charging RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 2 of 118

Downloaded from www.Manualslib.com manuals search engine Contents

Page

07

10

11

12

VALUES AND SETTINGS

Capacities - Grades 07-1

Accessories belt tension 07-2

Checking the accessories belt tension 07-3

Tightening the cylinder head 07-5

Tyres and wheels 07-6

Brakes 07-7

Brake compensator 07-8

Underbody height 07-9

Front axle angle checking values 07-11

Rear axle angle checking values 07-13

ENGINE AND PERIPHERALS

Identification 10-1

Oil pressure 10-2

Engine and transmission assembly 10-3

Sump 10-8

TOP AND FRONT OF ENGINE

Timing belt 11-1

Cylinder head gasket 11-6

FUEL MIXTURE

Air inlet 12-1

TURBOCHARGING

Pressure regulating valve 12-2

Pressure adjustment 12-3

Turbocharger 12-4

Air-air exchanger 12-7

Manifolds 12-9

Priming catalytic converter 12-12Page

13

14

DIESEL EQUIPMENT

Technical specifications 13-1

Special features 13-3

Cleanliness 13-6

Location of components 13-9

Injection warning light 13-12

Immobiliser function 13-13

Injection programming/ air conditioning 13-14

Idle speed correction13-16

Pre-postheating control 13-17

Heater plugs 13-18

Thermoplunger 13-19

Low pressure pump (supercharging

pump)13-21

Fuel filter 13-22

High pressure pump 13-23

Injector gallery 13-27

Injectors 13-32

Checking diesel pressure and flow 13-37

Pressure sensor 13-38

Pressure regulator 13-39

Accelerator potentiometer 13-40

Centralised coolant temperature

