Injector RENAULT SCENIC 2009 J84 / 2.G Engine And Peripherals EDC16 Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 273

Page 208 of 273

DIESEL INJECTION

Fault finding – Command summary table13B

13B -208V3 MR-372-J84-13B250$720.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Command summary table

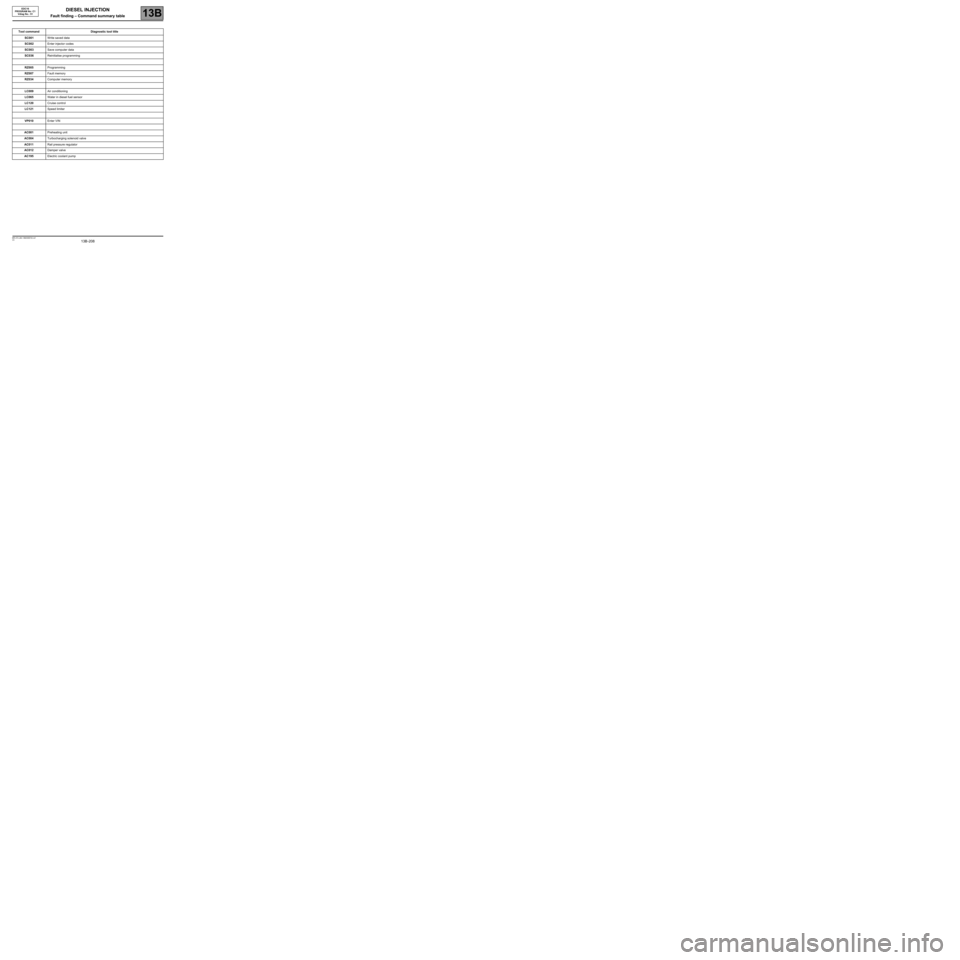

Tool command Diagnostic tool title

SC001Write saved data

SC002Enter injector codes

SC003Save computer data

SC036Reinitialise programming

RZ005Programming

RZ007Fault memory

RZ034Computer memory

LC009Air conditioning

LC065Water in diesel fuel sensor

LC120Cruise control

LC121Speed limiter

VP010Enter VIN

AC001Preheating unit

AC004Turbocharging solenoid valve

AC011Rail pressure regulator

AC012Damper valve

AC195Electric coolant pump

Page 209 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -209V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Interpretation of commands

SC001

WRITE SAVED DATA

NOTESAll data must be saved with command SC003 SAVE COMPUTER DATA for this

command to be run.

Writing is carried out after the computer has been reprogrammed or replaced.

Validating this command writes the data saved using command SC003 SAVE COMPUTER DATA.

