engine RENAULT SCENIC 2009 J84 / 2.G Engine And Peripherals EDC16 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 273

Page 201 of 273

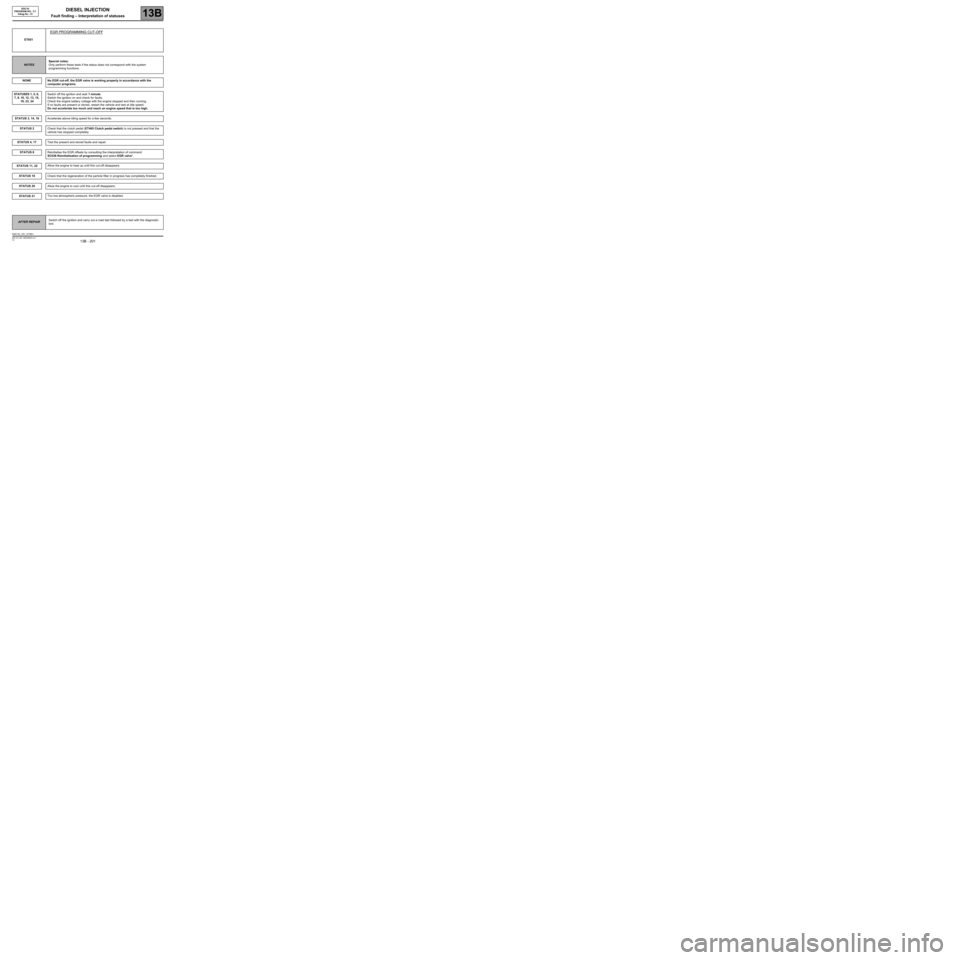

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

13B - 201V3 MR-372-J84-13B250$630.mif

STATUS 18

STATUS 20

STATUS 21

STATUS 11, 22

STATUS 8

STATUS 4, 17

STATUS 2

STATUS 3, 14, 16

STATUSES 1, 5, 6,

7, 9, 10, 12, 13, 15,

19, 23, 24

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

ET651

EGR PROGRAMMING CUT-OFF

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

NONE

No EGR cut-off, the EGR valve is working properly in accordance with the

computer programs.

Switch off the ignition and wait 1 minute.

Switch the ignition on and check for faults.

Check the engine battery voltage with the engine stopped and then running.

If no faults are present or stored, restart the vehicle and test at idle speed.

Do not accelerate too much and reach an engine speed that is too high.

Accelerate above idling speed for a few seconds.

Check that the clutch pedal (ET405 Clutch pedal switch) is not pressed and that the

vehicle has stopped completely.

Test the present and stored faults and repair.

Reinitialise the EGR offsets by consulting the interpretation of command

SC036 Reinitialisation of programming and select EGR valve".

Allow the engine to heat up until this cut-off disappears.