management 13-41

Computer 13-42

ANTIPOLLUTION

Oil vapour rebreathing 14-1

Exhaust gas recirculation 14-2

Page 3 of 118

Downloaded from www.Manualslib.com manuals search engine Contents

Page

16

19

21

62

STARTING - CHARGING

Alternator 16-1

Starter 16-4

COOLING SYSTEM

Filling - bleeding 19-1

Diagram 19-2

Thermoplunger unit 19-3

Radiator 19-4

Water pump 19-5

ENGINE MOUNTING

Suspended engine mounting 19-6

Exhaust

Catalytic converter 19-7

MANUAL GEARBOX

Identification 21-1

Gears 21-1

Capacity - Lubricants 21-2

AIR CONDITIONING

General 62-1

Compressor 62-2

Dehydration canister 62-3

Condenser 62-4

Pressure relief valve 62-5

Connecting hoses 62-6

Page 21 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-5

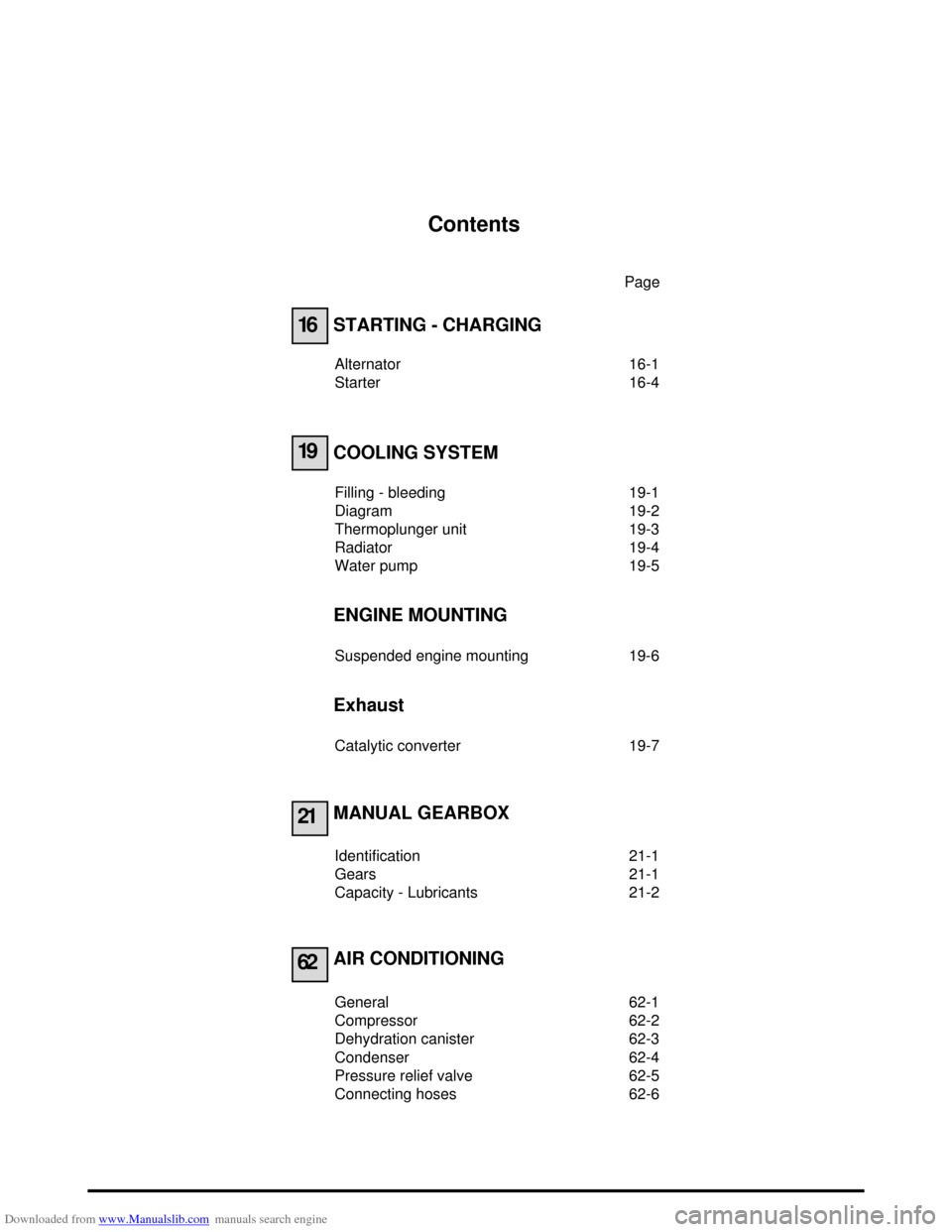

– the closure panel for the plenum chamber.

Remove (all types):

– the shock absorber cap protectors,

– the clutch cable,

– the brake servo vacuum pipe,

– the air intake pipe,

– the turbocharging air ducts between the exchanger

and the engine,

– the hoses on the heater radiator,

– the pipes (6) and the connectors (7),– the battery mounting,

– the expansion bottle mountings and the expansion

bottle,

– the precatalytic converter mountings and the

precatalytic converter,

– the relay plate at (1) and the fuse holder (2) as well

as the connectors (3) and (4),

– the injection computer connectors (8),

– the earth strap (9),

– the fuel pipes (10) and fit cleanliness plugs.

