check engine RENAULT KANGOO 2013 X61 / 2.G Power Steering Pump Assembly Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 30, PDF Size: 0.36 MB

Page 7 of 30

36B-7V1 MR-376-X76-36B000$040.mif

36B

GEPDA

Vdiag No.: 04

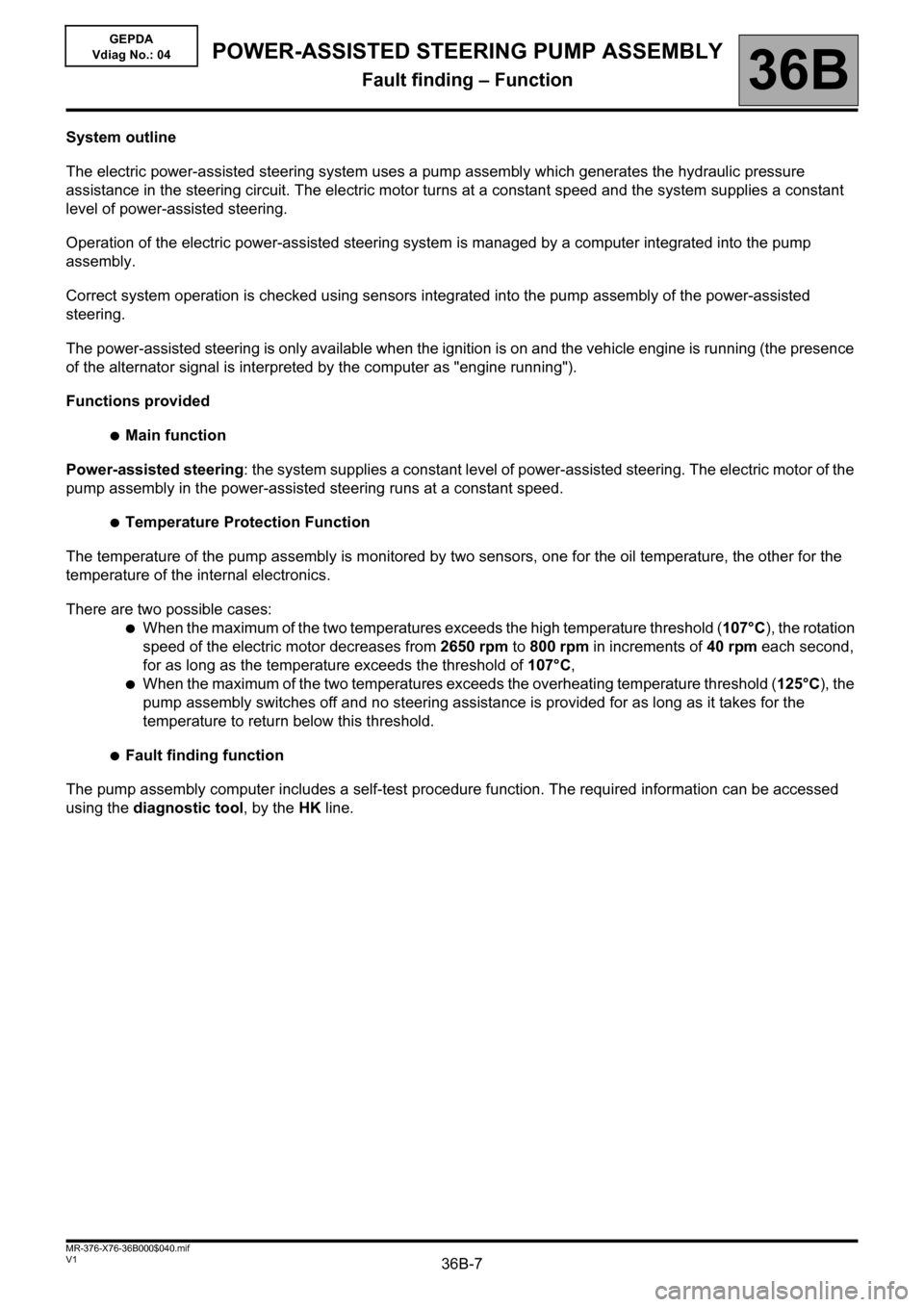

System outline

The electric power-assisted steering system uses a pump assembly which generates the hydraulic pressure

assistance in the steering circuit. The electric motor turns at a constant speed and the system supplies a constant

level of power-assisted steering.

Operation of the electric power-assisted steering system is managed by a computer integrated into the pump

assembly.

Correct system operation is checked using sensors integrated into the pump assembly of the power-assisted

steering.

The power-assisted steering is only available when the ignition is on and the vehicle engine is running (the presence

of the alternator signal is interpreted by the computer as "engine running").

Functions provided

●Main function

Power-assisted steering: the system supplies a constant level of power-assisted steering. The electric motor of the

pump assembly in the power-assisted steering runs at a constant speed.

●Temperature Protection Function

The temperature of the pump assembly is monitored by two sensors, one for the oil temperature, the other for the

temperature of the internal electronics.