The data is as follows:

–vehicle idle speed,

–injector calibration codes (if the vehicle is fitted with IMA),

–programming of exhaust gas recirculation valve data,

–options available on the vehicle and managed by the computer (E.g. air conditioning).

This data configures the computer and prevents:

–engine malfunction after reprogramming or replacing the computer,

–incorrect interpretation of the information provided by the CLIP diagnostic tool.

EDC16_V51_SC001

Page 210 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -210V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

SC002

ENTER INJECTOR CODES

NOTESThis command should be run after the injectors have been replaced and only if the

vehicle has been configured with IMA.

(ET104 USE OF INJECTOR CODES to YES).

If this command is not performed, the DF276 INJECTOR CODE PROGRAMMING

fault will be present.

WARNING

The letters J and Q, and figures 0 and 9 are not used in IMA coding.

If these characters are used the entry will be invalid.

Cylinder no. 1 is the cylinder located at the engine flywheel end.

Procedure to be followed:

–Read the 6-character alphanumeric codes etched on the upper section of the injector bodies.

–Use command SC002.

–Select the cylinder number for the cylinder concerned in the Desired, column, then confirm.

–Enter the injector code displayed for the cylinder.

–Enter the new codes for each cylinder, then confirm.

–When the command is completed, the modified codes appear in the Current column.

–Check that the codes correspond to those read earlier.

–If the codes entered appear in neither the Current column nor the Desired column, check the codes read and

make sure the data has been entered correctly,

The possible confusions are:

digit "1" with the letter "I"

figure 8 with the letter B

figure 5 with the letter S

–Exit fault finding mode.

–Switch off the ignition and wait for 1 min.

–Switch the ignition back on and check for faults.

–DF276 INJECTOR CODE PROGRAMMING should be stored.

If fault DF276 is still present, the command has not been performed correctly.

Start the procedure again and follow the instructions.

If the codes are still not recognised, check whether the computer's standby has been correctly set:

Switch off the ignition and wait for 1 min.

If the warning light flashes when the ignition is switched off, the computer has not been put on standby and the

command will be ignored.

If all these checks still do not enable the command to be confirmed, contact the Techline.

EDC16_V51_SC002

Page 211 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B-211V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

SC003

SAVE COMPUTER DATA

NOTESThe data is saved before computer reprogramming or the computer is replaced.

On the CLIP tool, select the SC003 Save computer data.

If the following message appears:

"a saved file exists, do you want to overwrite this data?"

(this file corresponds to the last save carried out on the tool)

Select YES.

Confirming this command saves the following vehicle-specific data:

–injector codes,

–the EGR valve data programming;

–options available on the vehicle and managed by the computer (E.g. air conditioning).

This information will be saved on the CLIP tool.

After saving has finished, use the command SC001 Enter saved data to be able to set the new computer

parameters, after programming and reprogramming.

EDC16_V51_SC003

Page 214 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -214V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

RZ034

COMPUTER MEMORY

NOTESIMPORTANT

Only use this command if DF038 Computer is Present.

Ignition on and engine stopped.

Command RZ034 reinitialises the computer memory.

–With the ignition on:

–Use command RZ034.

–Switch off the ignition and wait for the message Communication lost with computer.

–Switch on the ignition again.

–Run the programming commands (see Configuration and programming)

–Use command SC036 Reinitialise programming and choose After injection computer replacement with

no save option,

–Enter the injector codes using command SC002 Enter injector codes (see Interpretation of commands),

–Switch off the ignition and wait for the message Communication lost with computer.

Perform a road test to reinitialise the parameters of the vehicle.

EDC16_V51_RZ034

Page 219 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -219V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

AC011

CONTINUED

Step 2

In the event of rail overpressure:

Check the injectors are working:

see test 8 Incorrect injector operation.

Check that the rail pressure sensor is operating correctly:

Fault interpretation DF007 RAIL PRESSURE SENSOR CIRCUIT.

Carry out the necessary repairs.

If these checks do not reveal any faults, and if the fault is still present, replace the rail pressure sensor.

In the event of rail underpressure:

Check that the rail pressure sensor is operating correctly:

Fault interpretation DF007 RAIL PRESSURE SENSOR CIRCUIT.

Check the low pressure diesel circuit priming.

Check the conformity of the diesel filter connections.

