stop start RENAULT SCENIC 2009 J84 / 2.G Engine And Peripherals EDC16 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 273

Page 12 of 273

DIESEL INJECTION

Fault finding – System operation13B

13B - 12V3 MR-372-J84-13B250$135.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

c) Hosted functions:

Air conditioning management assistance:

In the case of vehicles with climate control, the EDC16 system has the option of deactivating the air conditioning via

the UCH, under certain conditions of use:

–when requested by the driver,

–when starting the engine,

–if the engine overheats (in order to reduce the power the engine has to supply),

–when the engine speed is kept at a very high level (to protect the compressor),

–during transitory phases (such as demands for high acceleration when overtaking, anti-stall and start-up) These

conditions are only taken into account when they do not occur repeatedly, to prevent instability in the system

(erratic deactivations),

–when certain faults appear.

Cold loop air conditioning management:

The air conditioning is the cold loop type and its management shared between several computers.

The injection computer is responsible for:

–authorising cold requests according to the refrigerant pressure, the engine coolant temperature and the engine

speed,

–calculating the power absorbed by the compressor (from the refrigerant pressure),

–requesting operation of the GMV, from the UPC, according to the vehicle speed, the refrigerant pressure and the

engine coolant temperature.

The driver requests the air conditioning to be switched on by means of the ventilation selector coupled to a switch.

The cold air request is authorised or denied depending on the pressure measured. If this pressure is outside the

operating limits, the cold loop program is not activated.

Management of the damper valve:

The damper valve currently has three functions:

–the valve closes in order to block the passage of air towards the cylinders to shut off the engine. The aim of this is

to stop the engine as quickly as possible and to reduce instabilities as the engine is switched off.

–"valving" function depending on the engine operation: the damper valve closes by a few % to create a ''venturi''

effect at the EGR valve passage section.

The aim of this is to accelerate the air flow of EGR gases and to reduce the emission of pollutants.

Page 35 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-35V3 MR-372-J84-13B250$315.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF005

PRESENT

OR

STOREDENGINE SPEED SENSOR CIRCUIT

1.DEF : No signal

2.DEF : Inconsistent signal

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present:

–when an attempt is made to start the engine,

–when the engine is running.

Special notes:

Use bornier Ele. 1681 or Ele. 1590 for all operations on the computer connectors.

The engine speed sensor is consistent with the camshaft sensor.

If the fault is present:

–it is impossible to start the engine or the engine stops,

–the level 2 warning light is lit.

Check the engine speed sensor connections.

Check the injection computer connections.

If one of the connectors is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check that the sensor is correctly mounted and that the flywheel target is not damaged.

Check that the gap between the engine speed sensor and the flywheel is 0.5 to 1.8 mm.

Measure the resistance of the engine speed sensor between terminals A and B of its black connector.

If the winding resistance is not between 510 Ω and 850 Ω at an engine temperature of 20˚C, replace the engine

speed sensor.

Check for continuity and the absence of interference resistance of the following connections:

Injection computer brown 48-track connector B

track B1Track A engine speed sensor

Injection computer brown 48-track connector B

track C1Track B engine speed sensor

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Repair if necessary.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V51_DF005

Page 36 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-36V3 MR-372-J84-13B250$315.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF007

PRESENT

OR

STOREDRAIL PRESSURE SENSOR CIRCUIT

CC.0 : Short circuit to earth

CO.1 : Short circuit or open circuit to + 12 V

1.DEF : Offset at minimum threshold

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after repeated engine starts or with the engine running.

Special notes:

Use bornier Ele. 1681 or Ele. 1590 for all operations on the computer connectors.

If the fault is present:

–the engine will stop immediately,

–it is impossible to restart,

–the level 2 warning light is lit.

Priorities when dealing with a number of faults:

Deal with fault DF013 Sensor supply voltage no. 3 first, if it is present or stored.

CC.0

NOTESNone

Check the rail pressure sensor connectors.

Check the injection computer connections.

Repair if necessary.