There are two possible cases:

●When the maximum of the two temperatures exceeds the high temperature threshold (107°C), the rotation

speed of the electric motor decreases from 2650 rpm to 800 rpm in increments of 40 rpm each second,

for as long as the temperature exceeds the threshold of 107°C,

●When the maximum of the two temperatures exceeds the overheating temperature threshold (125°C), the

pump assembly switches off and no steering assistance is provided for as long as it takes for the

temperature to return below this threshold.

●Fault finding function

The pump assembly computer includes a self-test procedure function. The required information can be accessed

using the diagnostic tool, by the HK line.

POWER-ASSISTED STEERING PUMP ASSEMBLY

Fault finding – Function

Page 9 of 30

36B-9V1 MR-376-X76-36B000$070.mif

36B

GEPDA

Vdiag No.: 04

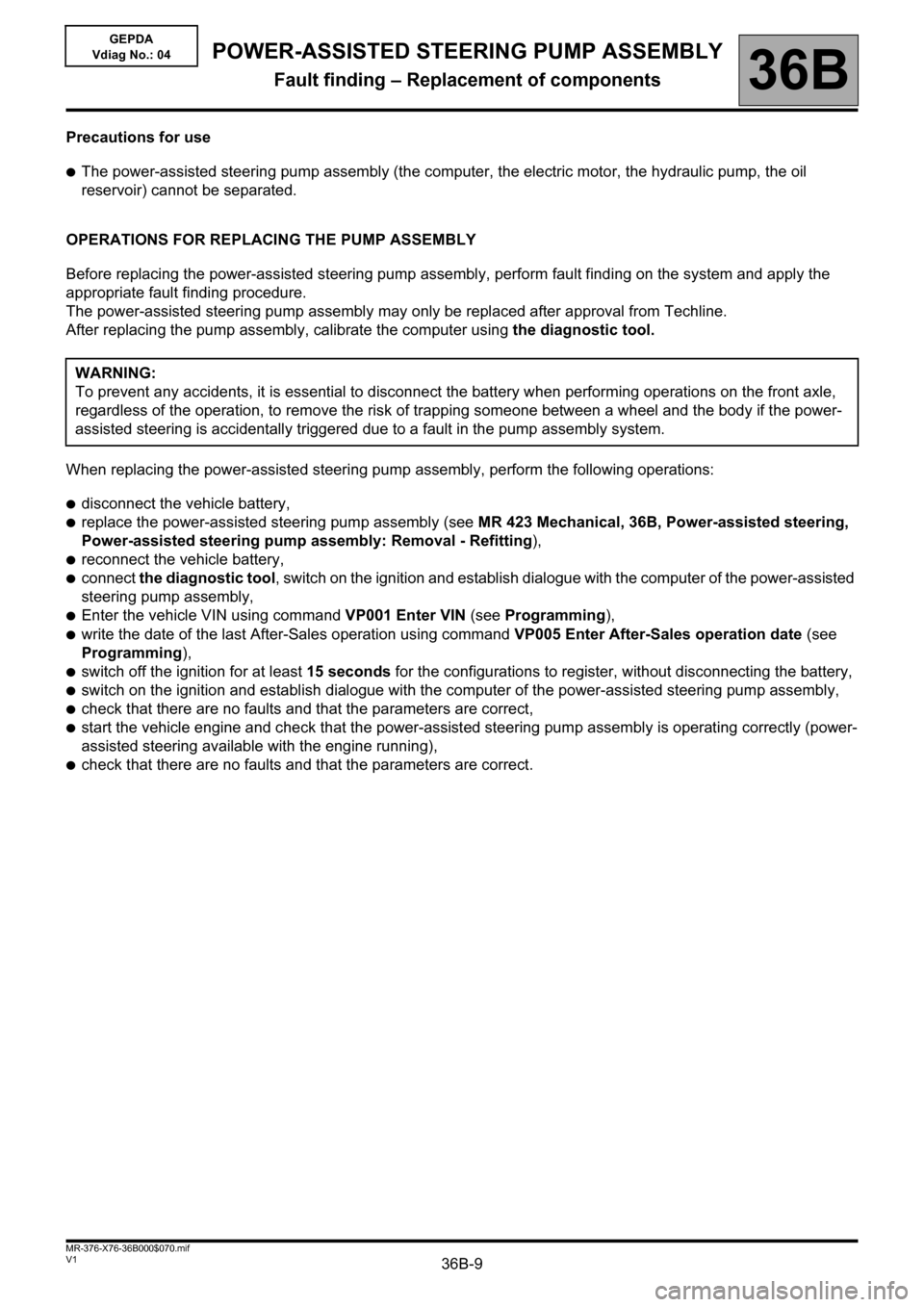

Precautions for use

●The power-assisted steering pump assembly (the computer, the electric motor, the hydraulic pump, the oil

reservoir) cannot be separated.

OPERATIONS FOR REPLACING THE PUMP ASSEMBLY

Before replacing the power-assisted steering pump assembly, perform fault finding on the system and apply the

appropriate fault finding procedure.

