engine oil RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 2 of 118

Downloaded from www.Manualslib.com manuals search engine Contents

Page

07

10

11

12

VALUES AND SETTINGS

Capacities - Grades 07-1

Accessories belt tension 07-2

Checking the accessories belt tension 07-3

Tightening the cylinder head 07-5

Tyres and wheels 07-6

Brakes 07-7

Brake compensator 07-8

Underbody height 07-9

Front axle angle checking values 07-11

Rear axle angle checking values 07-13

ENGINE AND PERIPHERALS

Identification 10-1

Oil pressure 10-2

Engine and transmission assembly 10-3

Sump 10-8

TOP AND FRONT OF ENGINE

Timing belt 11-1

Cylinder head gasket 11-6

FUEL MIXTURE

Air inlet 12-1

TURBOCHARGING

Pressure regulating valve 12-2

Pressure adjustment 12-3

Turbocharger 12-4

Air-air exchanger 12-7

Manifolds 12-9

Priming catalytic converter 12-12Page

13

14

DIESEL EQUIPMENT

Technical specifications 13-1

Special features 13-3

Cleanliness 13-6

Location of components 13-9

Injection warning light 13-12

Immobiliser function 13-13

Injection programming/ air conditioning 13-14

Idle speed correction13-16

Pre-postheating control 13-17

Heater plugs 13-18

Thermoplunger 13-19

Low pressure pump (supercharging

pump)13-21

Fuel filter 13-22

High pressure pump 13-23

Injector gallery 13-27

Injectors 13-32

Checking diesel pressure and flow 13-37

Pressure sensor 13-38

Pressure regulator 13-39

Accelerator potentiometer 13-40

Centralised coolant temperature

management 13-41

Computer 13-42

ANTIPOLLUTION

Oil vapour rebreathing 14-1

Exhaust gas recirculation 14-2

Page 4 of 118

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Capacities - Grades

07

107

VALUES AND SETTINGS

Capacities - Grades

* Adjust using the dipstick

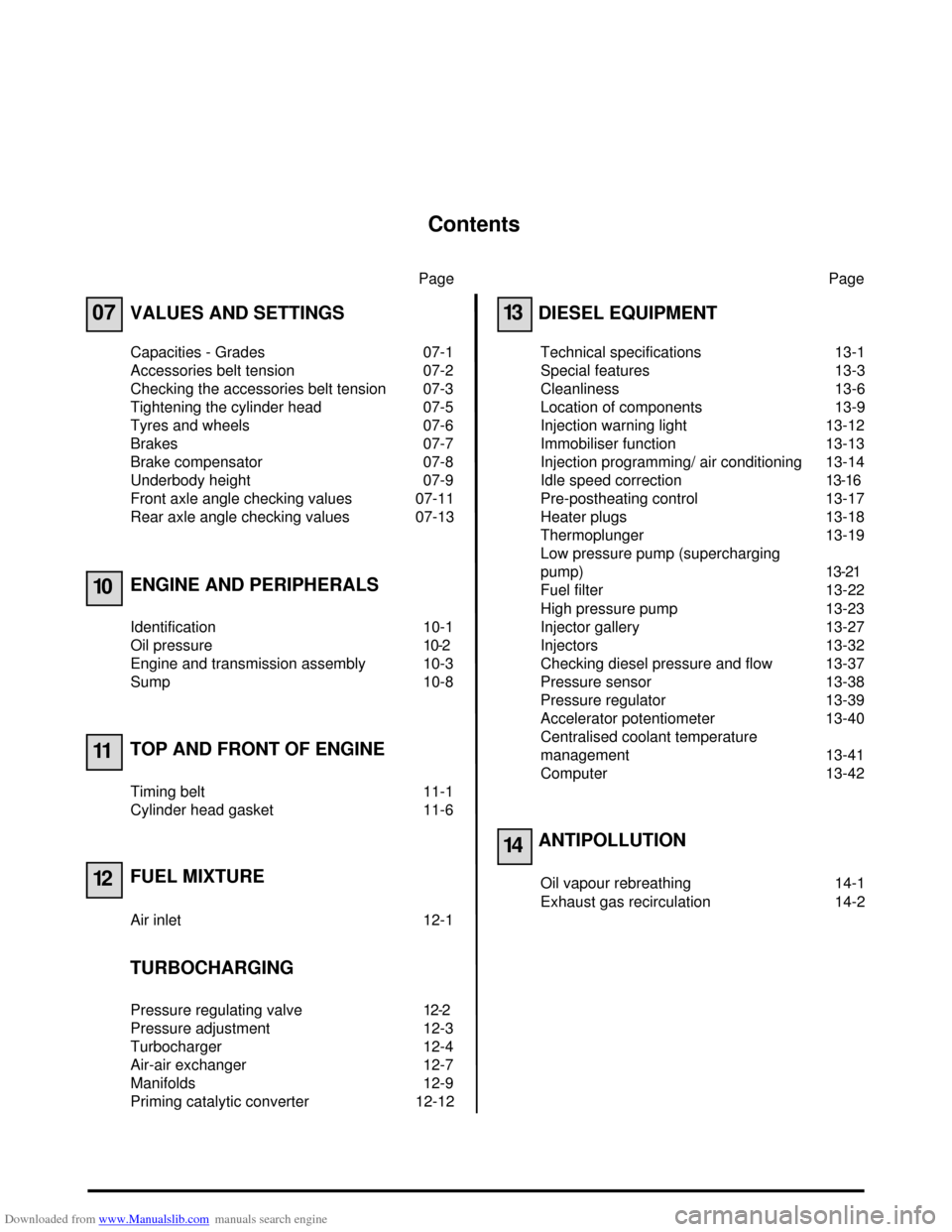

(1) After replacing the oil filterComponentsCapacity in

litres

(approx.)*Grade

Diesel engine

(oil)