Check the continuity and insulation to earth of the following connections:

Injection computer brown 48-track connector B

track G3Track 2 rail pressure sensor

Brown 48-track connector B injection computer

track A4Track 3 rail pressure sensor

Repair if necessary.

If the fault is still present, replace the rail pressure sensor and tighten to 35 ± 5 Nm.

Follow the recommended safety advice (see cleanliness advice).

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V51_DF007

Page 51 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-51V3 MR-372-J84-13B250$315.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF013

PRESENT

OR

STOREDSENSOR SUPPLY VOLTAGE No. 3

1.DEF : Sensor reference voltage too low

2.DEF : Sensor reference voltage too high

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present following a road test or after attempting to start the engine

several times.

Special notes:

If the fault is present:

–the EGR function is inhibited,

–the engine stops,

–the level 2 warning light is lit,

–the OBD warning light will come on after three consecutive driving cycles (starting

+ 5 seconds + switching off the ignition and waiting 1 minute).

Use bornier Ele. 1681 or Ele. 1590 for any operation on the injection computer

connectors.

WARNING

This fault may appear if the wiring harness has been damaged.

Follow the procedure described in the Wiring Check in the Introduction.

This check enables the condition and the conformity of the engine wiring harness to be checked.

The sensors connected to supply no. 3 are:

–Rail pressure sensor.

–Air flow sensor..

To locate a faulty sensor and/or connection, disconnect one of these sensors then check whether the fault

becomes stored.

If the fault is still present, repeat the operation with the other sensors.

(Wait a few seconds after each disconnection so that the computer can carry out the check).

If the fault is stored after a disconnection, replace the faulty sensor or repair its connection.

Clear the faults created by the multiple disconnections.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V51_DF013

Page 78 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-78V3 MR-372-J84-13B250$360.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

