fuel filter RENAULT SCENIC 2009 J84 / 2.G Engine And Peripherals EDC16 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 273

Page 6 of 273

DIESEL INJECTION

Fault finding – Introduction13B

13B - 6V3 MR-372-J84-13B250$045.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

5. FAULT FINDING LOG

You will always be asked for this log:

●when requesting technical assistance from Techline,

●for approval requests when replacing parts for which approval is mandatory,

●to be attached to monitored parts for which reimbursement is requested. The log is needed for warranty

reimbursement, and enables better analysis of the parts removed.

6. SAFETY ADVICE

Safety rules must be observed during any work on a component to prevent any damage or injury:

–make sure that the battery is properly charged to avoid damaging the computers with a low load,

–use the appropriate tools.

7. CLEANLINESS ADVICE TO FOLLOW WHEN CARRYING OUT OPERATIONS ON THE HIGH PRESSURE

DIRECT INJECTION SYSTEM

Risks relating to contamination

The system is highly sensitive to contamination. The risks associated with contamination are:

–damage to or destruction of the high pressure injection system and the engine,

–a component seizing or leaking.

All After-Sales operations must be performed under very clean conditions. This means that no impurities (particles a

few microns in size) should be allowed to penetrate the system during dismantling or get into the circuits via the fuel

unions.

The cleanliness guidelines must be applied from the filter through to the injectors.IMPORTANT!IMPORTANT

Any fault on a complex system requires thorough fault finding with the appropriate tools. The

FAULT FINDING LOG, which should be completed during the procedure, enables you to keep

track of the procedure which is carried out. It is an essential document when consulting the

manufacturer.

IT IS THEREFORE COMPULSORY TO COMPLETE A FAULT FINDING LOG

EVERY TIME A FAULT FINDING PROCEDURE IS PERFORMED

Page 9 of 273

DIESEL INJECTION

Fault finding – System operation13B

13B - 9V3 MR-372-J84-13B250$135.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – System operation

System outline

The high pressure injection system is designed to deliver a precise quantity of diesel fuel to the engine at a set

moment.

It is fitted with a 112-track BOSCH EDC16 C3 type computer.

The system is comprised of:

–a priming bulb on the low pressure circuit,

–a diesel filter,

–a high pressure pump with a built-in low pressure pump (transfer pump),

–a high pressure regulator mounted on the pump,

–an injector rail,

–a diesel fuel pressure sensor built into the rail,

–four solenoid injectors,

–a coolant temperature sensor,

–a cylinder reference sensor,

–an engine speed sensor,

–a turbocharger pressure sensor,

–an accelerator pedal potentiometer,

–an EGR solenoid valve,

–an atmospheric pressure sensor integrated into the injection computer,

–an air flow sensor with an air temperature sensor,

–a turbocharging pressure limitation solenoid valve,

–a motorised damper valve.

The common rail direct high pressure injection system works sequentially (based on the petrol engine multipoint

injection).

This injection system reduces operating noise, reduces the volume of pollutant gases and particles and produces

high engine torque at low engine speeds thanks to a pre-injection procedure.

The high pressure pump generates the high pressure and transmits it to the injector rail. The actuator located on the

pump controls the quantity of diesel fuel supplied, according to the requirement determined by the computer. The rail

supplies each injector through a steel pipe.

MR-372-J84-13B250$135.mif

Page 11 of 273

DIESEL INJECTION

Fault finding – System operation13B

13B - 11V3 MR-372-J84-13B250$135.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

b) Multiplex connection between the different vehicle computers.

The electronic system fitted in this vehicle is multiplexed.

This enables dialogue between the various vehicle computers. As a result:

–the activation of the fault warning lights on the instrument panel is performed by the multiplex network, with the

vehicle speed sensor on the gearbox deactivated,

–vehicle faults are displayed by the multiplex network,

–the vehicle speed sensor on the gearbox is not needed.

The vehicle speed signal on the instrument panel is transmitted by the ABS computer via a wire connection, then

sent out on the multiplex network by the instrument panel. The vehicle speed signal is used mainly by the injection

computer and the airbag computer.

