relay RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 236, PDF Size: 1.32 MB

Page 18 of 236

13B - 18

DIESEL INJECTION

Fault finding - Allocation of computer tracks13B

V10 MR-372-J84-13B150$141.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

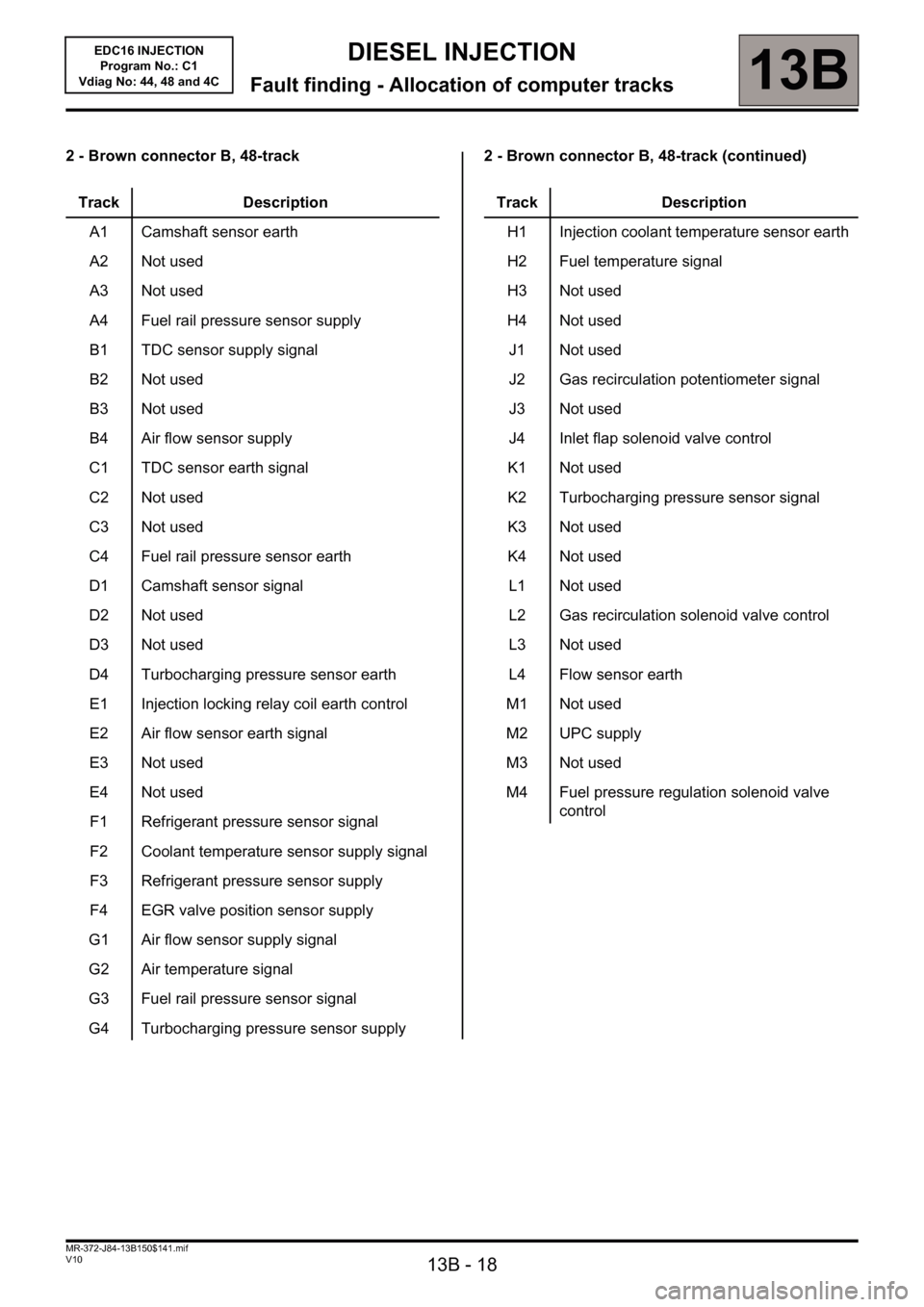

2 - Brown connector B, 48-track 2 - Brown connector B, 48-track (continued)