F9QIn case of oil

change

4,5

4,6 (1)European Union countries

Under no circumstances should ACEA B1 oils be used for diesel

engines

Other countries

ComponentsCapacity

in litresGrade Special notes

Gearbox

JC5 3.1All countries: TRANSELF TRX 75 W 80 W

(Standards API GL5 or MIL-L 2105 G or D)

Coolant

circuit

F9Q 7.5Glacéol RX

(type D)Protection to - 20 ˚C ± 2˚C for warm, moderate and cold

climates.

Protection to - 37˚C ± 2˚C for very cold climates.

07-1

Page 8 of 118

Downloaded from www.Manualslib.com manuals search engine VALUES AND SETTINGS

Tightening the cylinder head

07

07-5

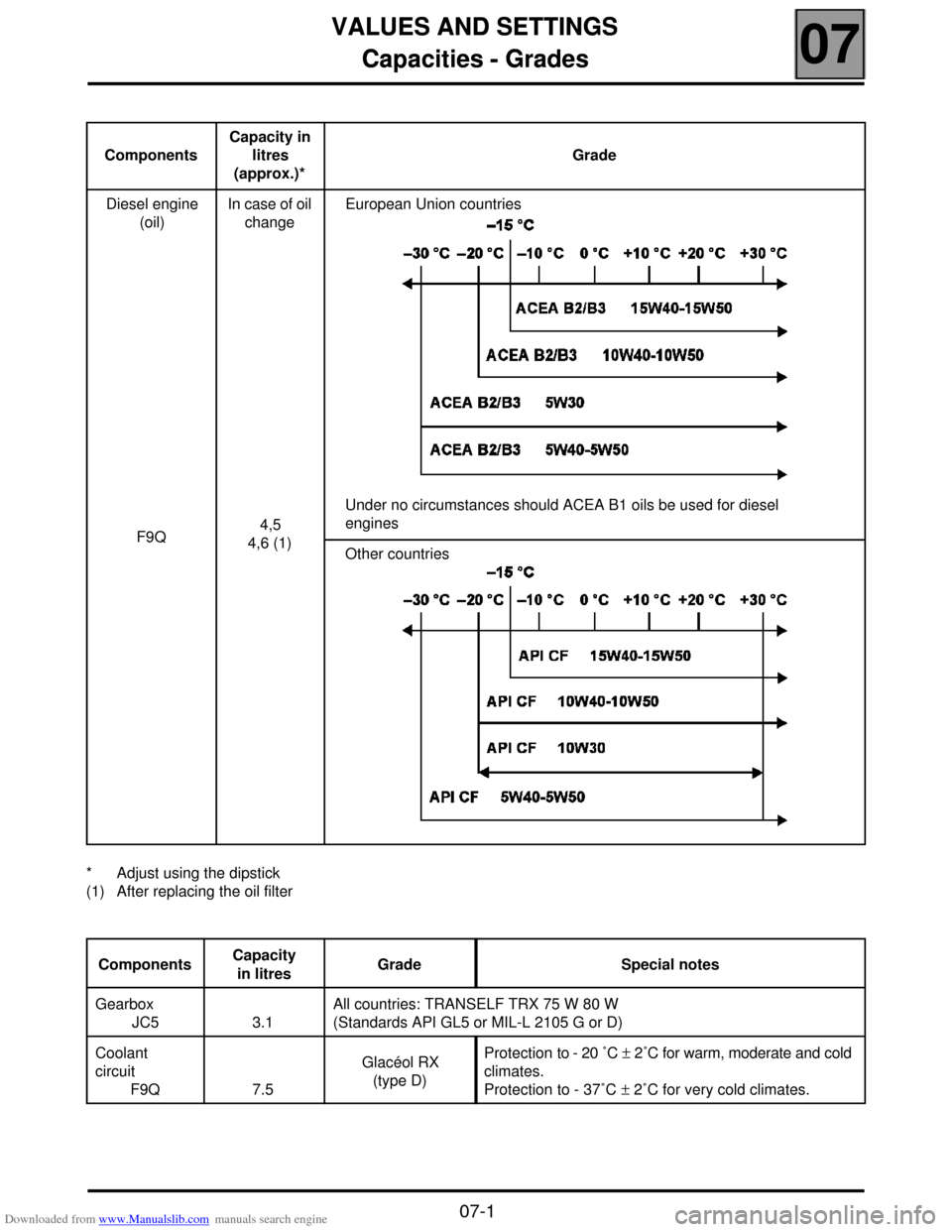

Tightening the cylinder head

METHOD FOR TIGHTENING THE CYLINDER HEAD

REMINDER: in order to tighten the bolts correctly, use

a syringe to remove any oil which may have entered

the cylinder head mounting bolt holes.

All the cylinder head bolts must always be changed

after removal. There is no cylinder head retightening

operation.

Preseating the gasket

Tighten all the bolts to 3 daN.m, then angle tighten to

100˚ ± 4˚ in the order shown below.

Wait 3 minutes settling time.