Check that the regeneration of the particle filter in progress has completely finished.

Allow the engine to cool until this cut-off disappears.

Too low atmospheric pressure, the EGR valve is disabled.

AFTER REPAIRSwitch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

EDC16_V51_ET651

Page 206 of 273

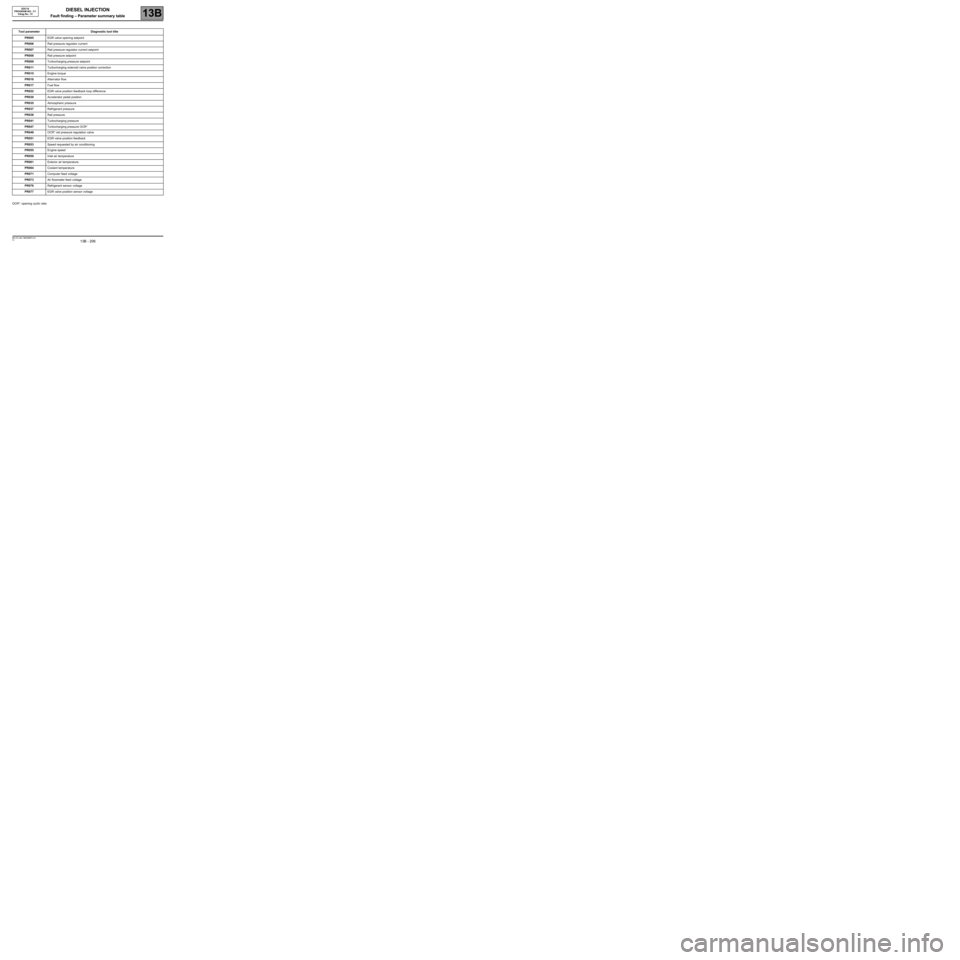

DIESEL INJECTION

Fault finding – Parameter summary table13B

13B - 206V3 MR-372-J84-13B250$675.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Parameter summary table