Track Description

A1 Camshaft sensor earth

A2 Not used

A3 Not used

A4 Fuel rail pressure sensor supply

B1 TDC sensor supply signal

B2 Not used

B3 Not used

B4 Air flow sensor supply

C1 TDC sensor earth signal

C2 Not used

C3 Not used

C4 Fuel rail pressure sensor earth

D1 Camshaft sensor signal

D2 Not used

D3 Not used

D4 Turbocharging pressure sensor earth

E1 Injection locking relay coil earth control

E2 Air flow sensor earth signal

E3 Not used

E4 Not used

F1 Refrigerant pressure sensor signal

F2 Coolant temperature sensor supply signal

F3 Refrigerant pressure sensor supply

F4 EGR valve position sensor supply

G1 Air flow sensor supply signal

G2 Air temperature signal

G3 Fuel rail pressure sensor signal

G4 Turbocharging pressure sensor supply

Track Description

H1 Injection coolant temperature sensor earth

H2 Fuel temperature signal

H3 Not used

H4 Not used

J1 Not used

J2 Gas recirculation potentiometer signal

J3 Not used

J4 Inlet flap solenoid valve control

K1 Not used

K2 Turbocharging pressure sensor signal

K3 Not used

K4 Not used

L1 Not used

L2 Gas recirculation solenoid valve control

L3 Not used

L4 Flow sensor earth

M1 Not used

