engine RENAULT SCENIC 2008 J84 / 2.G Engine And Peripherals - Starting Charging Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2008, Model line: SCENIC, Model: RENAULT SCENIC 2008 J84 / 2.GPages: 21, PDF Size: 0.08 MB

Page 1 of 21

1Engine and peripherals

V1 MR-372-J84-16A000$TOC.mif

V1

16A

"The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories from

which his vehicles are constructed."

V1

All rights reserved by Renault s.a.s.

Edition Anglaise

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault s.a.s.

© Renault s.a.s. 2008

STARTING - CHARGING

Scénic II ph 2

Fault finding – Role of components 16A - 2

Fault finding – Operating diagram 16A - 3

Fault finding – Features 16A - 4

Fault finding – Customer complaints 16A - 5

Fault finding – Fault finding charts 16A - 6

Fault finding – Tests 16A - 15

Page 2 of 21

16A-2V1 MR-372-J84-16A000$010.mif

16A

Scénic II ph 2

•Battery

The principal purpose of the battery is to provide the powerful current briefly required by the starter motor to start the

engine. For optimum starting, the current supplied by the battery must be sent to the starter motor with minimum

loss. To achieve this, the electrical connections (wires, terminals, connectors, etc.) must be in good condition.

When the engine is not running, the battery must feed the accessories that operate constantly, even with the ignition

switched off, such as the alarm, radio codes, computers, etc.

•Starter

This turns the engine over to make it start, and requires a very powerful electric current, which the battery must be

able to supply.

•Alternator

The alternator only operates when the engine is running. Its function is to recharge the battery, and at the same time

to supply the electrical power required to operate all the electrical accessories on the vehicle.

The alternator on Mégane II phase 2 is a controlled alternator. The UPC* controls the regulation via a serial

connection.

•Engine Compartment Connection Unit or Protection and Switching Unit

The UPC* is connected to the alternator by a serial connection. The UPC* intelligently manages the alternator

regulation voltage according to the engine phase, the battery charge, and the temperature.

•The UCH

The UCH* interprets the starting request and analyses if the starting conditions are satisfied, in order to transmit the

request to the UPC*.

*UPC: Engine Compartment Connection Unit or Protection and Switching Unit

*UCH: Passenger Compartment Central Unit

STARTING - CHARGING

Fault finding – Role of components

Page 4 of 21

16A-4V1 MR-372-J84-16A000$030.mif

16A

Scénic II ph 2

The function of the charging circuit is to:

•Ensure that electrical energy is supplied to the vehicle whilst respecting the dynamic performance constraints of

the engine and transmission assembly: the alternator resisting torques and the torque gradients measured must

be managed.

•To control alternator loading and load shedding during engine management authorisation or variation of the

electrical load.

•To ensure the quality of the on board network voltage in terms of the voltage level and variation (voltage gradient

management).

•To optimise the battery charge by applying a voltage to its terminals correlating to its initial charge status (in sleep

mode) and to its internal temperature.

•To inform the engine management about the mechanical power taken from the accessories pulley, the alternator

charge rate and the rotor excitation current value.

•To run fault finding on the charging circuit: "Battery" warning light display.

The function of the starting circuit is to:

•start the vehicle when there is a starting request from the ignition key.