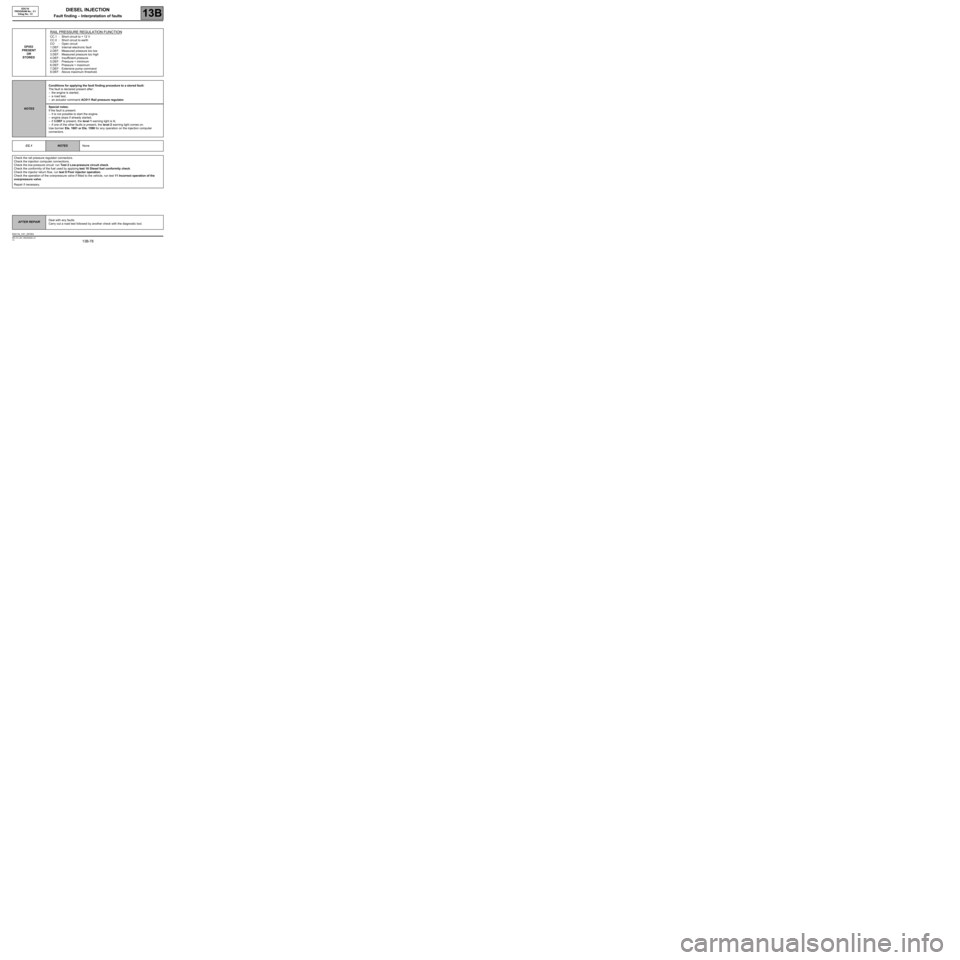

DF053

PRESENT

OR

STORED

RAIL PRESSURE REGULATION FUNCTION

CC.1 : Short circuit to + 12 V

CC.0 : Short circuit to earth

CO : Open circuit

1.DEF : Internal electronic fault

2.DEF : Measured pressure too low

3.DEF : Measured pressure too high

4.DEF : Insufficient pressure

5.DEF : Pressure < minimum

6.DEF : Pressure > maximum

7.DEF : Extensive pump command

8.DEF : Above maximum threshold.

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

–the engine is started,

–a road test,

–an actuator command AC011 Rail pressure regulator.

Special notes:

If the fault is present:

–It is not possible to start the engine.

–engine stops if already started,

–if 3.DEF is present, the level 1 warning light is lit,

–if one of the other faults is present, the level 2 warning light comes on.

Use bornier Ele. 1681 or Ele. 1590 for any operation on the injection computer

connectors.

CC.1

NOTESNone

Check the rail pressure regulator connectors.

Check the injection computer connections.

Check the low-pressure circuit: run Test 2 Low-pressure circuit check.

Check the conformity of the fuel used by applying test 10 Diesel fuel conformity check.

Check the injector return flow, run test 8 Poor injector operation.

Check the operation of the overpressure valve if fitted to the vehicle, run test 11 Incorrect operation of the

overpressure valve.

Repair if necessary.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V51_DF053

Page 88 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-88V3 MR-372-J84-13B250$360.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

