relay RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 236, PDF Size: 1.32 MB

Page 101 of 236

13B-101

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

V10 MR-372-J84-13B150$376.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

DF272

CONTINUED 2

1.DEF

NOTESNone.

Check the EGR valve connections.

Check the injection computer connections.

Repair if necessary.

Check the resistance of the EGR solenoid valve between tracks 1 and 5.

If the resistance is not approximately 8 Ω ±0.5 at 20°C, replace the EGR valve.

Check for continuity, insulation and the absence of interference resistance on the following connections:

Injection computer brown 48-track connector B, track L2 Track 5 of the EGR valve

UPC PPM1 black connector track 1 Track 1 of the EGR valve

Check for + 12 V after relay (UPC) on track 1 of the EGR valve.

Repair if necessary.

If the fault persists, check that the computer output stage is working correctly:

– Run actuator command AC002 EGR solenoid valve.

– If there is no perceptible movement of the valve, ensure that the computer output is functioning:

– Leave the EGR valve connected.

– Connect a "wire clip" to the violet wire between the valve and the injection computer (connection

between track 6 of the valve and track J2 of the injection computer connector B).

– Connect the positive terminal of the voltmeter to the wire clip.

– Connect the negative terminal of the voltmeter to the battery earth.

– Run command AC002 EGR solenoid valve.

– The voltage should vary over 10 cycles between 1.05 V and 3.5 V.

– If the voltage varies between these values, replace the EGR valve.

– If the voltage does not vary or varies between incorrect values, contact the Techline.

AFTER REPAIRDeal with any faults.

Carry out a road test, then check with the diagnostic tool.

Page 151 of 236

DIESEL INJECTION

Fault finding - Interpretation of statuses13B

13B-151V10 MR-372-J84-13B150$564.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

ET007

PRE-POSTHEATING UNIT CONTROL

NOTESOnly perform the tests if the statuses do not correspond with the system programming

functions.

YES

NO

When the vehicle is started from cold, the injection computer controls the pre/postheating

unit so that the vehicle can be started.

Status ET007 changes to YES a few seconds after the ignition is switched on and during

pre/postheating.

If the vehicle does not start and status ET007 changes to YES, check:

–the F2 (70A) supply fuse on the preheating unit,

– the resistance of the heater plugs.

Replace any plugs with a resistance greater than 2 Ω.

If the vehicle starts and the status ET007 remains YES during the engine functional

stage, refer to the interpretation of faults:

DF017 Preheating relay control circuit.

DF025 Pre-postheating unit diagnostic connection.

After the engine is started and preheating, the injection computer should stop the pre/

postheating unit operating.

Status ET007 Should change to NO.

In the event that the vehicle does not start and status ET007 remains at NO, check the

continuity and the absence of interference resistance of the following connections:

Injection computer grey 32-track connector C, track A4 Track 9 preheating

unit

Injection computer grey 32-track connector C, track E2 Track 8 preheating

unit

Repair if necessary.

If the fault is still present, refer to the interpretation of faults:

DF017 Preheating relay control circuit.

DF025 Pre-postheating unit diagnostic connection.

AFTER REPAIRCarry out a road test followed by another check with the diagnostic tool.

EDC16_V44_ET007/EDC16_V48_ET007/EDC16_V4C_ET007

Page 183 of 236

13B - 183

DIESEL INJECTION

Fault finding - Interpretation of parameters13B

V10 MR-372-J84-13B150$658.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

PR037

REFRIGERANT PRESSURE

NOTESThere must be no present or stored faults.

Perform this fault finding procedure after an inconsistency is displayed in the

Parameters menu or after a customer complaint (no air conditioning, etc.).

Step 1

– Start the engine, switch on the air conditioning and increase the engine speed to 1,500 rpm:

– Display PR037 Refrigerant pressure in the Cold loop function on the diagnostic tool:

If the pressure is greater than ~27bar, go to step 2.

If the pressure does not rise, or remains below normal:

– Ensure that the air conditioning compressor and the relay are operating correctly.

– Check the conformity of the refrigerant pressure sensor by comparing* the value displayed by the tool (PR192)

with the reading given by the charging station high pressure gauge.

