brake RENAULT SCENIC 2009 J84 / 2.G Automatic Transmission AJ0 BVA User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 162

Page 22 of 162

AUTOMATIC TRANSMISSION

Fault finding - Replacement of components

23A

23A-22V3 MR-372-J84-23A000$270.mif

AJ0 BVA

Vdiag No.: 04, 05

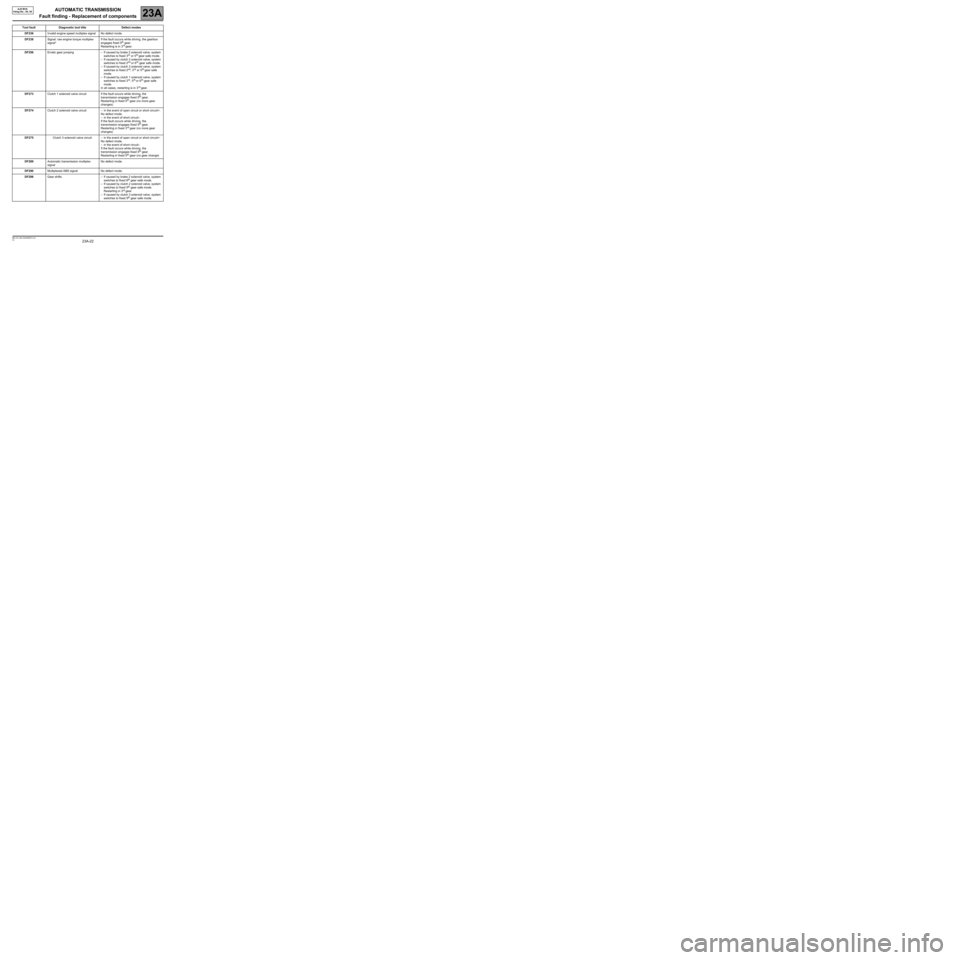

Tool fault Diagnostic tool title Defect modes

DF236Invalid engine speed multiplex signal No defect mode.

DF238Signal: raw engine torque multiplex

signal*If the fault occurs while driving, the gearbox

engages fixed 5

th gear.

Restarting is in 3rd gear.

DF256Erratic gear jumping – If caused by brake 2 solenoid valve, system

switches to fixed 3

rd or 5th gear safe mode.

–If caused by clutch 2 solenoid valve, system

switches to fixed 2

nd or 6th gear safe mode.

–If caused by clutch 3 solenoid valve, system

switches to fixed 2

nd, 3rd or 5th gear safe

mode.

–If caused by clutch 1 solenoid valve, system

switches to fixed 3

rd, 5th or 6th gear safe

mode.

In all cases, restarting is in 3

rd gear.

DF273Clutch 1 solenoid valve circuit If the fault occurs while driving, the

transmission engages fixed 5

th gear.

Restarting in fixed 5th gear (no more gear

changes).

DF274Clutch 2 solenoid valve circuit – in the event of open circuit or short circuit+:

No defect mode.

–in the event of short circuit-:

If the fault occurs while driving, the

transmission engages fixed 5

th gear.

Restarting in fixed 3rd gear (no more gear

changes)

DF275Clutch 3 solenoid valve circuit – in the event of open circuit or short circuit+:

No defect mode.

–in the event of short circuit-:

If the fault occurs while driving, the

transmission engages fixed 5

th gear.

Restarting in fixed 5th gear (no gear change)

DF289Automatic transmission multiplex

signalNo defect mode.