The power-assisted steering pump assembly may only be replaced after approval from Techline.

After replacing the pump assembly, calibrate the computer using the diagnostic tool.

When replacing the power-assisted steering pump assembly, perform the following operations:

●disconnect the vehicle battery,

●replace the power-assisted steering pump assembly (see MR 423 Mechanical, 36B, Power-assisted steering,

Power-assisted steering pump assembly: Removal - Refitting),

●reconnect the vehicle battery,

●connect the diagnostic tool, switch on the ignition and establish dialogue with the computer of the power-assisted

steering pump assembly,

●Enter the vehicle VIN using command VP001 Enter VIN (see Programming),

●write the date of the last After-Sales operation using command VP005 Enter After-Sales operation date (see

Programming),

●switch off the ignition for at least 15 seconds for the configurations to register, without disconnecting the battery,

●switch on the ignition and establish dialogue with the computer of the power-assisted steering pump assembly,

●check that there are no faults and that the parameters are correct,

●start the vehicle engine and check that the power-assisted steering pump assembly is operating correctly (power-

assisted steering available with the engine running),

●check that there are no faults and that the parameters are correct. WARNING:

To prevent any accidents, it is essential to disconnect the battery when performing operations on the front axle,

regardless of the operation, to remove the risk of trapping someone between a wheel and the body if the power-

assisted steering is accidentally triggered due to a fault in the pump assembly system.

POWER-ASSISTED STEERING PUMP ASSEMBLY

Fault finding – Replacement of components

Page 15 of 30

36B-15V1 MR-376-X76-36B000$100.mif

36B

GEPDA

Vdiag No.: 04

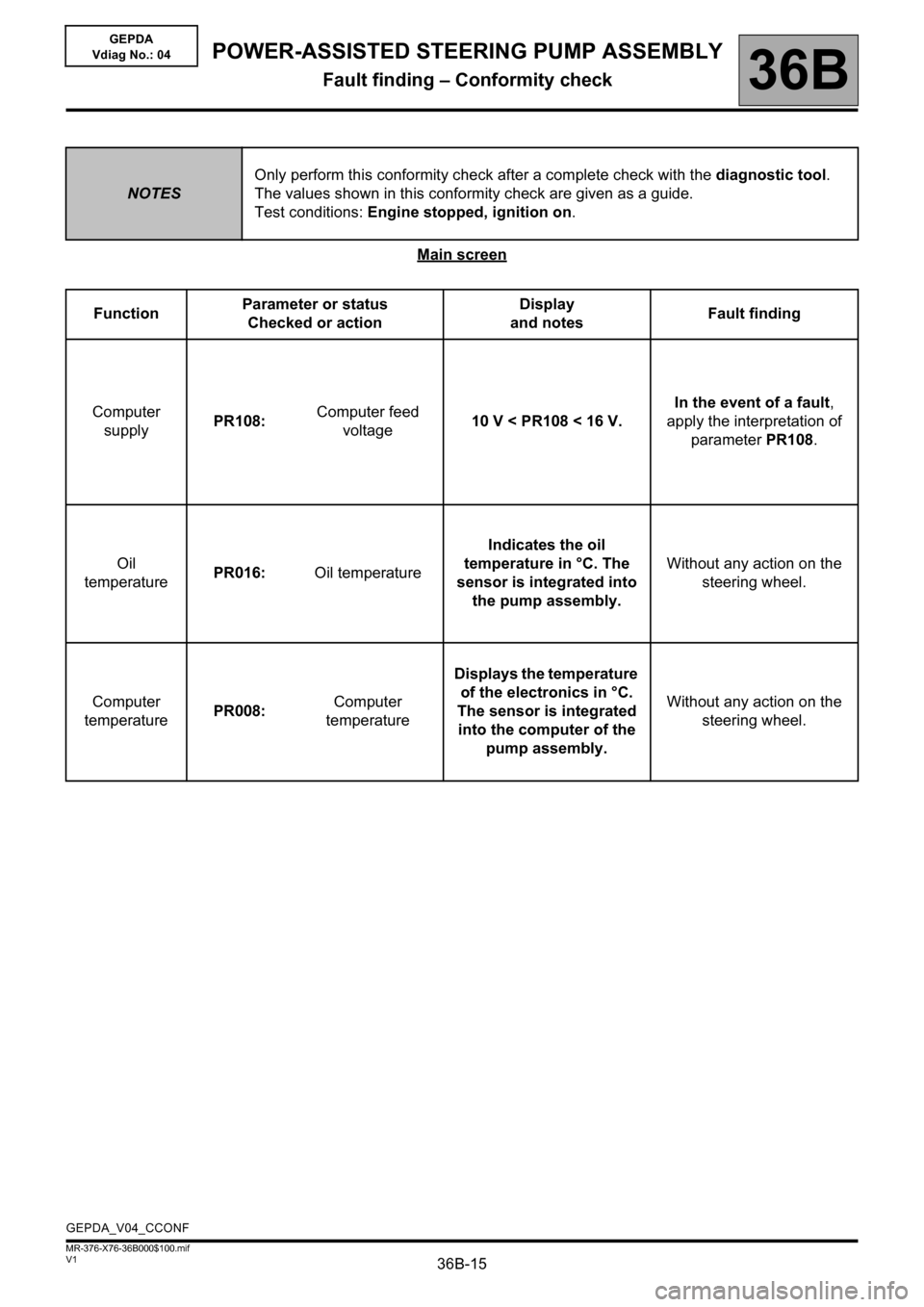

Main screen

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Test conditions: Engine stopped, ignition on.