OCR*: opening cyclic ratioTool parameter Diagnostic tool title

PR005EGR valve opening setpoint

PR006Rail pressure regulator current

PR007Rail pressure regulator current setpoint

PR008Rail pressure setpoint

PR009Turbocharging pressure setpoint

PR011Turbocharging solenoid valve position correction

PR015Engine torque

PR016Alternator flow

PR017Fuel flow

PR022EGR valve position feedback loop difference

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR041Turbocharging pressure

PR047Turbocharging pressure OCR*

PR048OCR* rail pressure regulation valve

PR051EGR valve position feedback

PR053Speed requested by air conditioning

PR055Engine speed

PR059Inlet air temperature

PR061Exterior air temperature

PR064Coolant temperature

PR071Computer feed voltage

PR073Air flowmeter feed voltage

PR076Refrigerant sensor voltage

PR077EGR valve position sensor voltage

MR-372-J84-13B250$675.mif

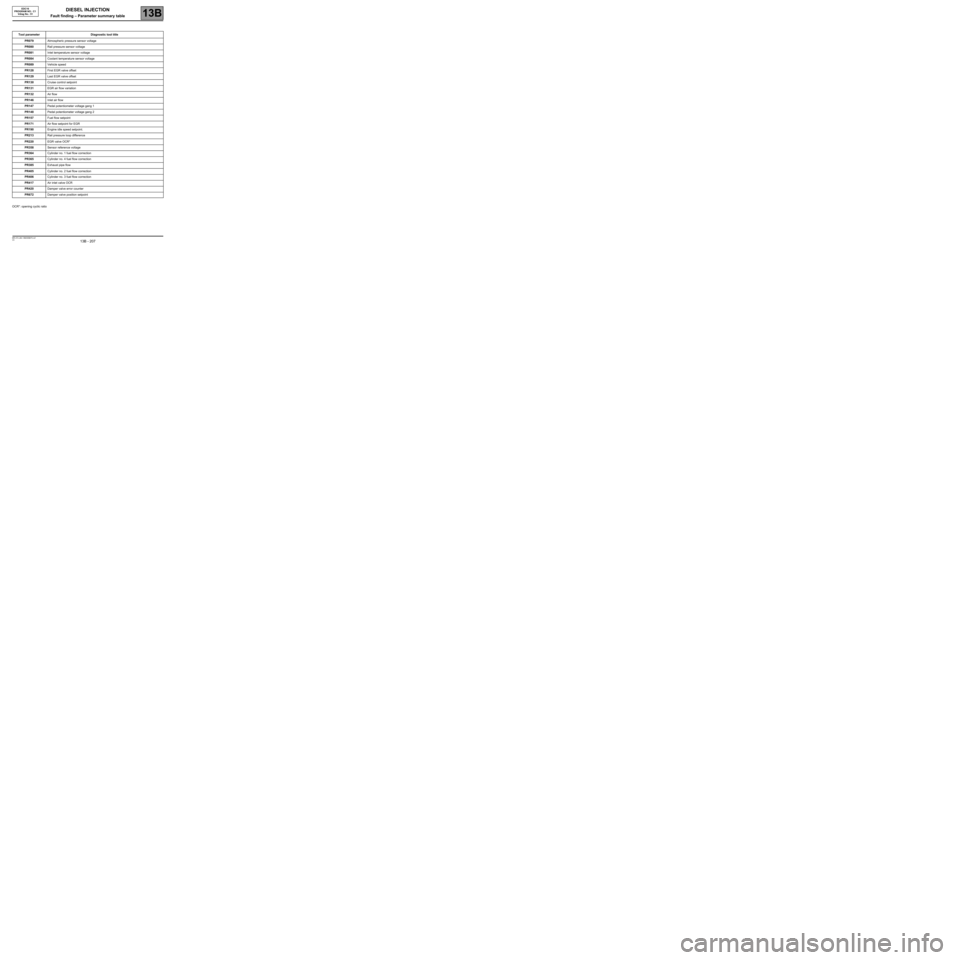

Page 207 of 273

DIESEL INJECTION

Fault finding – Parameter summary table13B

13B - 207V3 MR-372-J84-13B250$675.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

OCR*: opening cyclic ratioTool parameter Diagnostic tool title

PR079Atmospheric pressure sensor voltage

PR080Rail pressure sensor voltage

PR081Inlet temperature sensor voltage

PR084Coolant temperature sensor voltage

PR089Vehicle speed

PR128First EGR valve offset

PR129Last EGR valve offset

PR130Cruise control setpoint

PR131EGR air flow variation

PR132Air flow

PR146Inlet air flow

PR147Pedal potentiometer voltage gang 1

PR148Pedal potentiometer voltage gang 2

PR157Fuel flow setpoint

PR171Air flow setpoint for EGR

PR190Engine idle speed setpoint.

