sensor RENAULT SCENIC 2008 J84 / 2.G Automatic Transmission Siemens TA2000 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2008, Model line: SCENIC, Model: RENAULT SCENIC 2008 J84 / 2.GPages: 128, PDF Size: 0.43 MB

Page 9 of 128

AUTOMATIC TRANSMISSION

Fault finding – System operation23A

23A-9V4 MR-372-J84-23A050$132.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

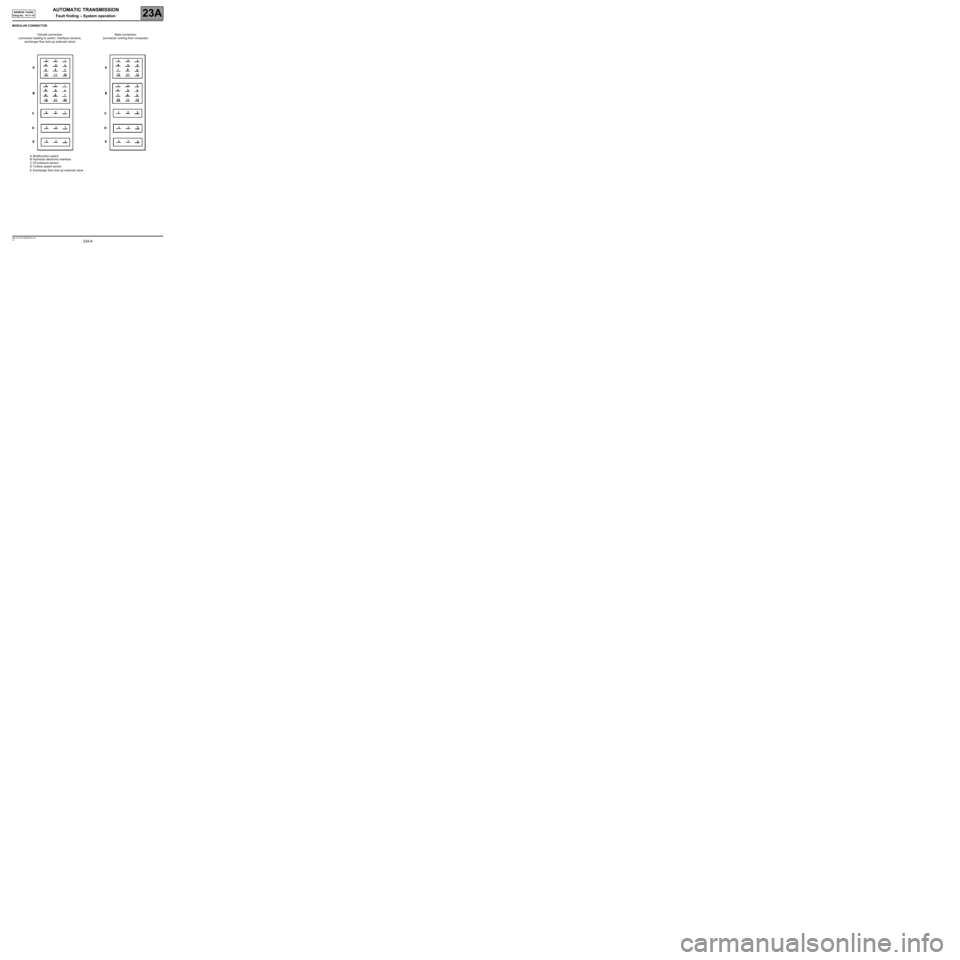

MODULAR CONNECTOR

AMultifunction switch

BHydraulic electronic interface

COil pressure sensor

DTurbine speed sensor

EExchanger flow lock-up solenoid valveFemale connection

(connector leading to switch, interface) sensors,

exchanger flow lock-up solenoid valve)Male connection

(connector coming from computer)

Page 10 of 128

AUTOMATIC TRANSMISSION

Fault finding – System operation23A

23A-10V4 MR-372-J84-23A050$132.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

