RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Workshop Manual

Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 201 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 201

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 201V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

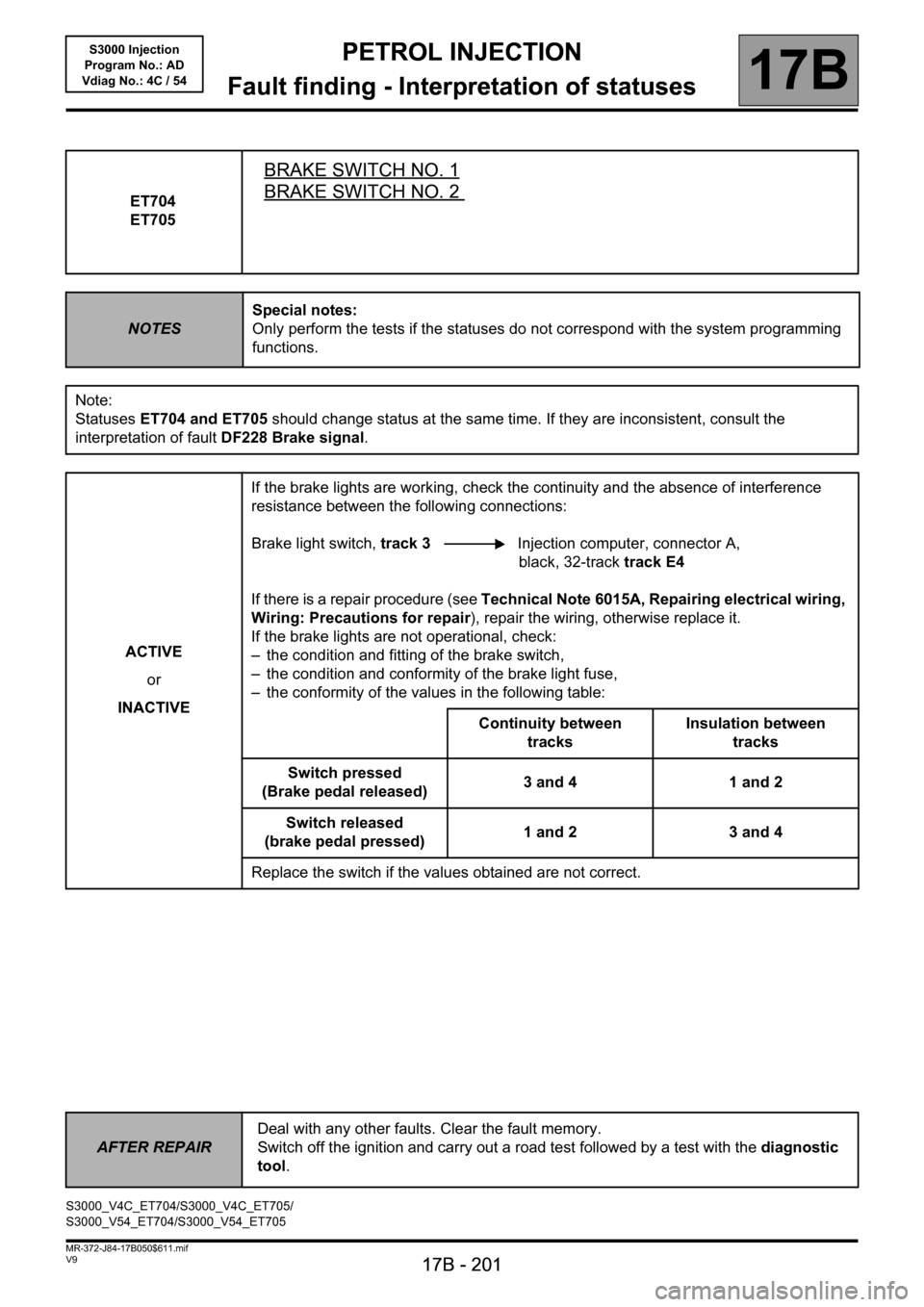

ET704

ET705

BRAKE SWITCH NO. 1

BRAKE SWITCH NO. 2

NOTESSpecial notes:

Only perform the tests if the statuses do not correspond with the system programming

functions.