FunctionParameter or status

Checked or actionDisplay

and notesFault finding

Computer

supplyPR108: Computer feed

voltage10 V < PR108 < 16 V.In the event of a fault,

apply the interpretation of

parameter PR108.

Oil

temperaturePR016: Oil temperatureIndicates the oil

temperature in °C. The

sensor is integrated into

the pump assembly.Without any action on the

steering wheel.

Computer

temperaturePR008: Computer

temperatureDisplays the temperature

of the electronics in °C.

The sensor is integrated

into the computer of the

pump assembly.Without any action on the

steering wheel.

GEPDA_V04_CCONF

POWER-ASSISTED STEERING PUMP ASSEMBLY

Fault finding – Conformity check

Page 16 of 30

36B-16V1 MR-376-X76-36B000$100.mif

POWER-ASSISTED STEERING PUMP ASSEMBLY

Fault finding – Conformity check36B

GEPDA

Vdiag No.: 04

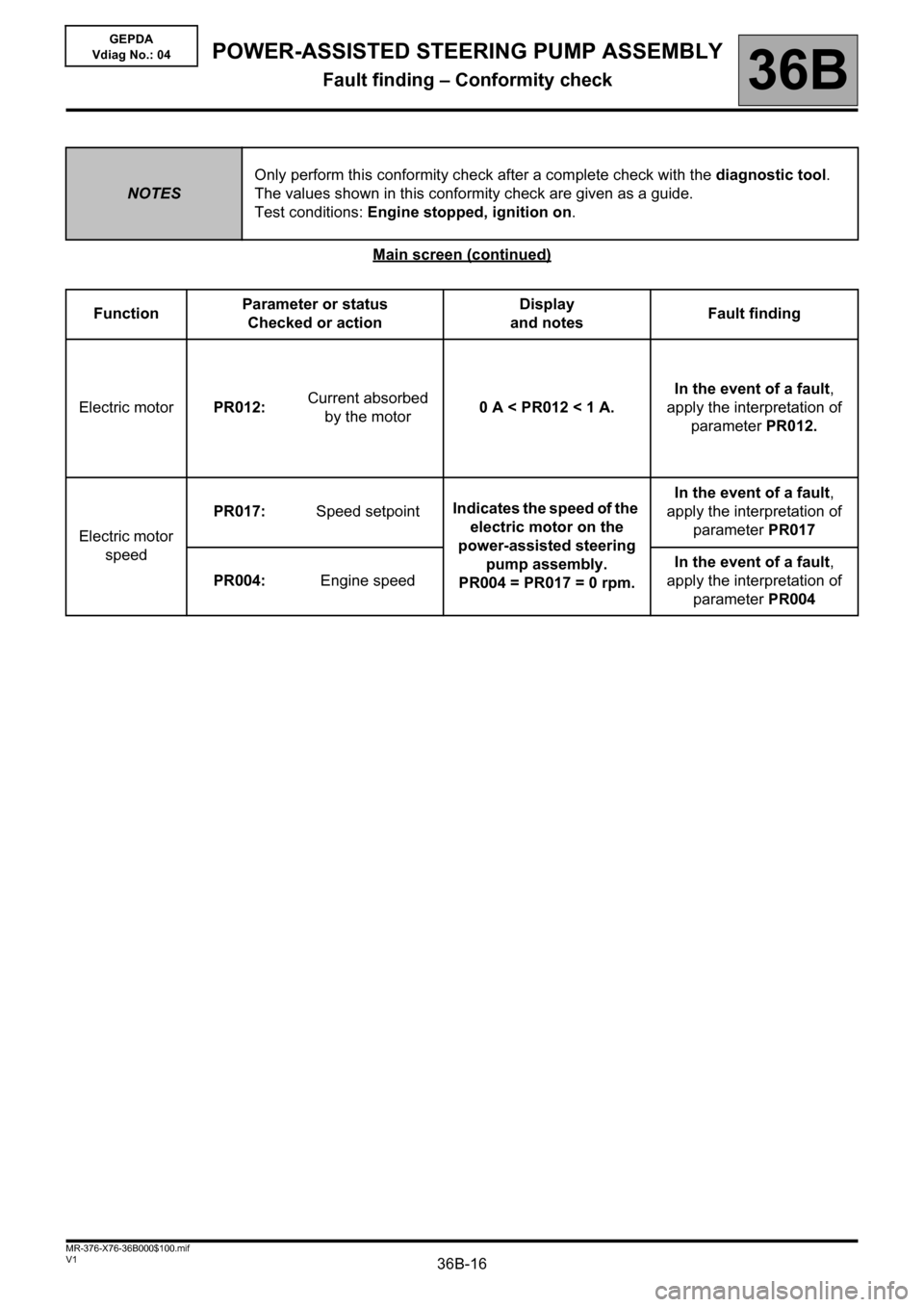

Main screen (continued)

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Test conditions: Engine stopped, ignition on.

