relay RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 103 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-103

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-103V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

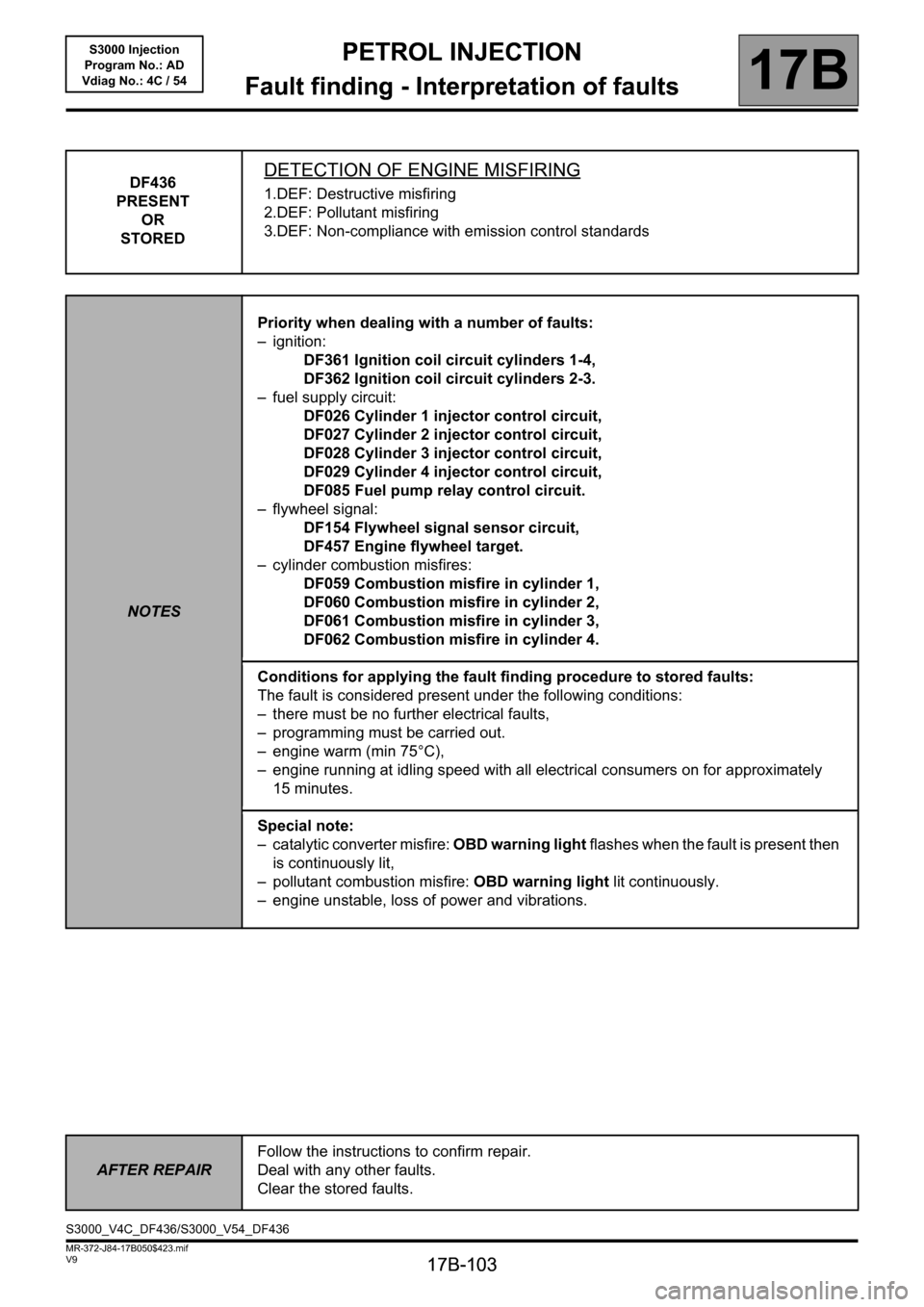

DF436

PRESENT

OR

STOREDDETECTION OF ENGINE MISFIRING

1.DEF: Destructive misfiring

2.DEF: Pollutant misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– ignition:

DF361 Ignition coil circuit cylinders 1-4,

DF362 Ignition coil circuit cylinders 2-3.

– fuel supply circuit:

DF026 Cylinder 1 injector control circuit,

DF027 Cylinder 2 injector control circuit,

DF028 Cylinder 3 injector control circuit,

DF029 Cylinder 4 injector control circuit,

DF085 Fuel pump relay control circuit.

– flywheel signal:

DF154 Flywheel signal sensor circuit,

DF457 Engine flywheel target.

– cylinder combustion misfires:

DF059 Combustion misfire in cylinder 1,

DF060 Combustion misfire in cylinder 2,

DF061 Combustion misfire in cylinder 3,

DF062 Combustion misfire in cylinder 4.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– engine warm (min 75°C),

– engine running at idling speed with all electrical consumers on for approximately

15 minutes.

Special note:

– catalytic converter misfire: OBD warning light flashes when the fault is present then

is continuously lit,

– pollutant combustion misfire: OBD warning light lit continuously.

– engine unstable, loss of power and vibrations.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF436/S3000_V54_DF436

Page 107 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-107

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-107V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF570

PRESENT

OR

STOREDCOOLANT PUMP RELAY

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present when the engine is running or on command AC195

Electric coolant pump.

Check the cleanliness, condition and fitting of the coolant pump.

Top up the coolant if necessary.

If the fault is still present, manipulate the harness to see if the status changes.

Look for any harness damage, and check the condition and connection points of the injection computer and the

coolant pump connectors.

Repair if necessary.

If the fault is still present, check for +12V on track 2 of the coolant pump.

If +12V is not present on track 2 of the coolant pump, check the following connection for insulation, continuity

and the absence of interference resistance:

Coolant pump track 2 track 6, connector CN, of the Protection and

Switching Unit

Repair if necessary.

If the fault is still present, check the insulation, continuity and the absence of interference resistance on the

following connection:

Computer, connectorB, track L4 track 1 of the coolant pump

Repair if necessary.