DF290Multiplexed ABS signal No defect mode.

DF298Gear shifts – If caused by brake 2 solenoid valve, system

switches to fixed 6

th gear safe mode.

–If caused by clutch 2 solenoid valve, system

switches to fixed 5

th gear safe mode.

Restarting in 3rd gear.

–If caused by clutch 3 solenoid valve, system

switches to fixed 5

th gear safe mode.

Page 23 of 162

AUTOMATIC TRANSMISSION

Fault finding - Replacement of components

23A

23A-23V3 MR-372-J84-23A000$270.mif

AJ0 BVA

Vdiag No.: 04, 05

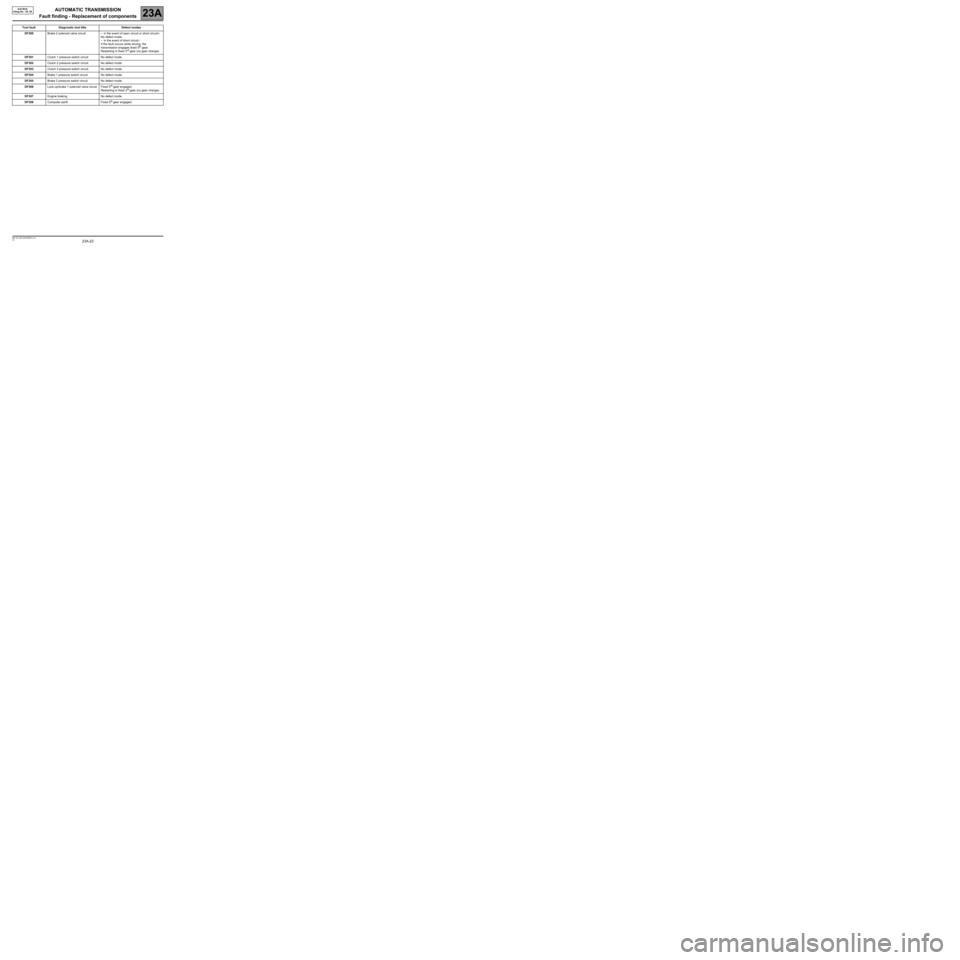

Tool fault Diagnostic tool title Defect modes

DF300Brake 2 solenoid valve circuit – in the event of open circuit or short circuit+:

No defect mode.

–in the event of short circuit-:

If the fault occurs while driving, the

transmission engages fixed 5

th gear.

Restarting in fixed 3rd gear (no gear change)

DF301Clutch 1 pressure switch circuit No defect mode.

DF302Clutch 2 pressure switch circuit No defect mode.

DF303Clutch 3 pressure switch circuit No defect mode.

DF304Brake 1 pressure switch circuit No defect mode.

DF305Brake 2 pressure switch circuit No defect mode.

DF306Lock-up/brake 1 solenoid valve circuit Fixed 5

th gear engaged.

Restarting in fixed 3rd gear (no gear change).

DF307Engine braking No defect mode.

DF308Computer earth Fixed 5

th gear engaged.