M2 UPC supply

M3 Not used

M4 Fuel pressure regulation solenoid valve

control

Page 19 of 236

13B - 19

DIESEL INJECTION

Fault finding - Allocation of computer tracks13B

V10 MR-372-J84-13B150$141.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

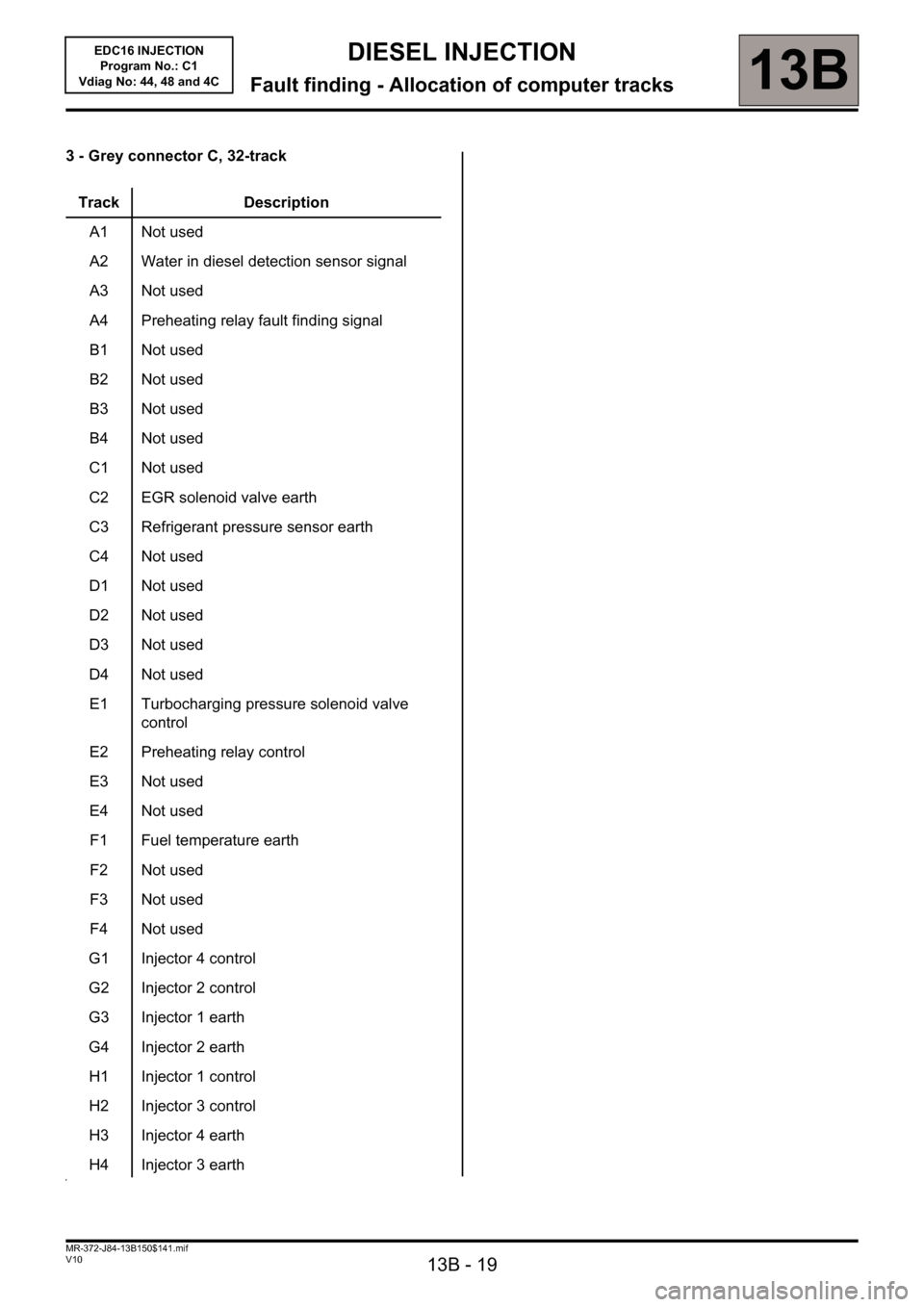

3 - Grey connector C, 32-track

Track Description

A1 Not used

A2 Water in diesel detection sensor signal

A3 Not used

A4 Preheating relay fault finding signal

B1 Not used

B2 Not used

B3 Not used

B4 Not used

C1 Not used

C2 EGR solenoid valve earth

C3 Refrigerant pressure sensor earth

C4 Not used

D1 Not used

D2 Not used

D3 Not used

D4 Not used

E1 Turbocharging pressure solenoid valve

control

E2 Preheating relay control

E3 Not used

E4 Not used

F1 Fuel temperature earth

F2 Not used

F3 Not used

F4 Not used

G1 Injector 4 control

G2 Injector 2 control

G3 Injector 1 earth

G4 Injector 2 earth

H1 Injector 1 control

H2 Injector 3 control

H3 Injector 4 earth

H4 Injector 3 earth

Page 23 of 236

13B - 23

DIESEL INJECTION

Fault finding - Fault summary table13B

V10 MR-372-J84-13B150$235.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4CDIESEL INJECTION