If the fault is still present, check that the resistance between tracks 1 and 2 of the coolant pump is neither zero

nor infinite.

Replace the coolant pump if necessary.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF570/S3000_V54_DF570

Page 108 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-108

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-108V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

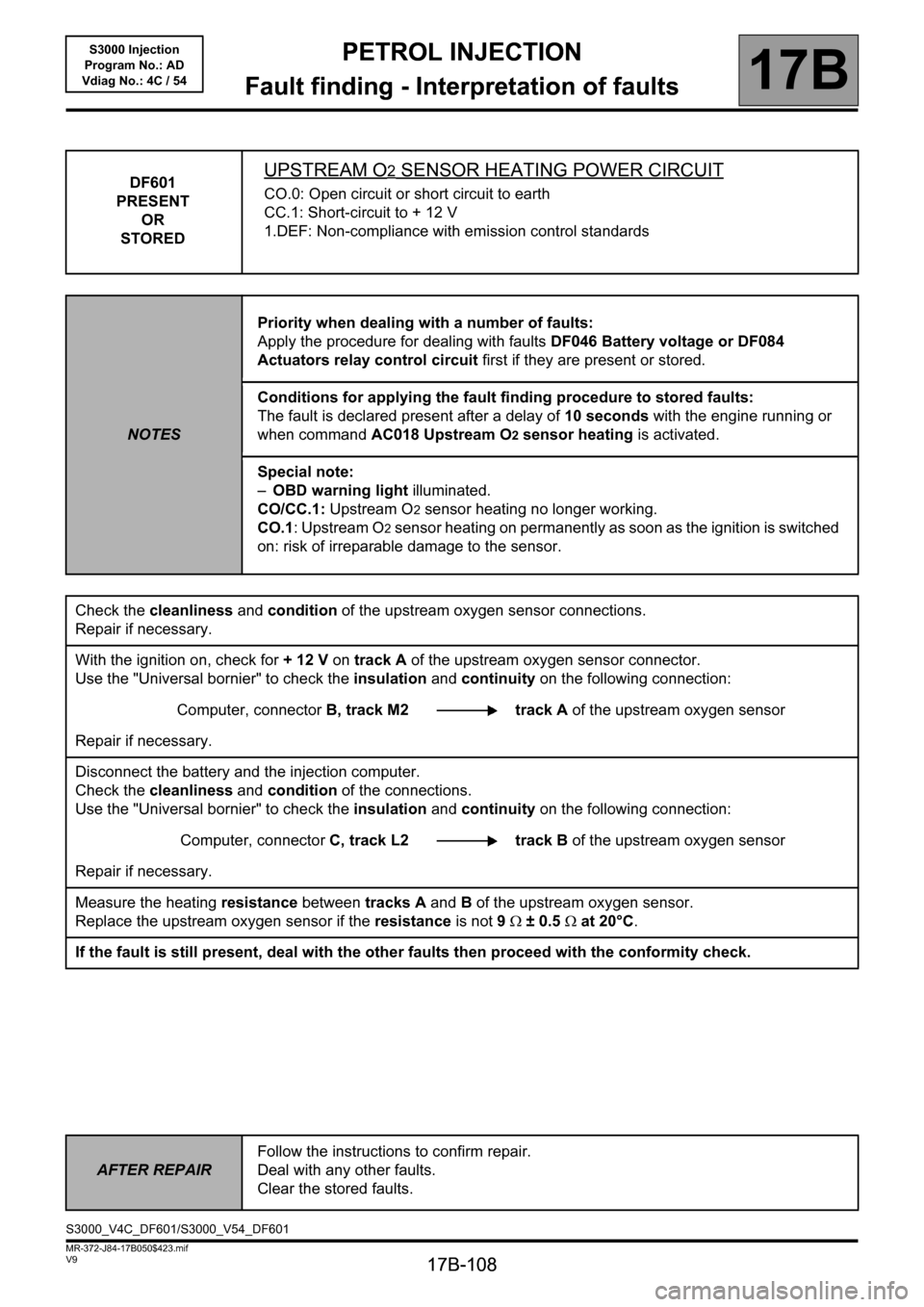

DF601

PRESENT

OR

STOREDUPSTREAM O2 SENSOR HEATING POWER CIRCUIT

CO.0: Open circuit or short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with faults DF046 Battery voltage or DF084

Actuators relay control circuit first if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after a delay of 10 seconds with the engine running or

when command AC018 Upstream O2 sensor heating is activated.

Special note:

–OBD warning light illuminated.

CO/CC.1: Upstream O

2 sensor heating no longer working.

CO.1: Upstream O

2 sensor heating on permanently as soon as the ignition is switched

on: risk of irreparable damage to the sensor.

Check the cleanliness and condition of the upstream oxygen sensor connections.

Repair if necessary.

With the ignition on, check for + 12 V on track A of the upstream oxygen sensor connector.

Use the "Universal bornier" to check the insulation and continuity on the following connection:

Computer, connectorB, track M2 track A of the upstream oxygen sensor

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity on the following connection:

Computer, connectorC, track L2 track B of the upstream oxygen sensor

Repair if necessary.

Measure the heating resistance between tracks A and B of the upstream oxygen sensor.