Page 24 of 162

AUTOMATIC TRANSMISSION

Fault finding - Replacement of components

23A

23A-24V3 MR-372-J84-23A000$270.mif

AJ0 BVA

Vdiag No.: 04, 05

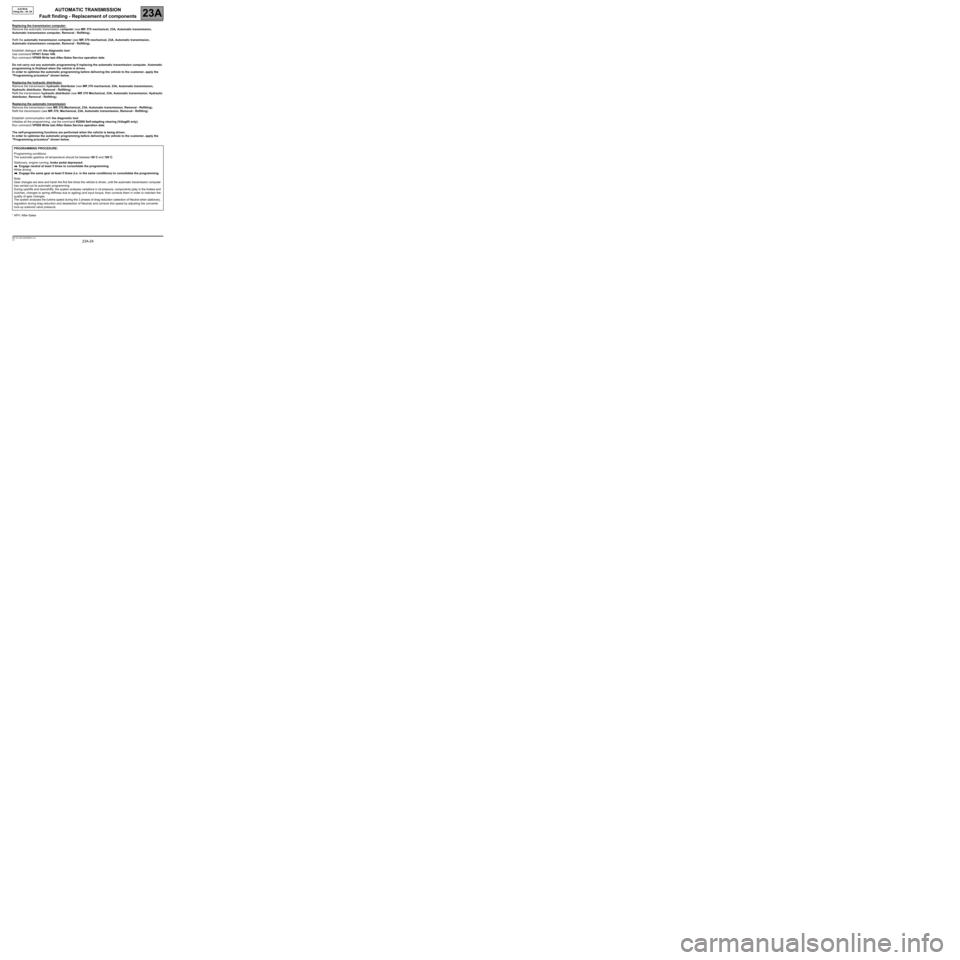

Replacing the transmission computer:

Remove the automatic transmission computer (see MR 370 mechanical, 23A, Automatic transmission,

Automatic transmission computer, Removal - Refitting).

Refit the automatic transmission computer (see MR 370 mechanical, 23A, Automatic transmission,

Automatic transmission computer, Removal - Refitting).

Establish dialogue with the diagnostic tool.

Use command VP001 Enter VIN.

Run command VP009 Write last After-Sales Service operation date.

Do not carry out any automatic programming if replacing the automatic transmission computer. Automatic

programming is finalised when the vehicle is driven.

In order to optimise the automatic programming before delivering the vehicle to the customer, apply the

"Programming procedure" shown below.

Replacing the hydraulic distributor:

Remove the transmission hydraulic distributor (see MR 370 mechanical, 23A, Automatic transmission,

Hydraulic distributor, Removal - Refitting).

Refit the transmission hydraulic distributor (see MR 370 Mechanical, 23A, Automatic transmission, Hydraulic

distributor, Removal - Refitting).

Replacing the automatic transmission

Remove the transmission (see MR 370,Mechanical, 23A, Automatic transmission, Removal - Refitting).

Refit the transmission (see MR 370, Mechanical, 23A, Automatic transmission, Removal - Refitting).

Establish communication with the diagnostic tool.

Initialise all the programming, use the command RZ009 Self-adapting clearing (Vdiag05 only).

Run command VP009 Write last After-Sales Service operation date.

The self-programming functions are performed when the vehicle is being driven.

In order to optimise the automatic programming before delivering the vehicle to the customer, apply the

"Programming procedure" shown below.

* APV: After-SalesPROGRAMMING PROCEDURE:

Programming conditions:

The automatic gearbox oil temperature should be between 60˚C and 100˚C.

Stationary, engine running, brake pedal depressed:

Engage neutral at least 5 times to consolidate the programming.

While driving:

Engage the same gear at least 5 times (i.e. in the same conditions) to consolidate the programming.

Note:

Gear changes are slow and harsh the first few times the vehicle is driven, until the automatic transmission computer

has carried out its automatic programming.