STARTING - CHARGING

Fault finding – Features

Page 6 of 21

16A-6V1 MR-372-J84-16A000$050.mif

16A

Scénic II ph 2

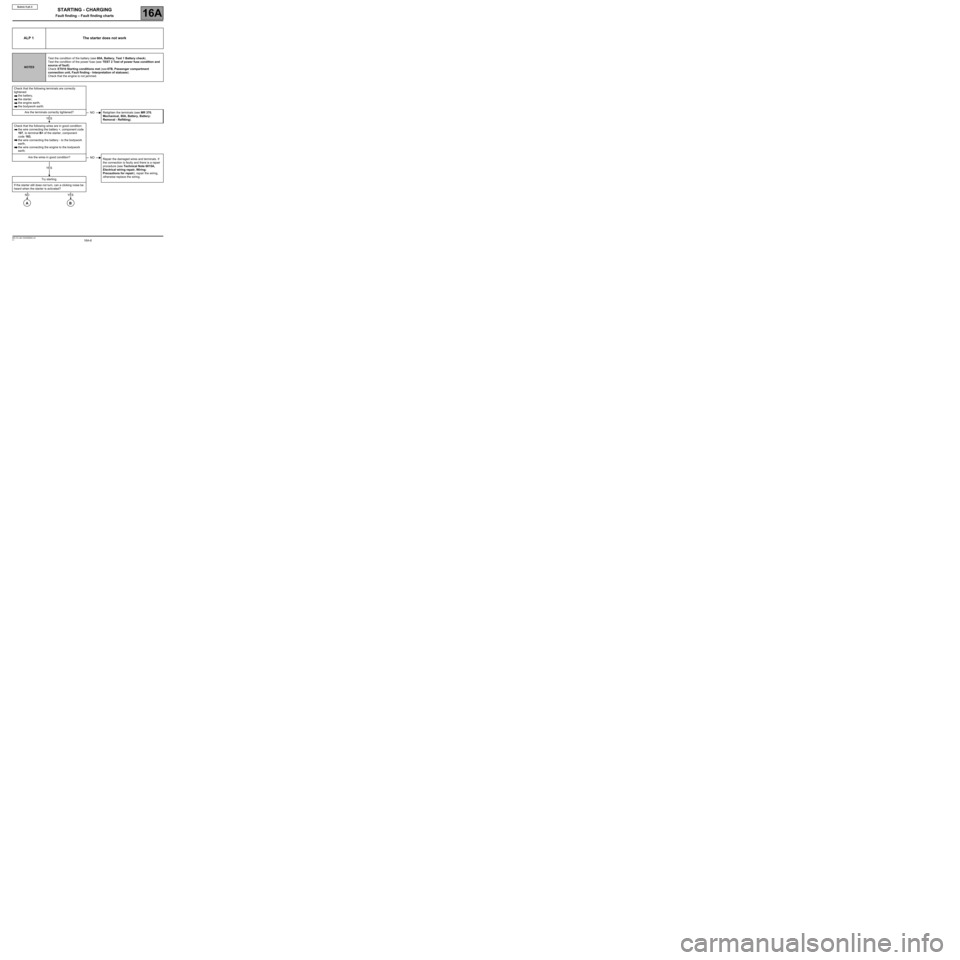

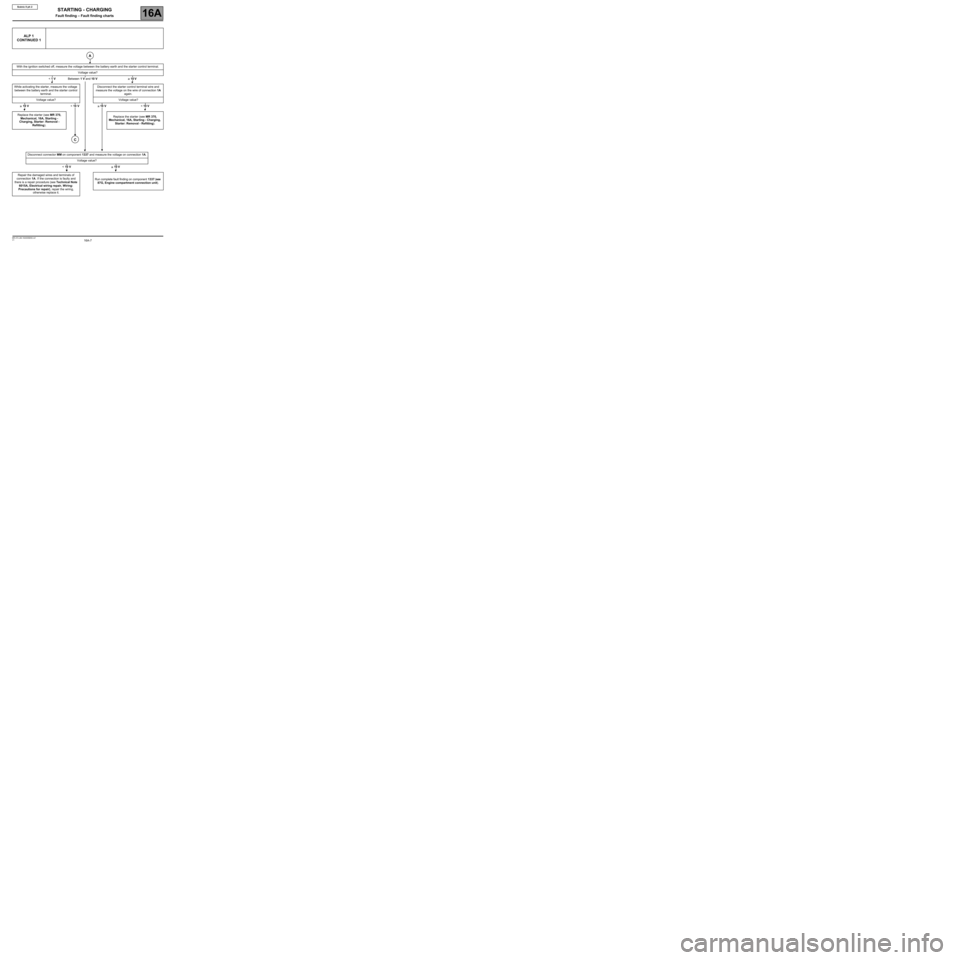

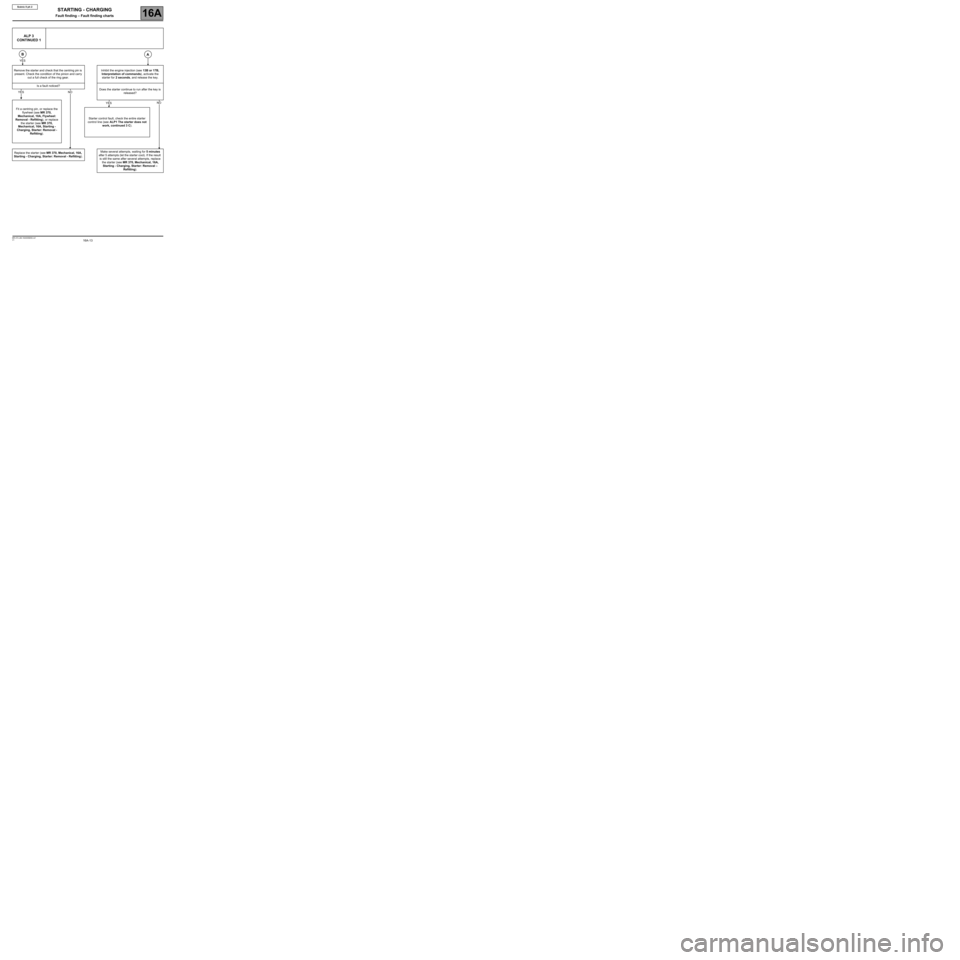

ALP 1 The starter does not work

NOTESTest the condition of the battery (see 80A, Battery, Test 1 Battery check).

Test the condition of the power fuse (see TEST 2 Test of power fuse condition and

source of fault).

Check ET010 Starting conditions met (see 87B, Passenger compartment

connection unit, Fault finding - Interpretation of statuses).

Check that the engine is not jammed.

Check that the following terminals are correctly

tightened:

the battery,

the starter,

the engine earth,

the bodywork earth.

Are the terminals correctly tightened?

Retighten the terminals (see MR 370,

Mechanical, 80A, Battery, Battery:

Removal - Refitting).

Check that the following wires are in good condition:

the wire connecting the battery +, component code

107, to terminal B+ of the starter, component

code 163,

the wire connecting the battery - to the bodywork

earth,

the wire connecting the engine to the bodywork

earth.

Are the wires in good condition?

Repair the damaged wires and terminals. If

the connection is faulty and there is a repair

procedure (see Technical Note 6015A,

Electrical wiring repair, Wiring:

Precautions for repair), repair the wiring,

otherwise replace the wiring.

Try starting.

If the starter still does not turn, can a clicking noise be

heard when the starter is activated?

NO

YES

NO

YES

A

NO

B

YES

STARTING - CHARGING

Fault finding – Fault finding charts

Page 7 of 21

16A-7V1 MR-372-J84-16A000$050.mif

STARTING - CHARGING

Fault finding – Fault finding charts16A

Scénic II ph 2

ALP 1

CONTINUED 1

With the ignition switched off, measure the voltage between the battery earth and the starter control terminal.

Voltage value?

While activating the starter, measure the voltage

between the battery earth and the starter control

terminal.Disconnect the starter control terminal wire and

measure the voltage on the wire of connection 1A

again.

Voltage value? Voltage value?

Replace the starter (see MR 370,

Mechanical, 16A, Starting -

Charging, Starter: Removal -

Refitting).Replace the starter (see MR 370,

Mechanical, 16A, Starting - Charging,

Starter: Removal - Refitting).

Disconnect connector MM on component 1337 and measure the voltage on connection 1A.

Voltage value?

Repair the damaged wires and terminals of

connection 1A. If the connection is faulty and

there is a repair procedure (see Technical Note

6015A, Electrical wiring repair, Wiring:

Precautions for repair), repair the wiring,

otherwise replace it.Run complete fault finding on component 1337 (see

87G, Engine compartment connection unit).