Tightening the cylinder head:

– cylinder head tightening is carried out in stages, and

the following procedure is applied successively to

bolts 1-2 then 3-4, 5-6, 7-8 and 9-10,

– slacken bolts 1-2 until they are completely free,

– tighten bolts 1-2 to 2.5 daN.m, then angle tighten to

213 ± 7˚,

– repeat the slackening and tightening operations for

bolts 3-4, 5-6, 7-8 and 9-10.

There is no cylinder head retightening operation.

90775S

Page 18 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Oil pressure

10

10-2

Oil pressure

CHECKING

The oil pressure should be checked when the engine

is warm (approximately 80 °C).

Contents of kit Mot. 836-05.

USE

C + F

Connect the pressure gauge in place of the oil

pressure switch.

Oil pressure

1000 rpm 1.2 bar

3000 rpm 3.5 barsSPECIAL TOOLING REQUIRED

Mot. 836-05 Boxed kit for measuring oil

pressure

ESSENTIAL SPECIAL TOOLING

22 mm long socket

87363R1

Page 23 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-7

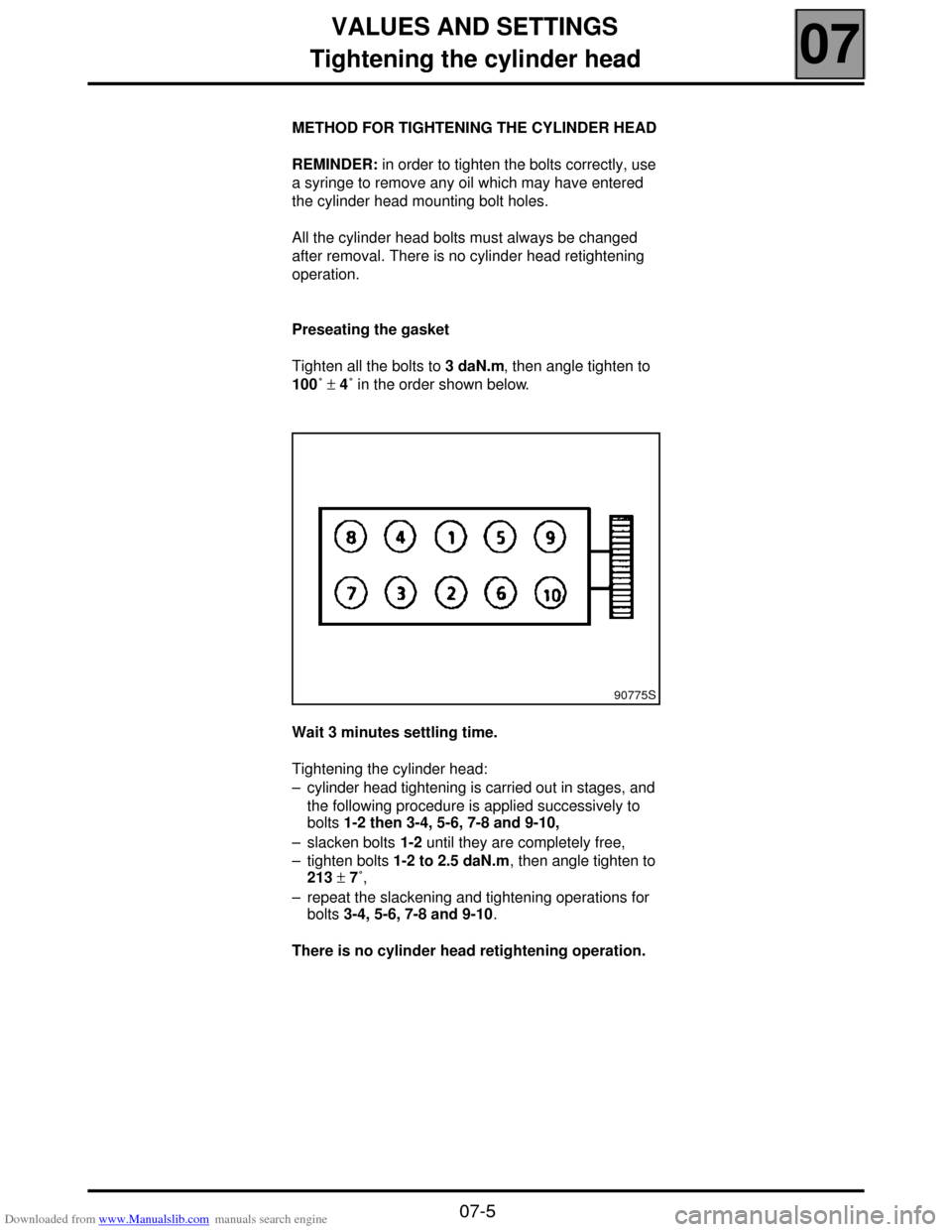

Fit tool Mot. 1040-01 under the engine sub-frame.

Lower the lift until the tool touches the ground.

Remove the sub-frame mounting bolts and take out

the engine and transmission assembly by lifting the

body.

When starting to lift the body, ensure that the catalytic

converter is removed and extract the radiator from its

upper mountings (then place it on the sub-frame).

NOTE: for any operation requiring the engine, gearbox

and sub-frame assembly to be separated, take care to

mark the position of tool Mot. 1159 on the sub-frame.REFITTING

The alignment of the sub-frame with the body will be

made easier by positioning two threaded rods

Mot. 1233-01 in the two front mountings of the sub-

frame on the body.

When lowering the body onto the engine - gearbox

assembly, ensure that the catalytic converter is

refitted.