Fault finding - Fault summary table

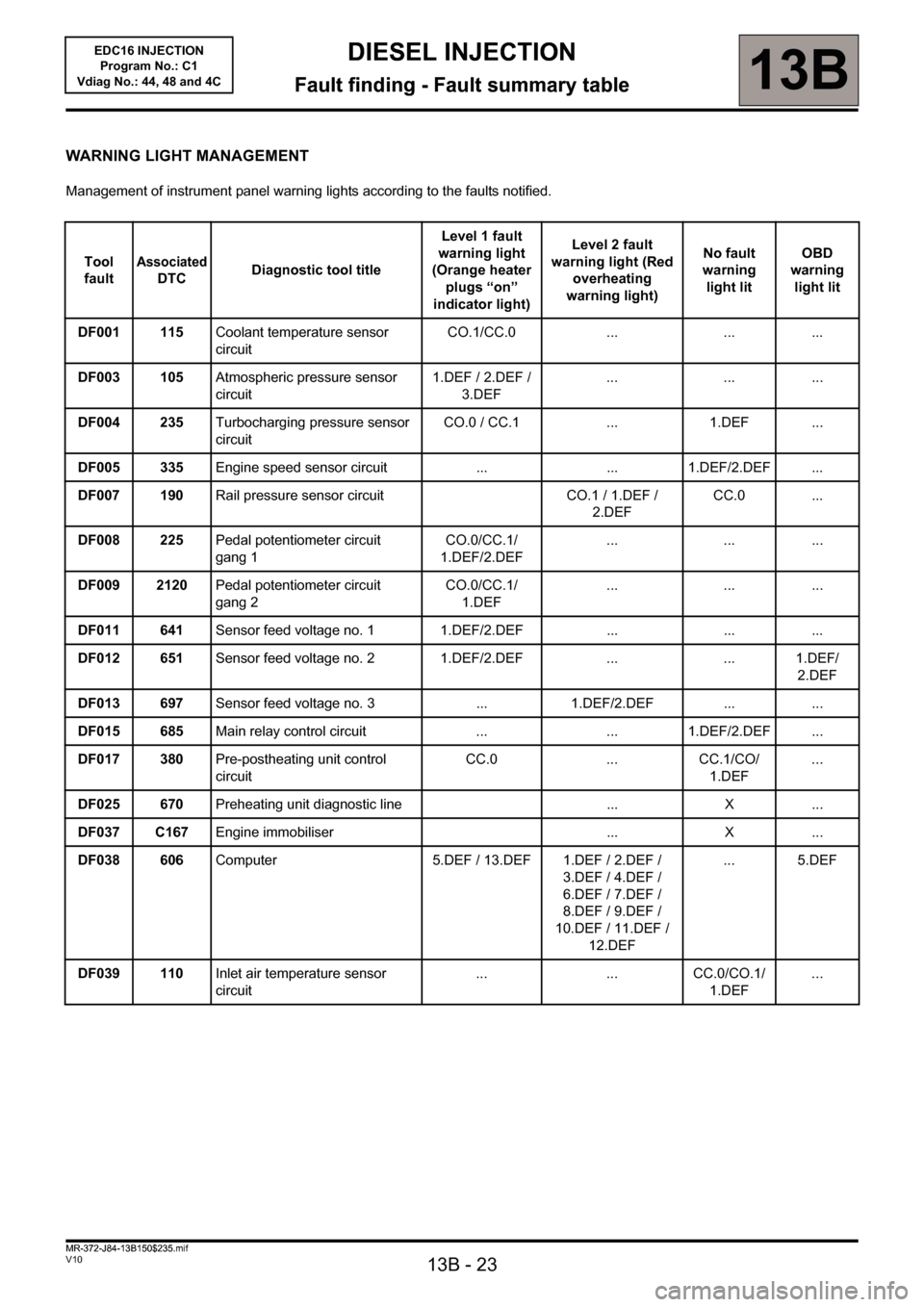

WARNING LIGHT MANAGEMENT

Management of instrument panel warning lights according to the faults notified.

Tool

fault

Associated

DTCDiagnostic tool titleLevel 1 fault

warning light

(Orange heater

plugs “on”

indicator light)Level 2 fault

warning light (Red

overheating

warning light)No fault

warning

light litOBD

warning

light lit

DF001 115Coolant temperature sensor

circuitCO.1/CC.0 ... ... ...

DF003 105Atmospheric pressure sensor

circuit1.DEF / 2.DEF /

3.DEF... ... ...

DF004 235Turbocharging pressure sensor

circuitCO.0 / CC.1 ... 1.DEF ...

DF005 335Engine speed sensor circuit ... ... 1.DEF/2.DEF ...

DF007 190Rail pressure sensor circuit CO.1 / 1.DEF /

2.DEFCC.0 ...