Note:

Statuses ET704 and ET705 should change status at the same time. If they are inconsistent, consult the

interpretation of fault DF228 Brake signal.

ACTIVE

or

INACTIVEIf the brake lights are working, check the continuity and the absence of interference

resistance between the following connections:

Brake light switch, track 3 Injection computer, connector A,

black, 32-track track E4

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the brake lights are not operational, check:

– the condition and fitting of the brake switch,

– the condition and conformity of the brake light fuse,

– the conformity of the values in the following table:

Continuity between

tracksInsulation between

tracks

Switch pressed

(Brake pedal released)3 and 4 1 and 2

Switch released

(brake pedal pressed)1 and 2 3 and 4

Replace the switch if the values obtained are not correct.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

S3000_V4C_ET704/S3000_V4C_ET705/

S3000_V54_ET704/S3000_V54_ET705

Page 202 of 230

PETROL INJECTION

17B

17B - 202

17B

17B - 202V9 MR-372-J84-17B050$658.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

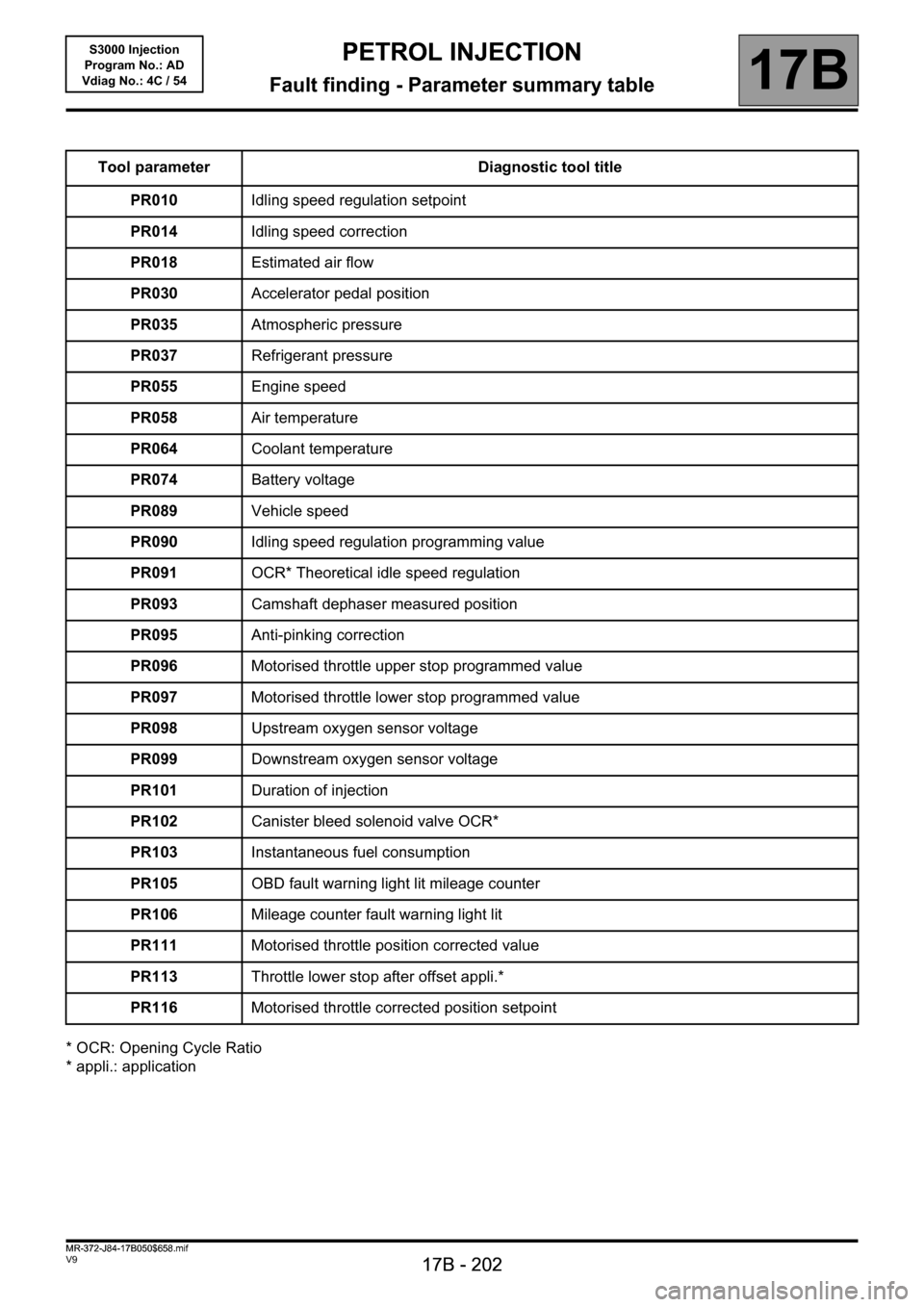

Fault finding - Parameter summary table

* OCR: Opening Cycle Ratio

* appli.: applicationTool parameter Diagnostic tool title

PR010Idling speed regulation setpoint

PR014Idling speed correction

PR018Estimated air flow

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR055Engine speed

PR058Air temperature

PR064Coolant temperature

PR074Battery voltage

PR089Vehicle speed

PR090Idling speed regulation programming value

PR091OCR* Theoretical idle speed regulation

PR093Camshaft dephaser measured position

PR095Anti-pinking correction

PR096Motorised throttle upper stop programmed value

PR097Motorised throttle lower stop programmed value

PR098Upstream oxygen sensor voltage

PR099Downstream oxygen sensor voltage

PR101Duration of injection

PR102Canister bleed solenoid valve OCR*

PR103Instantaneous fuel consumption

PR105OBD fault warning light lit mileage counter

PR106Mileage counter fault warning light lit

PR111Motorised throttle position corrected value

PR113Throttle lower stop after offset appli.*

PR116Motorised throttle corrected position setpoint

MR-372-J84-17B050$658.mif

Page 203 of 230

PETROL INJECTION

Fault finding - Parameter summary table

17B

17B - 203

17B

17B - 203V9 MR-372-J84-17B050$658.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