Tighten the sub-frame mounting bolts to a torque of:

– 6.2 daN.m at the front,

–10.5 daN.m at the rear.

See section 19 "Suspended engine mounting" for

the tightening torques for the engine and gearbox

assembly mountings.

Refitting is the reverse of removal.

Refit the heat shields correctly.

Apply Loctite FRENBLOC to the caliper mounting

bolts and tighten them to the recommended torque.

Press the brake pedal several times to bring the

pistons into contact with the brake pads.

Fill:

– the engine and gearbox with oil (if necessary),

– the cooling circuit and bleed it (see section 19

"Filling - bleeding").

Fill the refrigerant circuit using the filling equipment (if

fitted).

98755R1

Page 26 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Sump

10

10-10

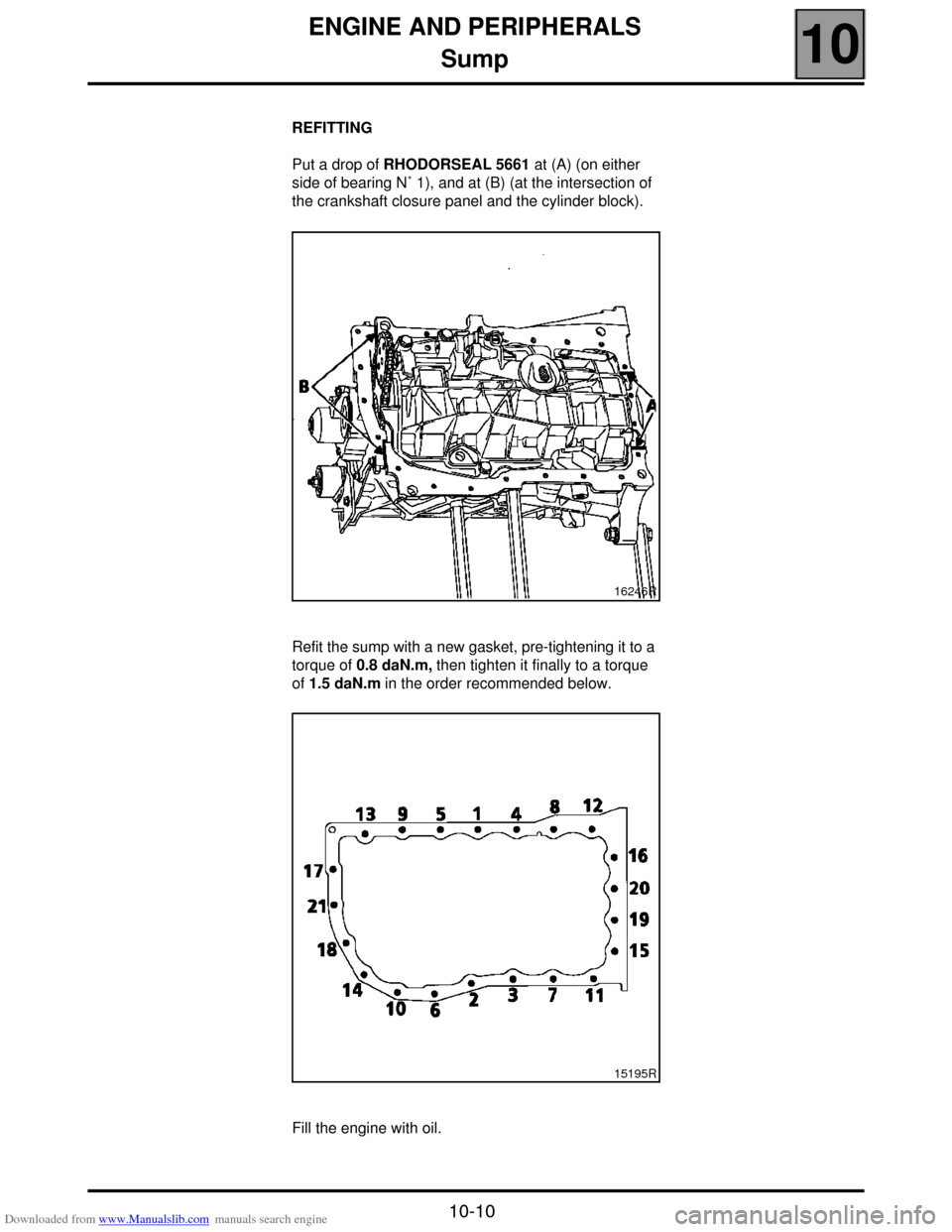

REFITTING

Put a drop of RHODORSEAL 5661 at (A) (on either

side of bearing N˚ 1), and at (B) (at the intersection of

the crankshaft closure panel and the cylinder block).

Refit the sump with a new gasket, pre-tightening it to a

torque of 0.8 daN.m, then tighten it finally to a torque

of 1.5 daN.m in the order recommended below.

Fill the engine with oil.