11036R2

16869R

16872R

16870R

Page 40 of 118

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Pressure regulating valve

12

12-2

TURBOCHARGING

Pressure regulating valve

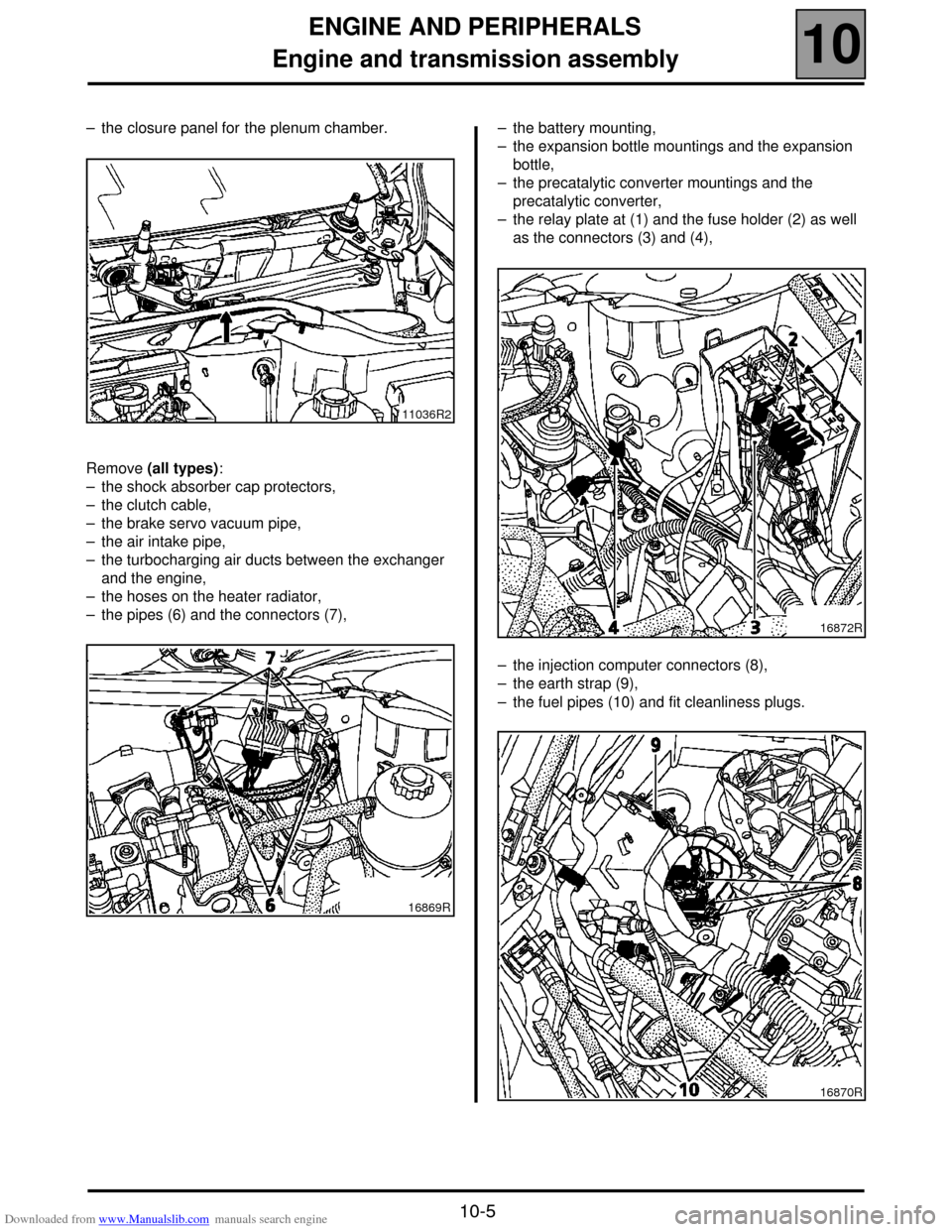

The LDA (A) of the pressure regulation valve is controlled by a solenoid valve (B) which is controlled by the injection

computer. This solenoid valve varies the underpressure as a function of the engine operating ranges, which allows

the turbocharging pressure to be regulated.

The pressure regulation valve is open in rest position. The engine operates as normally aspirated.

The solenoid valve, closed in rest position, is supplied after starting the engine, after a delay dependent on the coolant

temperature.

Delay (s)

Temperature (˚C)

Page 41 of 118

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Pressure adjustment

12

12-3

Pressure adjustment

TURBOCHARGING PRESSURE LIMITATION

VALVE (WASTEGATE)

NB: the limitation valve operates in the opposite

way to the usual fittings.

The absence of control pressure causes a

turbocharging pressure limitation.

Check that there are no leaks between the vacuum

pump and the limitation valve.