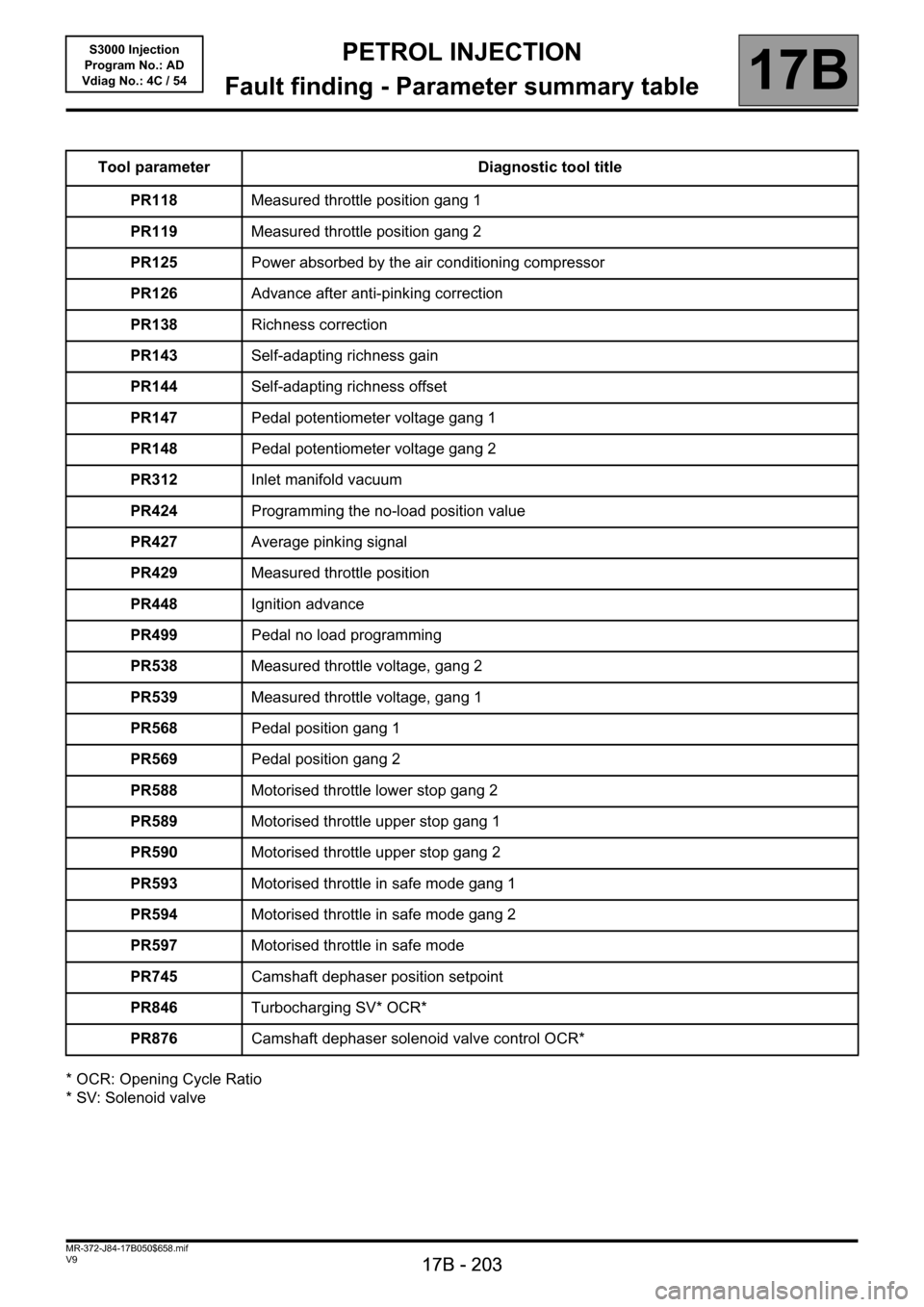

* OCR: Opening Cycle Ratio

* SV: Solenoid valveTool parameter Diagnostic tool title

PR118Measured throttle position gang 1

PR119Measured throttle position gang 2

PR125Power absorbed by the air conditioning compressor

PR126Advance after anti-pinking correction

PR138Richness correction

PR143Self-adapting richness gain

PR144Self-adapting richness offset

PR147Pedal potentiometer voltage gang 1

PR148Pedal potentiometer voltage gang 2

PR312Inlet manifold vacuum

PR424Programming the no-load position value

PR427Average pinking signal

PR429Measured throttle position

PR448Ignition advance

PR499Pedal no load programming

PR538Measured throttle voltage, gang 2

PR539Measured throttle voltage, gang 1

PR568Pedal position gang 1

PR569Pedal position gang 2

PR588Motorised throttle lower stop gang 2

PR589Motorised throttle upper stop gang 1

PR590Motorised throttle upper stop gang 2

PR593Motorised throttle in safe mode gang 1

PR594Motorised throttle in safe mode gang 2

PR597Motorised throttle in safe mode

PR745Camshaft dephaser position setpoint

PR846Turbocharging SV* OCR*

PR876Camshaft dephaser solenoid valve control OCR*

Page 204 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 204

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 204V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Interpretation of parameters