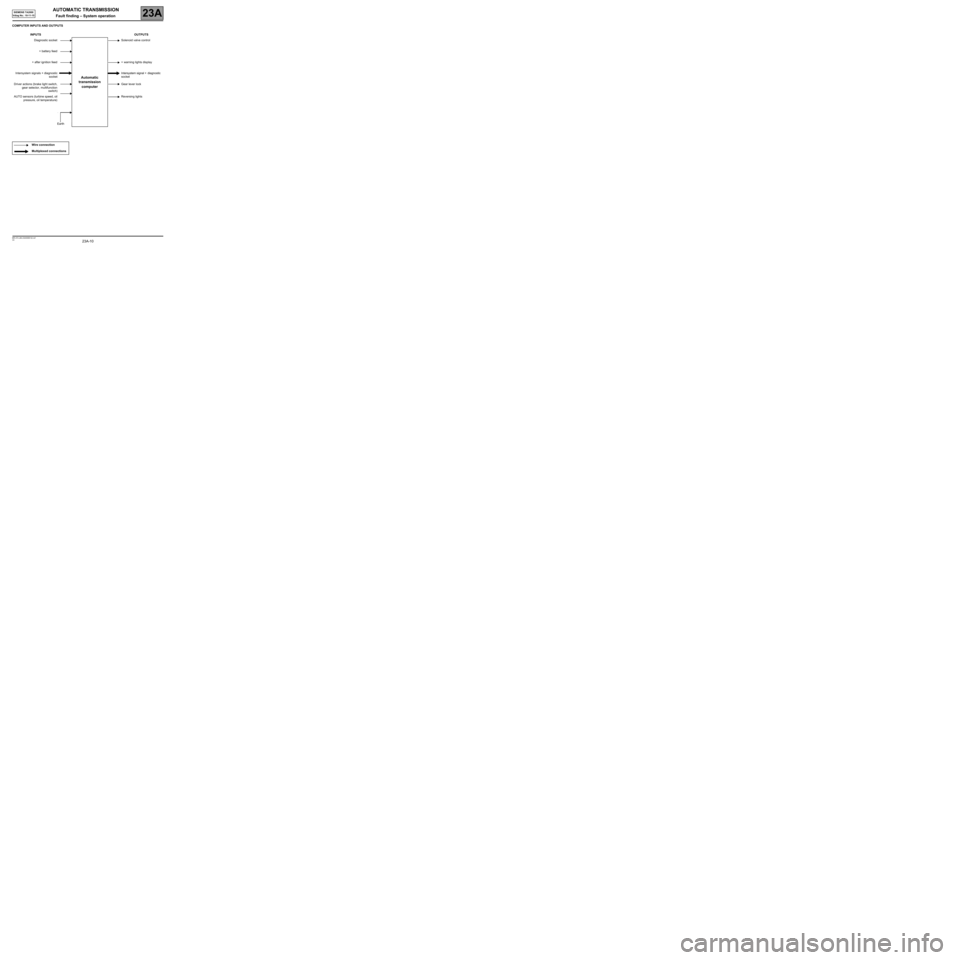

COMPUTER INPUTS AND OUTPUTS

INPUTS OUTPUTS

Diagnostic socket

Automatic

transmission

computer

Solenoid valve control

+ battery feed

+ after ignition feed + warning lights display

Intersystem signals + diagnostic

socketIntersystem signal + diagnostic

socket

Driver actions (brake light switch,

gear selector, multifunction

switch)Gear lever lock

AUTO sensors (turbine speed, oil

pressure, oil temperature)Reversing lights

Earth

Wire connection

Multiplexed connections

Page 15 of 128

AUTOMATIC TRANSMISSION

Fault finding – Fault summary table23A

23A - 15V4 MR-372-J84-23A050$264.mif

SIEMENS TA2000

Vdiag No.: 10-11-15AUTOMATIC TRANSMISSION

Fault finding – Fault summary table

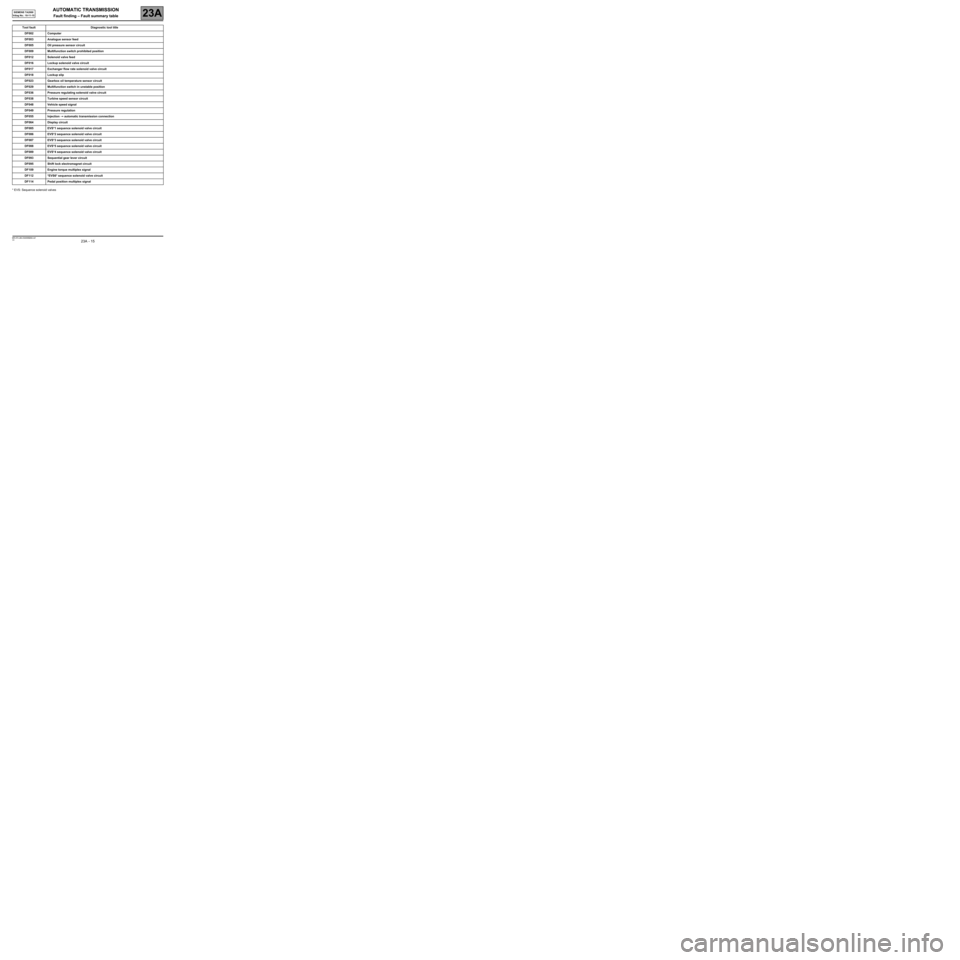

* EVS: Sequence solenoid valvesTool fault Diagnostic tool title

DF002 Computer

DF003 Analogue sensor feed

DF005 Oil pressure sensor circuit

DF009 Multifunction switch prohibited position

DF012 Solenoid valve feed

DF016 Lockup solenoid valve circuit

DF017 Exchanger flow rate solenoid valve circuit

DF018 Lockup slip

DF023 Gearbox oil temperature sensor circuit

DF029 Multifunction switch in unstable position

DF036 Pressure regulating solenoid valve circuit

DF038 Turbine speed sensor circuit

DF048 Vehicle speed signal

DF049 Pressure regulation

DF055 Injection →→ → →

automatic transmission connection

DF064 Display circuit

DF085 EVS*1 sequence solenoid valve circuit

DF086 EVS*2 sequence solenoid valve circuit

DF087 EVS*3 sequence solenoid valve circuit

DF088 EVS*5 sequence solenoid valve circuit

DF089 EVS*4 sequence solenoid valve circuit

DF093 Sequential gear lever circuit

DF095 Shift lock electromagnet circuit

DF109 Engine torque multiplex signal

DF112 *EVS6* sequence solenoid valve circuit

DF114 Pedal position multiplex signal

MR-372-J84-23A050$264.mif

Page 18 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of faults23A

23A-18V4 MR-372-J84-23A050$330.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

