reset RENAULT KANGOO 2013 X61 / 2.G Petrol V42 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 279, PDF Size: 1.29 MB

Page 13 of 279

17B-13V2 MR-376-X76-17B050$060.mif

PETROL INJECTION

Fault finding – Replacement of components17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

Programming the alcohol level

– Put the vehicle under + after ignition and wait for the value of parameter PR064 Coolant temperature to be greater

than or equal to 80°C.

– There must be no present or stored faults.

– With the ignition on and engine stopped, note the value of PR743 Estimated alcohol level in the tank.

– Carry out resetting using command RZ064 Programming the alcohol level.

– Start the engine and allow the engine to idle for 5 minutes.

– Check the correct programming using parameter PR743; its value must have changed.

– If programming was not performed correctly, repeat the operation from the start.

– If the fault is still present, contact the Techline.

Injection computer initialisation

Start and stop the engine to initialise the computer and wait for the loss of communication message to appear on the

diagnostic tool. If the message does not appear, wait for 9 minutes.

The computer is automatically configured according to the sensors and options present on the vehicle.

If the data were not saved before the operation, carry out the following operations:

– Programming the VIN code

– Enter the V.I.N. using command VP010 Enter VIN.

– Injector programming

Program the injectors by accessing the sub-section entitled Injector replacement operations.

– Programming the TDC sensor

Program the TDC sensor by accessing the sub-section entitled TDC (Top Dead Centre) sensor replacement

operations.

– Programming the motorised throttle

Program the motorised throttle by accessing the sub-section entitled Throttle valve replacement operations.

– Injection computer initialisation

Start and stop the engine to initialise the computer and wait for the loss of communication message to appear on the

diagnostic tool, if the message does not appear, wait for 9 minutes.

The computer is automatically configured according to the sensors and options present on the vehicle.

Page 14 of 279

17B-14V2 MR-376-X76-17B050$060.mif

PETROL INJECTION

Fault finding – Replacement of components17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

THROTTLE VALVE REPLACEMENT OPERATIONS

– When replacing the inlet throttle valve, switch on the vehicle + after ignition feed, after replacing the part.

– Carry out resetting using command RZ031 Throttle stop programming.

– Switch off the ignition. The inlet valve will run a new programming procedure whilst maintaining the supply (power

latch) due to the reinitialisation phase.

– Check that the programming is correct using status ET051 Throttle stop programming, it must be at 1.

If programming was not performed correctly, repeat the operation from the start.

– If the fault is still present, contact the Techline.

OPERATIONS FOR REPLACING THE BRAKE PEDAL SWITCH

– When replacing the brake pedal switch, switch on the vehicle + after ignition feed, after replacing the part.

– Check that the switch statuses change as follows, when the brake pedal is activated:

–ET039 Brake pedal = 1 and ET799 Brake Wire Contact = 1 when the brake pedal is released

–ET039 Brake pedal = 2 and ET799 Brake Wire Contact = 2 when the brake pedal is depressed

OPERATIONS FOR REPLACING THE TDC (TOP DEAD CENTRE) SENSOR

– Switch on the vehicle + after ignition feed,

– Carry out resetting using command RZ037 Flywheel target programming.

Operation for Programming

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator and clutch pedals) between 3500 and

3000 rpm, in 3rd gear for a BVM* for at least 3 seconds.

– Decelerate a second time with injection cut-off (i.e. feet off the brake, accelerator and clutch pedals) between 2400

and 2000 rpm, in 3rd gear for a BVM* for at least 14 seconds (K4M, K7M engine) or 3 seconds (D4D, F4R, K4M

engine of Duster).

*BVM: Manual gearbox

The programming was successful when status ET089 Flywheel target programming has the value1.

Page 15 of 279

17B-15V2 MR-376-X76-17B050$060.mif

PETROL INJECTION

Fault finding – Replacement of components17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

OPERATIONS FOR REPLACING THE INJECTORS

– Switch on the vehicle + after ignition feed after replacing the part.

Carry out resetting using command RZ033 Richness regulation programming.

– Switch off the ignition.

A power latch is necessary to save the reset data.

– Switch on the vehicle + after ignition feed and check the values of the following parameters:

PR624 Richness regulation programming offset

PR625 Richness regulation programming gain

– Test the injectors using the following commands:

AC005 Cylinder 1 injector

AC006 Cylinder 2 injector

AC007 Cylinder 3 injector

AC008 Cylinder 4 injector.

OPERATIONS OF REPLACING THE CAMSHAFT DEPHASER SOLENOID VALVE

– Switch on the vehicle + after ignition feed.

– Reset to zero using command RZ001 Fault memory.

– Start the engine and allow the engine to idle for at least 60 seconds.

– Switch off the engine.

– Wait for the end of the power-latch phase and switch on the vehicle + after ignition.

– Check that ET845 Camshaft dephaser s.v.* programming is PERFORMED.

