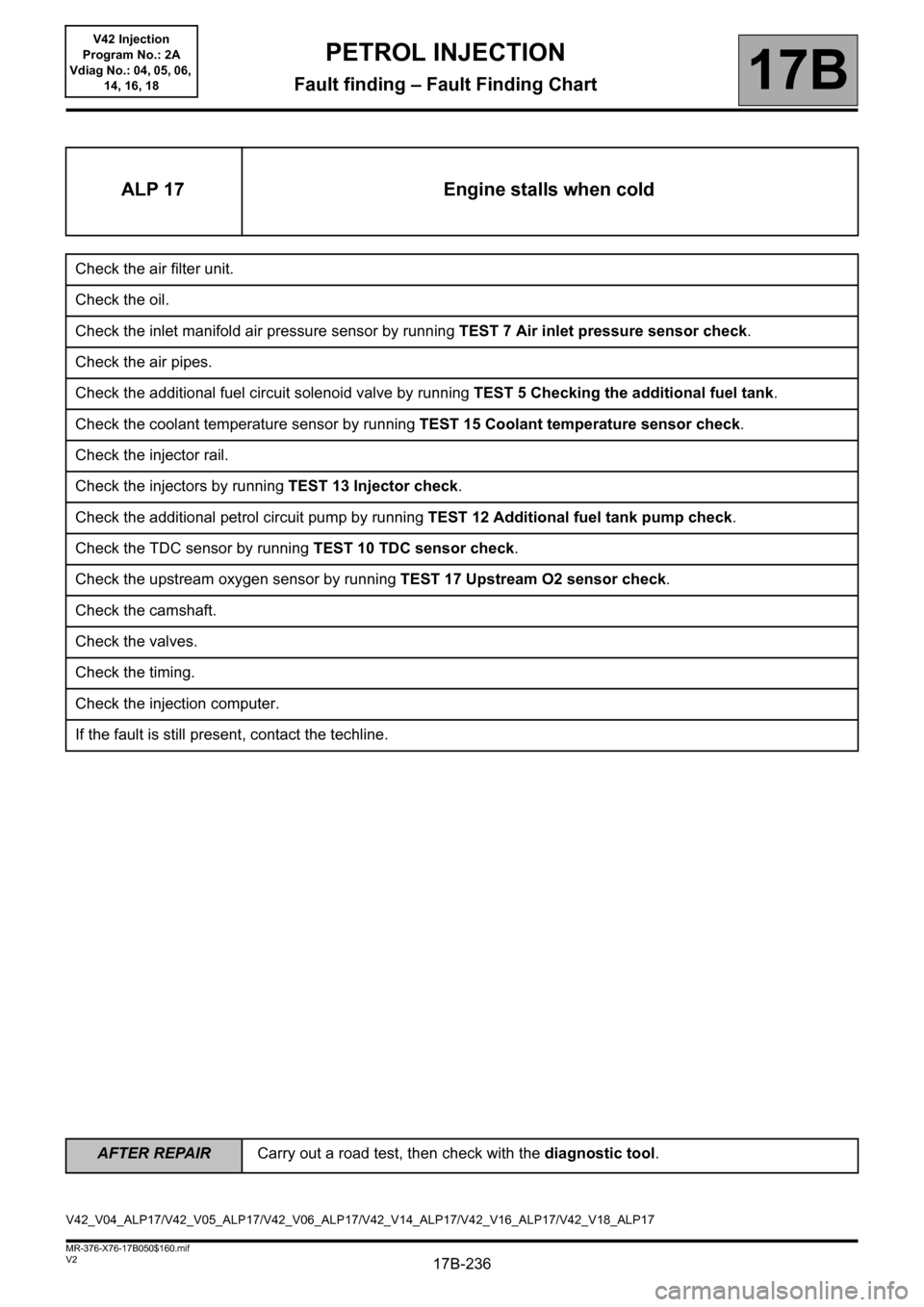

ALP 17 Engine stalls when cold

Check the air filter unit.

Check the oil.

Check the inlet manifold air pressure sensor by running TEST 7 Air inlet pressure sensor check.

Check the air pipes.

Check the additional fuel circuit solenoid valve by running TEST 5 Checking the additional fuel tank.

Check the coolant temperature sensor by running TEST 15 Coolant temperature sensor check.