DF008 225Pedal potentiometer circuit

gang 1CO.0/CC.1/

1.DEF/2.DEF... ... ...

DF009 2120Pedal potentiometer circuit

gang 2CO.0/CC.1/

1.DEF... ... ...

DF011 641Sensor feed voltage no. 1 1.DEF/2.DEF ... ... ...

DF012 651Sensor feed voltage no. 2 1.DEF/2.DEF ... ... 1.DEF/

2.DEF

DF013 697Sensor feed voltage no. 3 ... 1.DEF/2.DEF ... ...

DF015 685Main relay control circuit ... ... 1.DEF/2.DEF ...

DF017 380Pre-postheating unit control

circuitCC.0 ... CC.1/CO/

1.DEF...

DF025 670Preheating unit diagnostic line ... X ...

DF037 C167Engine immobiliser ... X ...

DF038 606Computer 5.DEF / 13.DEF 1.DEF / 2.DEF /

3.DEF / 4.DEF /

6.DEF / 7.DEF /

8.DEF / 9.DEF /

10.DEF / 11.DEF /

12.DEF... 5.DEF

DF039 110Inlet air temperature sensor

circuit... ... CC.0/CO.1/

1.DEF...

MR-372-J84-13B150$235.mif

Page 45 of 236

13B-45

DIESEL INJECTION

Fault finding - Interpretation of faults13B

V10 MR-372-J84-13B150$282.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

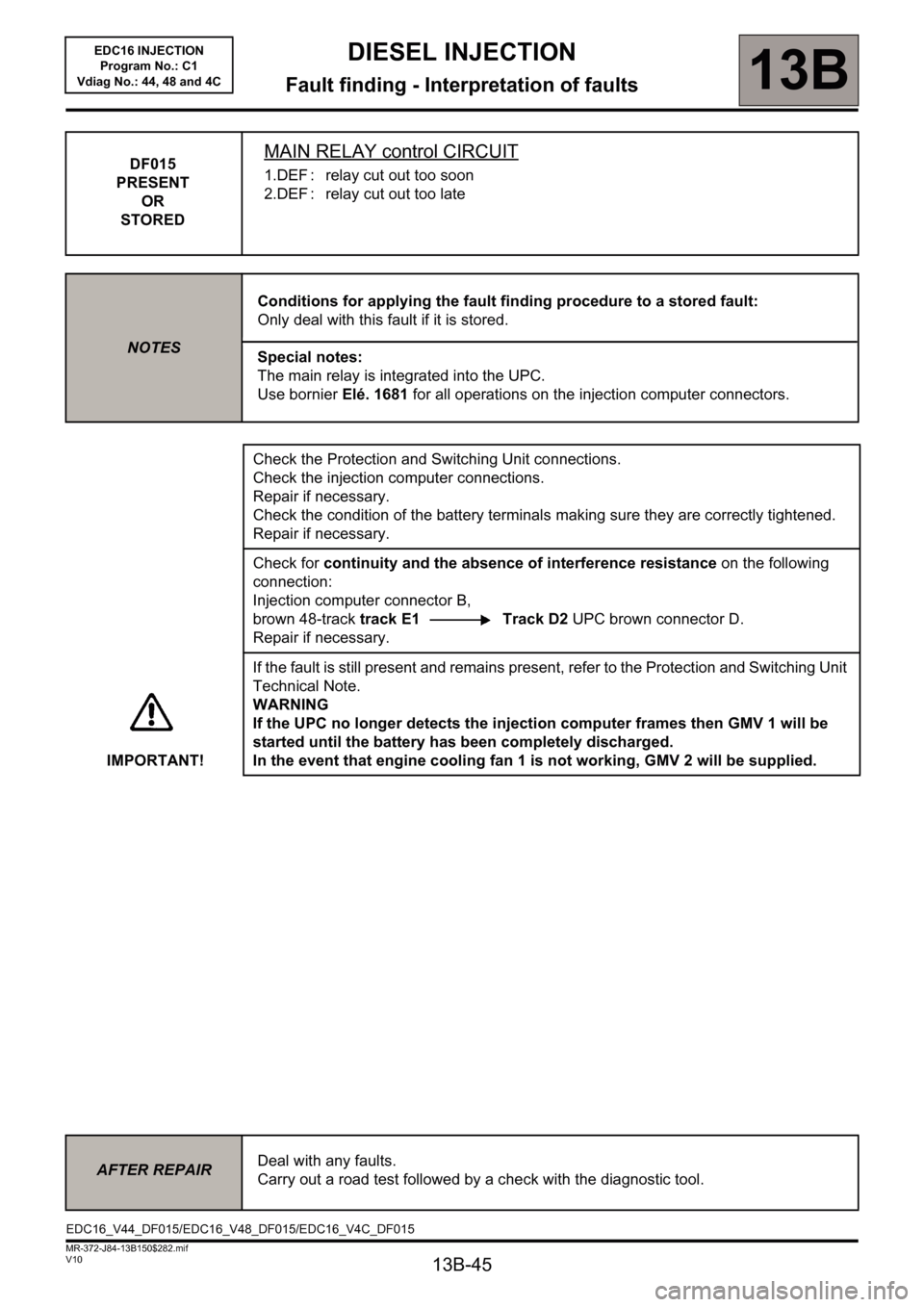

DF015

PRESENT

OR

STOREDMAIN RELAY control CIRCUIT

1.DEF : relay cut out too soon

2.DEF : relay cut out too late

NOTESConditions for applying the fault finding procedure to a stored fault:

Only deal with this fault if it is stored.

Special notes:

The main relay is integrated into the UPC.

Use bornier Elé. 1681 for all operations on the injection computer connectors.

Check the Protection and Switching Unit connections.

Check the injection computer connections.

Repair if necessary.

Check the condition of the battery terminals making sure they are correctly tightened.

Repair if necessary.

Check for continuity and the absence of interference resistance on the following

connection:

Injection computer connector B,

brown 48-track track E1 Track D2 UPC brown connector D.

Repair if necessary.

IMPORTANT!If the fault is still present and remains present, refer to the Protection and Switching Unit

Technical Note.