During upshifts and downshifts, the system analyses variations in oil pressure, components (play in the brakes and

clutches, changes to spring stiffness due to ageing) and input torque, then corrects them in order to maintain the

quality of gear changes.

The system analyses the turbine speed during the 3 phases of drag reduction (selection of Neutral when stationary,

regulation during drag reduction and deselection of Neutral) and corrects this speed by adjusting the converter

lock-up solenoid valve pressure.

Page 26 of 162

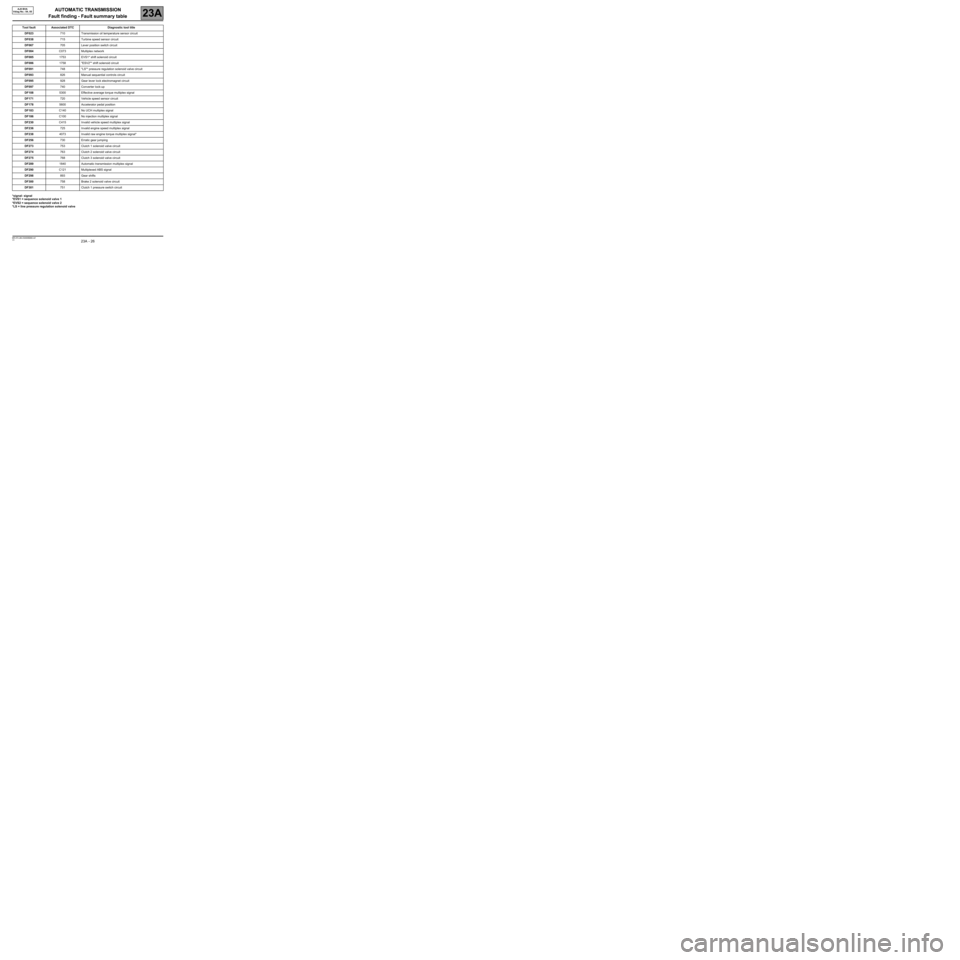

AUTOMATIC TRANSMISSION

Fault finding - Fault summary table

23A

23A - 26V3 MR-372-J84-23A000$360.mif

AJ0 BVA

Vdiag No.: 04, 05AUTOMATIC TRANSMISSION

Fault finding - Fault summary table

*signal: signal

*EVS1 = sequence solenoid valve 1

*EVS2 = sequence solenoid valve 2

*LS = line pressure regulation solenoid valveTool fault Associated DTC Diagnostic tool title