A

< 1 VBetween 1 V and 10 V≥ 10 V

≥ 10 V< 10 V

C

≥ 10 V< 10 V

< 10 V≥ 10 V

Page 8 of 21

16A-8V1 MR-372-J84-16A000$050.mif

STARTING - CHARGING

Fault finding – Fault finding charts16A

Scénic II ph 2

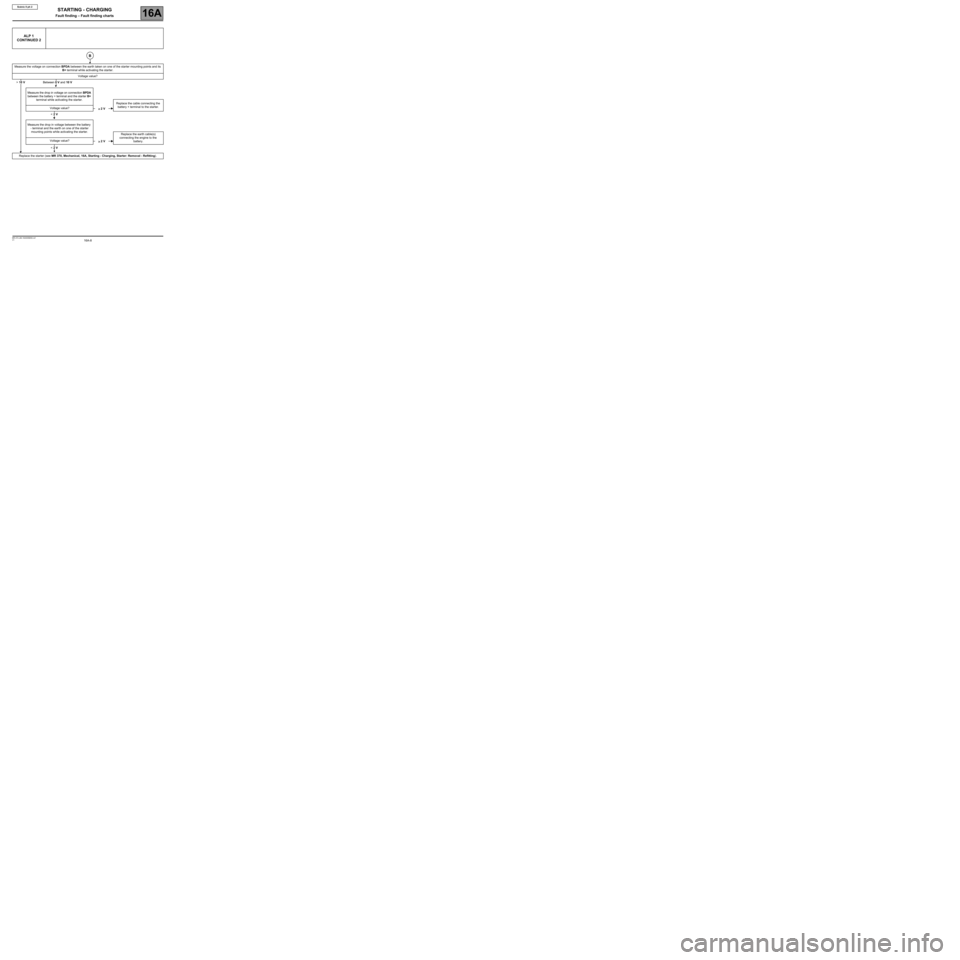

ALP 1

CONTINUED 2

Measure the voltage on connection BPDA between the earth taken on one of the starter mounting points and its

B+ terminal while activating the starter.

Voltage value?

Measure the drop in voltage on connection BPDA

between the battery + terminal and the starter B+

terminal while activating the starter.

Replace the cable connecting the

battery + terminal to the starter.

Voltage value?

Measure the drop in voltage between the battery

- terminal and the earth on one of the starter

mounting points while activating the starter.

Replace the earth cable(s)

connecting the engine to the

battery. Voltage value?

Replace the starter (see MR 370, Mechanical, 16A, Starting - Charging, Starter: Removal - Refitting).