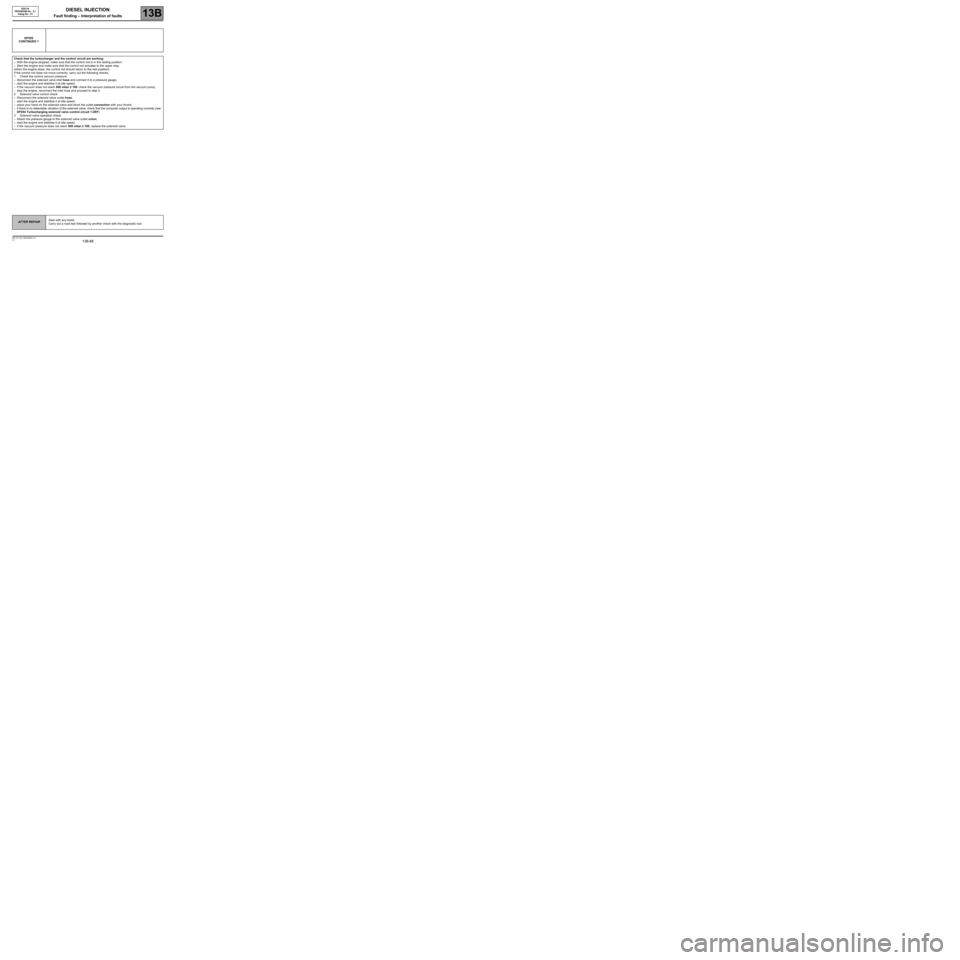

DF055

CONTINUED 1

Check that the turbocharger and the control circuit are working:

–With the engine stopped, make sure that the control rod is in the resting position.

–Start the engine and make sure that the control rod actuates to the upper stop.

(when the engine stops, the control rod should return to the rest position).

If the control rod does not move correctly, carry out the following checks:

1Check the control vacuum pressure:

–disconnect the solenoid valve inlet hose and connect it to a pressure gauge,

–start the engine and stabilise it at idle speed,

–If the vacuum does not reach 800 mbar ± 100: check the vacuum pressure circuit from the vacuum pump,

–stop the engine, reconnect the inlet hose and proceed to step 2.

2Solenoid valve control check:

–Disconnect the solenoid valve outlet hose,

–start the engine and stabilise it at idle speed,

–place your hand on the solenoid valve and block the outlet connection with your thumb,

–if there is no detectable vibration of the solenoid valve, check that the computer output is operating correctly (see

DF054 Turbocharging solenoid valve control circuit 1.DEF).

3Solenoid valve operation check:

–Attach the pressure gauge to the solenoid valve outlet union,

–start the engine and stabilise it at idle speed,

–if the vacuum pressure does not reach 800 mbar ± 100, replace the solenoid valve.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

Page 113 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-113V3 MR-372-J84-13B250$405.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