DF023710 Transmission oil temperature sensor circuit

DF038715 Turbine speed sensor circuit

DF067705 Lever position switch circuit

DF084C073 Multiplex network

DF0851753 EVS1* shift solenoid circuit

DF0861758 "ESV2"* shift solenoid circuit

DF091748 "LS"* pressure regulation solenoid valve circuit

DF093826 Manual sequential controls circuit

DF095928 Gear lever lock electromagnet circuit

DF097740 Converter lock-up

DF1085300 Effective average torque multiplex signal

DF171720 Vehicle speed sensor circuit

DF1785600 Accelerator pedal position

DF183C140 No UCH multiplex signal

DF186C100 No injection multiplex signal

DF230C415 Invalid vehicle speed multiplex signal

DF236725 Invalid engine speed multiplex signal

DF2384073 Invalid raw engine torque multiplex signal*

DF256730 Erratic gear jumping

DF273753 Clutch 1 solenoid valve circuit

DF274763 Clutch 2 solenoid valve circuit

DF275768 Clutch 3 solenoid valve circuit

DF2891840 Automatic transmission multiplex signal

DF290C121 Multiplexed ABS signal

DF298893 Gear shifts

DF300758 Brake 2 solenoid valve circuit

DF301751 Clutch 1 pressure switch circuit

MR-372-J84-23A000$360.mif

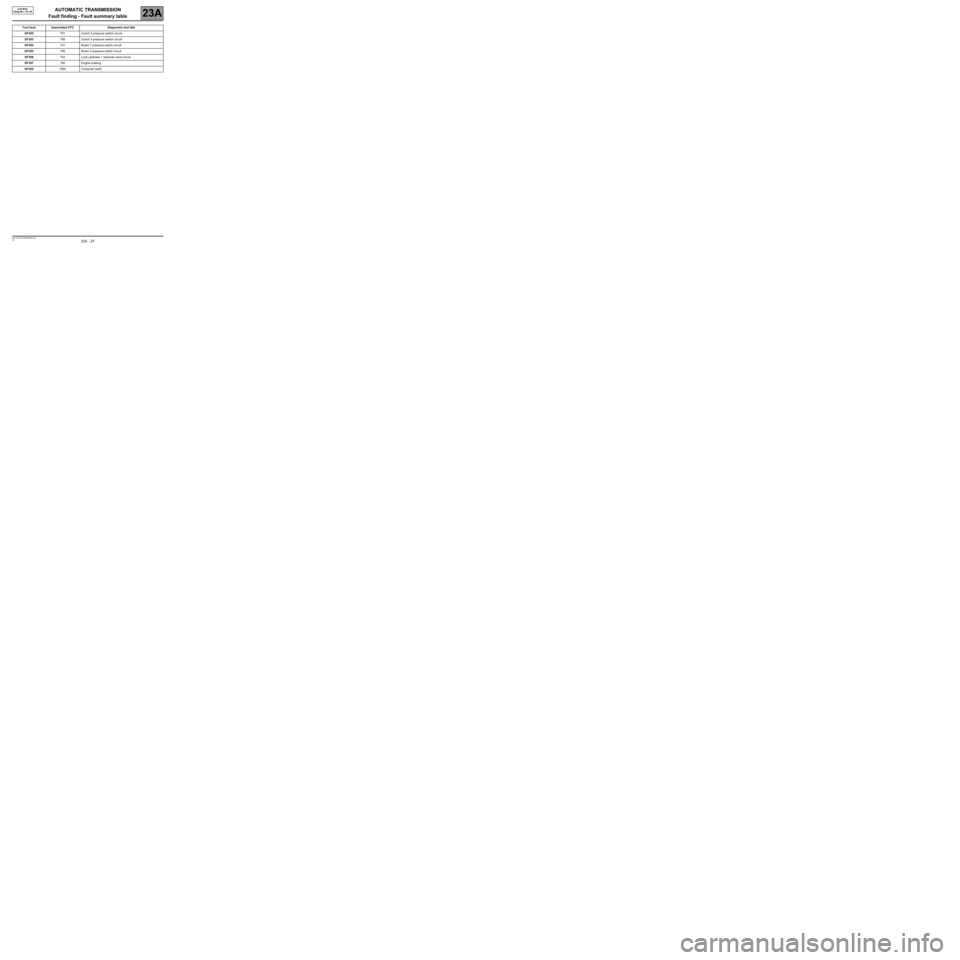

Page 27 of 162

AUTOMATIC TRANSMISSION

Fault finding - Fault summary table

23A

23A - 27V3 MR-372-J84-23A000$360.mif

AJ0 BVA

Vdiag No.: 04, 05

Tool fault Associated DTC Diagnostic tool title

DF302761 Clutch 2 pressure switch circuit

DF303766 Clutch 3 pressure switch circuit

DF304741 Brake 1 pressure switch circuit

DF305756 Brake 2 pressure switch circuit

DF306743 Lock-up/brake 1 solenoid valve circuit

DF307780 Engine braking

DF3081560 Computer earth

Page 50 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 50V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05