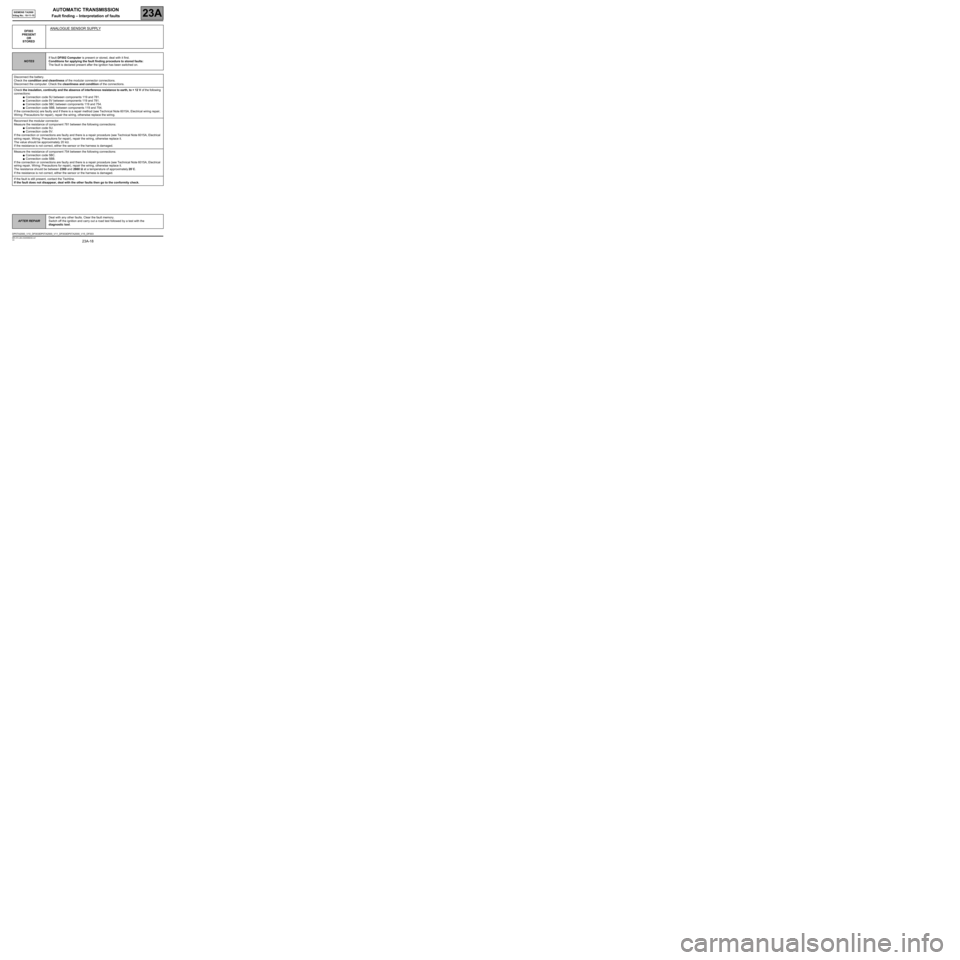

DF003

PRESENT

OR

STOREDANALOGUE SENSOR SUPPLY

NOTESIf fault DF002 Computer is present or stored, deal with it first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition has been switched on.

Disconnect the battery.

Check the condition and cleanliness of the modular connector connections.

Disconnect the computer. Check the cleanliness and condition of the connections.

Check the insulation, continuity and the absence of interference resistance to earth, to + 12 V of the following

connections:

●Connection code 5U between components 119 and 781.

●Connection code 5V between components 119 and 781.

●Connection code 5BC between components 119 and 754.

●Connection code 5BB, between components 119 and 754.

If the connection(s) are faulty and if there is a repair method (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Reconnect the modular connector.

Measure the resistance of component 781 between the following connections:

●Connection code 5U.

●Connection code 5V.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

The value should be approximately 20 kΩ.

If the resistance is not correct, either the sensor or the harness is damaged.

Measure the resistance of component 754 between the following connections:

●Connection code 5BC.

●Connection code 5BB.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

The resistance should be between 2360 and 2660 ΩΩ Ω Ω

at a temperature of approximately 20˚C.

If the resistance is not correct, either the sensor or the harness is damaged.

If the fault is still present, contact the Techline.