If the pressure difference = ±1.5bar, (or 1500 mbar):

Check the continuity and the absence of interference resistance on the connections between:

Injection computer, grey 24-track connector C,

track C3Track A of the refrigerant pressure sensor

Injection computer, brown 48-track connector

B, track F1Track C of the refrigerant pressure sensor

Injection computer, brown 48-track connector

B, track F3Track B of the refrigerant pressure sensor

If these connections are not faulty, replace the refrigerant pressure sensor.

If there is no difference, the refrigerant pressure sensor is correct: go to step 2.

Step 2

– Perform fault finding on the air conditioning.

*Note:

The diagnostic tool displays the absolute pressure, the charging station high pressure gauge displays the relative

pressure.

The normal difference between the two is equal to atmospheric pressure, i.e. ~1,000mbar.

AFTER REPAIRRepeat the conformity check from the start.

EDC16_V44_PR037/EDC16_V48_PR037/EDC16_V4C_PR037

Page 194 of 236

13B - 194

DIESEL INJECTION

Fault finding - Interpretation of commands13B

V10 MR-372-J84-13B150$752.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

AC001

PREHEATING UNIT

NOTESThis command is only carried out if fault DF025 Preheating unit fault finding

connection or DF081 Preheating relay circuit is present or stored and if no other

fault is present.

Refer to the Wiring diagrams Technical Note for the vehicle to locate the fuses and

relays concerned.

Connect the diagnostic tool and turn on the ignition.

With the preheating unit connected:

– connect the negative terminal of the voltmeter to track 8 of the preheating unit,

– connect the positive terminal of the voltmeter to the + 12 V battery,

– run command AC001 Preheating unit.

if the voltmeter does not indicate the battery voltage while the command is running (ten one-second ON/OFF

cycles), contact the Techline:

1. Check the condition of theF01 (70A) fuse which supplies the preheating unit. Replace it if necessary.

2. Check the continuity and the absence of interference resistance on the following connections:

Injection computer connector C, track E2 Track 8 of the preheating unit connector

Injection computer connector C, track A4 Track 9 of the pre-postheating unit connector

Repair if necessary.

3. Check the connections on the preheating unit, heater plugs and injection computer.

Repair if necessary.

4 Measure the resistance of the heater plugs. If the resistance is greater than 2Ω replace the faulty plug(s).

5. Check the continuity and the absence of interference resistance between:

– preheating unit track 1Heater plug for cylinder 3

– preheating unit track 2Heater plug for cylinder 4

– preheating unit track 6Heater plug for cylinder 1

– preheating unit track 7Heater plug for cylinder 2

6. Then check for +12V on track 3 of the preheating relay connector.

If the fault is still present, replace the preheating unit.

AFTER REPAIRRestart the conformity check from the beginning.

EDC16_V44_AC001/EDC16_V48_AC001/EDC16_V4C_AC001

Page 197 of 236

13B - 197

DIESEL INJECTION

Fault finding - Interpretation of commands13B

V10 MR-372-J84-13B150$752.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

AC004

TURBOCHARGING SOLENOID VALVE

NOTESThis command is run if a fault is detected in the turbocharging circuit.

This command checks that the turbocharger and the control circuit are working properly.

Introduction

1 - Check the sealing of the high-pressure air circuit:

Pipe not joined or pierced, pressure sensor disconnected or poorly fitted (seal present), intercooler pierced.

To test the intercooler: stabilise the engine speed between 3,500 and 4,000 rpm with the vehicle stopped and

check that there are no leaks.

Check the resistance of the turbocharging limitation solenoid valve between tracks 1 and 2:

Replace the solenoid valve if the resistance is not: 15.4 Ω ± 0.7 at 20 °C.

Check the injection computer connections.

Check for continuity and the absence of interference resistance on the following connection:

Injection computer grey 32-track connector C, track E1 Track 1 turbocharging solenoid valve

Repair if necessary.

Check for the presence of +12V after relay on track 2 of the turbocharging solenoid valve.

2 - Turbocharger control circuit check

– With the engine stopped, make sure that the control rod is in the rest position.

– Start the engine and make sure that the control rod operates to the high stop.