Check the condition of the filter (clogging and water saturation).

Check there are no air bubbles between the filter and the high pressure pump.

Check the sealing of the high pressure and low pressure diesel circuit.

(odour and visual inspections): pump body, overpressure valve, pipes, rail and injector unions, injector wells.

Check the conformity of the seal fitting on the pressure regulator.

Check the injectors are working:

see test 8 Incorrect injector operation.

Carry out the necessary repairs.

If these checks do not reveal any faults, and if the fault is still present, replace the rail pressure sensor.

Page 225 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -225V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

ALP2

CONTINUED 1

Check that the heater plugs are actuated using the AC001 Preheating unit command.

Check the sealing and condition of the inlet circuit: run test 3 Turbocharged air inlet circuit check and follow the

fault finding procedure.

Check that there are no foreign bodies on the flowmeter grille: run test 4 Air flowmeter and follow the fault finding

procedure.

Check that the exhaust is not blocked: run test 1 Exhaust pipe check and follow the related fault finding

procedure.

Check the consistency of the signal from the engine coolant temperature sensor.

Check the pressure regulator is working properly (see command AC011 Rail pressure regulator).

Check the operation of the injectors (excessive return leak, clogging, seizing): run test 8 Poor injector operation.

Check the engine timing (and the position of the high pressure pump sprocket).

Check the balance of the compressions, according to the power consumption during the starting phase

(Compression test menu on the CLIP Technic tool).

If you do not have the CLIP Technic or if there is an imbalance, use a compression gauge to get an accurate

measurement.

after the operation, clear the faults caused by disconnecting the regulator and the heater plugs.

End of part A

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.

Page 227 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -227V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

ALP3 Injection noise

NOTESBefore dealing with this customer complaint, check that there are no faults, and

the conformity (or otherwise) of the parameters and statuses using the

diagnostic tool.

If the customer complaint is not ironed out, perform the following checks:

If the injection noise occurs after starting from cold:

Check the low pressure diesel circuit priming.

Check the fuel heater supply.

Check the operation of the preheating system.

Check that fuel and engine temperatures are consistent.

If the injection noise occurs at idle speed:

Check the condition of the injector connector and pressure regulator terminals.

Check the conformity of the air flow signal: use fault finding procedures: PR132 Air flow or run test 3

Turbocharged air inlet circuit check.

If the complaint is still present, perform the injector fault finding procedure: run test 8 Poor injector operation.

does the injection noise occur at all engine speeds?

Run fault finding on the injectors: run test 8 Incorrect injector operation.

Check the condition of the injector connector and pressure regulator terminals.

Check the conformity of the fuel used, apply test 10 Diesel fuel conformity check.

If the diesel fuel is not correct: – Replace the diesel fuel.

–Change the diesel filter.

–Bleed the low and high pressure diesel circuit.

Check the conformity of the air flow signal: use the interpretation of the fault finding procedure PR132 Air flow.

If the customer complaint is still present:

Run command AC011 Rail pressure regulator.

Then apply the conformity check to confirm:

–the conformity of the fuel pressure between PR008 Rail pressure setpoint and PR038 Rail Pressure,

–the conformity of the pump fuel flow between PR157 Fuel flow setpoint and PR017 Fuel flow.

If the fault is still present, contact the Techline.

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V51_ALP3

Page 228 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -228V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