B

> 10 VBetween 0 V and 10 V

≥ 2 V

< 2 V

≥ 2 V

< 2 V

Page 11 of 21

16A-11V1 MR-372-J84-16A000$050.mif

STARTING - CHARGING

Fault finding – Fault finding charts16A

Scénic II ph 2

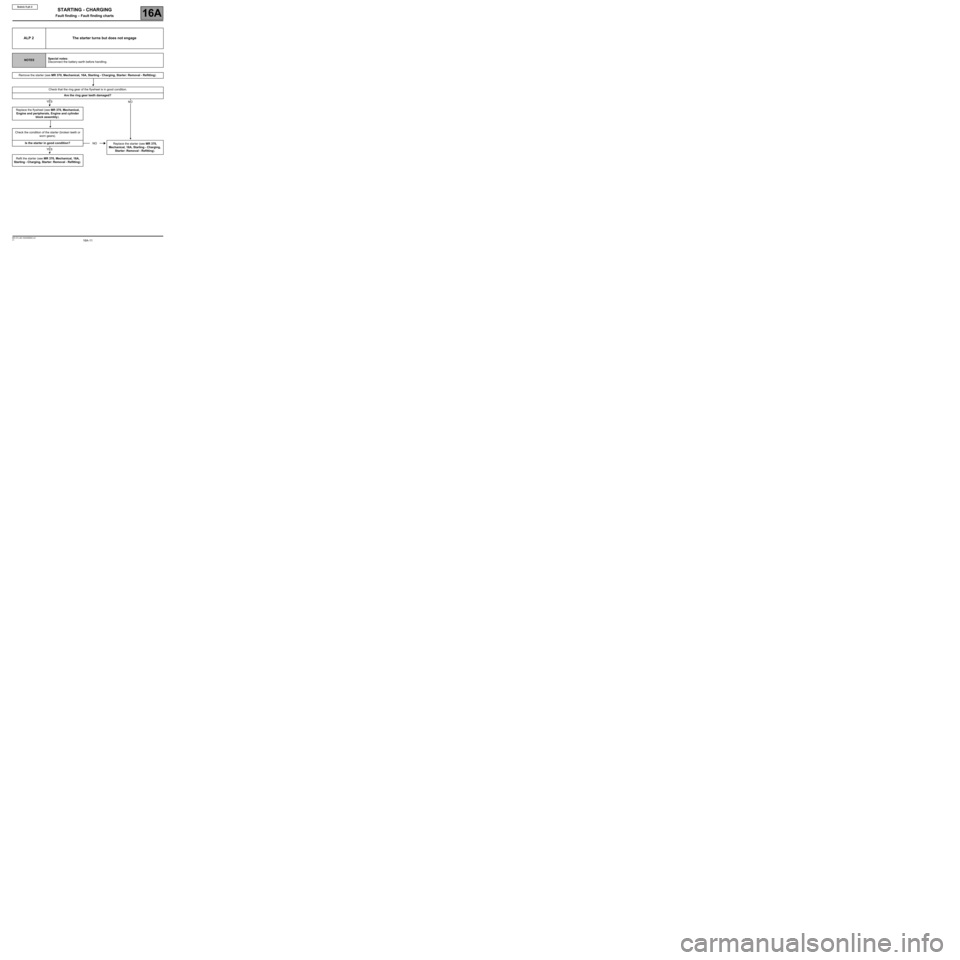

ALP 2 The starter turns but does not engage

NOTESSpecial notes:

Disconnect the battery earth before handling.

Remove the starter (see MR 370, Mechanical, 16A, Starting - Charging, Starter: Removal - Refitting).

Check that the ring gear of the flywheel is in good condition.

Are the ring gear teeth damaged?

Replace the flywheel (see MR 370, Mechanical,

Engine and peripherals, Engine and cylinder

block assembly).

Check the condition of the starter (broken teeth or

worn gears).

Is the starter in good condition?

Replace the starter (see MR 370,

Mechanical, 16A, Starting - Charging,

Starter: Removal - Refitting).

Refit the starter (see MR 370, Mechanical, 16A,

Starting - Charging, Starter: Removal - Refitting).