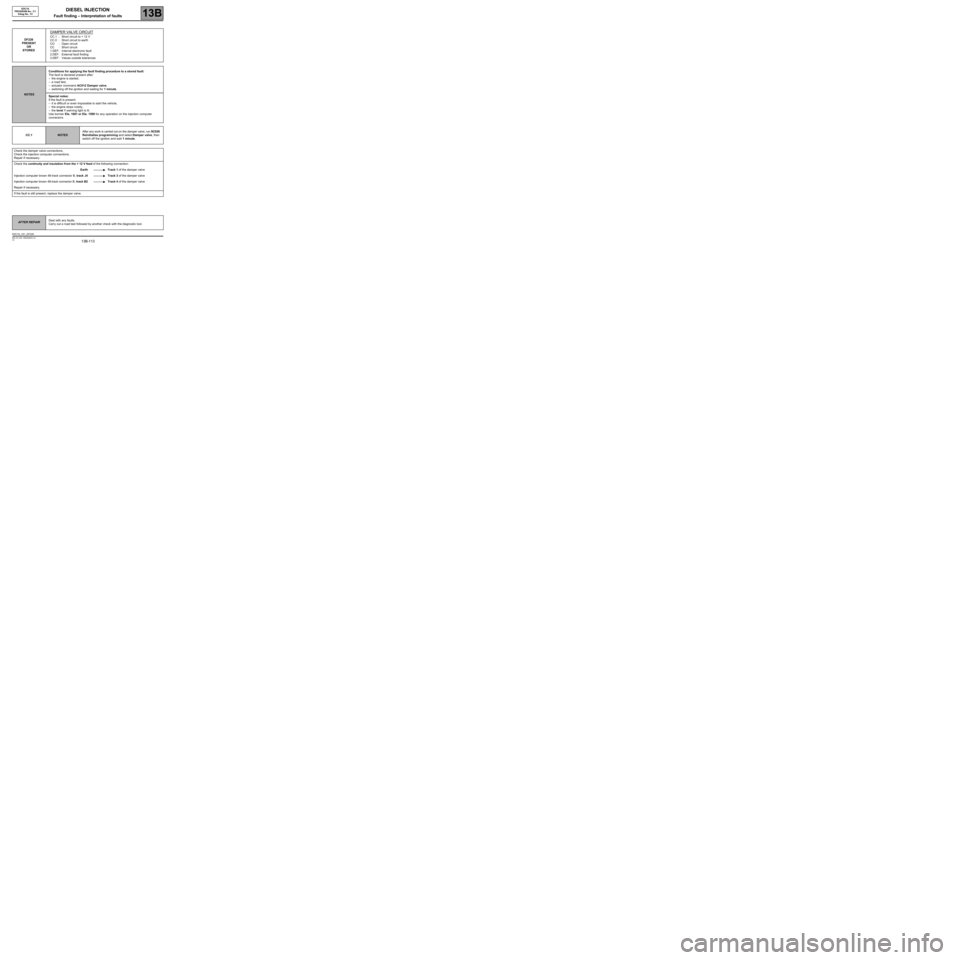

DF226

PRESENT

OR

STORED

DAMPER VALVE CIRCUIT

CC.1 : Short circuit to + 12 V

CC.0 : Short circuit to earth

CO : Open circuit

CC : Short circuit

1.DEF : Internal electronic fault

2.DEF : External fault finding

3.DEF : Values outside tolerances

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

–the engine is started,

–a road test,

–actuator command AC012 Damper valve;

–switching off the ignition and waiting for 1 minute.

Special notes:

If the fault is present:

–it is difficult or even impossible to start the vehicle,

–the engine stops noisily,

–the level 1 warning light is lit.

Use bornier Ele. 1681 or Ele. 1590 for any operation on the injection computer

connectors.

CC.1

NOTESAfter any work is carried out on the damper valve, run SC036

Reinitialise programming and select Damper valve, then

switch off the ignition and wait 1 minute.

Check the damper valve connections.

Check the injection computer connections.

Repair if necessary.

Check the continuity and insulation from the + 12 V feed of the following connection:

Earth Track 1 of the damper valve

Injection computer brown 48-track connector B, track J4 Track 3 of the damper valve

Injection computer brown 48-track connector B, track B2 Track 4 of the damper valve

Repair if necessary.

If the fault is still present, replace the damper valve.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V51_DF226