Some vehicles have adopted a sensor for detecting water in the diesel fuel, located in the filter. If there is water in the

diesel fuel, the orange "Injection and pre-post heating" warning light will come on.

The system can inject diesel fuel into the engine at a pressure of up to 1600 bar. Before each operation, check that

the injector rail is depressurised and that the fuel temperature is not too high.

You must respect the cleanliness guidelines and safety advice specified in this document for any work on the high

pressure injection system.

Removal of the internal parts of the pump and injectors is prohibited. Only the fuel flow actuator, the diesel fuel

temperature sensor and the venturi can be replaced.

For safety reasons, it is strictly prohibited to undo a high pressure pipe union when the engine is running.

It is not possible to remove the pressure sensor from the fuel rail because this may cause circuit contamination

faults. If the pressure sensor fails, the pressure sensor, the rail and the five high pressure pipes must be replaced.

It is forbidden to remove any injection pump pulley bearing the number 070 575. If the pump needs to be replaced,

replace the pulley.

Supplying + 12 V directly to any component in the system is prohibited.

Ultrasonic decoking and cleaning are prohibited.

Never start the engine unless the battery is connected correctly.

Disconnect the injection computer when carrying out any welding work on the vehicle.WARNING

The engine must not operate with:

–Diesel fuel containing more than 10 % diester,

–petrol, even in tiny quantities.

Page 83 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-83V3 MR-372-J84-13B250$360.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF053

CONTINUED 5

In the event of rail overpressure:

Check the operation of the injectors: refer to test 8 Poor injector operation.

Check that the rail pressure sensor is operating correctly using command AC011 Rail pressure regulator. Display

parameter PR038 Rail pressure, and refer to the conformity check to check the operating values.

If these checks do not reveal any faults, and if the fault is still present, replace the injection pump.

in the event of rail underpressure:

Check that the rail pressure sensor is operating correctly using command AC011 Rail pressure regulator. Display

parameter PR038 Rail pressure, and refer to the conformity check to check the operating values.

Check the low pressure diesel circuit priming.

Check the conformity of the diesel filter connections.

Check the condition of the filter (clogging and water saturation).

Check that there are no air bubbles between the filter and the high pressure pump.

Check the low and high pressure diesel fuel circuit sealing (visual inspections, odour, etc.): pump housing,

pressure relief valve, pipes, rail and injector unions, injector wells, etc.

Check the operation of the injectors: refer to test 8 Poor injector operation.

Carry out the necessary operations.

If the fault is still present, replace the injection pump.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

Page 94 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-94V3 MR-372-J84-13B250$405.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF057

PRESENT

OR

STOREDWATER IN DIESEL FUEL DETECTOR CIRCUIT

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the engine is started or following a road test.

Check the conformity of the fuel used by applying test 10 Diesel fuel conformity check.

Check the sealing of the tank and low pressure circuit by applying test 2 Low pressure circuit check.

A) Make sure the water in diesel fuel detection sensor is properly connected.

–If not, clear the fault,

–Carry out a road test (speed > 12 mph (20 km/h) and engine speed > 1200 rpm) for more than 30 seconds.

–If the fault does not recur, end the fault finding procedure.

–If the fault does recur, go to step C.

B) If the water detection sensor is absent:

–Insulate the electrical connector not connected to the vehicle (risk of dampness, oxidation, and erratic

appearance of faults).

Check that the configuration reading LC065 Water detected in the diesel is NONE.

If LC065 is WITH, run command RZ005 Programming to reinitialise the vehicle configurations.

–Clear the faults.

–Carry out a road test (speed > 12 mph (20 km/h) and engine speed > 1200 rpm) for more than 30 seconds.

–If the fault does not recur, end the fault finding procedure.

C) If the sensor is properly connected:

–Bleed the diesel filter unit (see MR 364, Mechanics, 13A, Fuel supply).

–Clear the fault.

–Carry out a road test (speed > 12 mph (20 km/h) and engine speed > 1200 rpm) for more than 30 seconds.

–If the fault does not recur, end the fault finding procedure.