16246R

15195R

Page 34 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Cylinder head gasket

11

11 - 8

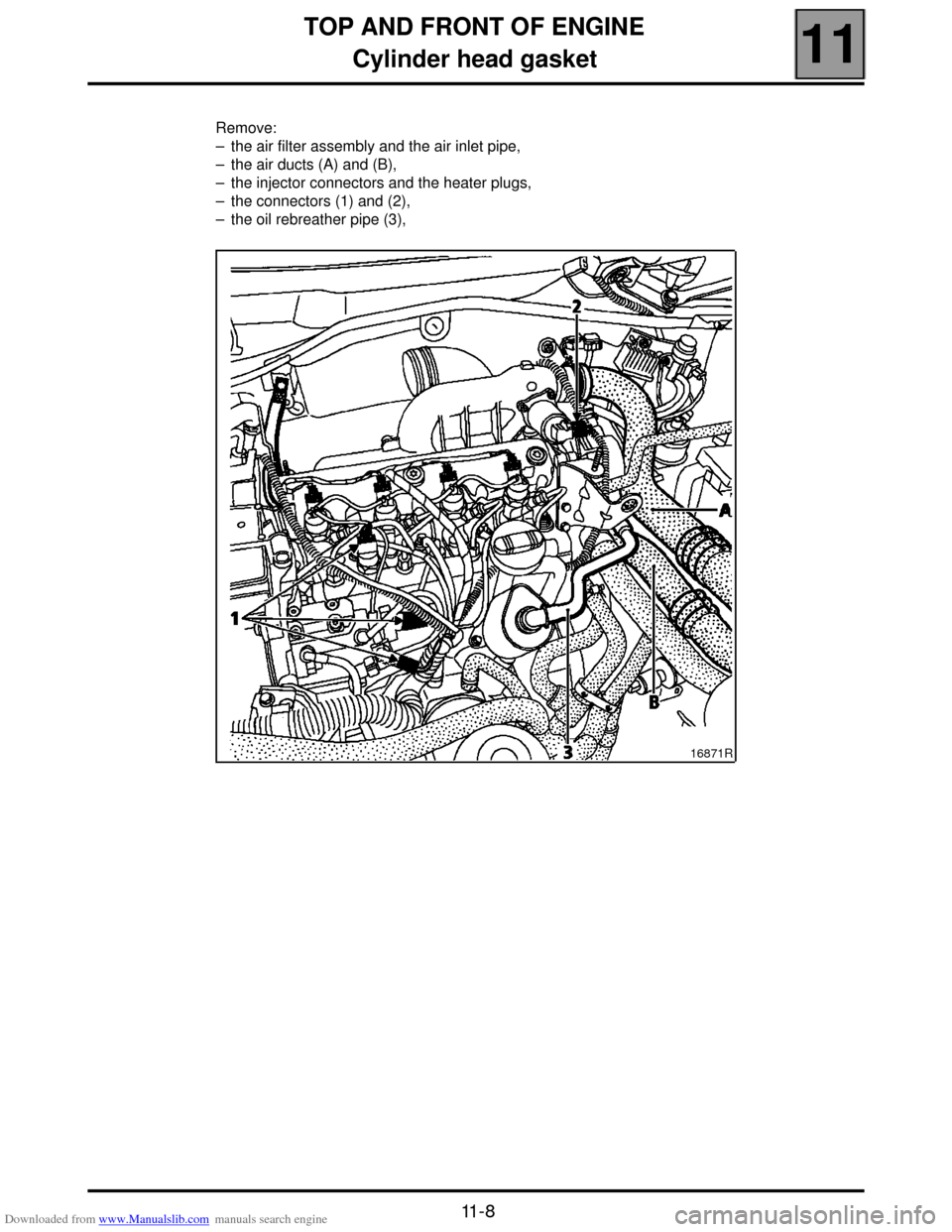

Remove:

– the air filter assembly and the air inlet pipe,

– the air ducts (A) and (B),

– the injector connectors and the heater plugs,

– the connectors (1) and (2),

– the oil rebreather pipe (3),

16871R

Page 36 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Cylinder head gasket