If the fault does not disappear, deal with the other faults then go to the conformity check.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the

diagnostic tool.

DP0TA2000_V10_DF003/DP0TA2000_V11_DF003/DP0TA2000_V15_DF003

Page 19 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of faults23A

23A-19V4 MR-372-J84-23A050$330.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

DF005

PRESENT

OR

STOREDOIL PRESSURE SENSOR CIRCUIT

CO.0 : Open circuit or short circuit to earth

NOTESConditions for applying the fault finding procedure to stored faults:

The fault appears after a timed period of 10 seconds with the engine running

at 2000 rpm.

Special notes:

Use bornier Elé. 1681 for all operations on the computer connectors.

Disconnect the battery.

Disconnect the modular connector, and check the cleanliness and condition of the connections.

Disconnect the computer. Check the cleanliness and condition of the connections.

Check the insulation, continuity and the absence of interference resistance to earth, to + 12 V of the following

connection:

●Connection code 5U between components 119 and 781.

●Connection code 5W between components 119 and 781.

●Connection code 5V between components 119 and 781.

If the connection(s) are faulty and if there is a repair method (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Reconnect the modular connector.

Measure the resistance of component 781 between connections 5V and 5W on the computer connector

(female connector).

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Replace the sensor if the resistance is not approximately 20 kΩΩ Ω Ω

.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the

diagnostic tool.

DP0TA2000_V10_DF005/DP0TA2000_V11_DF005/DP0TA2000_V15_DF005

Page 26 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of faults23A

23A-26V4 MR-372-J84-23A050$330.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

DF018

PRESENT

OR

STOREDCONVERTER LOCKUP SLIPPAGE

NOTESCarry out injection system fault finding and check that it is operating correctly.

If the following faults are present or stored, deal with them first:

–DF003 Analogue sensor supply.

–DF005 Oil pressure sensor circuit

–DF016 Converter lock-up solenoid valve circuit.

–DF036 Pressure modulating solenoid valve circuit.

–DF038: Turbine speed sensor circuit.

–DF049 Gearbox oil pressure regulation.

Conditions for applying the fault finding procedure to stored faults:

The fault is reported present after driving in fixed 3

rd gear with speed stabilisation for

more than 3 minutes.

To check that there are no faults with the converter lock-up solenoid valve, use the interpretation of fault

DF016 Converter lock-up solenoid valve circuit.

To check that there are no faults with the turbine speed sensor, apply the interpretation of fault DF038 Turbine

speed sensor circuit.

Check gearbox oil grade and level.

If an operation is necessary (see MR 364 Mechanical, 23A, Automatic transmission, Filling-Levels

(for Mégane II) and MR 370 Mechanical, 23A, Automatic transmission, Draining-Filling (for Scénic II)).

Check that the transmission is not leaking oil.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

DP0TA2000_V10_DF018/DP0TA2000_V11_DF018/DP0TA2000_V15_DF018

Page 27 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of faults23A

23A-27V4 MR-372-J84-23A050$330.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

DF018

CONTINUED

Carry out a conformity check to detect any possible faults.

Check the setting point of the converter (see MR 364 Mechanical, 23A, Automatic transmission, Checking the

setting point of the converter (for Mégane II and Scénic II)

If the setting point value is not correct, carry out the following checks:

–Check the oil pressure using PR003 Oil pressure:

–Warm engine with gearbox oil temperature between 65 and 90˚C.

–Take the line pressure reading under the following 3 conditions:

Important

The vehicle must be stationary: handbrake on and brake pedal depressed, no accessories operating

(e.g.: air conditioning)

1Engine speed idling:

Shift the gear lever to R, N and D, the pressure reading must be greater than 2.5 bar.

2Engine speed at 1200 rpm:

–gear lever in R position, the pressure reading must be greater than 4 bars.

–gear lever in D position, the pressure reading in first gear must be greater than 5.5 bars.

3Engine speed at 2200 rpm:

–gear lever in R position, the pressure reading must be greater than 11 bars.

–gear lever in D position, the pressure reading in first gear must be greater than 11 bars.

If the line pressure value read under one of these 3 conditions is incorrect, replace the line pressure sensor.

If the line pressures recorded under these 3 conditions are good, then the pressure sensor is operating correctly.