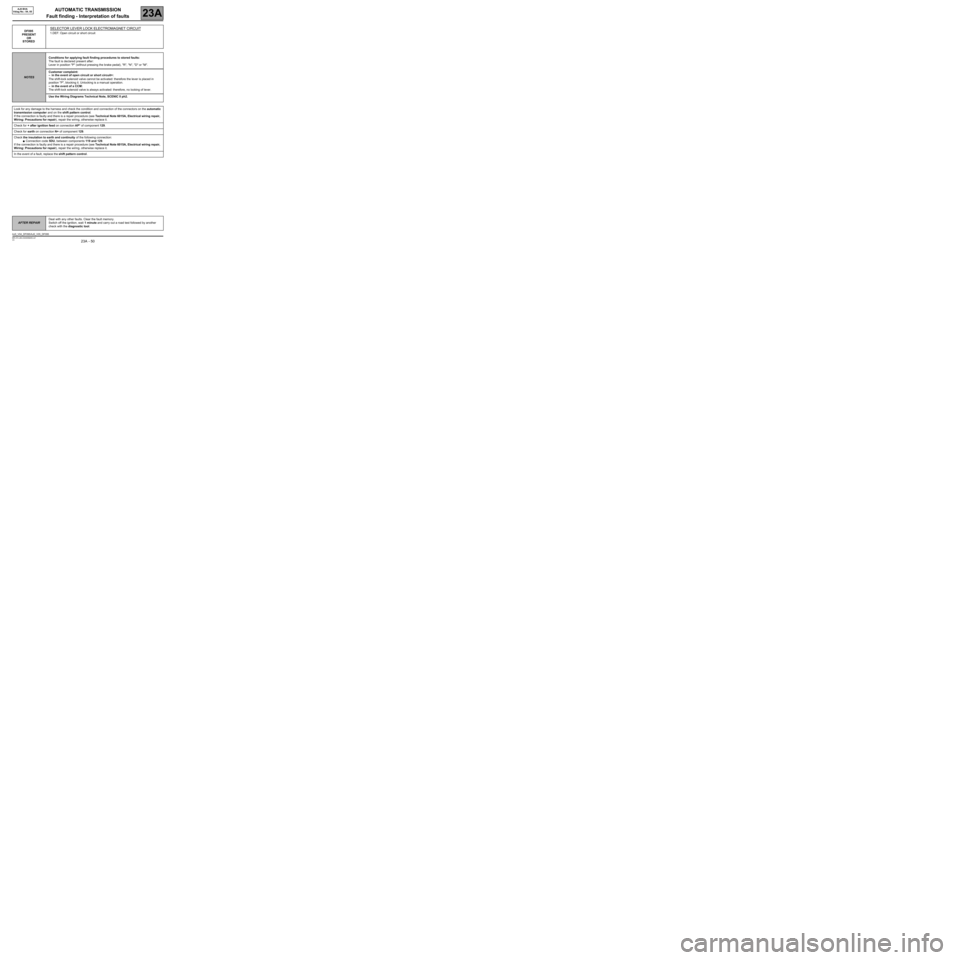

DF095

PRESENT

OR

STOREDSELECTOR LEVER LOCK ELECTROMAGNET CIRCUIT

1.DEF: Open circuit or short circuit

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after:

Lever in position "P" (without pressing the brake pedal), "R", "N", "D" or "M".

Customer complaint:

–in the event of open circuit or short circuit+:

The shift-lock solenoid valve cannot be activated: therefore the lever is placed in

position "P", blocking it. Unlocking is a manual operation.

–in the event of a CCM:

The shift-lock solenoid valve is always activated: therefore, no locking of lever.

Use the Wiring Diagrams Technical Note, SCENIC II ph2.

Look for any damage to the harness and check the condition and connection of the connectors on the automatic

transmission computer and on the shift pattern control.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check for + after ignition feed on connection AP* of component 129.

Check for earth on connection N+ of component 129.

Check the insulation to earth and continuity of the following connection:

●Connection code 5DU, between components 119 and 129.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

In the event of a fault, replace the shift pattern control.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

AJ0_V04_DF095/AJ0_V05_DF095

Page 51 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 51V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05