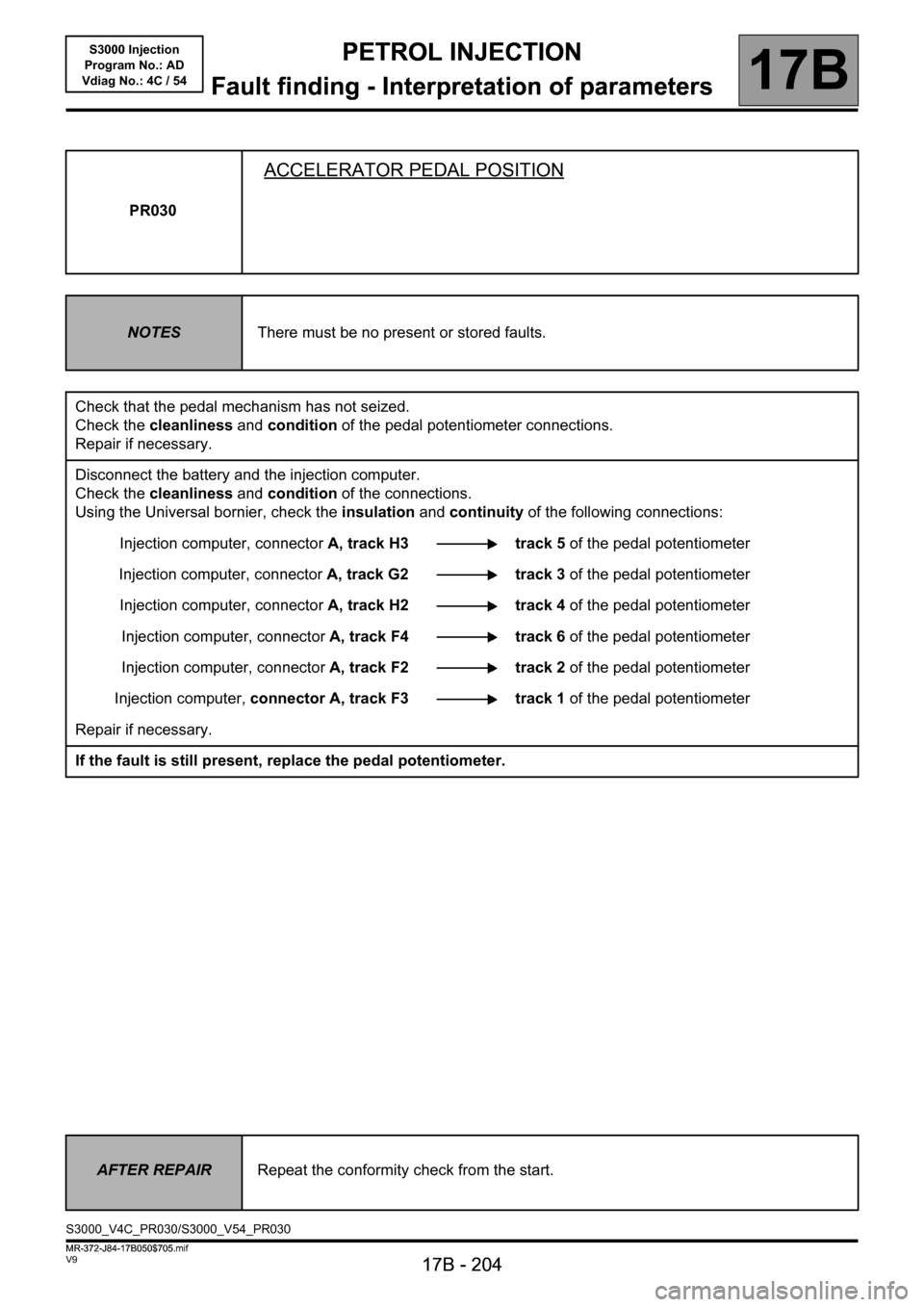

PR030

ACCELERATOR PEDAL POSITION

NOTESThere must be no present or stored faults.

Check that the pedal mechanism has not seized.

Check the cleanliness and condition of the pedal potentiometer connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorA, track H3 track 5 of the pedal potentiometer

Injection computer, connectorA, track G2 track 3 of the pedal potentiometer

Injection computer, connectorA, track H2 track 4 of the pedal potentiometer

Injection computer, connector A, track F4 track 6 of the pedal potentiometer

Injection computer, connectorA, track F2 track 2 of the pedal potentiometer

Injection computer, connector A, track F3 track 1 of the pedal potentiometer

Repair if necessary.