11

11-10

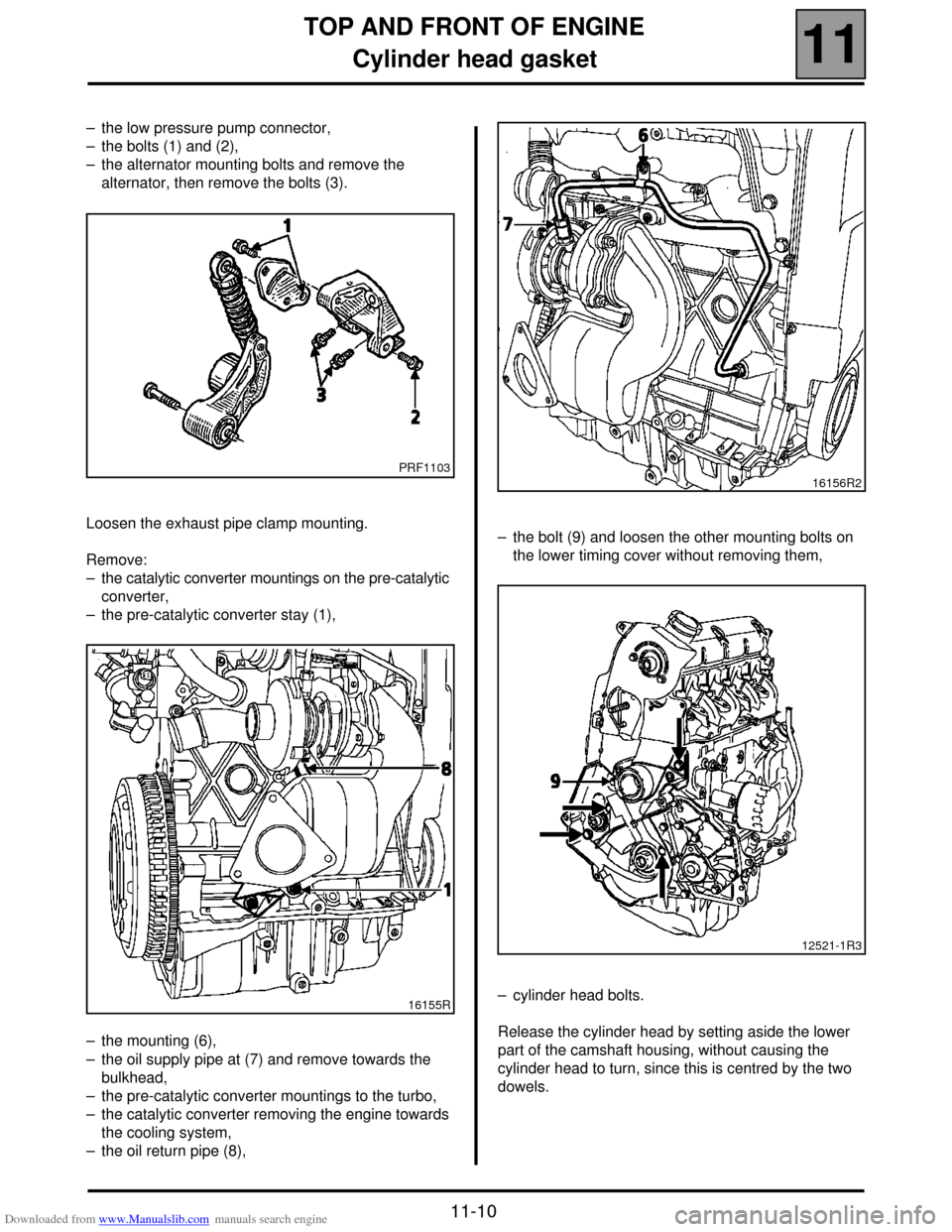

– the low pressure pump connector,

– the bolts (1) and (2),

– the alternator mounting bolts and remove the

alternator, then remove the bolts (3).

Loosen the exhaust pipe clamp mounting.

Remove:

– the catalytic converter mountings on the pre-catalytic

converter,

– the pre-catalytic converter stay (1),

– the mounting (6),

– the oil supply pipe at (7) and remove towards the

bulkhead,

– the pre-catalytic converter mountings to the turbo,

– the catalytic converter removing the engine towards

the cooling system,

– the oil return pipe (8),– the bolt (9) and loosen the other mounting bolts on

the lower timing cover without removing them,

– cylinder head bolts.

Release the cylinder head by setting aside the lower

part of the camshaft housing, without causing the

cylinder head to turn, since this is centred by the two

dowels.

PRF1103

16155R

16156R2

12521-1R3

Page 37 of 118

Downloaded from www.Manualslib.com manuals search engine TOP AND FRONT OF ENGINE

Cylinder head gasket

11

11-11

CLEANING

It is very important not to scratch the gasket faces

of any aluminium component.

Use the Décapjoint product to dissolve any part of the

gasket which remains attached.

W ear gloves whilst carrying out the following

operation.

– Apply the product to the parts to be cleaned; wait

about ten minutes, then remove it using a wooden

spatula.

W e must draw your attention to the care which

must be taken during this operation, to prevent

any foreign bodies from being introduced into the

oil ways (ducts located in the cylinder block and in

the cylinder head).

CHECKING THE GASKET FACE

Check for gasket face bow using a straight edge and a

set of shims.

Maximum deformation: 0.05 mm.

No regrinding of the cylinder head is permitted.