Replace the upstream oxygen sensor if the resistance is not 9Ω ± 0.5Ω at 20°C.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF601/S3000_V54_DF601

Page 109 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-109

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-109V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

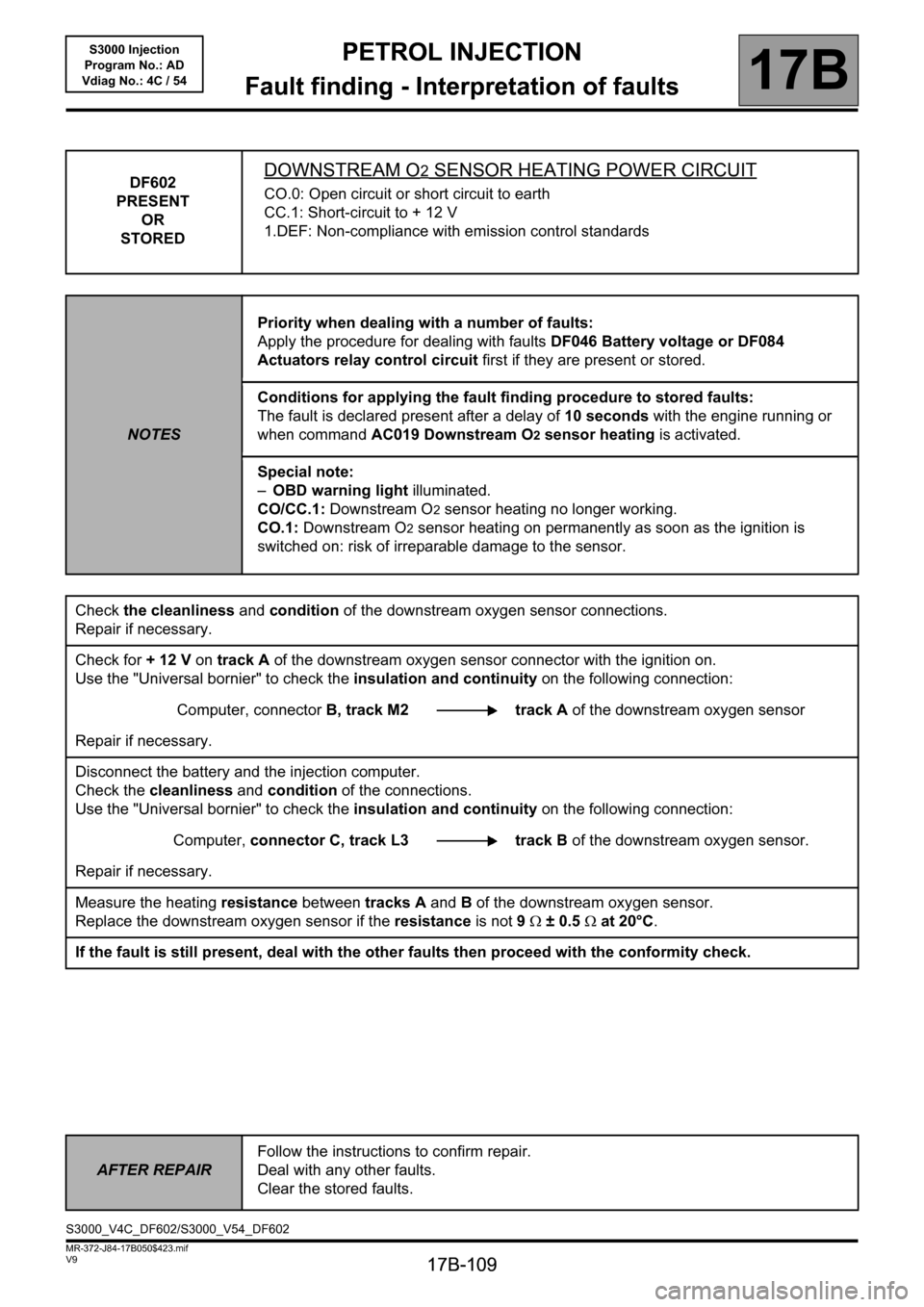

DF602

PRESENT

OR

STOREDDOWNSTREAM O2 SENSOR HEATING POWER CIRCUIT

CO.0: Open circuit or short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with faults DF046 Battery voltage or DF084

Actuators relay control circuit first if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after a delay of 10 seconds with the engine running or

when command AC019 Downstream O2 sensor heating is activated.

Special note:

–OBD warning light illuminated.

CO/CC.1: Downstream O

2 sensor heating no longer working.

CO.1: Downstream O

2 sensor heating on permanently as soon as the ignition is

switched on: risk of irreparable damage to the sensor.

Check the cleanliness and condition of the downstream oxygen sensor connections.

Repair if necessary.

Check for + 12 V on track A of the downstream oxygen sensor connector with the ignition on.

Use the "Universal bornier" to check the insulation and continuity on the following connection:

Computer, connectorB, track M2 track A of the downstream oxygen sensor

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity on the following connection:

Computer, connector C, track L3 track Bof the downstream oxygen sensor.

Repair if necessary.

Measure the heating resistance between tracks A and B of the downstream oxygen sensor.

Replace the downstream oxygen sensor if the resistance is not 9Ω ± 0.5Ω at 20°C.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF602/S3000_V54_DF602