YESNO

NO

YES

Page 12 of 21

16A-12V1 MR-372-J84-16A000$050.mif

STARTING - CHARGING

Fault finding – Fault finding charts16A

Scénic II ph 2

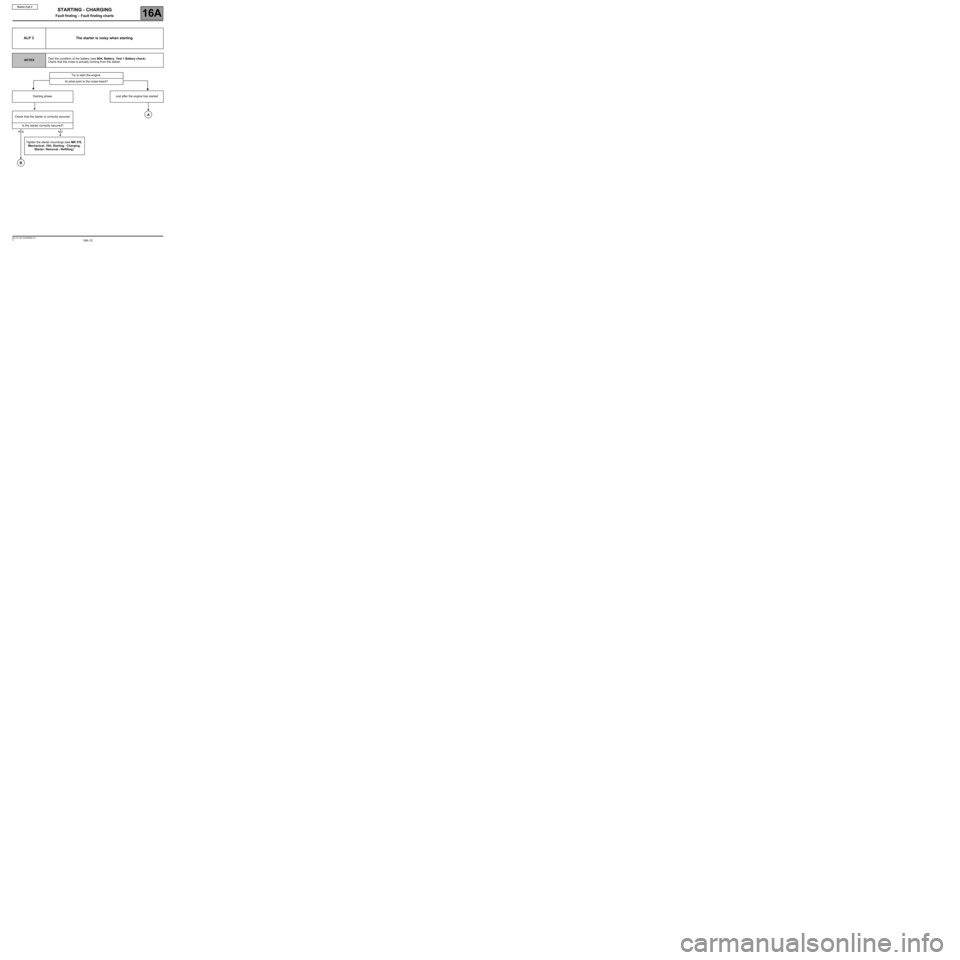

ALP 3 The starter is noisy when starting

NOTESTest the condition of the battery (see 80A, Battery, Test 1 Battery check).

Check that the noise is actually coming from the starter.

Try to start the engine.

At what point is the noise heard?

Starting phase Just after the engine has started

Check that the starter is correctly secured.

Is the starter correctly secured?

Tighten the starter mountings (see MR 370,

Mechanical, 16A, Starting - Charging,

Starter: Removal - Refitting).

A

YES

B

NO

Page 13 of 21

16A-13V1 MR-372-J84-16A000$050.mif

STARTING - CHARGING

Fault finding – Fault finding charts16A

Scénic II ph 2

ALP 3

CONTINUED 1

Remove the starter and check that the centring pin is

present. Check the condition of the pinion and carry

out a full check of the ring gear.Inhibit the engine injection (see 13B or 17B,

Interpretation of commands), activate the

starter for 2 seconds, and release the key.

Is a fault noticed?

Does the starter continue to run after the key is

released?

Fit a centring pin, or replace the

flywheel (see MR 370,

Mechanical, 10A, Flywheel:

Removal - Refitting), or replace

the starter (see MR 370,

Mechanical, 16A, Starting -

Charging, Starter: Removal -

Refitting).Starter control fault, check the entire starter

control line (see ALP1 The starter does not

work, continued 3 C).

Replace the starter (see MR 370, Mechanical, 16A,

Starting - Charging, Starter: Removal - Refitting).Make several attempts, waiting for 5 minutes

after 5 attempts (let the starter cool). If the result

is still the same after several attempts, replace

the starter (see MR 370, Mechanical, 16A,

Starting - Charging, Starter: Removal –

Refitting).