D) If the fault recurs:

–Check for continuity and the absence of interference resistance on the connection between:

Injection computer 32-track grey connector track A2 Track 3 of the water detection sensor

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V51_DF057

Page 95 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-95V3 MR-372-J84-13B250$405.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF057

CONTINUED

Check the power supply to the water detection sensor:

+ 12 V after relay track 1 water detection sensor

earth track 2 water detection sensor

Carry out the necessary repairs.

If none of these checks reveal any faults:

–Replace the water detection sensor (see MR 364, Mechanics, 13A, Fuel supply).

–Clear the fault.

–Carry out a road test (speed > 12 mph (20 km/h) and engine speed > 1200 rpm) for more than 30 seconds,

to confirm the repair.

Note:

if the level of water in the fuel filter unit is lower than the sensor electrodes, certain driving conditions (on a bend,

hill) may causethe injection warning light to light up erratically.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

Page 130 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B -130V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF778

PRESENT

OR

STOREDTURBINE UPSTREAM TEMPERATURE CONTROL

1.DEF: Temperature measured too high

2.DEF: Parameter at max limit

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present:

–the engine is started with a speed greater than 1750 rpm and a fuel flow greater than

30 mg/st,

–a road test.

Special notes:

If the fault is present:

–particle filter regeneration is inhibited,

–the vehicle performance is reduced,

–the level 1 warning light is illuminated.

IMPORTANT

This fault can result in a rapid and significant fouling of the particle filter.

Apply TEST 3 Turbocharged air inlet circuit check.

Check the turbine upstream temperature sensor connections.

check the engine management computer connections.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V51_DF778

Page 227 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -227V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

ALP3 Injection noise

NOTESBefore dealing with this customer complaint, check that there are no faults, and

the conformity (or otherwise) of the parameters and statuses using the

diagnostic tool.

If the customer complaint is not ironed out, perform the following checks:

If the injection noise occurs after starting from cold:

Check the low pressure diesel circuit priming.

Check the fuel heater supply.

Check the operation of the preheating system.

Check that fuel and engine temperatures are consistent.

If the injection noise occurs at idle speed:

Check the condition of the injector connector and pressure regulator terminals.

Check the conformity of the air flow signal: use fault finding procedures: PR132 Air flow or run test 3

Turbocharged air inlet circuit check.

If the complaint is still present, perform the injector fault finding procedure: run test 8 Poor injector operation.

does the injection noise occur at all engine speeds?

Run fault finding on the injectors: run test 8 Incorrect injector operation.

Check the condition of the injector connector and pressure regulator terminals.

Check the conformity of the fuel used, apply test 10 Diesel fuel conformity check.

If the diesel fuel is not correct: – Replace the diesel fuel.

–Change the diesel filter.

–Bleed the low and high pressure diesel circuit.

Check the conformity of the air flow signal: use the interpretation of the fault finding procedure PR132 Air flow.

If the customer complaint is still present:

Run command AC011 Rail pressure regulator.

Then apply the conformity check to confirm:

–the conformity of the fuel pressure between PR008 Rail pressure setpoint and PR038 Rail Pressure,

–the conformity of the pump fuel flow between PR157 Fuel flow setpoint and PR017 Fuel flow.

If the fault is still present, contact the Techline.

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V51_ALP3

Page 228 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -228V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