Page 122 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-122

PETROL INJECTION

Fault finding - Conformity check

17B

17B-122V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

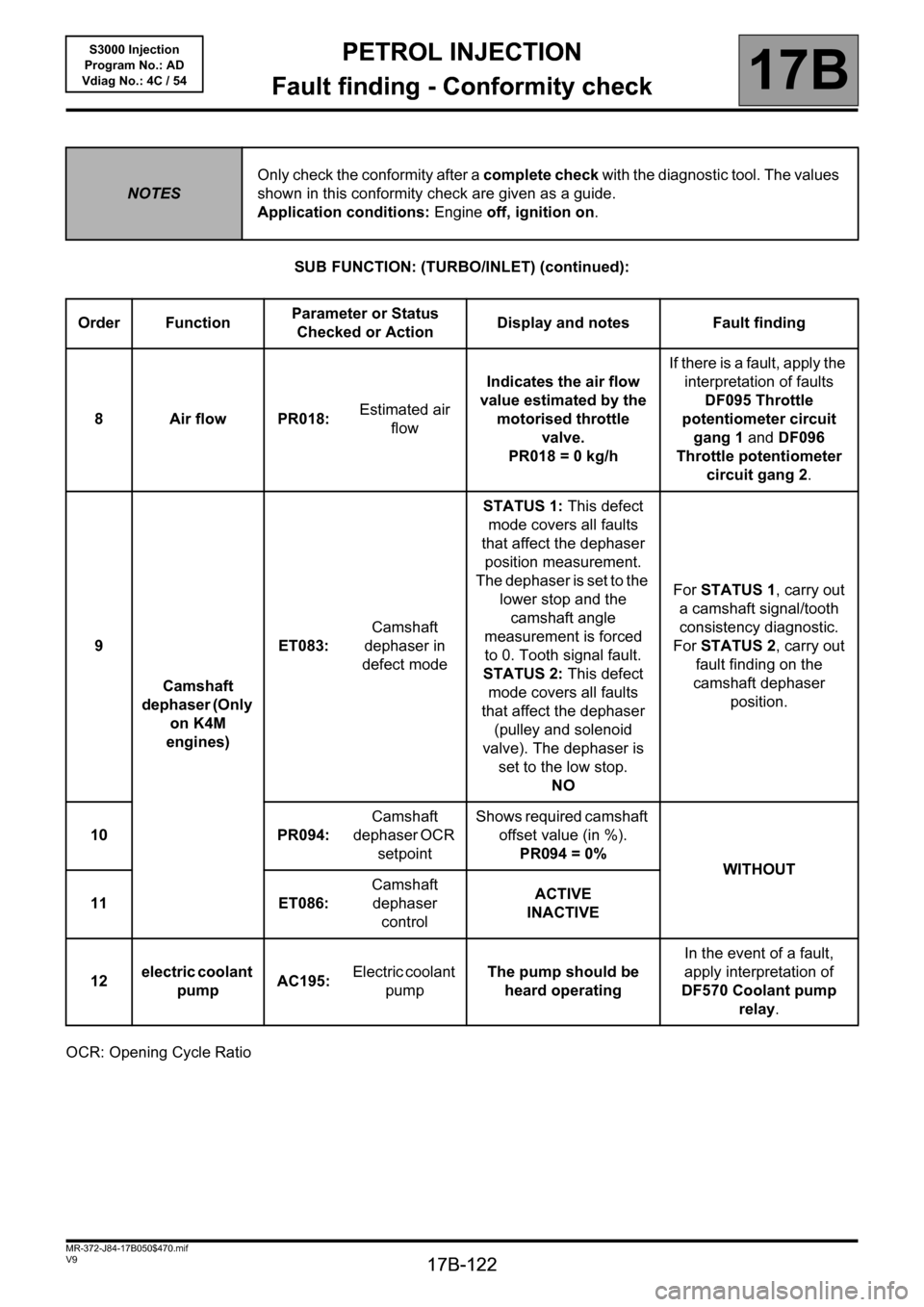

SUB FUNCTION: (TURBO/INLET) (continued):

OCR: Opening Cycle Ratio

NOTESOnly check the conformity after a complete check with the diagnostic tool. The values

shown in this conformity check are given as a guide.

Application conditions: Engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

8 Air flow PR018:Estimated air

flowIndicates the air flow

value estimated by the

motorised throttle

valve.

PR018= 0kg/hIf there is a fault, apply the

interpretation of faults

DF095 Throttle

potentiometer circuit

gang 1 and DF096

Throttle potentiometer

circuit gang 2.

9

Camshaft

dephaser (Only

on K4M

engines)ET083:Camshaft

dephaser in

defect modeSTATUS 1: This defect

mode covers all faults

that affect the dephaser

position measurement.

The dephaser is set to the

lower stop and the

camshaft angle

measurement is forced

to 0. Tooth signal fault.

STATUS 2: This defect

mode covers all faults

that affect the dephaser

(pulley and solenoid

valve). The dephaser is

set to the low stop.

NOFor STATUS 1, carry out

a camshaft signal/tooth

consistency diagnostic.

For STATUS 2, carry out

fault finding on the

camshaft dephaser

position.

10 PR094:Camshaft

dephaser OCR

setpointShows required camshaft

offset value (in %).

PR094 = 0%

WITHOUT

11 ET086:Camshaft

dephaser

controlACTIVE

INACTIVE

12electric coolant

pumpAC195:Electric coolant

pumpThe pump should be

heard operatingIn the event of a fault,

apply interpretation of

DF570 Coolant pump

relay.