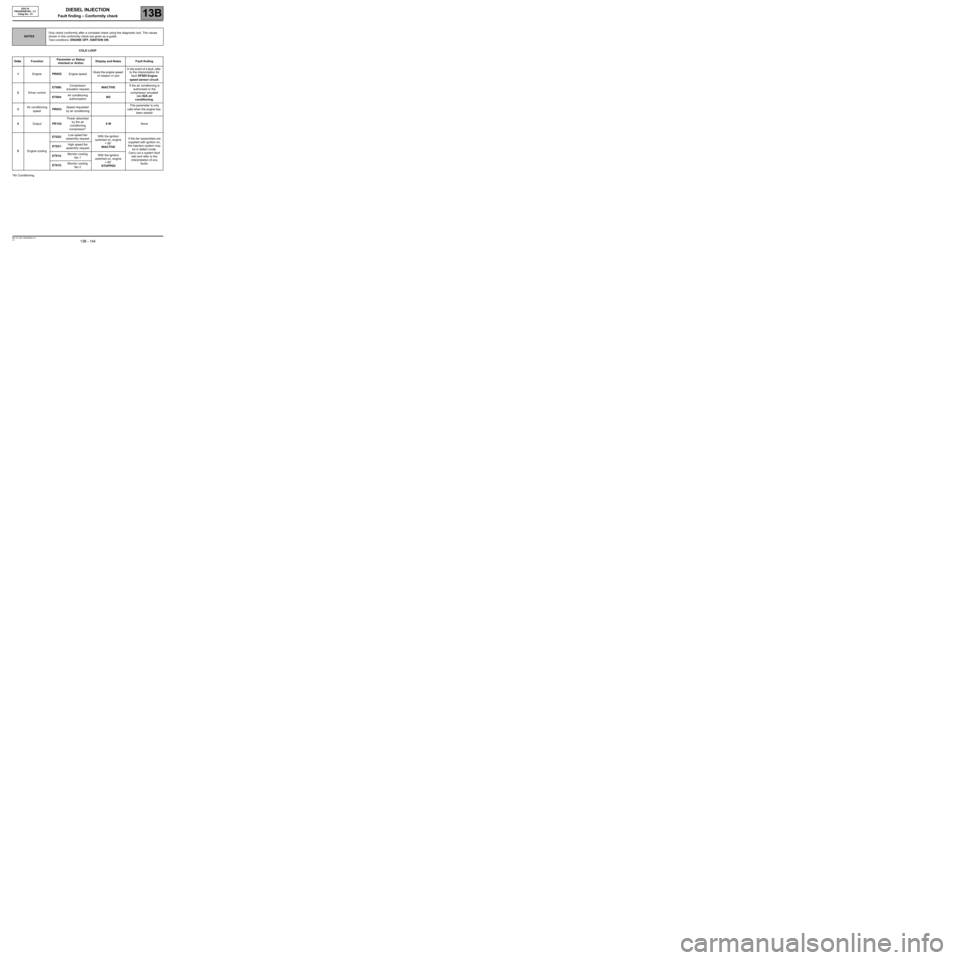

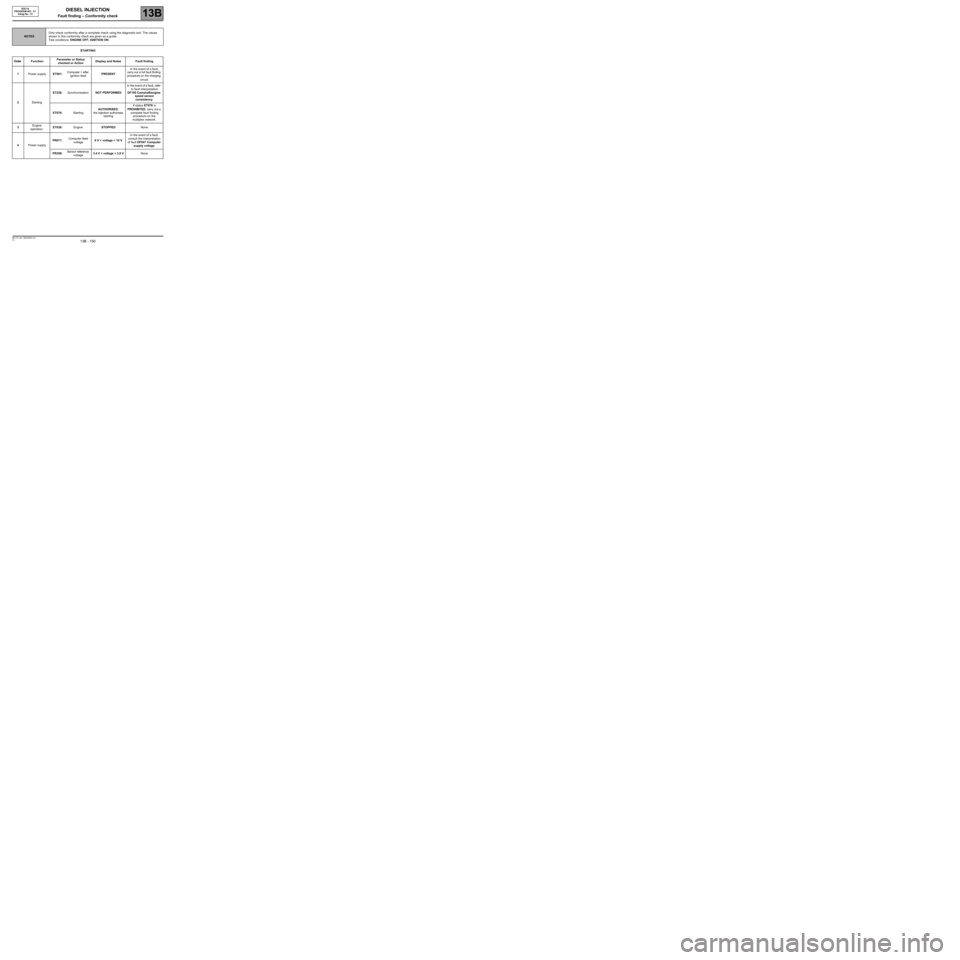

Page 144 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 144V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

COLD LOOP

*Air Conditioning

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test conditions: ENGINE OFF, IGNITION ON.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1EnginePR055:Engine speedGives the engine speed

of rotation in rpmIn the event of a fault, refer

to the interpretation for

fault DF005 Engine

speed sensor circuit.

2Driver controlET088:Compressor

actuation requestINACTIVEIf the air conditioning is

authorised or the

compressor actuated

see 62A air

conditioning. ET004:Air conditioning

authorisationNO

3Air conditioning

speedPR053:Speed requested

by air conditioningThis parameter is only

valid when the engine has

been started

4OutputPR125:Power absorbed

by the air

conditioning

compressor*0 WNone

5Engine coolingET022:Low speed fan

assembly requestWith the ignition

switched on, engine

< 80˚

INACTIVEIf the fan assemblies are

supplied with ignition on,

the injection system may

be in defect mode.

Carry out a system fault

test and refer to the

interpretation of any

faults. ET021:High speed fan

assembly request

ET014:Monitor cooling

fan 1With the ignition

switched on, engine

< 80˚

STOPPED ET015:Monitor cooling

fan 2

Page 150 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 150V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

STARTING

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test conditions: ENGINE OFF, IGNITION ON.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Power supplyET001:Computer + after

ignition feedPRESENTIn the event of a fault,

carry out a full fault finding

procedure on the charging

circuit.

2StartingET238:SynchronisationNOT PERFORMEDIn the event of a fault, refer

to fault interpretation

DF195 Camshaft/engine

speed sensor

consistency.

ET076:StartingAUTHORISED:

the injection authorises

startingIf status ET076 is

PROHIBITED, carry out a

complete fault finding

procedure on the

multiplex network.

3Engine

operation.ET038:EngineSTOPPEDNone

4Power supplyPR071:Computer feed

voltage9 V < voltage < 16 VIn the event of a fault,

consult the interpretation

of fault DF047 Computer

supply voltage.