*s.v.: solenoid valve

Page 213 of 279

17B-213V2 MR-376-X76-17B050$140.mif

17B

V42 Injection

Program No.: 2A

Vdiag No.: 04, 05, 06,

14, 16, 18

*TDC: Top Dead Centre

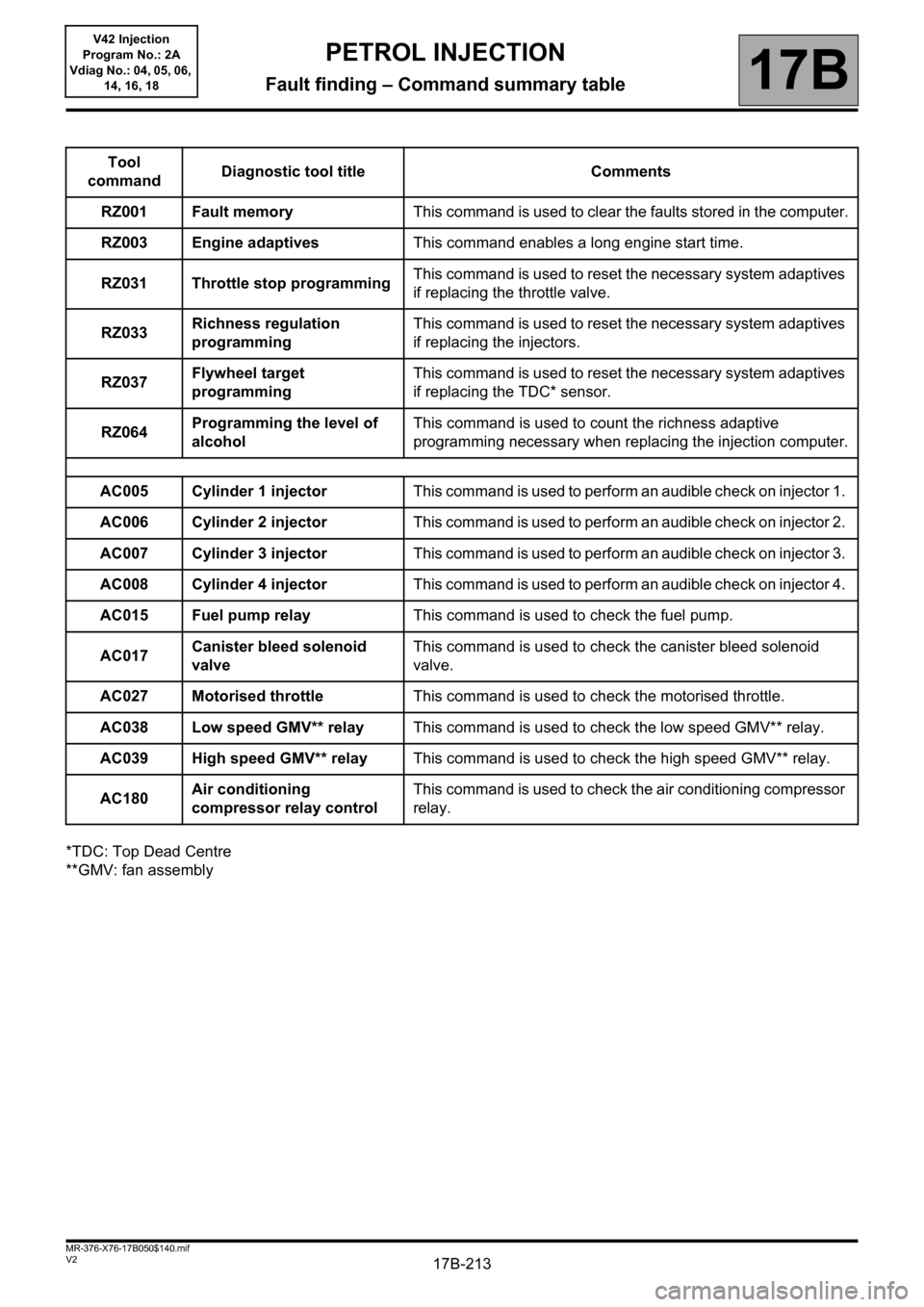

**GMV: fan assemblyTool

commandDiagnostic tool title Comments

RZ001 Fault memoryThis command is used to clear the faults stored in the computer.

RZ003 Engine adaptivesThis command enables a long engine start time.

RZ031 Throttle stop programmingThis command is used to reset the necessary system adaptives

if replacing the throttle valve.

RZ033Richness regulation

programmingThis command is used to reset the necessary system adaptives

if replacing the injectors.

RZ037Flywheel target

programmingThis command is used to reset the necessary system adaptives

if replacing the TDC* sensor.

RZ064Programming the level of

alcoholThis command is used to count the richness adaptive

programming necessary when replacing the injection computer.

AC005 Cylinder 1 injectorThis command is used to perform an audible check on injector 1.

AC006 Cylinder 2 injectorThis command is used to perform an audible check on injector 2.

AC007 Cylinder 3 injectorThis command is used to perform an audible check on injector 3.

AC008 Cylinder 4 injectorThis command is used to perform an audible check on injector 4.

AC015 Fuel pump relayThis command is used to check the fuel pump.

AC017Canister bleed solenoid

valveThis command is used to check the canister bleed solenoid

valve.

AC027 Motorised throttleThis command is used to check the motorised throttle.

AC038 Low speed GMV** relayThis command is used to check the low speed GMV** relay.

AC039 High speed GMV** relayThis command is used to check the high speed GMV** relay.

AC180Air conditioning

compressor relay controlThis command is used to check the air conditioning compressor

relay.

PETROL INJECTION

Fault finding – Command summary table