Page 126 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-126

PETROL INJECTION

Fault finding - Conformity check

17B

17B-126V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

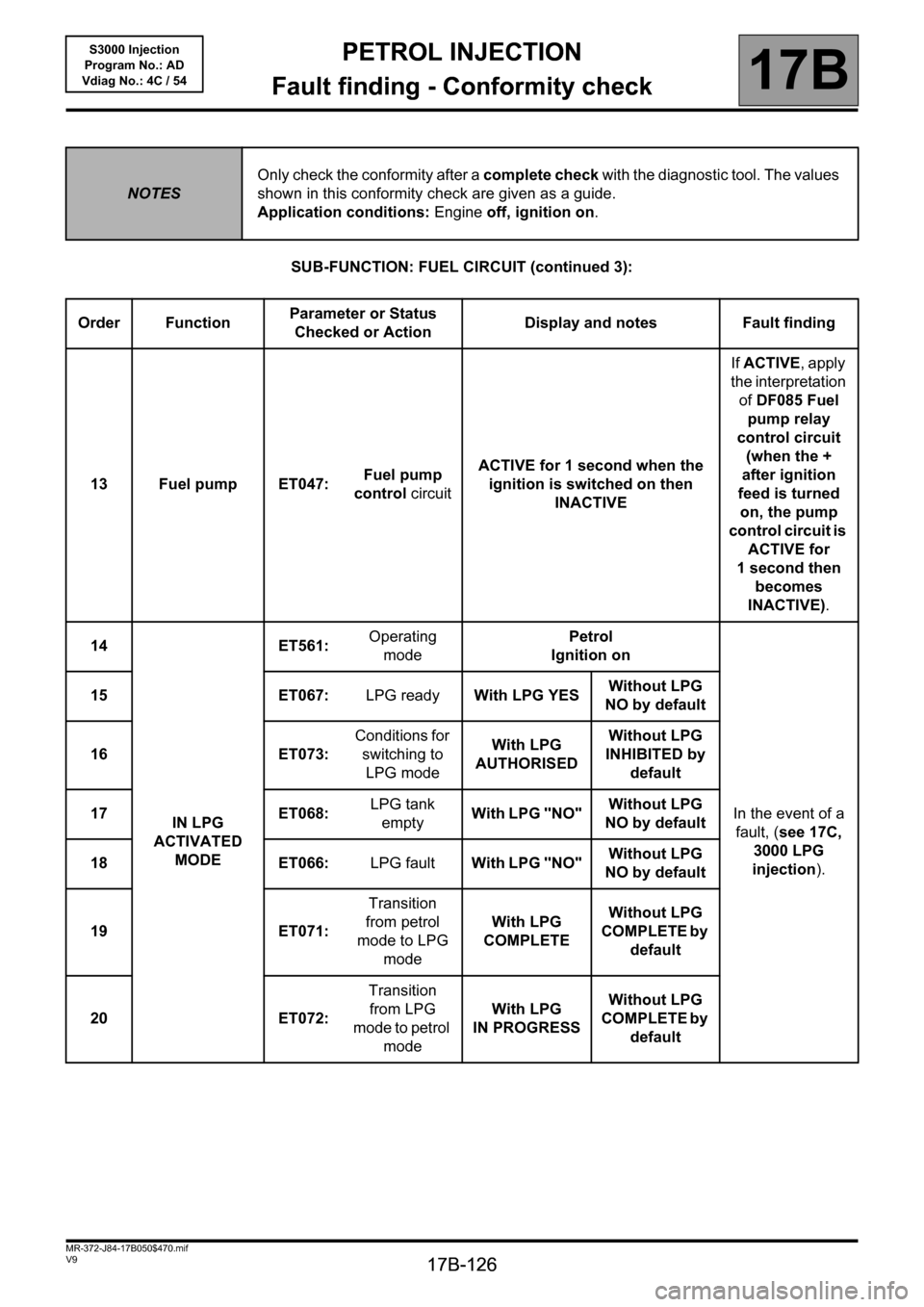

SUB-FUNCTION: FUEL CIRCUIT (continued 3):

NOTESOnly check the conformity after a complete check with the diagnostic tool. The values

shown in this conformity check are given as a guide.

Application conditions: Engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

13 Fuel pump ET047:Fuel pump

control circuitACTIVE for 1 second when the

ignition is switched on then

INACTIVEIf ACTIVE, apply

the interpretation

of DF085 Fuel

pump relay

control circuit

(when the +

after ignition

feed is turned

on, the pump

control circuit is

ACTIVE for

1 second then

becomes

INACTIVE).