Replace the pressure regulating solenoid valve.

If the fault is still present after the pressure regulating solenoid valve has been replaced, replace the hydraulic

distributor and during refitting, take into account Technical Note 4194A Automatic transmission indicator strip

flashing for the adjustment of the ball detent blade.

If the fault is still present, contact the Techline

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

Page 28 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of faults23A

23A-28V4 MR-372-J84-23A050$330.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

DF023

PRESENT

OR

STOREDGEARBOX OIL TEMPERATURE SENSOR CIRCUIT

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after a road test.

Special notes:

Use bornier Elé. 1681 for all operations on the computer connectors.

Disconnect the battery.

Disconnect the modular connector, and check the cleanliness and condition of the connections.

Disconnect the computer. Check the cleanliness and condition of the connections.

Repair.

Check the insulation, continuity and the absence of interference resistance to earth, to + 12 V and the

following connections:

●Connection code 5BC between components 119 and 754.

●Connection code 5BB between components 119 and 754.

If the connection(s) are faulty and if there is a repair method (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Reconnect the modular connector.

Measure the resistance of component 754 between the following connections:

●Connection code 5BC.

●Connection code 5BB.

If the connection(s) are faulty and if there is a repair method (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Replace the sensor or the wiring if the resistance is not between:

2360 ΩΩ Ω Ω

and 2660 ΩΩ Ω Ω

at 20˚C

290 ΩΩ Ω Ω

and 327 ΩΩ Ω Ω

at 80˚C

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the

diagnostic tool.

DP0TA2000_V10_DF023/DP0TA2000_V11_DF023/DP0TA2000_V15_DF023

Page 33 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of faults23A

23A-33V4 MR-372-J84-23A050$330.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

DF038

PRESENT

OR

STOREDTURBINE SPEED SENSOR CIRCUIT

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present when the engine is running and the gear lever is at P.

Disconnect the battery.

Disconnect the modular connector, and check the cleanness and condition of the connections.

Disconnect the computer. Check the cleanliness and condition of the connections.

Use the universal bornier Elé. 1681. Check the continuity and insulation of the following connections:

●Connection code 5DA, between components 119 and 1017.

●Connection code 5DB, between components 119 and 1017.

If the connection(s) are faulty and if there is a repair method (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Reconnect the modular connector.

Measure the resistance of component 1017 between the following connections:

●Connection code 5DA.

●Connection code 5DB.

If the connection(s) are faulty and if there is a repair method (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

The turbine speed sensor resistance is 300 ΩΩ Ω Ω

± 40 ΩΩ Ω Ω

at a temperature of approximately 20˚C.

If the value is not correct, replace the turbine speed sensor.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the

diagnostic tool.

DP0TA2000_V10_DF038/DP0TA2000_V11_DF038/DP0TA2000_V15_DF038

Page 35 of 128

AUTOMATIC TRANSMISSION

Fault finding – Interpretation of faults23A

23A-35V4 MR-372-J84-23A050$330.mif

SIEMENS TA2000

Vdiag No.: 10-11-15

DF049

PRESENT

OR

STOREDGEARBOX OIL PRESSURE REGULATION

1.DEF : Pressure regulation

NOTESCarry out injection system fault finding and check that it is operating correctly.

If the following faults are present or stored, deal with them first:

–DF003 Sensor feeds.

–DF005 Oil pressure sensor circuit.

–DF023 Gearbox oil temperature sensor circuit.

–DF036 Pressure modulating solenoid valve circuit.

–DF038: Turbine speed sensor circuit.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after a road test.

To make sure there are no problems with the pressure lock-up solenoid valve, use the interpretation of fault DF036

Pressure regulating solenoid valve circuit.

Check gearbox oil grade and level.

If an operation is necessary (see MR 364 Mechanical, 23A, Automatic transmission, Filling-Levels

(for Mégane II) and MR 370 Mechanical, 23A, Automatic transmission, Draining-Filling (for Scénic II)).

Check that the gearbox is not leaking oil.

Carry out a conformity check to detect any possible faults.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

DP0TA2000_V10_DF049/DP0TA2000_V11_DF049/DP0TA2000_V15_DF049