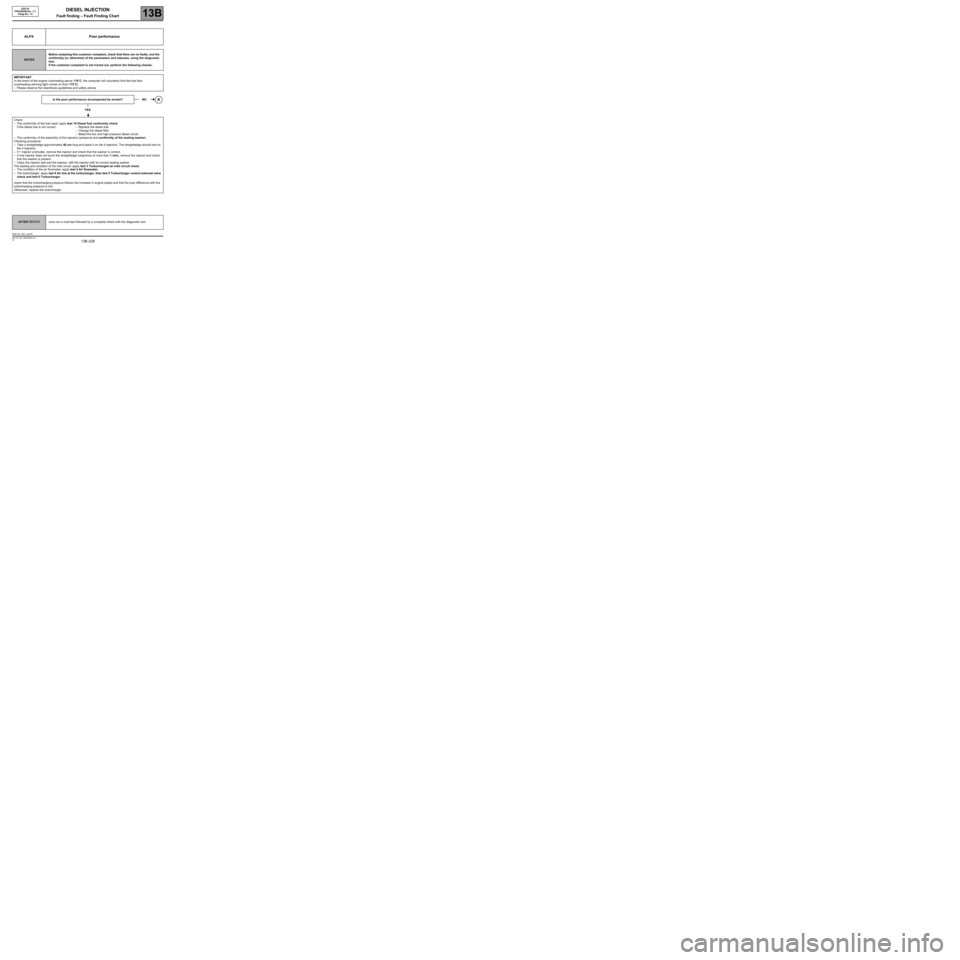

ALP4 Poor performance

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not ironed out, perform the following checks:

IMPORTANT

In the event of the engine overheating above 119˚C, the computer will voluntarily limit the fuel flow

(overheating warning light comes on from 115˚C).

–Please observe the cleanliness guidelines and safety advice.

Is the poor performance accompanied by smoke?

YES

Check:

–The conformity of the fuel used: apply test 10 Diesel fuel conformity check.

If the diesel fuel is not correct: – Replace the diesel fuel.

–Change the diesel filter.

–Bleed the low and high pressure diesel circuit.

–The conformity of the assembly of the injectors (presence and conformity of the sealing washer).

Checking procedure:

–Take a straightedge approximately 40 cm long and place it on the 4 injectors. The straightedge should rest on

the 4 injectors.

–If 1 injector protrudes, remove the injector and check that the washer is correct.

–If one injector does not touch the straightedge (clearance of more than 1 mm), remove the injector and check

that the washer is present.

–Clean the injector well and the injector, refit the injector with its correct sealing washer.

The sealing and condition of the inlet circuit: apply test 3 Turbocharged air inlet circuit check.

–The condition of the air flowmeter: apply test 4 Air flowmeter.

–The turbocharger: apply test 9 Air line at the turbocharger, then test 5 Turbocharger control solenoid valve

check and test 6 Turbocharger.

check that the turbocharging pressure follows the increase in engine speed and that the loop difference with the

turbocharging pressure is low.

Otherwise, replace the turbocharger.