WARNING

If the UPC no longer detects the injection computer frames then GMV 1 will be

started until the battery has been completely discharged.

In the event that engine cooling fan 1 is not working, GMV 2 will be supplied.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by a check with the diagnostic tool.

EDC16_V44_DF015/EDC16_V48_DF015/EDC16_V4C_DF015

Page 48 of 236

13B-48

DIESEL INJECTION

Fault finding - Interpretation of faults13B

V10 MR-372-J84-13B150$282.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

DF025

PRESENT

OR

STOREDPRE-POSTHEATING UNIT DIAGNOSTIC LINE

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after several attempts to start the engine, or following

actuator command AC001 Preheating unit.

Special notes:

It is difficult or even impossible to start the engine when cold.

Use bornier Elé. 1681 for all operations on the injection computer connectors.

Check the pre-postheating unit connections.

Check the connections on all the heater plugs.

Repair if necessary.

Check the resistance of the heater plugs:

Replace any plug whose resistance is not below 2Ω at + 20°C.

Check the continuity and absence of interference resistance of the following connections:

– Preheating unit track 1 Heater plug of cylinder 3

– Preheating unit track 2 Heater plug of cylinder 4

– Preheating unit track 6Heater plug of cylinder 1

– Preheating unit track 7 Heater plug of cylinder 2

Check for the presence of +12V battery on track 3 of the preheating relay (via maxi fuse).

Check the engine earthing.

If the fault is still present,

Check the injection computer connections.

Check for continuity and the absence of interference resistance on the following connection:

Injection computer, grey 32-track connector C, track A4 Track 9 preheating unit connector

If the fault is still present, replace the pre-postheating unit.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by a check with the diagnostic tool.