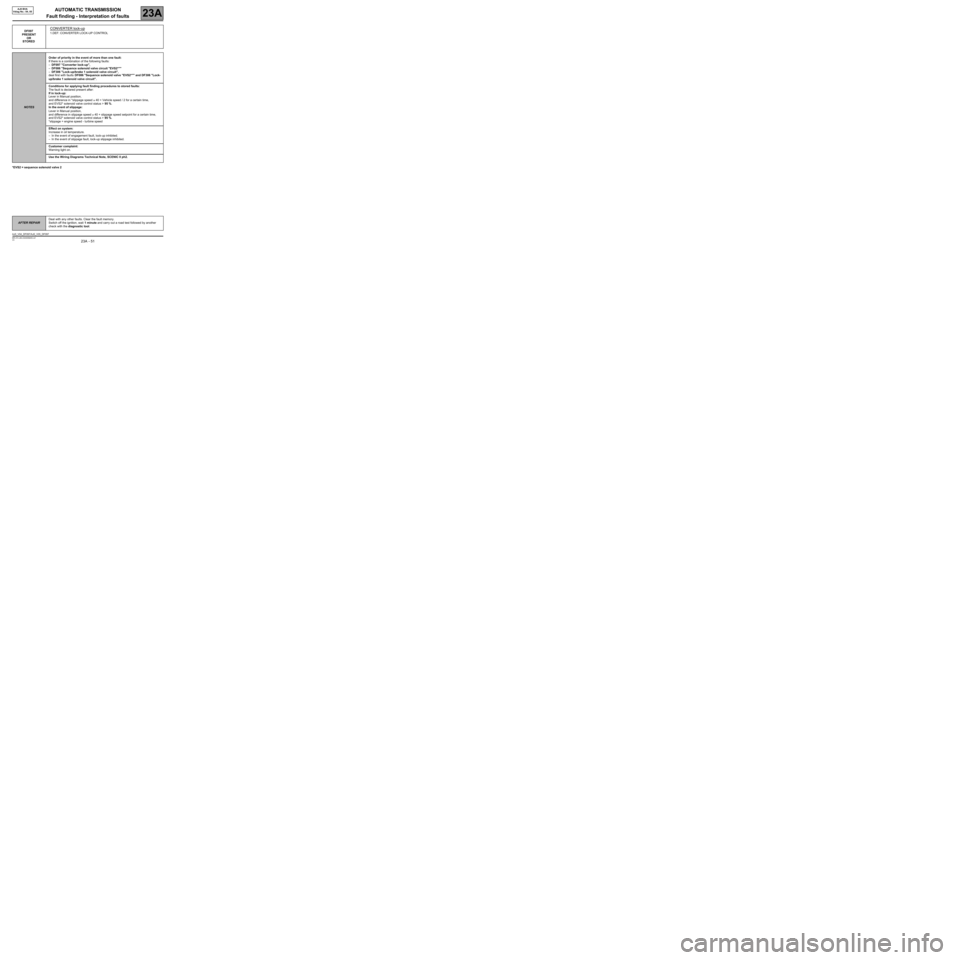

*EVS2 = sequence solenoid valve 2DF097

PRESENT

OR

STORED

CONVERTER lock-up

1.DEF: CONVERTER LOCK-UP CONTROL

NOTESOrder of priority in the event of more than one fault:

If there is a combination of the following faults:

–DF097 "Converter lock-up",

–DF086 "Sequence solenoid valve circuit "EVS2*""

–DF306 "Lock-up/brake 1 solenoid valve circuit",

deal first with faults DF086 "Sequence solenoid valve "EVS2*"" and DF306 "Lock-

up/brake 1 solenoid valve circuit".

Conditions for applying fault finding procedures to stored faults:

The fault is declared present after:

If in lock-up:

Lever in Manual position,

and difference in *slippage speed ≥ 40 + Vehicle speed / 2 for a certain time,

and EVS2* solenoid valve control status > 95 %.

In the event of slippage:

Lever in Manual position,

and difference in slippage speed ≥ 40 + slippage speed setpoint for a certain time,

and EVS2* solenoid valve control status > 95 %.

*slippage = engine speed - turbine speed

Effect on system:

Increase in oil temperature.

–In the event of engagement fault, lock-up inhibited.

–In the event of slippage fault, lock-up slippage inhibited.

Customer complaint:

Warning light on.

Use the Wiring Diagrams Technical Note, SCENIC II ph2.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

AJ0_V04_DF097/AJ0_V05_DF097

Page 54 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 54V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05