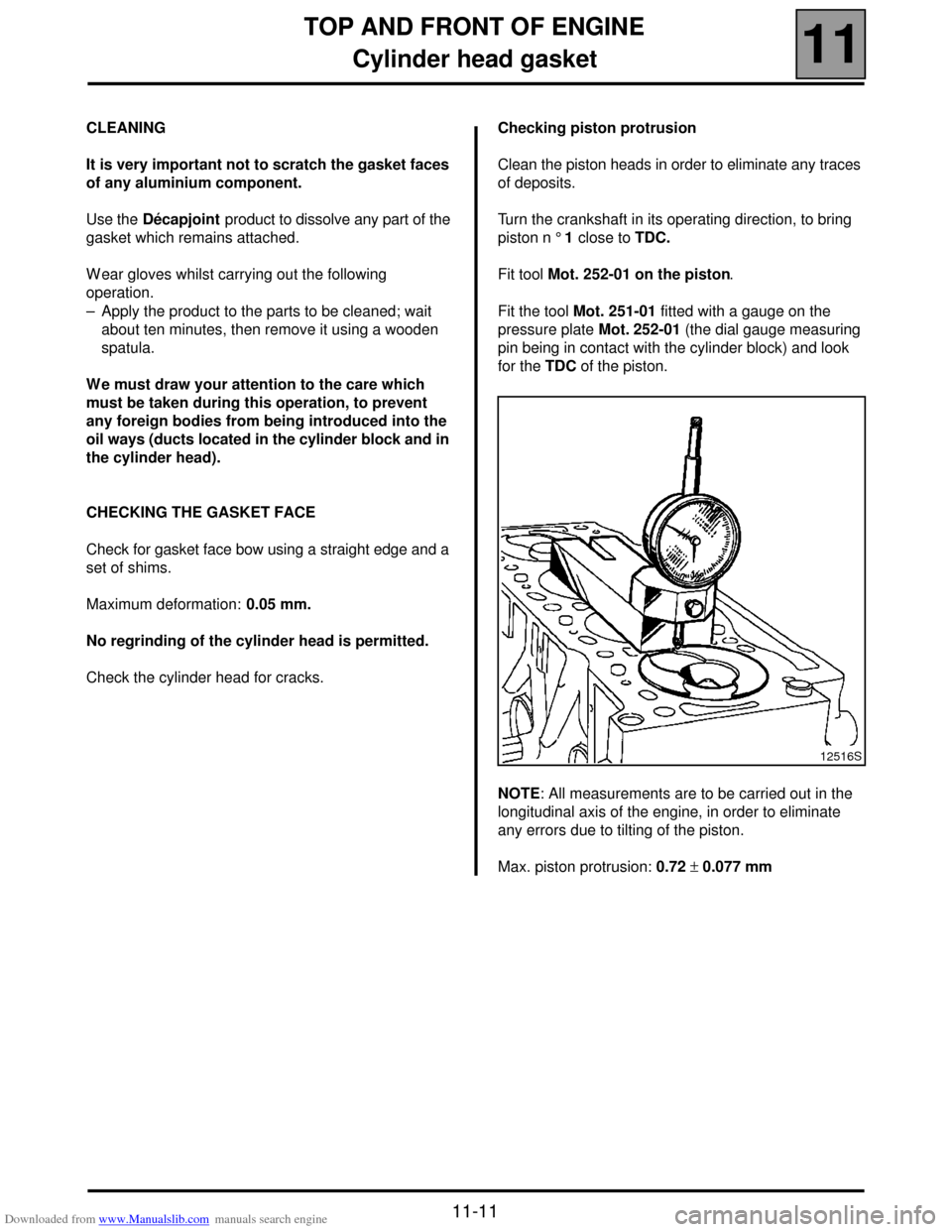

Check the cylinder head for cracks.Checking piston protrusion

Clean the piston heads in order to eliminate any traces

of deposits.

Turn the crankshaft in its operating direction, to bring

piston n ° 1 close to TDC.

Fit tool Mot. 252-01 on the piston.

Fit the tool Mot. 251-01 fitted with a gauge on the

pressure plate Mot. 252-01 (the dial gauge measuring

pin being in contact with the cylinder block) and look

for the TDC of the piston.

NOTE: All measurements are to be carried out in the

longitudinal axis of the engine, in order to eliminate

any errors due to tilting of the piston.