(when the engine is switched off, the control rod should return to the idle position)

If the control rod does not move correctly, carry out the following checks:

1) Vacuum pressure command check:

– Disconnect the solenoid valve inlet hose and connect it to a pressure gauge.

– Start the engine and run it at a stable idle speed.

– If the vacuum pressure does not reach 800 mbar ± 100: check the vacuum pressure circuit from the vacuum

pump.

– Stop the engine, reconnect the inlet hoses and go to step no. 2.

2) Solenoid valve control check:

– Disconnect the solenoid valve outlet hose.

– Start the engine and run it at a stable idle speed.

– Place your hand on the solenoid valve and block the outlet union with your thumb.

– If you notice no solenoid valve vibration, check the operation of the computer output (step 5).

3) Solenoid valve operation check:

– Connect the pressure gauge to the solenoid valve outlet union.

– Start the engine and run it at a stable idle speed.

If the vacuum pressure does not reach 800 mbar ± 100, replace the solenoid valve.

AFTER REPAIRRestart the conformity check from the beginning.

EDC16_V44_AC004/EDC16_V48_AC004/EDC16_V4C_AC004

Page 199 of 236

13B - 199

DIESEL INJECTION

Fault finding - Interpretation of commands13B

V10 MR-372-J84-13B150$752.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

* Opening Cyclic Ratio AC011

RAIL PRESSURE REGULATOR

NOTESThis command enables the operation of the injector high-pressure regulator circuit to

be checked.

Step 1

Measure the pressure regulator resistance between tracks 1 and 2.

– Replace the regulator if the resistance is not approximately: 3Ω ± 0.5 at 20 °C.

Check the continuity and the absence of interference resistance of the following connections:

Injection computer brown 48-track connectorB, trackM4 track 2 of the rail pressure regulator

connector.

+ 12 V after relaytrack 1 of the rail pressure regulator

connector.

If, when running command AC011, you can hear a slight whistling noise and the rattling from the regulator, go to

Step 2. Otherwise, ensure that the computer output is functioning correctly:

●Using a voltmeter:

With the solenoid valve connected, connect the voltmeter earth lead to track 2 of the fuel pressure solenoid valve

and the positive cable to track 1. Clear any fuel pressure solenoid valve faults, then run command AC011:

The voltmeter should display two successive voltages: ~ 2.5 V for an OCR at 20 % then ~ 8.75 V at an

OCR at 70 % (ten cycles)

●Or using an oscilloscope (range 5 V/division and with time base 1 ms/division):

With the solenoid valve connected, connect the earth of the oscilloscope to the battery earth and the positive test

pin to track 2 of the fuel pressure solenoid valve. Clear any fuel pressure solenoid valve faults then run command

AC011:

The oscilloscope should display a square-wave signal of 12.5 volts amplitude at a frequency of 185 Hz

(with an OCR going successively from 20 to 70 %).

– If the measurement is correct, replace the regulator.

– If the measurement is not correct, contact the Techline.

Step 2, next page

AFTER REPAIRRestart the conformity check from the beginning.