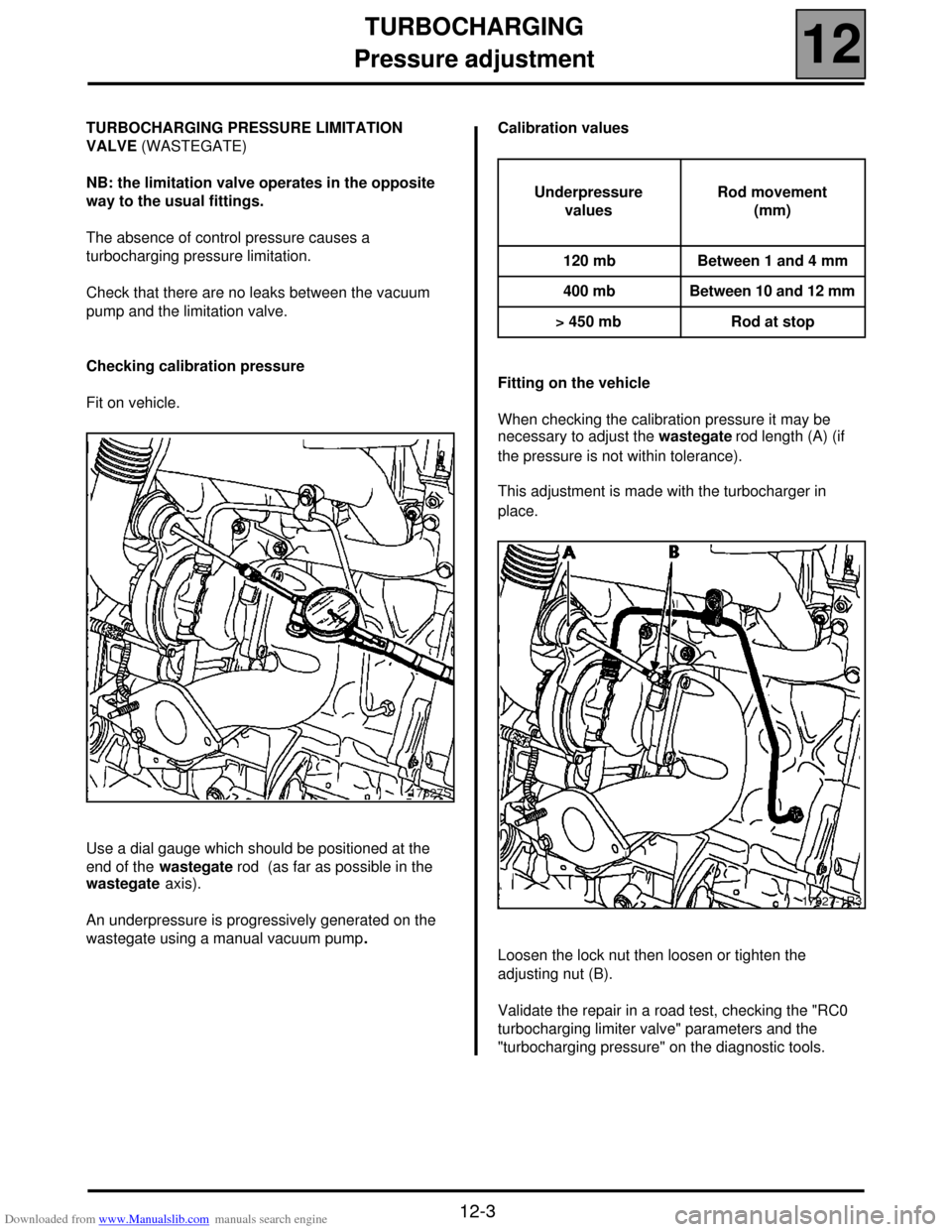

Checking calibration pressure

Fit on vehicle.

Use a dial gauge which should be positioned at the

end of the wastegate rod (as far as possible in the

wastegate axis).

An underpressure is progressively generated on the

wastegate using a manual vacuum pump.Calibration values

Fitting on the vehicle

When checking the calibration pressure it may be

necessary to adjust the wastegate rod length (A) (if

the pressure is not within tolerance).

This adjustment is made with the turbocharger in

place.

Loosen the lock nut then loosen or tighten the

adjusting nut (B).

Validate the repair in a road test, checking the "RC0

turbocharging limiter valve" parameters and the

"turbocharging pressure" on the diagnostic tools.

17827S

Underpressure

valuesRod movement

(mm)