If the fault is still present, replace the pedal potentiometer.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_PR030/S3000_V54_PR030

MR-372-J84-17B050$705.mif

Page 205 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 205

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 205V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR037

REFRIGERANT PRESSURE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the refrigerant pressure sensor and its connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the universal bornier in place of the computer, check for insulation and continuity on the following

connections:

Computer, connectorB, track J2 track B of the refrigerant sensor

Computer, connectorB, track J3 Track C of the refrigerant sensor

Computer, connectorB, track K2 track A of the refrigerant sensor

Repair if necessary.

If the fault is still present, replace the refrigerant fluid sensor.

If the fault is still present, check the air conditioning circuit (see MR 366 or 370 Mechanics, 62A,

Air conditioning).

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_PR037/S3000_V54_PR037

Page 206 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 206

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 206V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR074

BATTERY VOLTAGE

NOTESThere must be no present or stored faults.

Without electrical consumers (radio, air conditioning, fan assemblies,

headlights, etc.).

Ignition on

Then at idle speed

If the voltage is at minimum:

Check the battery and the charging circuit (see Technical Note 6014A Checking the

charging circuit).

If the voltage is at maximum:

Check that the charging voltage is correct with and without electrical consumer

(seeTechnical Note 6014A Checking the charging circuit).

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_PR074/S3000_V54_PR074

Page 207 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 207

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 207V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR095

ANTI-PINKING CORRECTION

NOTESThere must be no present or stored faults.

The pinking sensor must not supply a zero signal, proving that it is recording the mechanical vibrations

of the engine.

Check that there is the correct fuel in the fuel tank.

Repair if necessary.

Check the condition and conformity of the spark plugs.

Repair if necessary.

Check the pinking sensor tightness.

Repair if necessary.

Check the cleanliness and condition of the pinking sensor connectors.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorB, track B3 track 2 of the pinking sensor

Injection computer, connectorB, track B4 track 1 of the pinking sensor

Injection computer, connectorB, track B2 Pinking sensor screening

Repair if necessary.

If the fault is still present, replace the pinking sensor.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_PR095/S3000_V54_PR095

Page 208 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 208

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 208V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR098

UPSTREAM OXYGEN SENSOR VOLTAGE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the upstream oxygen sensor connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorC, track C1 track D of the upstream oxygen sensor

Injection computer, connectorC, track B1 track C of the upstream oxygen sensor

Repair if necessary.

Check the tightness of the upstream oxygen sensor.

Repair if necessary.

If the vehicle is driven frequently in town, carry out a decoking procedure.

Check that there are no leaks in the exhaust system, from the manifold to the catalytic converter.

Repair if necessary.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_PR098/S3000_V54_PR098

Page 209 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 209

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 209V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR098

CONTINUED

If the fault is still present, replace the upstream oxygen sensor.

If the fault has still not been cured, continue with the checks.

Check:

– the condition of the air filter,

– that the air inlet circuit is not blocked,

– the condition and conformity of the spark plugs,

– that the catalytic converter is not clogged,

– the sealing between the throttle valve and inlet manifold,

– the manifold pressure sensor sealing,

– the fuel vapour absorber bleed, which must not be jammed open,'

– the fuel vapour absorber bleed system sealing,

– the brake servo system sealing,

– the cylinder head oil vapour recovery system sealing,

– the sealing between the inlet manifold and cylinder head,

– the exhaust pipe sealing between the cylinder head and catalytic converter.

– the fuel flow rate and pressure.

If the idle speed is not stable, check:

– the timing adjustment,

– the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of engine),

– the cylinder compressions.

Drive the vehicle to check the repair.

AFTER REPAIRRepeat the conformity check from the start.

Page 210 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 210

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 210V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR099

DOWNSTREAM OXYGEN SENSOR VOLTAGE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the downstream oxygen sensor connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorC, track A2 track C of the downstream oxygen sensor

Injection computer, connectorC, track B2 track D of the downstream oxygen sensor

Repair if necessary.

Check the tightness of the downstream oxygen sensor.

Repair if necessary.

If the vehicle is driven frequently in town, carry out the unclogging procedure (oxygen sensors and catalytic

converter clogging).

Check that the exhaust pipe is completely leak free.

Repair if necessary.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_PR099/S3000_V54_PR099