NO

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V51_ALP4

Page 229 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -229V3 MR-372-J84-13B250$855.mif

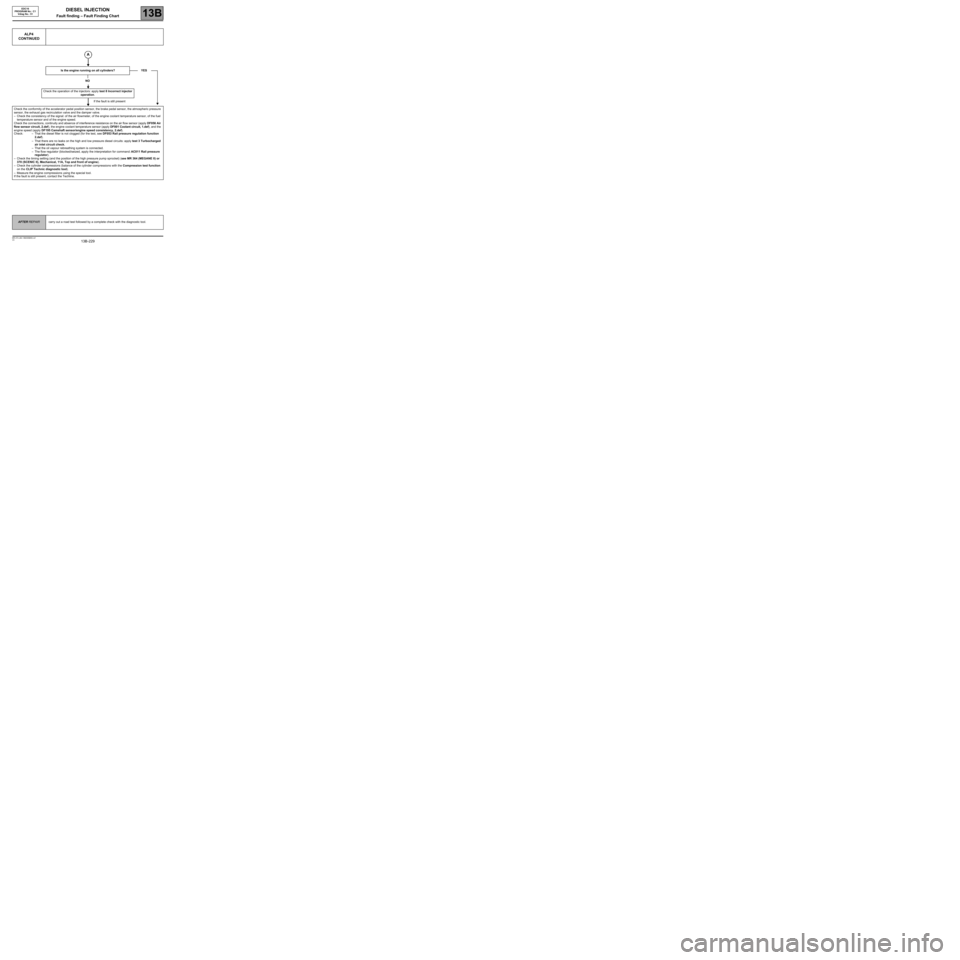

ALP4

CONTINUED

Is the engine running on all cylinders?

NO

Check the operation of the injectors: apply test 8 Incorrect injector

operation.

If the fault is still present

Check the conformity of the accelerator pedal position sensor, the brake pedal sensor, the atmospheric pressure

sensor, the exhaust gas recirculation valve and the damper valve.

–Check the consistency of the signal: of the air flowmeter, of the engine coolant temperature sensor, of the fuel

temperature sensor and of the engine speed.

Check the connections, continuity and absence of interference resistance on the air flow sensor (apply DF056 Air

flow sensor circuit, 2.def), the engine coolant temperature sensor (apply DF001 Coolant circuit, 1.def), and the

engine speed (apply DF195 Camshaft sensor/engine speed consistency, 2.def).

Check: – That the diesel filter is not clogged (for the test, see DF053 Rail pressure regulation function

2.def).

–That there are no leaks on the high and low pressure diesel circuits: apply test 3 Turbocharged

air inlet circuit check.

–That the oil vapour rebreathing system is connected.

–The flow regulator (blocked/seized, apply the interpretation for command: AC011 Rail pressure

regulator).

–Check the timing setting (and the position of the high pressure pump sprocket) (see MR 364 (MEGANE II) or

370 (SCENIC II), Mechanical, 11A, Top and front of engine).

–Check the cylinder compressions (balance of the cylinder compressions with the Compression test function

on the CLIP Technic diagnostic tool).

–Measure the engine compressions using the special tool.

If the fault is still present, contact the Techline.YES

EDC16

PROGRAM No.: C1

Vdiag No.: 51

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.