120 mb Between 1 and 4 mm

400 mb Between 10 and 12 mm

> 450 mb Rod at stop

17827-1R3

Page 42 of 118

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

12-4

Turbocharger

SPECIAL TOOLING REQUIRED

Elé. 1294 -01 Tool for removing windscreen

wiper arms

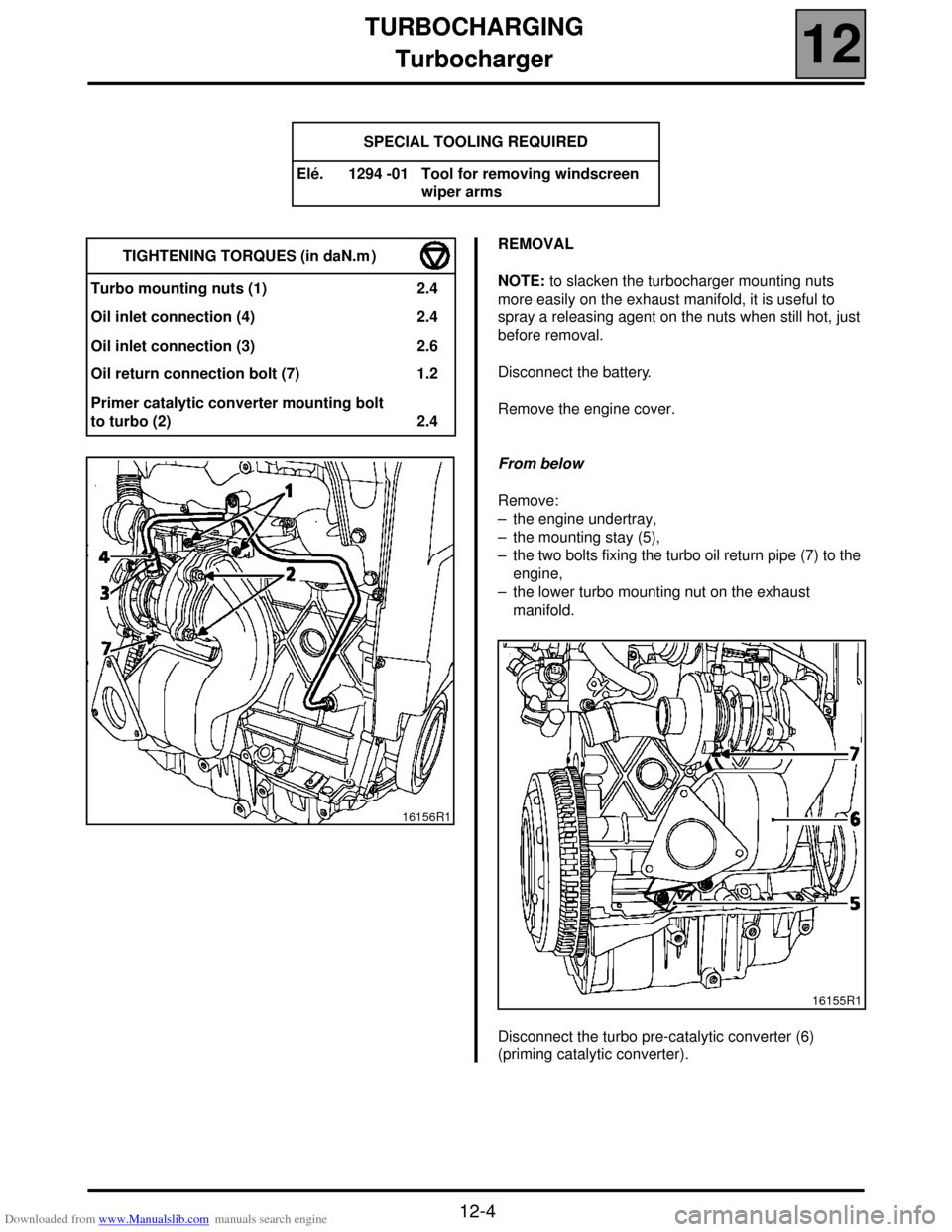

REMOVAL

NOTE: to slacken the turbocharger mounting nuts

more easily on the exhaust manifold, it is useful to

spray a releasing agent on the nuts when still hot, just

before removal.

Disconnect the battery.

Remove the engine cover.

From below

Remove:

– the engine undertray,

– the mounting stay (5),

– the two bolts fixing the turbo oil return pipe (7) to the

engine,

– the lower turbo mounting nut on the exhaust

manifold.

Disconnect the turbo pre-catalytic converter (6)

(priming catalytic converter). TIGHTENING TORQUES (in daN.m )