Check the injector rail.

Check the injectors by running TEST 13 Injector check.

Check the additional petrol circuit pump by running TEST 12 Additional fuel tank pump check.

Check the TDC sensor by running TEST 10 TDC sensor check.

Check the upstream oxygen sensor by running TEST 17 Upstream O2 sensor check.

Check the camshaft.

Check the valves.

Check the timing.

Check the injection computer.

If the fault is still present, contact the techline.

V42_V04_ALP17/V42_V05_ALP17/V42_V06_ALP17/V42_V14_ALP17/V42_V16_ALP17/V42_V18_ALP17

Page 237 of 279

17B-237

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$160.mif

PETROL INJECTION

Fault finding – Fault Finding Chart17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

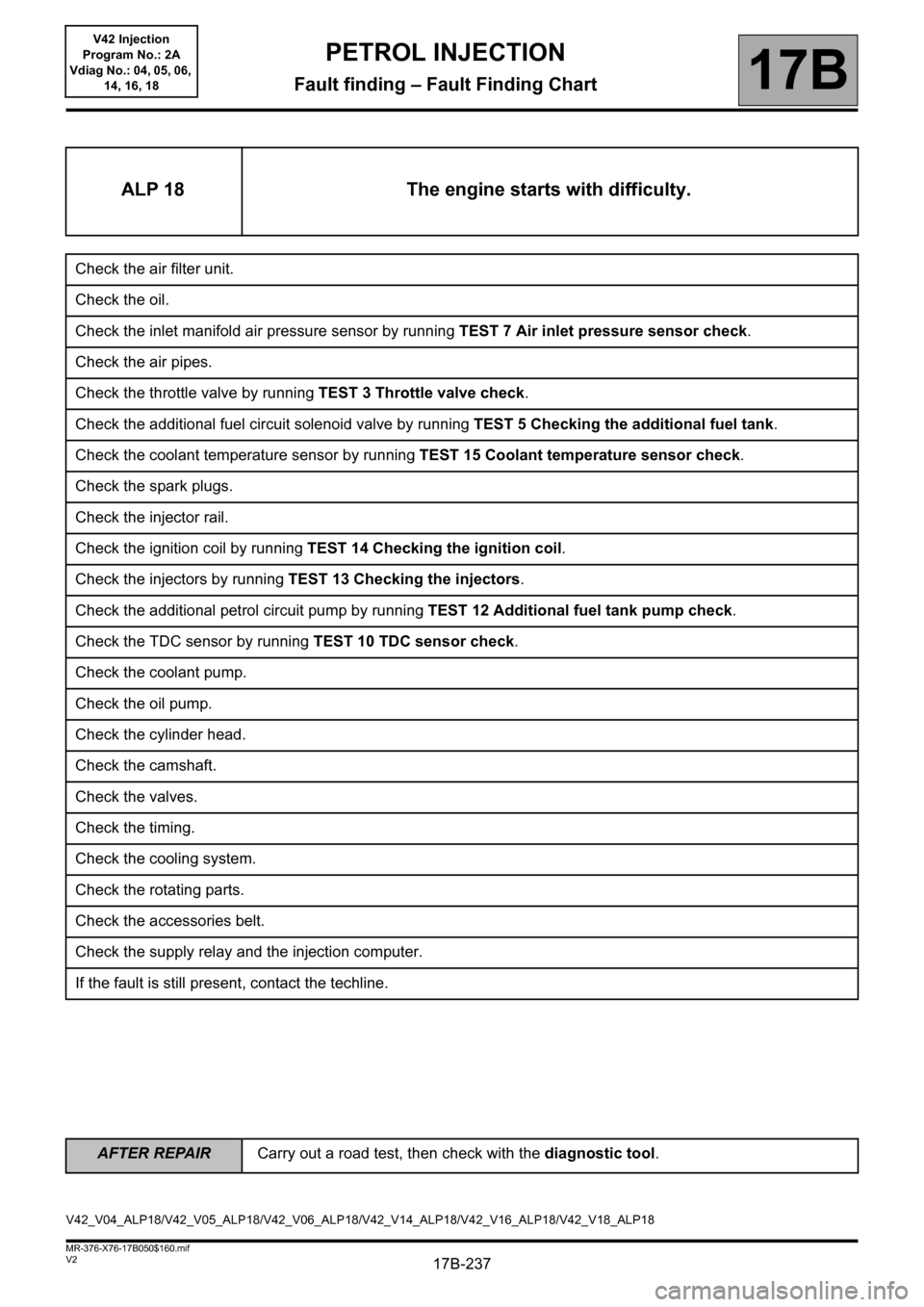

ALP 18 The engine starts with difficulty.