14

IN LPG

ACTIVATED

MODEET561:Operating

modePetrol

Ignition on

In the event of a

fault, (see 17C,

3000 LPG

injection). 15 ET067:LPG readyWith LPG YESWithout LPG

NO by default

16 ET073:Conditions for

switching to

LPG modeWith LPG

AUTHORISEDWithout LPG

INHIBITED by

default

17 ET068:LPG tank

emptyWith LPG "NO"Without LPG

NO by default

18 ET066:LPG faultWith LPG "NO"Without LPG

NO by default

19 ET071:Transition

from petrol

mode to LPG

modeWith LPG

COMPLETEWithout LPG

COMPLETE by

default

20 ET072:Transition

from LPG

mode to petrol

modeWith LPG

IN PROGRESSWithout LPG

COMPLETE by

default

Page 134 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-134

PETROL INJECTION

Fault finding - Conformity check

17B

17B-134V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

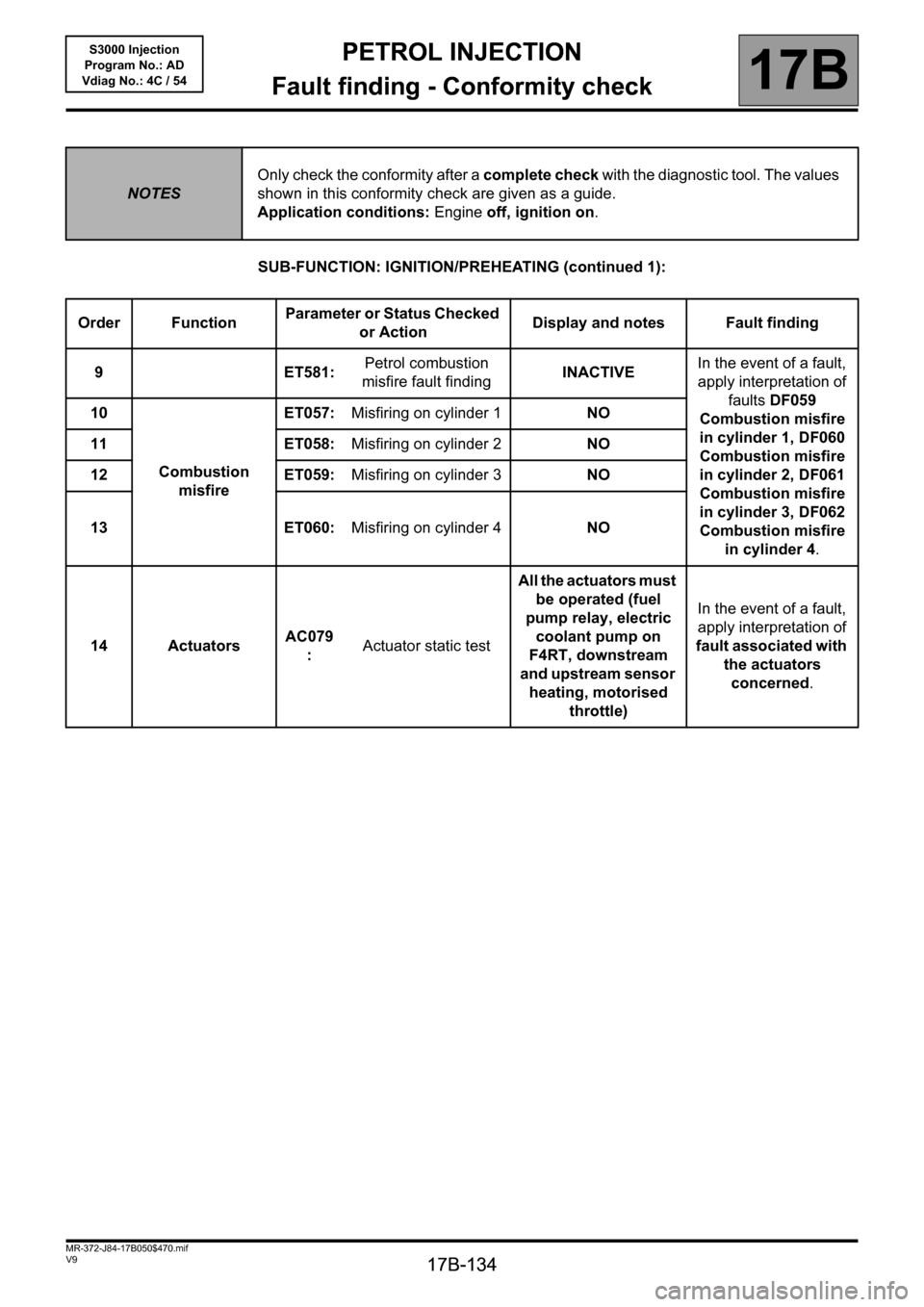

SUB-FUNCTION: IGNITION/PREHEATING (continued 1):

NOTESOnly check the conformity after a complete check with the diagnostic tool. The values

shown in this conformity check are given as a guide.

Application conditions: Engine off, ignition on.

Order FunctionParameter or Status Checked

or ActionDisplay and notes Fault finding

9ET581:Petrol combustion

misfire fault findingINACTIVEIn the event of a fault,

apply interpretation of

faults DF059

Combustion misfire

in cylinder 1, DF060

Combustion misfire

in cylinder 2, DF061

Combustion misfire

in cylinder 3, DF062

Combustion misfire

in cylinder 4. 10

Combustion

misfireET057:Misfiring on cylinder 1NO

11 ET058:Misfiring on cylinder 2NO

12 ET059:Misfiring on cylinder 3NO

13 ET060:Misfiring on cylinder 4NO

14 ActuatorsAC079

:Actuator static testAll the actuators must

be operated (fuel

pump relay, electric

coolant pump on

F4RT, downstream

and upstream sensor

heating, motorised

throttle)In the event of a fault,

apply interpretation of

fault associated with

the actuators

concerned.

Page 135 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-135

PETROL INJECTION

Fault finding - Conformity check

17B

17B-135V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

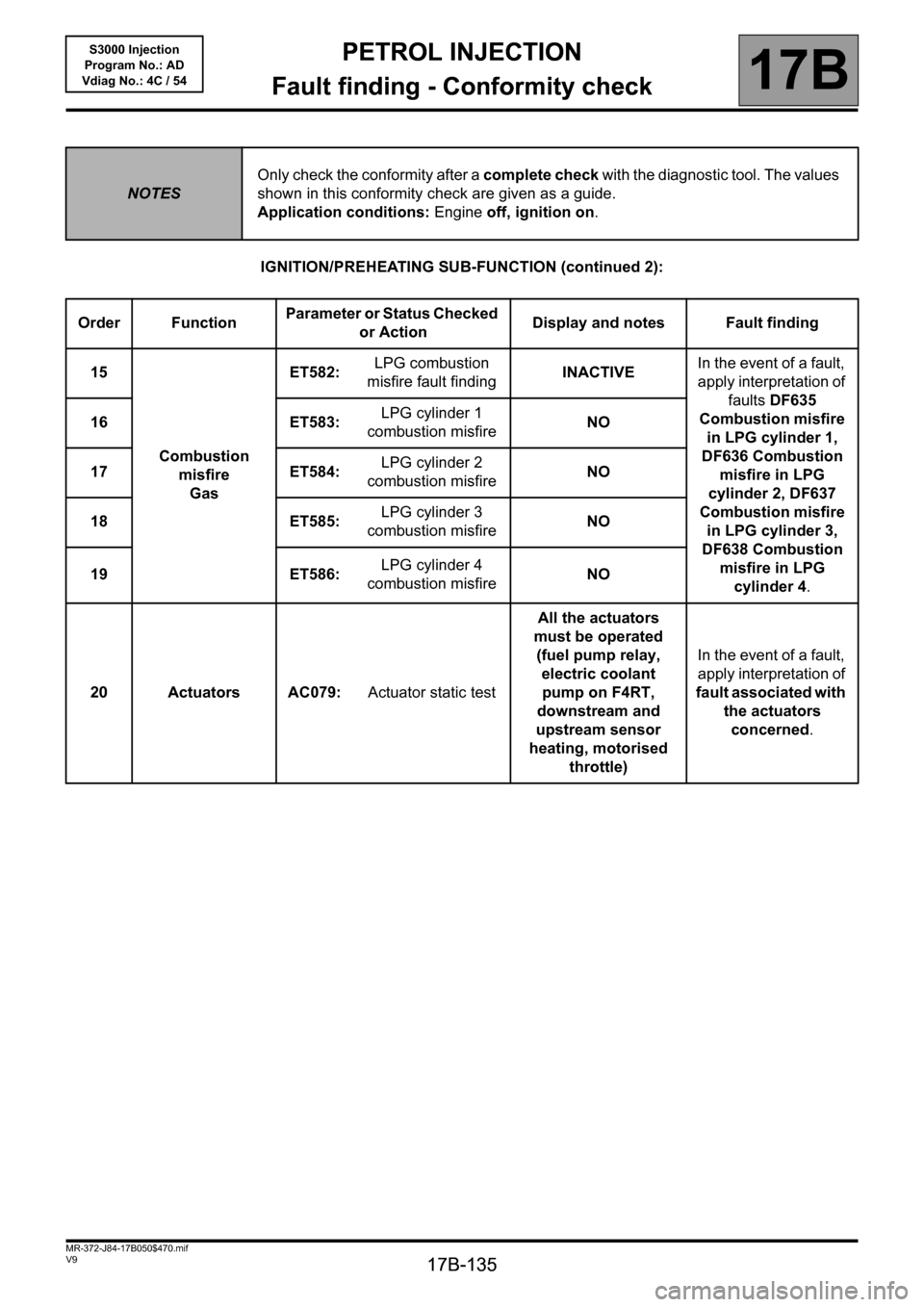

IGNITION/PREHEATING SUB-FUNCTION (continued 2):

NOTESOnly check the conformity after a complete check with the diagnostic tool. The values

shown in this conformity check are given as a guide.