Max. piston protrusion: 0.72 ± 0.077 mm

12516S

Page 42 of 118

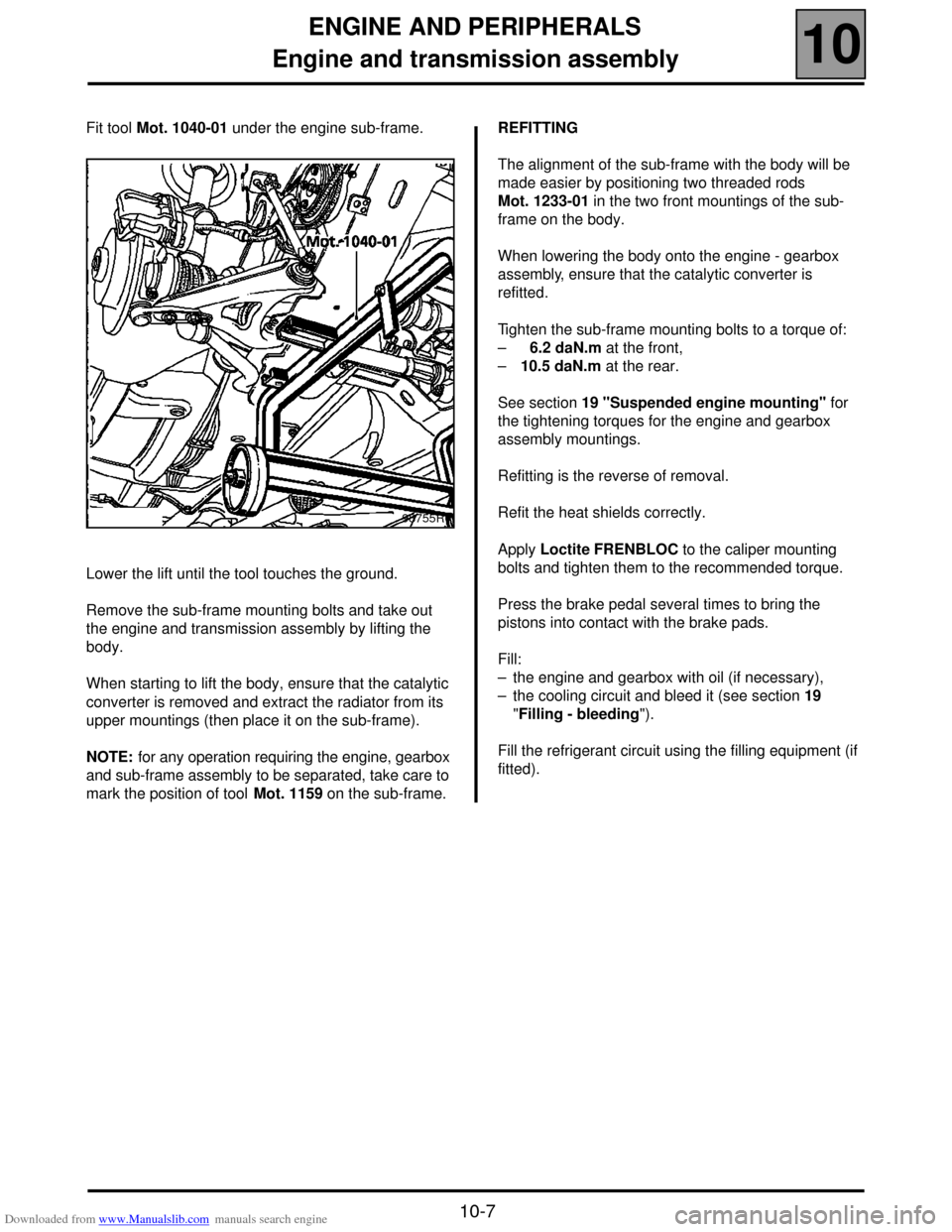

Downloaded from www.Manualslib.com manuals search engine TURBOCHARGING

Turbocharger

12

12-4

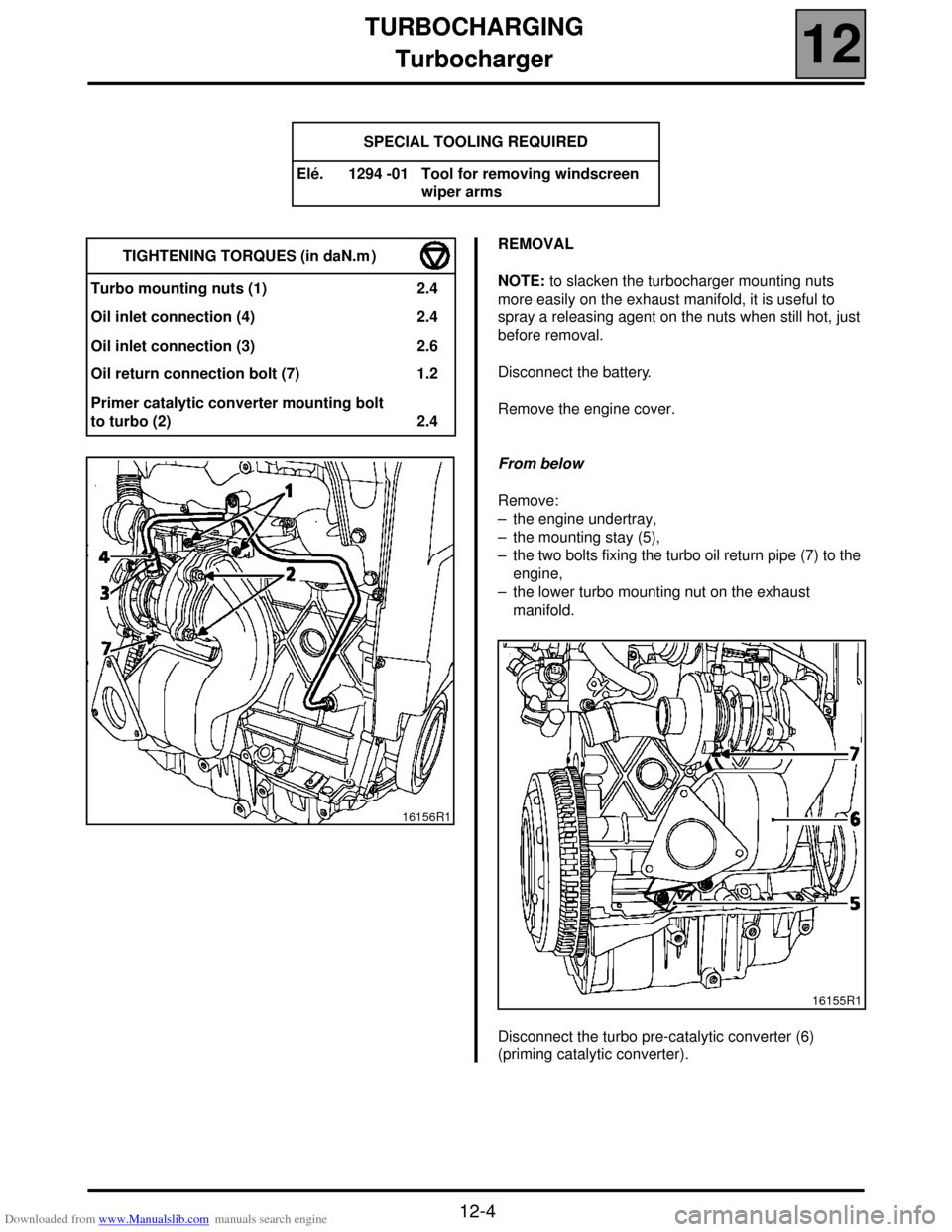

Turbocharger

SPECIAL TOOLING REQUIRED

Elé. 1294 -01 Tool for removing windscreen

wiper arms

REMOVAL

NOTE: to slacken the turbocharger mounting nuts

more easily on the exhaust manifold, it is useful to

spray a releasing agent on the nuts when still hot, just

before removal.

Disconnect the battery.

Remove the engine cover.

From below

Remove:

– the engine undertray,

– the mounting stay (5),

– the two bolts fixing the turbo oil return pipe (7) to the

engine,

– the lower turbo mounting nut on the exhaust

manifold.

Disconnect the turbo pre-catalytic converter (6)

(priming catalytic converter). TIGHTENING TORQUES (in daN.m )

Turbo mounting nuts (1) 2.4

Oil inlet connection (4) 2.4

Oil inlet connection (3) 2.6

Oil return connection bolt (7) 1.2

Primer catalytic converter mounting bolt

to turbo (2) 2.4

16156R1

16155R1