Check the air filter unit.

Check the oil.

Check the inlet manifold air pressure sensor by running TEST 7 Air inlet pressure sensor check.

Check the air pipes.

Check the throttle valve by running TEST 3 Throttle valve check.

Check the additional fuel circuit solenoid valve by running TEST 5 Checking the additional fuel tank.

Check the coolant temperature sensor by running TEST 15 Coolant temperature sensor check.

Check the spark plugs.

Check the injector rail.

Check the ignition coil by running TEST 14 Checking the ignition coil.

Check the injectors by running TEST 13 Checking the injectors.

Check the additional petrol circuit pump by running TEST 12 Additional fuel tank pump check.

Check the TDC sensor by running TEST 10 TDC sensor check.

Check the coolant pump.

Check the oil pump.

Check the cylinder head.

Check the camshaft.

Check the valves.

Check the timing.

Check the cooling system.

Check the rotating parts.

Check the accessories belt.

Check the supply relay and the injection computer.

If the fault is still present, contact the techline.

V42_V04_ALP18/V42_V05_ALP18/V42_V06_ALP18/V42_V14_ALP18/V42_V16_ALP18/V42_V18_ALP18

Page 238 of 279

17B-238

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$160.mif

PETROL INJECTION

Fault finding – Fault Finding Chart17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

ALP 19 Lack of power or torque

Check the air filter unit.

Check that the floor carpet is correctly positioned.

Check the engine cooling fan assembly.

Check the accelerator pedal potentiometer by running TEST 8 Accelerator pedal potentiometer check.

Check the air filter unit.

Check the air pressure sensor of the inlet manifold by running TEST 7 Inlet air pressure sensor check.

Check the air pipes.

Check the air inlet temperature sensor by running TEST 6 Checking the air temperature sensor.

Check the throttle valve by running TEST 3 Throttle valve check.

Check the additional fuel circuit solenoid valve by running TEST 5 Checking the additional fuel tank.

Check the spark plugs.

Check the injector rail.

Check the inlet manifold.

Check the ignition coil by running TEST 14 Checking the ignition coil.

Check the injectors by running TEST 13 Checking the injectors.

Check the additional petrol circuit pump by running TEST 12 Additional fuel tank pump check.

Check the TDC sensor by running TEST 10 TDC sensor check.

Check the pinking sensor by running TEST 11 Pinking sensor check.

Check the oil circuit.

Check the oil filter.

Check the upstream oxygen sensor by running TEST 17 Checking the upstream O2 sensor.

V42_V04_ALP19/V42_V05_ALP19/V42_V06_ALP19/V42_V14_ALP19/V42_V16_ALP19/V42_V18_ALP19

Page 244 of 279

17B-244

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$160.mif

PETROL INJECTION

Fault finding – Fault Finding Chart17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

ALP 24 Engine stalls

Check the fuel pump relay by running TEST 1 Petrol supply pump relay check.

Check the air filter unit.

Check the inlet manifold air pressure sensor by running TEST 7 Air inlet pressure sensor check.

Check the air pipes.

Check the additional fuel circuit solenoid valve by running TEST 5 Checking the additional fuel tank.

Check the injector rail.

Check the injectors by running TEST 13 Checking the injectors.

Check the additional petrol circuit pump by running TEST 12 Additional fuel tank pump check.

Check the TDC sensor by running TEST 10 TDC sensor check.

Check the upstream oxygen sensor by running TEST 17 Checking the upstream O2 sensor.

Check the downstream oxygen sensor by running TEST 18 Checking the downstream O2 sensor.

Check the camshaft.

Check the valves.

Check the timing.

Check the injection computer.

Check the injection computer supply relay.

If the fault is still present, contact the techline.

V42_V04_ALP24/V42_V05_ALP24/V42_V06_ALP24/V42_V14_ALP24/V42_V16_ALP24/V42_V18_ALP24

Page 247 of 279

17B-247

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$160.mif

PETROL INJECTION

Fault finding – Fault Finding Chart17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

ALP 27 Engine racing (without action on the accelerator pedal)

Check the accelerator pedal potentiometer by running TEST 8 Accelerator pedal potentiometer check.