Application conditions: Engine off, ignition on.

Order FunctionParameter or Status Checked

or ActionDisplay and notes Fault finding

15

Combustion

misfire

GasET582:LPG combustion

misfire fault findingINACTIVEIn the event of a fault,

apply interpretation of

faults DF635

Combustion misfire

in LPG cylinder 1,

DF636 Combustion

misfire in LPG

cylinder 2, DF637

Combustion misfire

in LPG cylinder 3,

DF638 Combustion

misfire in LPG

cylinder 4. 16 ET583:LPG cylinder 1

combustion misfireNO

17 ET584:LPG cylinder 2

combustion misfireNO

18 ET585:LPG cylinder 3

combustion misfireNO

19 ET586:LPG cylinder 4

combustion misfireNO

20 Actuators AC079:Actuator static testAll the actuators

must be operated

(fuel pump relay,

electric coolant

pump on F4RT,

downstream and

upstream sensor

heating, motorised

throttle)In the event of a fault,

apply interpretation of

fault associated with

the actuators

concerned.

Page 142 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-142

PETROL INJECTION

Fault finding - Conformity check

17B

17B-142V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

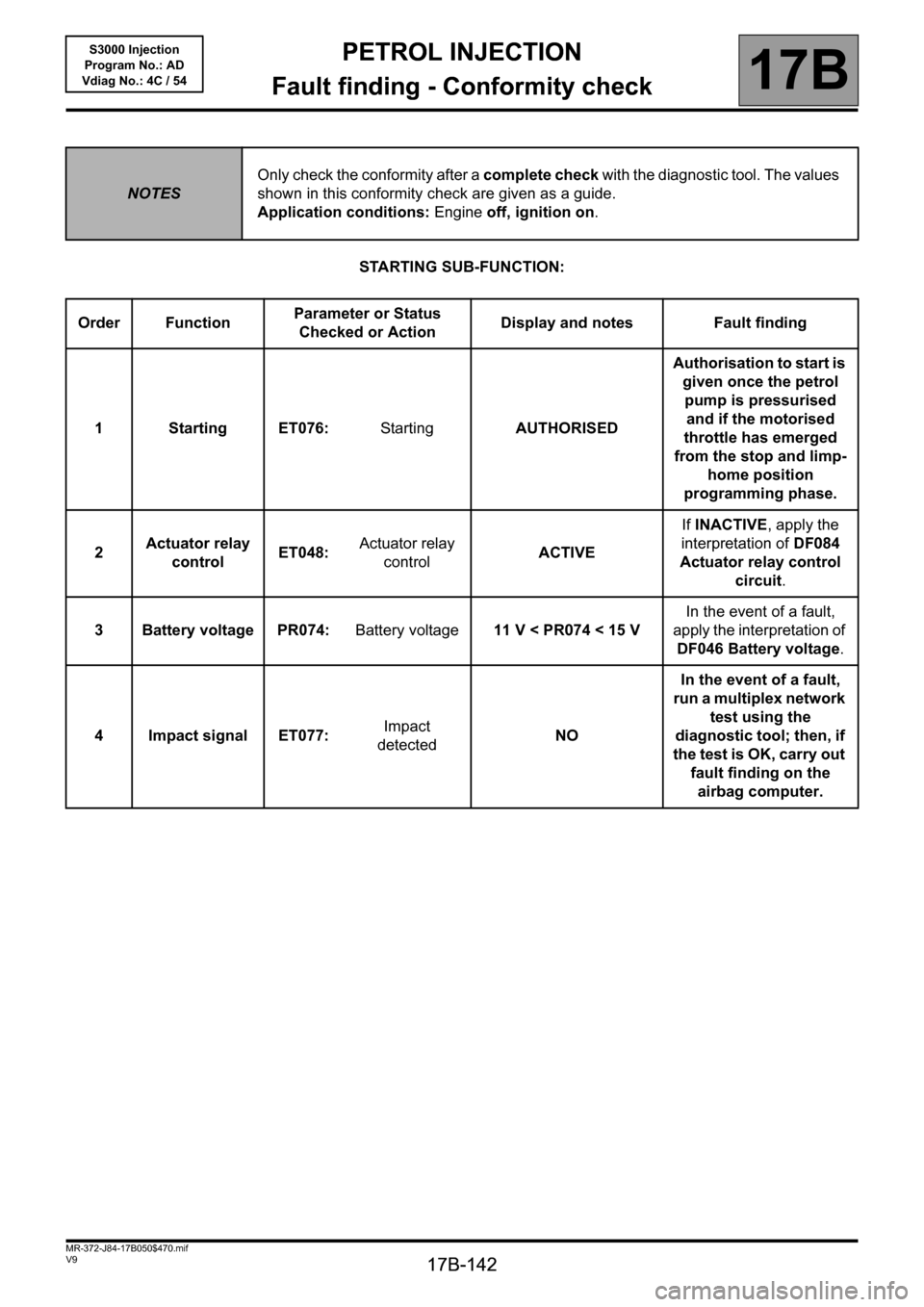

STARTING SUB-FUNCTION:

NOTESOnly check the conformity after a complete check with the diagnostic tool. The values

shown in this conformity check are given as a guide.