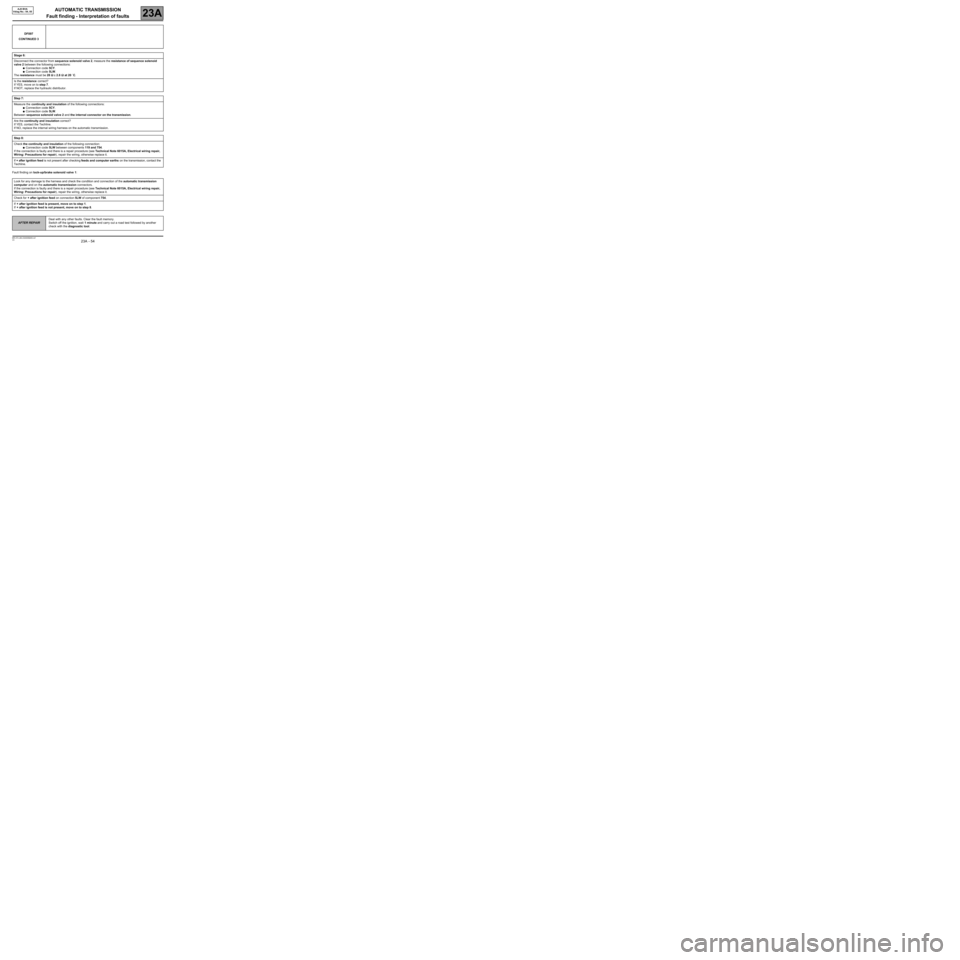

Fault finding on lock-up/brake solenoid valve 1: DF097

CONTINUED 3

Stage 6:

Disconnect the connector from sequence solenoid valve 2, measure the resistance of sequence solenoid

valve 2 between the following connections:

●Connection code 5CY.

●Connection code 5LW.

The resistance must be 28 ΩΩ Ω Ω

± 2.8 ΩΩ Ω Ω

at 20 ˚C.

Is the resistance correct?

If YES, move on to step 7.

If NOT, replace the hydraulic distributor.

Step 7:

Measure the continuity and insulation of the following connections:

●Connection code 5CY.

●Connection code 5LW.

Between sequence solenoid valve 2 and the internal connector on the transmission.

Are the continuity and insulation correct?

If YES, contact the Techline.

If NO, replace the internal wiring harness on the automatic transmission.

Step 8:

Check the continuity and insulation of the following connection:

●Connection code 5LW between components 119 and 754.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If + after ignition feed is not present after checking feeds and computer earths on the transmission, contact the

Techline.

Look for any damage to the harness and check the condition and connection of the automatic transmission

computer and on the automatic transmission connectors.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check for + after ignition feed on connection 5LW of component 754.

If + after ignition feed is present, move on to step 1.

If + after ignition feed is not present, move on to step 8.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

Page 55 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 55V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05

DF097

CONTINUED 4

Step 1:

Disconnect the connector from component 119, measure the resistance of the lock-up/brake solenoid valve

(on the connector of component 119) between the following connections:

●Connection code 5BF.

●Connection code 5LW.

The resistance must be 5.3 ΩΩ Ω Ω

± 0.5 ΩΩ Ω Ω

at 20 ˚C.

Is the resistance correct?

If YES, contact the Techline.

If NO, move on to step 2.

Step 2:

Disconnect connector R22 and check continuity and insulation of the following connections:

●Connection code 5BF.

●Connection code 5LW.

Between components 119 and R22.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Are the continuity and insulation correct?

If YES, move on to step 3.

If NO, replace the external wiring harness on the automatic transmission.

Stage 3:

Measure the resistance of lock-up/brake 1 solenoid valve (on connector R22) between the following

connections:

●Connection code 5BF.

●Connection code 5LW.

The resistance must be 5.3 ΩΩ Ω Ω

± 0.5 ΩΩ Ω Ω

at 20 ˚C.

Is the resistance correct?

If YES, and if the fault is still present, contact the Techline.

If NO, move on to step 4.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.

Page 56 of 162

AUTOMATIC TRANSMISSION

Fault finding - Interpretation of faults

23A

23A - 56V3 MR-372-J84-23A000$405.mif

AJ0 BVA

Vdiag No.: 04, 05

DF097

CONTINUED 5

Stage 4:

Drain the automatic transmission (see, MR 370, Mechanical, 23A Automatic transmission, Oil change) and

remove the transmission housing (see, MR 370, Mechanical, 23A Automatic transmission, Hydraulic

distributor).

Disconnect the connector from component 754, measure the resistance of lock-up/brake 1 solenoid valve

(on the connector of the internal wiring harness of the transmission) between the following connections:

●Connection code 5BF.

●Connection code 5LW.

The resistance must be 5.3 ΩΩ Ω Ω

± 0.5 ΩΩ Ω Ω

at 20 ˚C.

Is the resistance correct?

If YES, move on to step 5.

If NO, move on to step 6.

Stage 5:

Measure the continuity and insulation of the following connections:

●Connection code 5BF.

●Connection code 5LW.

Between components R22 and the internal connector in the transmission.

Are the continuity and insulation correct?

If YES, contact the Techline.

If NO, replace the intermediate wiring harness between connector R22 and the internal connector in the

transmission.

Stage 6:

Disconnect the connector from lock-up/brake 1 solenoid valve, measure the resistance of lock-up/brake 1

solenoid valve between the following connections:

●Connection code 5BF.

●Connection code 5LW.

The resistance must be 5.3 ΩΩ Ω Ω

± 0.5 ΩΩ Ω Ω

at 20 ˚C.

Is the resistance correct?

If YES, move on to step 7.

If NO, replace the hydraulic distributor.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by another

check with the diagnostic tool.