Check the throttle valve by running TEST 3 Throttle valve check.

Check the injection computer.

If the fault is still present, contact the techline.

V42_V04_ALP27/V42_V05_ALP27/V42_V06_ALP27/V42_V14_ALP27/V42_V16_ALP27/V42_V18_ALP27

Page 251 of 279

17B-251

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$180.mif

PETROL INJECTION

Fault finding – Tests17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

TEST 2 Alternator signal module check

NOTESSee the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2, Clio II F 6, Kangoo VLL.

With the engine running, check the alternator charge without any electrical consumers switched on using PR002

Alternator charge, then switch on the consumers and check the increase in PR002.

Check the cleanliness and condition of the alternator connector, component code 103 and of the injection

computer connector, component code 120.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector(s), otherwise replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connection.

–2K between components 103 and 120.

If the connection is faulty and if there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the check is correct, replace the alternator signal module, component code 103 (see MR 388 (Logan and

Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374 (Kangoo VLL),

Mechanical, 16A, Starting - Charging, Alternator: Removal - Refitting).

If the fault is still present, contact the techline.

V42_V04_TEST2/V42_V05_TEST2/V42_V06_TEST2/V42_V14_TEST2/V42_V16_TEST2/V42_V18_TEST2

Page 252 of 279

17B-252

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$180.mif

PETROL INJECTION

Fault finding – Tests17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

TEST 3 Throttle valve check

NOTESNone.

Check that parameter PR444 Idle speed regulation integral correction is between:

5 N.m < PR444 < 10 N.m (K4M, K7M engine) or -5 N.m < PR444 < 5 N.m (D4D, F4R and K4M engine of Duster).

The attempt is made with the engine idling and warm (75°C), without any electrical consumers switched on. The

value of PR444 must be read at least 20 minutes after the engine coolant temperature has reached 75°C.

If the value of PR444 is greater than 10 N.m (K4M, K7M engine) or 5 N.m (D4D, F4R and K4M engine of Duster),

reprogram the throttle valve using command RZ031 Throttle stop programming.

If the value of PR444 is less than -5 N.m, check the fitting of the throttle and check for possible air leaks (see MR

388 (Logan and Sandero), MR 451 (Duster), MR 423 (Thalia 2/Symbol 2), MR 430 (Clio II F 6) or MR 374

(Kangoo VLL), Mechanical, 12A, Fuel mixture, Throttle valve: Removal - Refitting).

If the fault is still present, contact the techline.

V42_V04_TEST3/V42_V05_TEST3/V42_V06_TEST3/V42_V14_TEST3/V42_V16_TEST3/V42_V18_TEST3

Page 253 of 279

17B-253

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V2 MR-376-X76-17B050$180.mif

PETROL INJECTION

Fault finding – Tests17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

TEST 4 Fuel vapour absorber solenoid valve check

NOTESSee the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2, Clio II F 6, Kangoo VLL.

Check the cleanliness, mounting, possible leaks and the hoses of the fuel vapour absorber solenoid valve,

component code 371 (see MR 388, Mechanical, 14A, Emission control, Fuel vapour recirculation circuit:

Check or MR 451 (Duster) or MR 423 (Thalia 2/Symbol 2), Mechanical, 14A, Emission control, Fuel vapour

absorber: Removal - Refitting).

Listen for the operation of the solenoid valve while running command AC017 Canister bleed solenoid valve.

With the engine idling, disconnect the pipe at the solenoid valve inlet and check that there is no suction on your

finger. (These steps allow the sealing of the solenoid valve to be checked for air tightness.)

Check the cleanliness and condition of the canister bleed solenoid valve connector, component code 371 and

of the injection computer connector, component code 120.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector(s), otherwise replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3FB between components 371 and 1047 (for Logan, Sandero, Duster) or 238 (for Thalia 2/Symbol 2, Kangoo

VLL) or 983 (for Clio II F 6),

–3BB between components 371 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

V42_V04_TEST4/V42_V05_TEST4/V42_V06_TEST4/V42_V14_TEST4/V42_V16_TEST4/V42_V18_TEST4