Turbo mounting nuts (1) 2.4

Oil inlet connection (4) 2.4

Oil inlet connection (3) 2.6

Oil return connection bolt (7) 1.2

Primer catalytic converter mounting bolt

to turbo (2) 2.4

16156R1

16155R1

Page 43 of 118

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

12-5

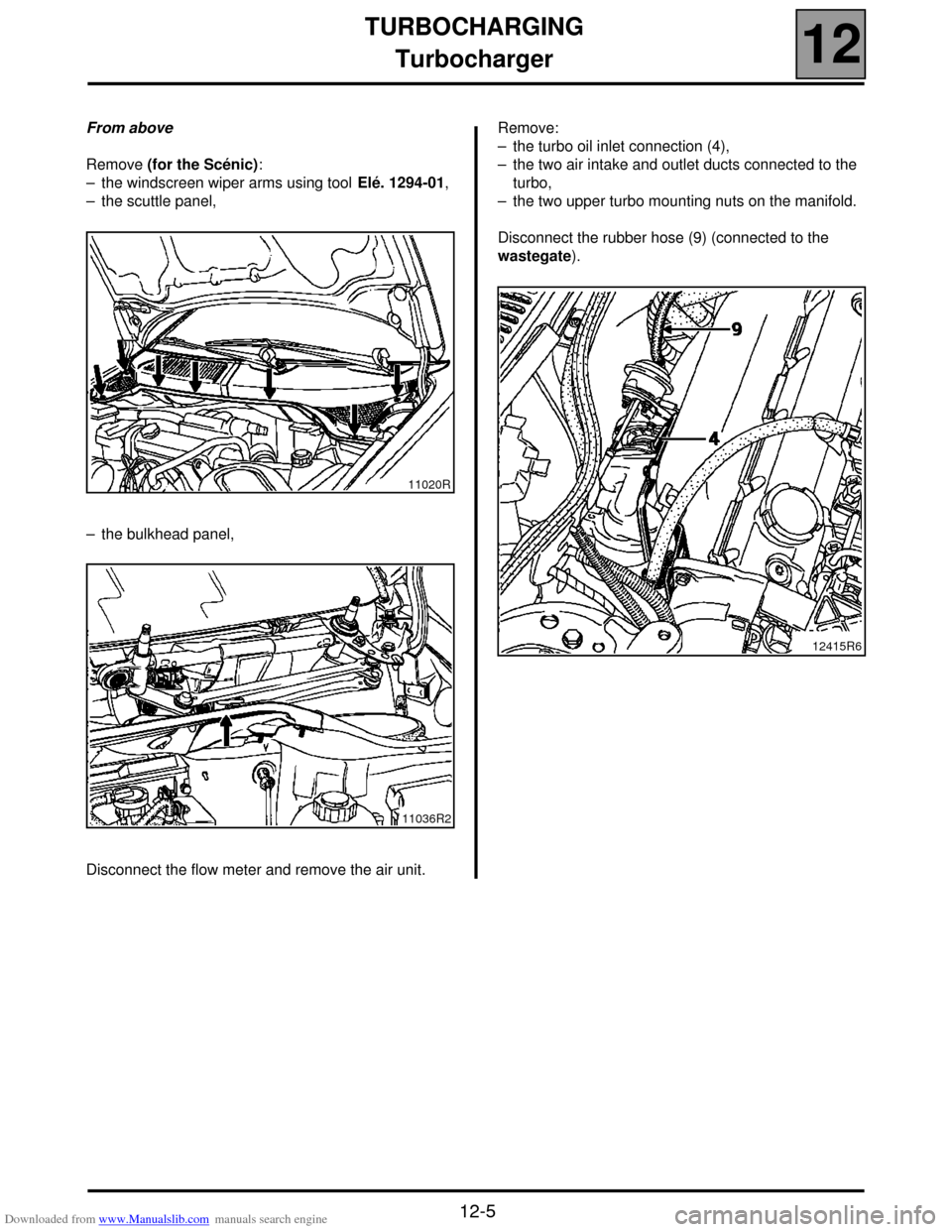

From above

Remove (for the Scénic):

– the windscreen wiper arms using tool Elé. 1294-01,

– the scuttle panel,

– the bulkhead panel,

Disconnect the flow meter and remove the air unit.Remove:

– the turbo oil inlet connection (4),

– the two air intake and outlet ducts connected to the

turbo,

– the two upper turbo mounting nuts on the manifold.

Disconnect the rubber hose (9) (connected to the

wastegate).

11020R

11036R2

12415R6

Page 44 of 118

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

12-6

REFITTING

For refitting operations, use the same procedure as for

removal in reverse.

IMPORTANT: you must change the copper gasket at

the turbo oil inlet connection.

IMPORTANT:

Before starting the engine disconnect the pressure

regulator manifold on the high pressure pump.

Then run the starter motor until the oil pressure

warning light goes out (wait a few seconds).

Reconnect the regulator, preheat and start the engine.

Run the engine at idling speed and check that there

are no leaks at the oil connections.

Erase the fault and check the turbocharging pressure

solenoid valve sensor.

16869S

Special precautions

!Before refitting, make sure that the lubrication is

correct for the turbocharger bearings. To do this

activate the starter motor having first

disconnected the high pressure manifold regulator

(do not start the engine) (erase the computer

memory). Sufficient oil should arrive via the oil

pressure pipes (place a container below). If this is

not the case, change the lubrication pipe.

!Ensure that no foreign bodies enter the turbine or

compressor during the refitting operation.

!If there has been a fault in the turbocharger, check

that the air-air exchanger is not full of oil.

If the air-air exchanger is full of oil, it must be

removed, flushed with a cleaning agent and then

left to drain properly.