PR213Rail pressure loop difference

PR220EGR valve OCR*

PR358Sensor reference voltage

PR364Cylinder no. 1 fuel flow correction

PR365Cylinder no. 4 fuel flow correction

PR385Exhaust pipe flow

PR405Cylinder no. 2 fuel flow correction

PR406Cylinder no. 3 fuel flow correction

PR417Air inlet valve OCR

PR420Damper valve error counter

PR672Damper valve position setpoint

Page 209 of 273

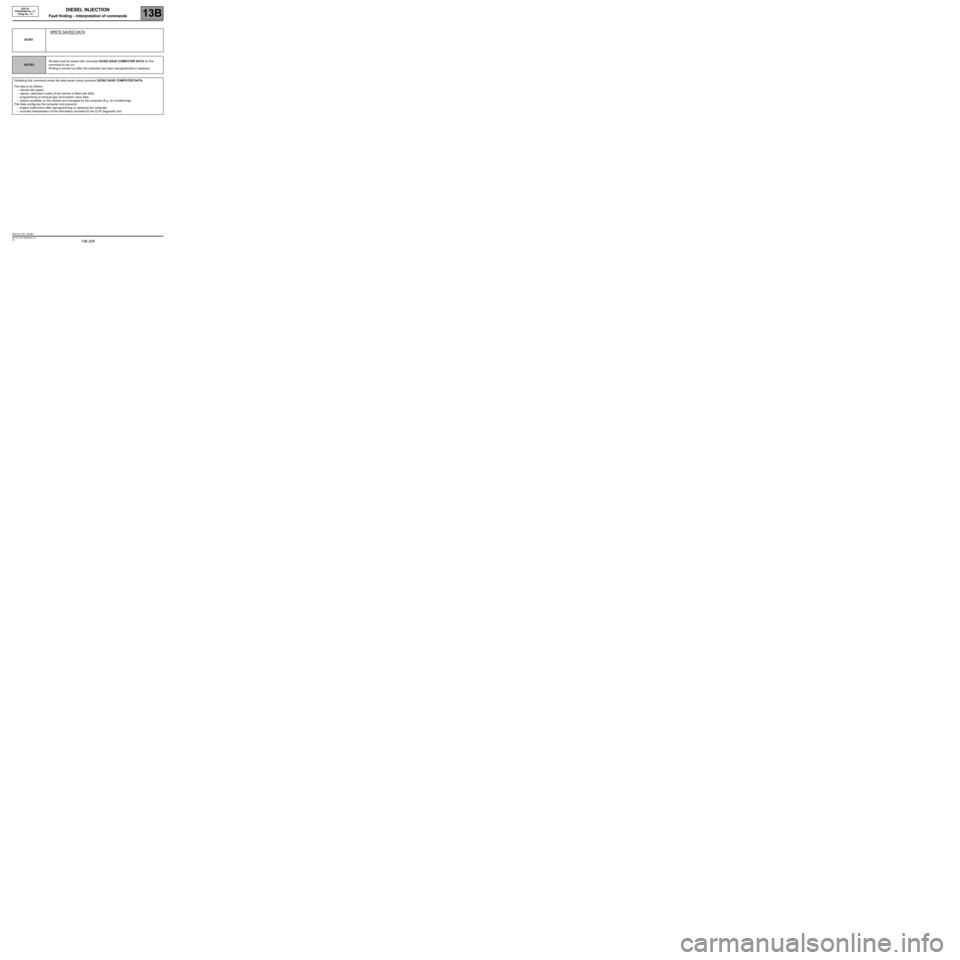

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -209V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Interpretation of commands

SC001

WRITE SAVED DATA

NOTESAll data must be saved with command SC003 SAVE COMPUTER DATA for this

command to be run.

Writing is carried out after the computer has been reprogrammed or replaced.

Validating this command writes the data saved using command SC003 SAVE COMPUTER DATA.

The data is as follows:

–vehicle idle speed,

–injector calibration codes (if the vehicle is fitted with IMA),

–programming of exhaust gas recirculation valve data,

–options available on the vehicle and managed by the computer (E.g. air conditioning).

This data configures the computer and prevents:

–engine malfunction after reprogramming or replacing the computer,

–incorrect interpretation of the information provided by the CLIP diagnostic tool.

EDC16_V51_SC001

Page 210 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -210V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

SC002

ENTER INJECTOR CODES

NOTESThis command should be run after the injectors have been replaced and only if the

vehicle has been configured with IMA.

(ET104 USE OF INJECTOR CODES to YES).

If this command is not performed, the DF276 INJECTOR CODE PROGRAMMING

fault will be present.

WARNING

The letters J and Q, and figures 0 and 9 are not used in IMA coding.

If these characters are used the entry will be invalid.