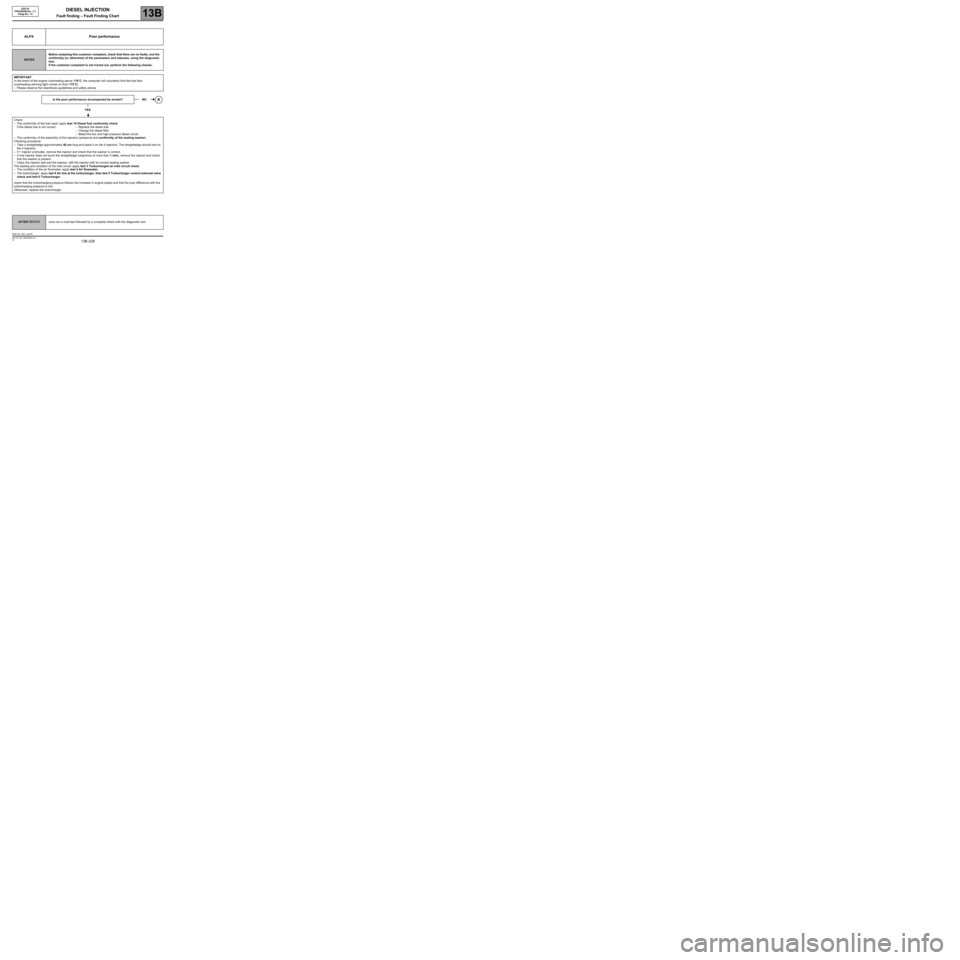

ALP4 Poor performance

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not ironed out, perform the following checks:

IMPORTANT

In the event of the engine overheating above 119˚C, the computer will voluntarily limit the fuel flow

(overheating warning light comes on from 115˚C).

–Please observe the cleanliness guidelines and safety advice.

Is the poor performance accompanied by smoke?

YES

Check:

–The conformity of the fuel used: apply test 10 Diesel fuel conformity check.

If the diesel fuel is not correct: – Replace the diesel fuel.

–Change the diesel filter.

–Bleed the low and high pressure diesel circuit.

–The conformity of the assembly of the injectors (presence and conformity of the sealing washer).

Checking procedure:

–Take a straightedge approximately 40 cm long and place it on the 4 injectors. The straightedge should rest on

the 4 injectors.

–If 1 injector protrudes, remove the injector and check that the washer is correct.

–If one injector does not touch the straightedge (clearance of more than 1 mm), remove the injector and check

that the washer is present.

–Clean the injector well and the injector, refit the injector with its correct sealing washer.

The sealing and condition of the inlet circuit: apply test 3 Turbocharged air inlet circuit check.

–The condition of the air flowmeter: apply test 4 Air flowmeter.

–The turbocharger: apply test 9 Air line at the turbocharger, then test 5 Turbocharger control solenoid valve

check and test 6 Turbocharger.

check that the turbocharging pressure follows the increase in engine speed and that the loop difference with the

turbocharging pressure is low.

Otherwise, replace the turbocharger.

NO

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V51_ALP4

Page 229 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -229V3 MR-372-J84-13B250$855.mif