FunctionParameter or status

Checked or actionDisplay

and notesFault finding

Electric motorPR012: Current absorbed

by the motor0 A < PR012 < 1 A.In the event of a fault,

apply the interpretation of

parameter PR012.

Electric motor

speedPR017: Speed setpoint Indicates the speed of the

electric motor on the

power-assisted steering

pump assembly.

PR004 = PR017 = 0 rpm.In the event of a fault,

apply the interpretation of

parameter PR017

PR004: Engine speed In the event of a fault,

apply the interpretation of

parameter PR004

Page 17 of 30

36B-17V1 MR-376-X76-36B000$100.mif

POWER-ASSISTED STEERING PUMP ASSEMBLY

Fault finding – Conformity check36B

GEPDA

Vdiag No.: 04

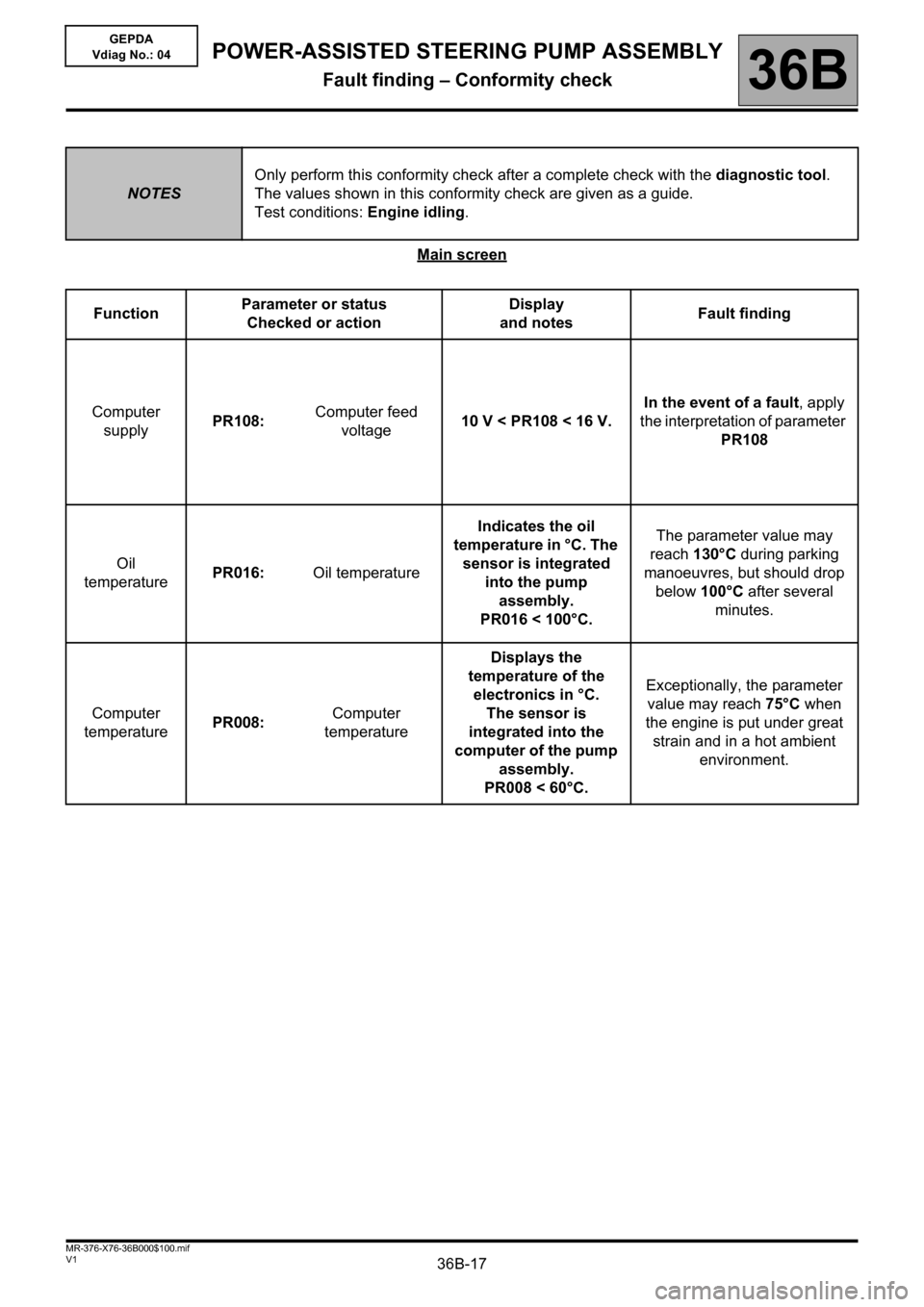

Main screen

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Test conditions: Engine idling.