EDC16_V44_AC011/EDC16_V48_AC011/EDC16_V4C_AC011

Page 206 of 236

13B-206

MR-372-J84-13B150$846.mif

V10

DIESEL INJECTION

Fault finding - Fault finding chart13B

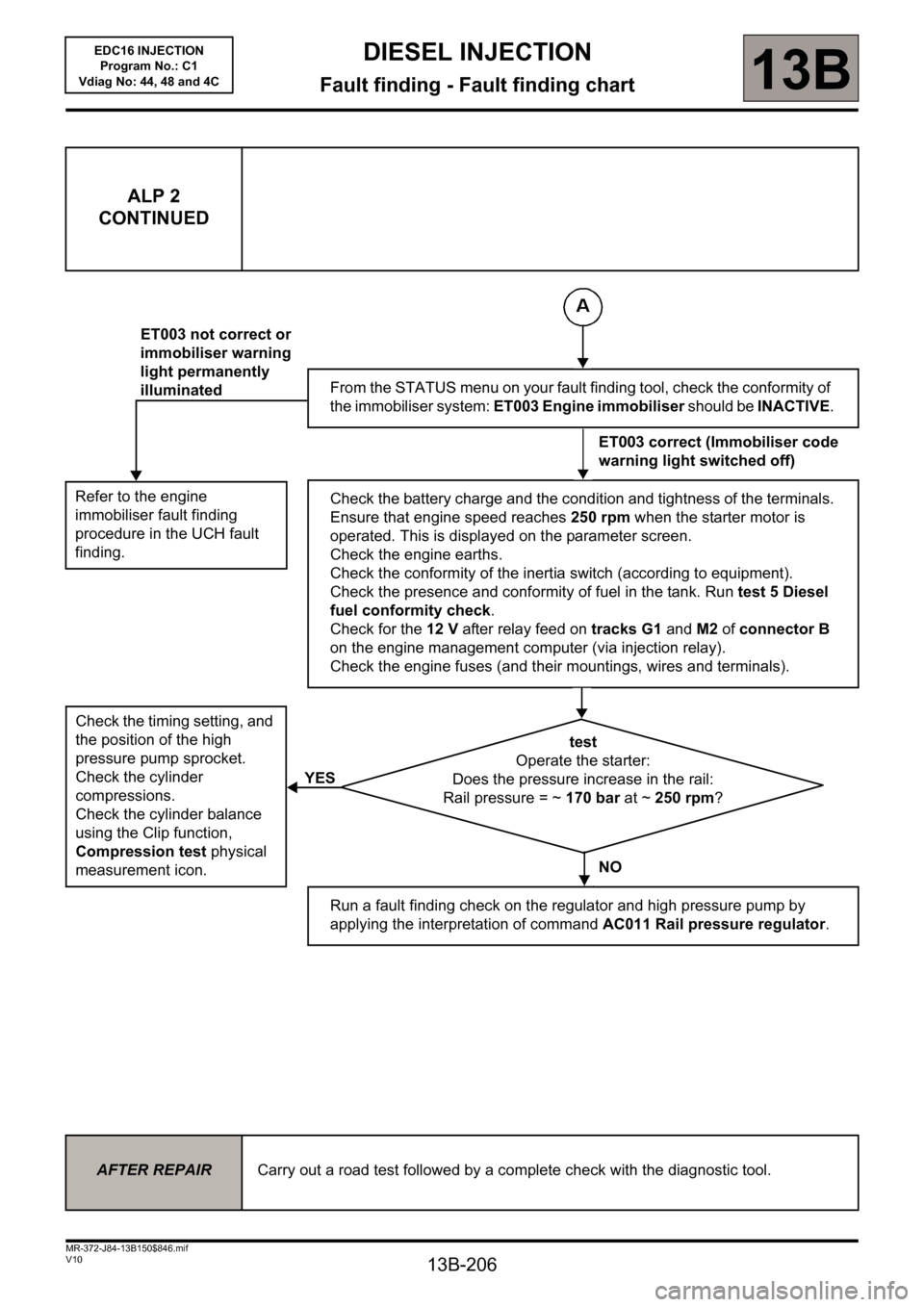

ALP 2

CONTINUED

Refer to the engine

immobiliser fault finding

procedure in the UCH fault

finding.

Check the timing setting, and

the position of the high

pressure pump sprocket.

Check the cylinder

compressions.

Check the cylinder balance

using the Clip function,

Compression test physical

measurement icon.

ET003 not correct or

immobiliser warning

light permanently

illuminated

YESFrom the STATUS menu on your fault finding tool, check the conformity of

the immobiliser system: ET003 Engine immobiliser should be INACTIVE.

ET003 correct (Immobiliser code

warning light switched off)

Check the battery charge and the condition and tightness of the terminals.

Ensure that engine speed reaches 250 rpm when the starter motor is

operated. This is displayed on the parameter screen.

Check the engine earths.

Check the conformity of the inertia switch (according to equipment).

Check the presence and conformity of fuel in the tank. Run test 5 Diesel

fuel conformity check.

Check for the 12 V after relay feed on tracks G1 and M2 of connector B

on the engine management computer (via injection relay).

Check the engine fuses (and their mountings, wires and terminals).

test

Operate the starter:

Does the pressure increase in the rail:

Rail pressure = ~ 170 bar at ~ 250 rpm?

NO

Run a fault finding check on the regulator and high pressure pump by

applying the interpretation of command AC011 Rail pressure regulator.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C