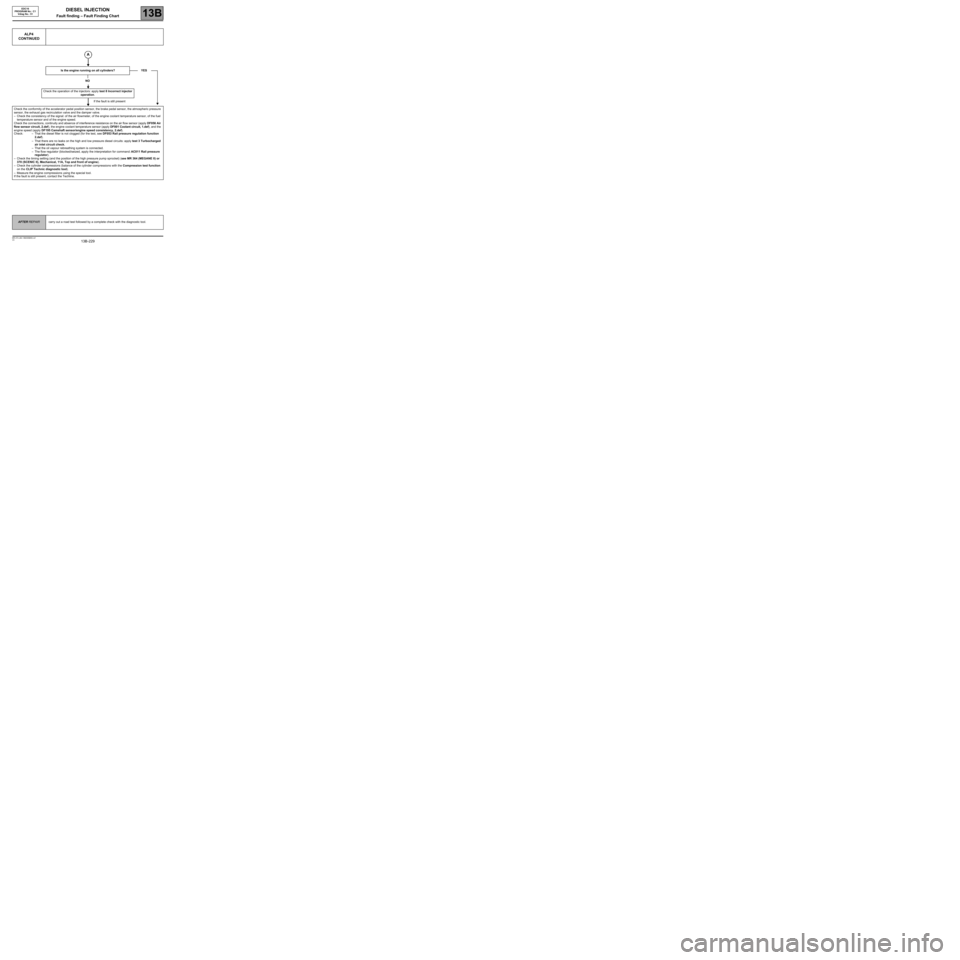

ALP4

CONTINUED

Is the engine running on all cylinders?

NO

Check the operation of the injectors: apply test 8 Incorrect injector

operation.

If the fault is still present

Check the conformity of the accelerator pedal position sensor, the brake pedal sensor, the atmospheric pressure

sensor, the exhaust gas recirculation valve and the damper valve.

–Check the consistency of the signal: of the air flowmeter, of the engine coolant temperature sensor, of the fuel

temperature sensor and of the engine speed.

Check the connections, continuity and absence of interference resistance on the air flow sensor (apply DF056 Air

flow sensor circuit, 2.def), the engine coolant temperature sensor (apply DF001 Coolant circuit, 1.def), and the

engine speed (apply DF195 Camshaft sensor/engine speed consistency, 2.def).

Check: – That the diesel filter is not clogged (for the test, see DF053 Rail pressure regulation function

2.def).

–That there are no leaks on the high and low pressure diesel circuits: apply test 3 Turbocharged

air inlet circuit check.

–That the oil vapour rebreathing system is connected.

–The flow regulator (blocked/seized, apply the interpretation for command: AC011 Rail pressure

regulator).

–Check the timing setting (and the position of the high pressure pump sprocket) (see MR 364 (MEGANE II) or

370 (SCENIC II), Mechanical, 11A, Top and front of engine).

–Check the cylinder compressions (balance of the cylinder compressions with the Compression test function

on the CLIP Technic diagnostic tool).

–Measure the engine compressions using the special tool.

If the fault is still present, contact the Techline.YES

EDC16

PROGRAM No.: C1

Vdiag No.: 51

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.