FunctionParameter or status

Checked or actionDisplay

and notesFault finding

Computer

supplyPR108: Computer feed

voltage10 V < PR108 < 16 V.In the event of a fault, apply

the interpretation of parameter

PR108

Oil

temperaturePR016: Oil temperatureIndicates the oil

temperature in °C. The

sensor is integrated

into the pump

assembly.

PR016 < 100°C.The parameter value may

reach 130°C during parking

manoeuvres, but should drop

below 100°C after several

minutes.

Computer

temperaturePR008: Computer

temperatureDisplays the

temperature of the

electronics in °C.

The sensor is

integrated into the

computer of the pump

assembly.

PR008 < 60°C.Exceptionally, the parameter

value may reach 75°C when

the engine is put under great

strain and in a hot ambient

environment.

Page 18 of 30

36B-18V1 MR-376-X76-36B000$100.mif

POWER-ASSISTED STEERING PUMP ASSEMBLY

Fault finding – Conformity check36B

GEPDA

Vdiag No.: 04

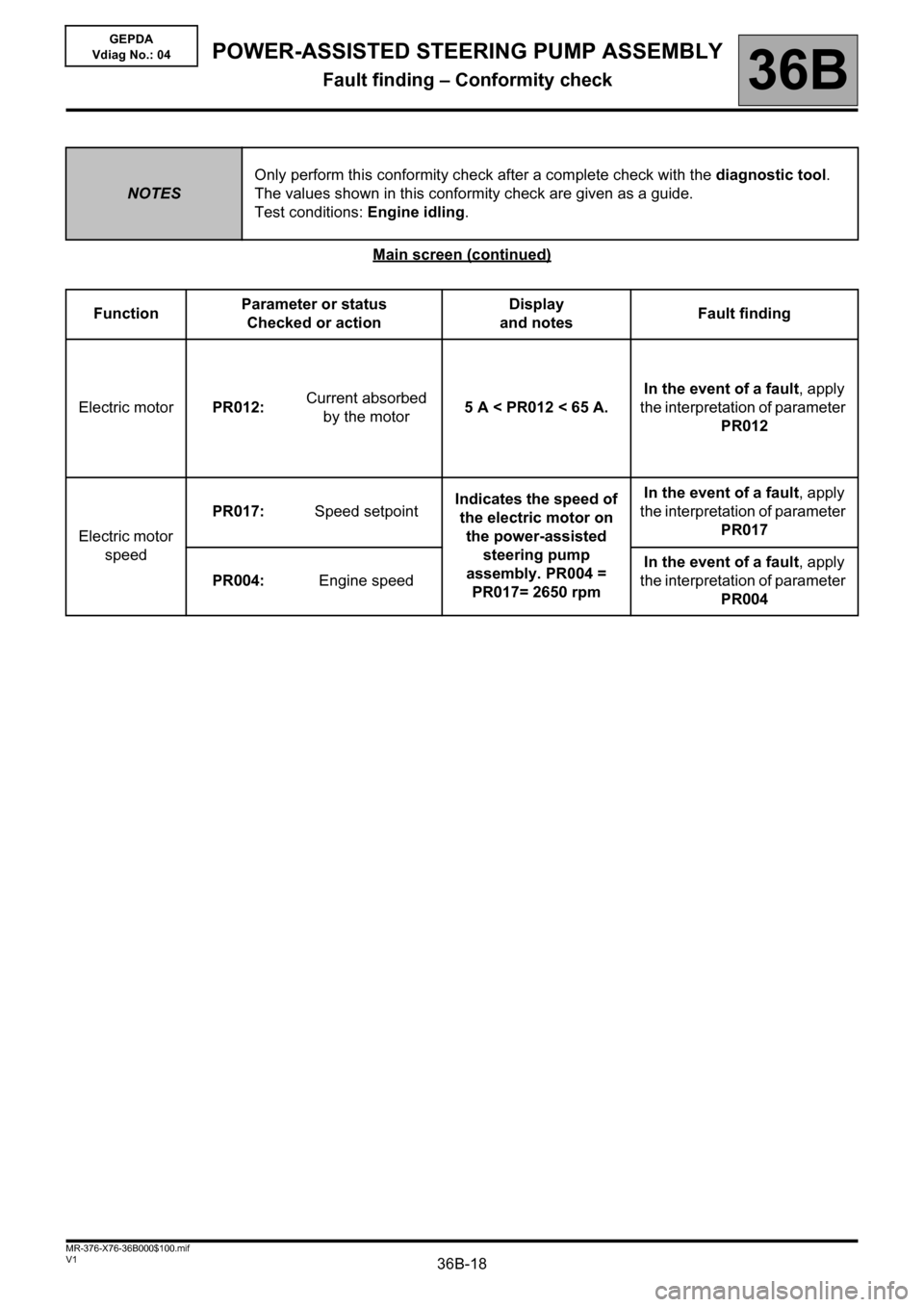

Main screen (continued)

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Test conditions: Engine idling.