Cylinder no. 1 is the cylinder located at the engine flywheel end.

Procedure to be followed:

–Read the 6-character alphanumeric codes etched on the upper section of the injector bodies.

–Use command SC002.

–Select the cylinder number for the cylinder concerned in the Desired, column, then confirm.

–Enter the injector code displayed for the cylinder.

–Enter the new codes for each cylinder, then confirm.

–When the command is completed, the modified codes appear in the Current column.

–Check that the codes correspond to those read earlier.

–If the codes entered appear in neither the Current column nor the Desired column, check the codes read and

make sure the data has been entered correctly,

The possible confusions are:

digit "1" with the letter "I"

figure 8 with the letter B

figure 5 with the letter S

–Exit fault finding mode.

–Switch off the ignition and wait for 1 min.

–Switch the ignition back on and check for faults.

–DF276 INJECTOR CODE PROGRAMMING should be stored.

If fault DF276 is still present, the command has not been performed correctly.

Start the procedure again and follow the instructions.

If the codes are still not recognised, check whether the computer's standby has been correctly set:

Switch off the ignition and wait for 1 min.

If the warning light flashes when the ignition is switched off, the computer has not been put on standby and the

command will be ignored.

If all these checks still do not enable the command to be confirmed, contact the Techline.

EDC16_V51_SC002

Page 212 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -212V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

SC036

REINITIALISE PROGRAMMING

NOTESThis command is used to reset the computer parameters according to the type of

operation or component repaired or replaced from the following list:

–the EGR valve,

–the damper valve.

Ignition on and engine stopped.

To run this command, select the SC036 Reinitialise programming scenario on the CLIP tool.

Procedure to be followed:

–on the main screen, select the component to reinitialise after an operation (removal - refitting or replacement

of component),

–select YES then OK to begin reinitialisation,

–select Finish on the Configuration done screen to return to the main screen,

–end of operation.

EDC16_V51_SC036

Page 214 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -214V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

RZ034

COMPUTER MEMORY

NOTESIMPORTANT

Only use this command if DF038 Computer is Present.

Ignition on and engine stopped.

Command RZ034 reinitialises the computer memory.

–With the ignition on:

–Use command RZ034.

–Switch off the ignition and wait for the message Communication lost with computer.

–Switch on the ignition again.

–Run the programming commands (see Configuration and programming)

–Use command SC036 Reinitialise programming and choose After injection computer replacement with

no save option,

–Enter the injector codes using command SC002 Enter injector codes (see Interpretation of commands),

–Switch off the ignition and wait for the message Communication lost with computer.

Perform a road test to reinitialise the parameters of the vehicle.

EDC16_V51_RZ034

Page 216 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -216V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

AC004

TURBOCHARGING SOLENOID VALVE

NOTESThis command is used to check the turbocharging circuit.

This command checks that the turbocharger and the control circuit are working properly.

Introduction

1-Check the sealing of the high pressure air circuit:

Pipes not joined or pierced, pressure sensor disconnected or poorly fitted (seal present), intercooler pierced.

To test the intercooler: stabilise the engine speed between 3,500 and 4,000 rpm with the vehicle stopped and

check that there are no leaks.

Check the resistance of the turbocharging limitation solenoid valve between tracks 1 and 2.

Replace the solenoid valve if its resistance is not 15.4 Ω ± 0.7 at 20˚C.

Check the injection computer connections.

Check for continuity and make sure there is no interference resistance on the following connection:

Injection computer grey 32-track connector C,

track E1Track 1 turbocharging solenoid valve

Repair if necessary.

Check for the presence of + 12 V after relay on track 2 of the turbocharging solenoid valve.

2 - Turbocharger control circuit check

–With the engine stopped, make sure that the control rod is in the resting position.

–Start the engine and make sure that the control rod actuates to the upper stop.

–(when the engine is switched off, the control rod should return to the rest position)

–If the control rod does not move correctly, carry out the following checks:

1) Vacuum pressure command check:

–Disconnect the solenoid valve inlet hose and connect it to a pressure gauge.

–Start the engine and run it at a stable idle speed.

–If the vacuum pressure does not reach 800 mbar ± 100: check the vacuum pressure circuit from the vacuum

pump.

–Stop the engine, reconnect the inlet hoses and go to step no. 2.

2) Solenoid valve control check:

–Disconnect the solenoid valve outlet hose.