B

YES

A

YESNO

YESNO

Page 15 of 21

16A-15V1 MR-372-J84-16A000$060.mif

16A

Scénic II ph 2

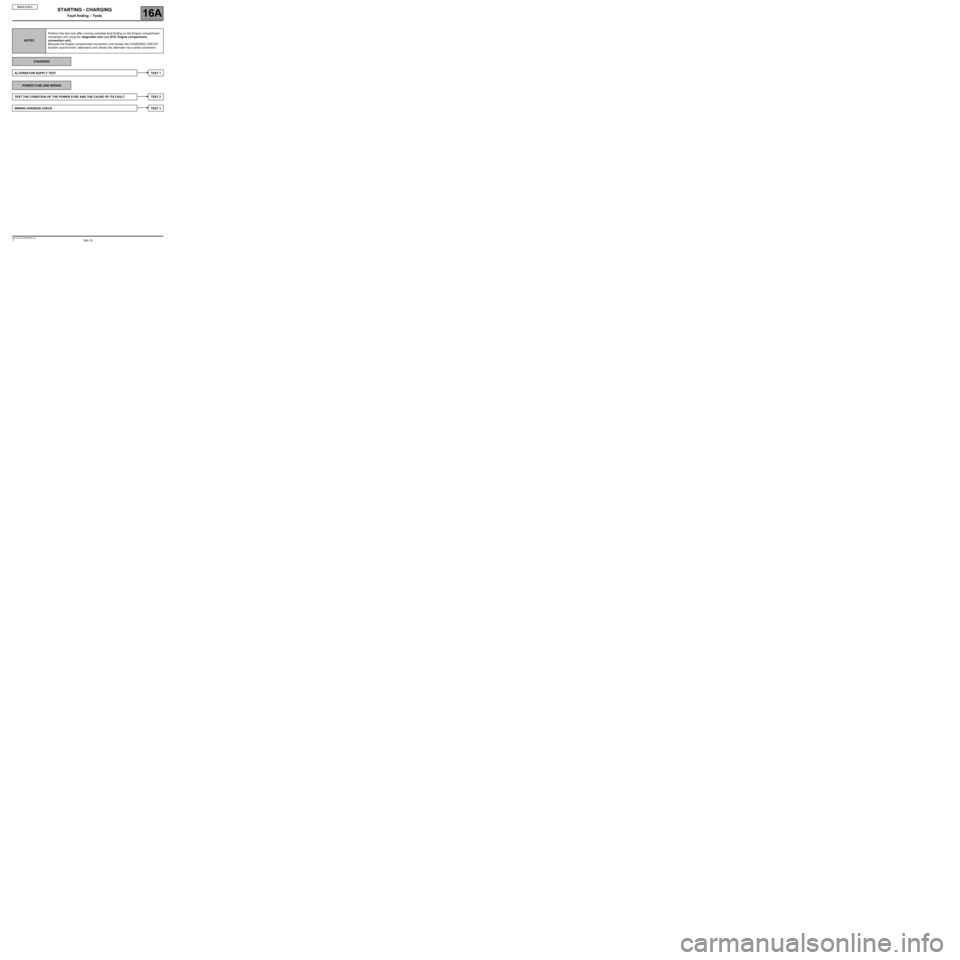

NOTESPerform this test only after running complete fault finding on the Engine compartment

connection unit using the diagnostic tool (see 87G, Engine compartment

connection unit).

Because the Engine compartment connection unit houses the CHARGING CIRCUIT

function (sub-function: alternator) and checks the alternator via a serial connection.

CHARGING

ALTERNATOR SUPPLY TESTTEST 1

POWER FUSE AND WIRING

TEST THE CONDITION OF THE POWER FUSE AND THE CAUSE OF ITS FAULT TEST 2

WIRING HARNESS CHECKTEST 3

STARTING - CHARGING

Fault finding – Tests