FunctionParameter or status

Checked or actionDisplay

and notesFault finding

Electric motorPR012: Current absorbed

by the motor5 A < PR012 < 65 A.In the event of a fault, apply

the interpretation of parameter

PR012

Electric motor

speedPR017: Speed setpoint Indicates the speed of

the electric motor on

the power-assisted

steering pump

assembly. PR004 =

PR017= 2650 rpmIn the event of a fault, apply

the interpretation of parameter

PR017

PR004: Engine speed In the event of a fault, apply

the interpretation of parameter

PR004

Page 25 of 30

36B-25V1 MR-376-X76-36B000$140.mif

36B

GEPDA

Vdiag No.: 04

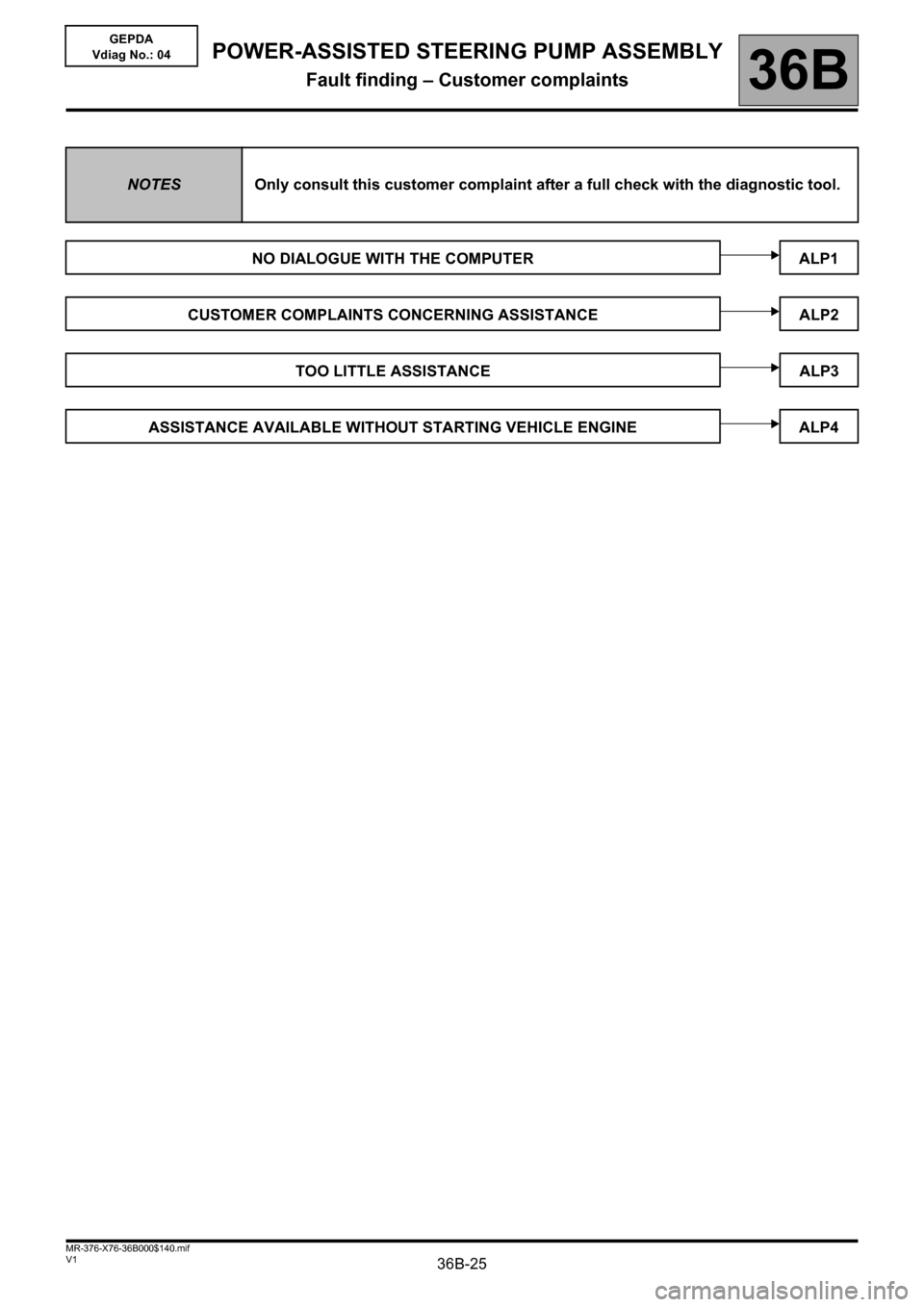

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

NO DIALOGUE WITH THE COMPUTER ALP1

CUSTOMER COMPLAINTS CONCERNING ASSISTANCE ALP2

TOO LITTLE ASSISTANCE ALP3

ASSISTANCE AVAILABLE WITHOUT STARTING VEHICLE ENGINE ALP4

POWER-ASSISTED STEERING PUMP ASSEMBLY

Fault finding – Customer complaints

Page 30 of 30

36B-30

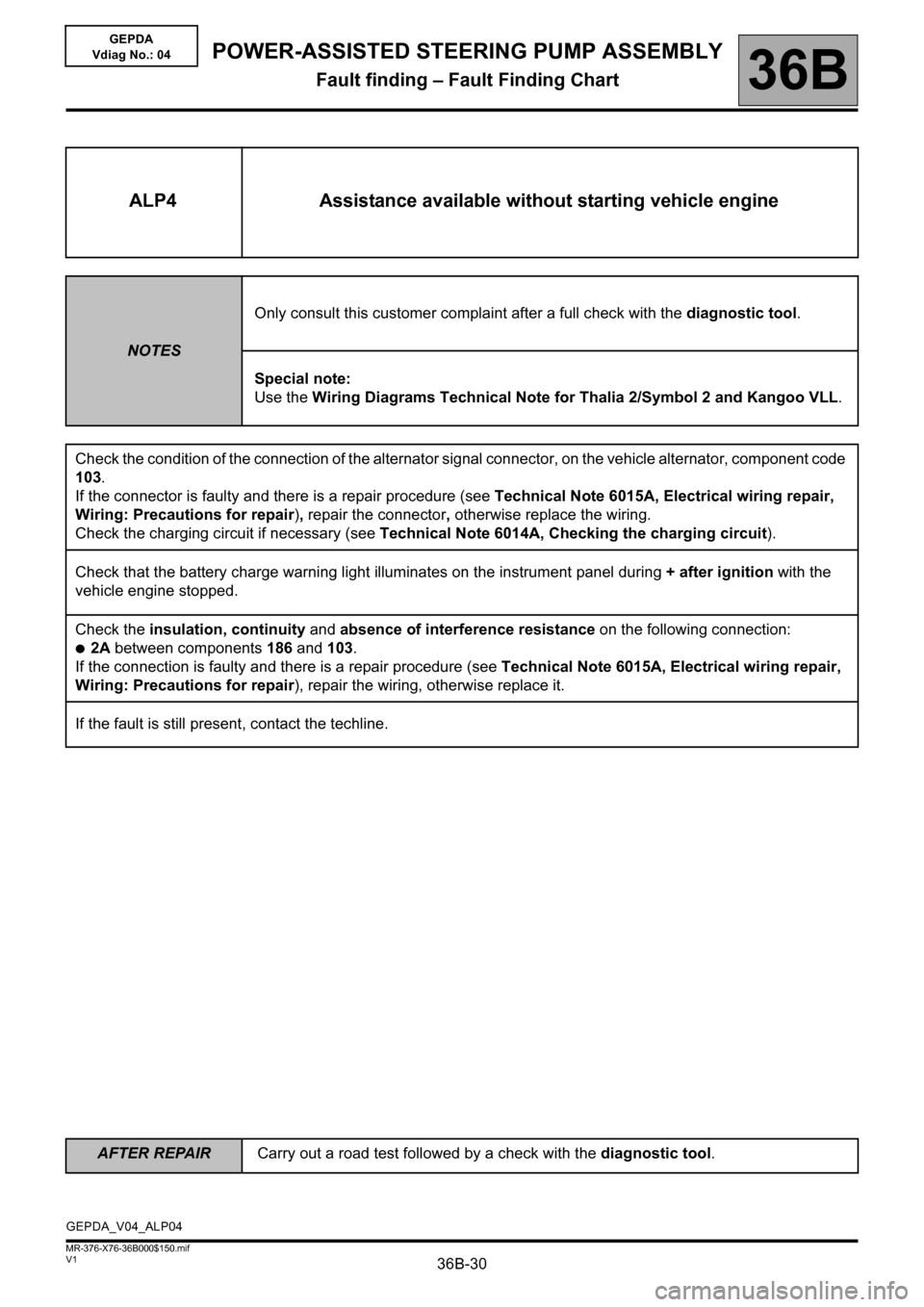

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-36B000$150.mif

POWER-ASSISTED STEERING PUMP ASSEMBLY

Fault finding – Fault Finding Chart36B

GEPDA

Vdiag No.: 04

ALP4 Assistance available without starting vehicle engine

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

Special note:

Use the Wiring Diagrams Technical Note for Thalia 2/Symbol 2 and Kangoo VLL.

Check the condition of the connection of the alternator signal connector, on the vehicle alternator, component code

103.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the charging circuit if necessary (see Technical Note 6014A, Checking the charging circuit).

Check that the battery charge warning light illuminates on the instrument panel during + after ignition with the

vehicle engine stopped.

Check the insulation, continuity and absence of interference resistance on the following connection:

●2A between components 186 and 103.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the techline.

GEPDA_V04_ALP04