!Check that the turbocharger oil return pipe is not

partially or completely blocked by scale. Check

also that it is perfectly tight. If not, replace it.

Page 45 of 118

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Air-air exchanger

12

12-7

Air-air exchanger

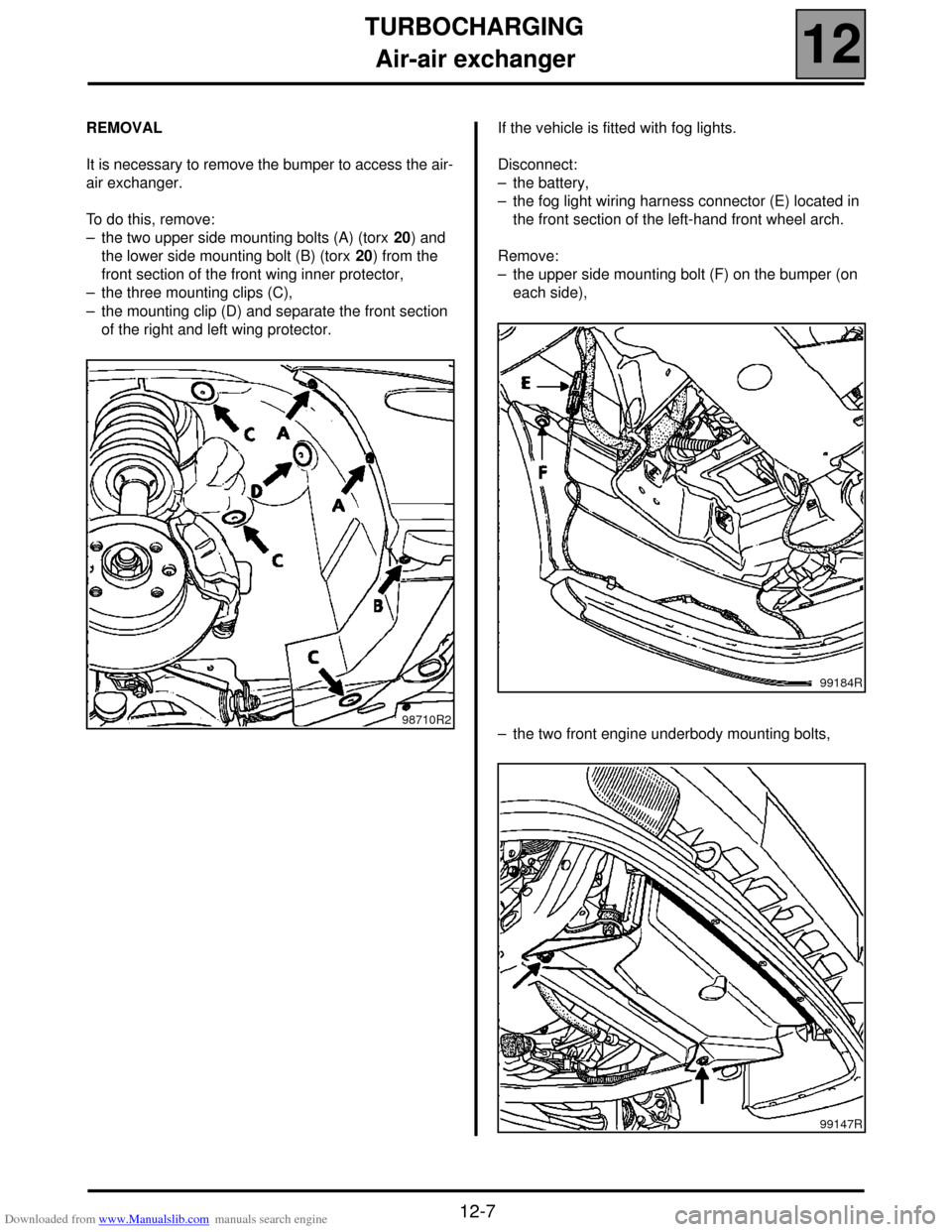

REMOVAL

It is necessary to remove the bumper to access the air-

air exchanger.

To do this, remove:

– the two upper side mounting bolts (A) (torx 20) and

the lower side mounting bolt (B) (torx 20) from the

front section of the front wing inner protector,

– the three mounting clips (C),

– the mounting clip (D) and separate the front section

of the right and left wing protector.If the vehicle is fitted with fog lights.