Application conditions: Engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1StartingET076:StartingAUTHORISEDAuthorisation to start is

given once the petrol

pump is pressurised

and if the motorised

throttle has emerged

from the stop and limp-

home position

programming phase.

2Actuator relay

controlET048:Actuator relay

controlACTIVEIf INACTIVE, apply the

interpretation of DF084

Actuator relay control

circuit.

3 Battery voltage PR074:Battery voltage11 V < PR074 < 15 VIn the event of a fault,

apply the interpretation of

DF046 Battery voltage.

4 Impact signal ET077:Impact

detectedNOIn the event of a fault,

run a multiplex network

test using the

diagnostic tool; then, if

the test is OK, carry out

fault finding on the

airbag computer.

Page 146 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-146

PETROL INJECTION

Fault finding - Conformity check

17B

17B-146V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

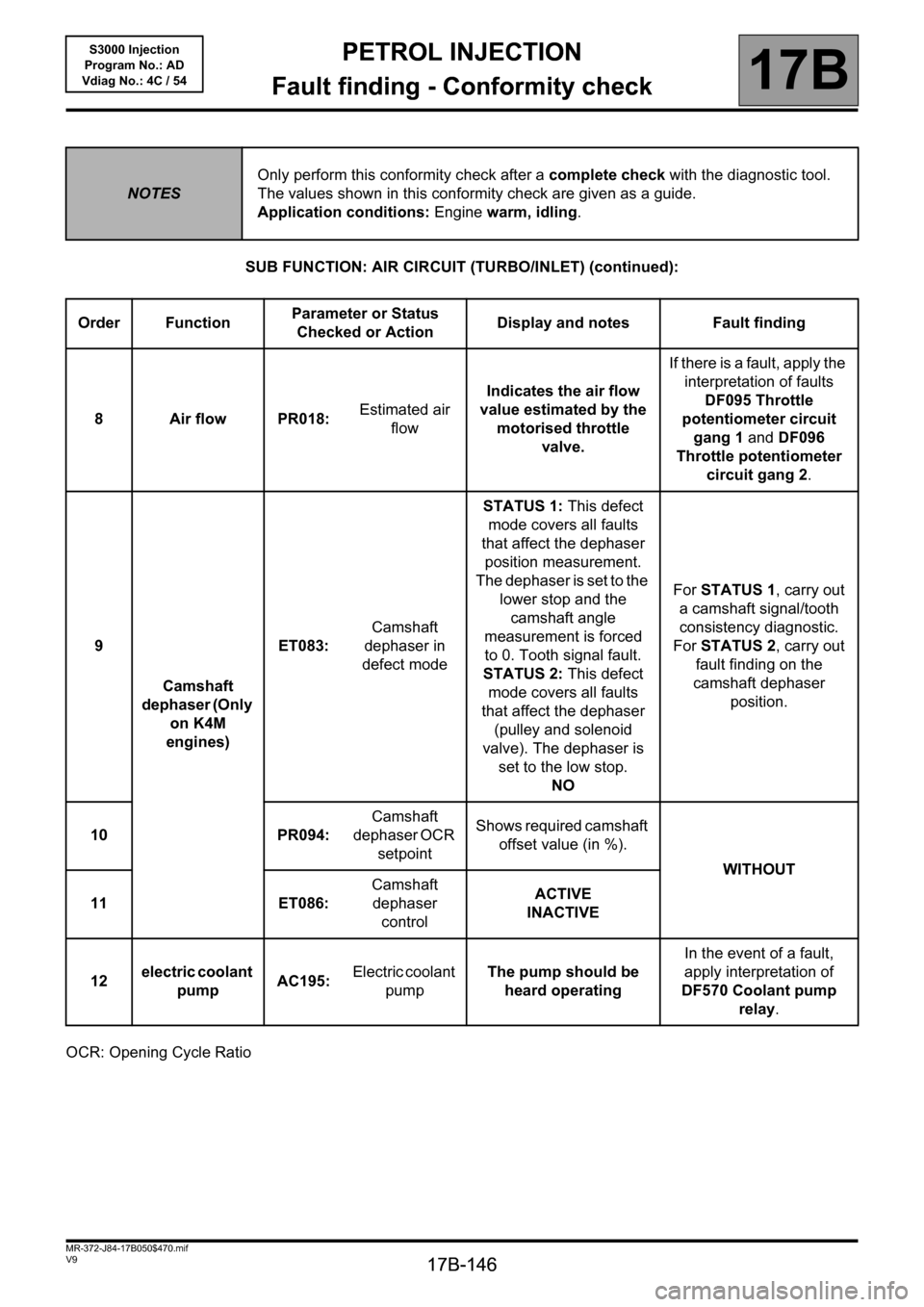

SUB FUNCTION: AIR CIRCUIT (TURBO/INLET) (continued):

OCR: Opening Cycle Ratio

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

8 Air flow PR018:Estimated air

flowIndicates the air flow

value estimated by the

motorised throttle

valve.If there is a fault, apply the

interpretation of faults

DF095 Throttle

potentiometer circuit

gang 1 and DF096

Throttle potentiometer

circuit gang 2.

9

Camshaft

dephaser (Only

on K4M

engines)ET083:Camshaft

dephaser in

defect modeSTATUS 1: This defect

mode covers all faults

that affect the dephaser

position measurement.

The dephaser is set to the

lower stop and the

camshaft angle

measurement is forced

to 0. Tooth signal fault.

STATUS 2: This defect

mode covers all faults

that affect the dephaser

(pulley and solenoid

valve). The dephaser is

set to the low stop.

NOFor STATUS 1, carry out

a camshaft signal/tooth

consistency diagnostic.

For STATUS 2, carry out

fault finding on the

camshaft dephaser

position.

10 PR094:Camshaft

dephaser OCR

setpointShows required camshaft

offset value (in %).

WITHOUT

11 ET086:Camshaft

dephaser

controlACTIVE

INACTIVE

12electric coolant

pumpAC195:Electric coolant

pumpThe pump should be

heard operatingIn the event of a fault,

apply interpretation of

DF570 Coolant pump

relay.