–Start the engine and run it at a stable idle speed.

–Place your hand on the solenoid valve and block the outlet union with your thumb.

–If you notice no solenoid valve vibration, check the operation of the computer output (step 5). Solenoid valve

operation check:

–Connect the pressure gauge to the solenoid valve outlet union.

–Start the engine and run it at a stable idle speed.

If the vacuum pressure does not reach 800 mbar ± 100, replace the solenoid valve.

EDC16_V51_AC004

Page 217 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -217V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

* Opening cyclic ratio signalAC004

CONTINUED

Turbocharger control circuit check (continued)

4) Turbocharger operation check:

a) Connect a vacuum pump to the hose connected to the turbocharger control diaphragm.

Apply a negative pressure of 800 ± 100 mbar:

If there is a leak, replace the turbocharger (diaphragm included).

b) Check the control rod movement and setting (see MR 364, Mechanics, 12B, Turbocharging).

If the control rod is sticking, replace the turbocharger.

c) Engine cold and stopped:

Remove the turbocharger inlet duct and check that the compressor turns freely on the axis.

d) If the fault persists:

Check that the exhaust manifold is not leaking.

Check that the exhaust is not blocked.

Carry out the necessary repairs.

5) Computer output stage check: (solenoid valve connected).

This operation can only be carried out if the checks indicated in step no. 2 are not conclusive.

Either with the voltmeter: Connect the voltmeter earth lead on track 2 of the solenoid valve and the positive

lead on track 1.

Clear any solenoid valve fault then run command AC004:

●The voltmeter should display ten cycles of two successive voltages ~ = battery voltage X opening cycle ratio*

in process.

that is: ~ 2.5 V (opening cyclic ratio* of 20%) then ~ 8.7 V (opening cyclic ratio* of 70%).

Or with the oscilloscope (at 5 V range/division and 1 ms/div time base): Connect the earth lead of the

oscilloscope to the battery earth and the positive test pin to track 2 of the solenoid valve.

Clear any solenoid valve faults, then run command AC004:

●the oscilloscope should display a square wave signal of 12.5 V in amplitude at a frequency of 140 Hz

(with an opening cyclic ratio* passing from ~ 20 to ~ 70%).

If the measurement is correct, replace the solenoid valve.

If the measurement does not show any control or continuous voltage, contact the Techline.

Page 220 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -220V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

AC012

DAMPER VALVE

NOTESThis command allows you to check the operation of the damper valve.

–Measure the resistance of the damper valve solenoid valve between tracks 1 and 2.

Replace the solenoid valve if the resistance is not: 46 ± 3 Ω at + 25˚C.

–Check for continuity and for the absence of interference resistance on the following connections:

Injection computer, brown 48-track connector

B, track M1track 1 of the damper valve solenoid valve

connector

+ 12 V after relaytrack 2 of the damper valve solenoid valve

connector

A) Engine running at idle speed

Make sure that there is a pressure of ~ 900 mbar on the solenoid valve inlet hose.

Make the necessary repairs (pressure circuit conformity and seal).

B) With the vehicle ignition on, engine stopped

Make sure the damper valve is open.

If not, clean or replace the air vent unit.

Disconnect the solenoid valve inlet and outlet hoses,

Connect a vacuum pump to the inlet union and apply a pressure of ~900 mbar

If there is a leak, replace the solenoid valve.

Run command AC012.

Otherwise, with the solenoid valve connected, check operation of the computer output stage with a voltmeter:

Voltmeter earth cabletrack 1 of the solenoid valve

Voltmeter positive leadtrack 2 of the solenoid valve

Clear any solenoid valve faults,

Run command AC012.

The voltmeter should display ten ON-OFF cycles (8.75 V then 2.5 V).

If the measurement is correct, replace the solenoid valve.

If the measurement does not show any lights, contact the Techline.

C) Vehicle with ignition off

Connect a vacuum pump to the flap control diaphragm and apply a pressure of ~900 mbar:

If the diaphragm does not maintain the negative pressure, replace the air vent unit (the diaphragm cannot be

disconnected).

If the diaphragm maintains the vacuum and the flap does not operate, clean or replace the air vent unit.

If the diaphragm maintains the underpressure and the valve operates, then operate it several times to ensure

that there is no blockage.

Check for clogging of the air vent unit and its valve, and clean if necessary.

EDC16_V51_AC012