PR358:Sensor reference

voltage3.4 V < voltage < 3.8 VNone

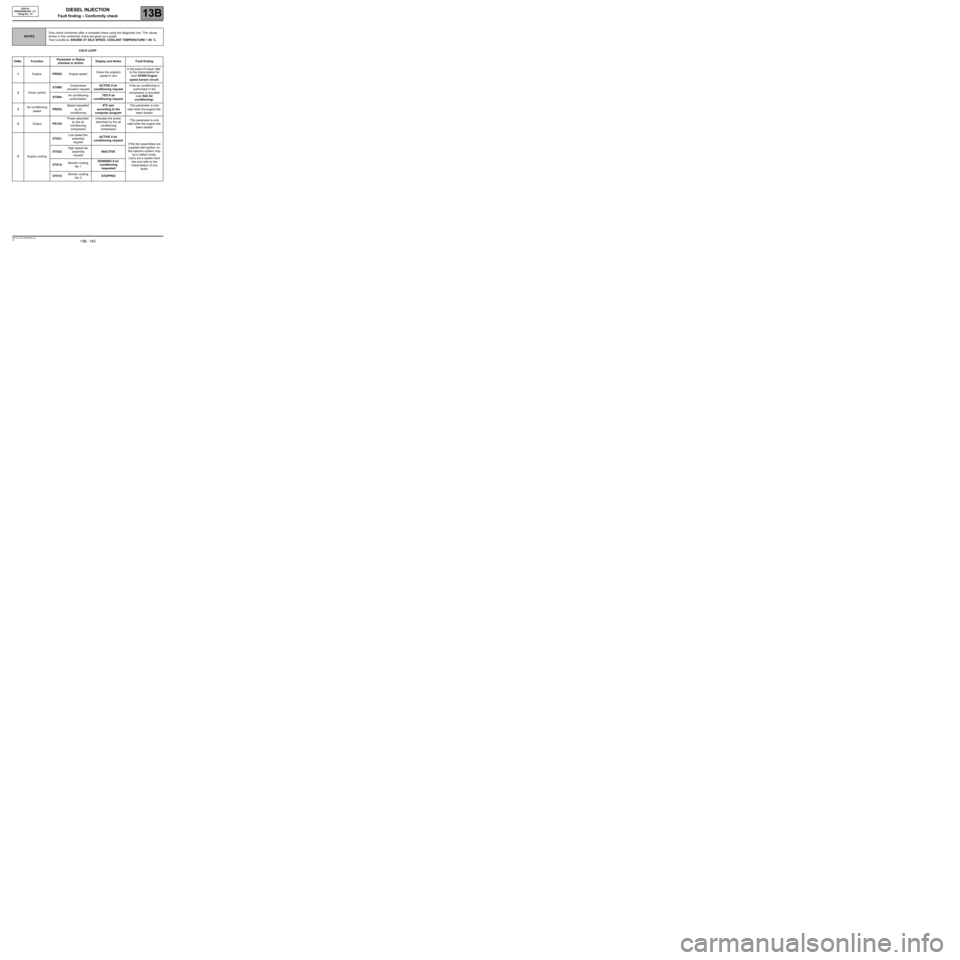

Page 163 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 163V3 MR-372-J84-13B250$540.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

COLD LOOP

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test Conditions: ENGINE AT IDLE SPEED, COOLANT TEMPERATURE > 80 ˚C.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1EnginePR055:Engine speedGives the engine's

speed in rpmIn the event of a fault, refer

to the interpretation for

fault DF005 Engine

speed sensor circuit.

2Driver controlET088:Compressor

actuation requestACTIVE if air

conditioning requestIf the air conditioning is

authorised or the

compressor is actuated

(see 62A Air

conditioning). ET004:Air conditioning

authorisationYES if air

conditioning request

3Air conditioning

speedPR053:Speed requested

by air

conditioning875 rpm

according to the

computer programThis parameter is only

valid when the engine has

been started

4OutputPR125:Power absorbed

by the air

conditioning

compressorIndicates the power

absorbed by the air

conditioning

compressorThis parameter is only

valid when the engine has

been started

5Engine coolingET021:Low speed fan

assembly

requestACTIVE if air

conditioning request

If the fan assemblies are

supplied with ignition on,

the injection system may

be in defect mode.

Carry out a system fault

test and refer to the

interpretation of any

faults. ET022:High speed fan

assembly

requestINACTIVE

ET014:Monitor cooling

fan 1RUNNING if air

conditioning

requested

ET015:Monitor cooling

fan 2STOPPED