Disconnect:

– the battery,

– the fog light wiring harness connector (E) located in

the front section of the left-hand front wheel arch.

Remove:

– the upper side mounting bolt (F) on the bumper (on

each side),

– the two front engine underbody mounting bolts,

98710R2

99184R

99147R

Page 46 of 118

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Air-air exchanger

12

12-8

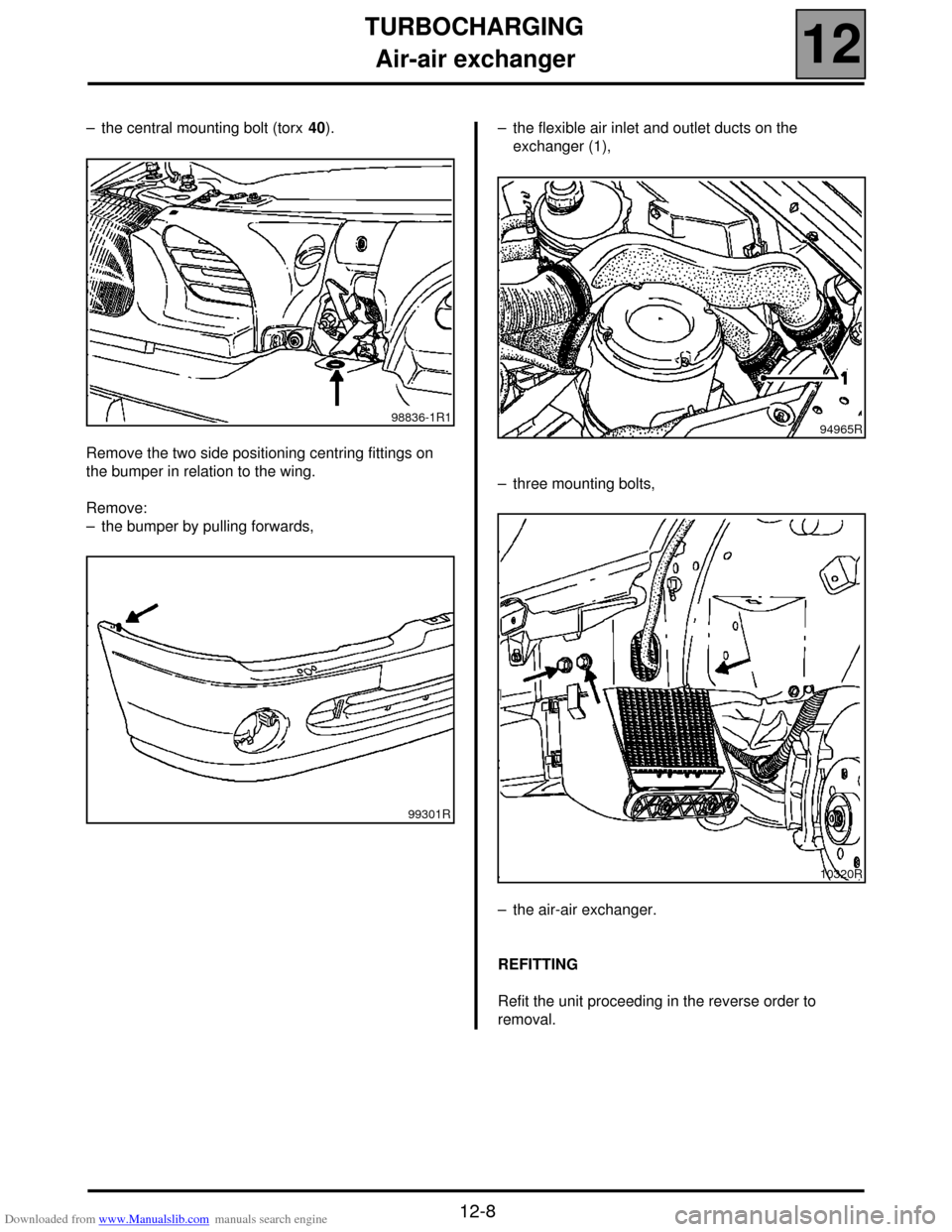

– the central mounting bolt (torx 40).

Remove the two side positioning centring fittings on

the bumper in relation to the wing.

Remove:

– the bumper by pulling forwards,– the flexible air inlet and outlet ducts on the

exchanger (1),

– three mounting bolts,

– the air-air exchanger.

REFITTING

Refit the unit proceeding in the reverse order to

removal.

98836-1R1

99301R94965R

10320R