EDC16_V44_DF025/EDC16_V48_DF025/EDC16_V4C_DF025

Page 60 of 236

13B-60

DIESEL INJECTION

Fault finding - Interpretation of faults13B

V10 MR-372-J84-13B150$329.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

DF047

PRESENT

OR

STOREDCOMPUTER SUPPLY VOLTAGE

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after several starting attempts, or with the engine running.

Special notes:

Computer operating voltage: 9 V < operating voltage < 16 V.

If the battery voltage is too low this may cause the level 1 fault warning light to

come on.

It is then not possible to start the engine.

Use bornier Elé. 1681 for all operations on the injection computer connectors.

Check for continuity and the absence of interference resistance on the following connection:

Injection computer connector A, black 32-track track D1 Track 1 black connector of the UPC

Repair if necessary.

Check the condition of the FD5 fuse on the UPC (poor contact, or oxidation on the relay mounting clips).

Repair if necessary.

If the fault does not recur, start the engine and wait 1 min.

Carry out a road test and check the system faults.

If there are no faults, fault finding is complete.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by a check with the diagnostic tool.

EDC16_V44_DF047/EDC16_V48_DF047/EDC16_V4C_DF047

Page 64 of 236

13B-64

DIESEL INJECTION

Fault finding - Interpretation of faults13B

V10 MR-372-J84-13B150$329.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

DF050

CONTINUED

2.DEF

NOTESNone.

Check the brake pedal switch connections.

Check the condition and adjustment of the brake pedal switch.

Repair if necessary.

Check the conformity of the brake switch:

Brake pedal released: continuity between tracks 3 and 4

infinite resistance across tracks 1 and 2

Brake pedal depressed: infinite resistance between tracks 3 and 4

continuity between tracks 1 and 2.

Replace the switch if necessary.

Check the condition of the 1H 15A fuse on the passenger compartment fuse and relay board.

Replace the fuse if necessary.

Check the following switch supplies:

+ 12 V after ignition Track 2 of the brake pedal switch connector

+ 12 V battery Track 4 of the brake pedal switch connector (via the UCH)

Replace the switch if necessary.

Check the continuity and insulation of the following connection:

Injection computer black 32-track connector A, track E4 Track 3 brake pedal switch

connector

Repair if necessary.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by a check with the diagnostic tool.

Page 67 of 236

13B-67

DIESEL INJECTION

Fault finding - Interpretation of faults13B

V10 MR-372-J84-13B150$329.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

DF053

CONTINUED 1

CC.0

CO

NOTESNone.

Check the fuel flow regulator connections.

Check the injection computer connections.

Check the low pressure circuit.

Check the conformity of the fuel used, apply test 5 Diesel fuel conformity check.

Check the injector return flow, run test 1 Injector test.

Check the operation of the overpressure valve if fitted to the vehicle, run test 6 Incorrect operation of the

overpressure valve.

Repair if necessary.

Measure the resistance of the flow regulator between tracks 1 and 2.

If the resistance is not 3Ω ±1 at 20°C, replace the injection pump.

Check the continuity and insulation from earth of the following connection:

Injection computer brown 48-track connector B, track M4 Track 2 of the fuel flow regulator

With the ignition on, check for + 12 V after relay feed on track 1 of the fuel flow regulator.

If the fault is still present, replace the injection pump.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

Page 85 of 236

13B-85

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

V10 MR-372-J84-13B150$376.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

DF097

PRESENT

OR

STOREDCAMSHAFT SENSOR CIRCUIT

1.DEF : no signal

2.DEF : inconsistent signal

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault declared present before an attempt is made to start the engine it will not be

possible to start the engine.

Use bornier Ele. 1681 for all operations on the injection computer connectors.

1.DEF

2.DEF

NOTESPriority when dealing with a number of faults:

In the event of more than one fault:

–DF056 Air flow sensor circuit,

–DF057 Water in diesel fuel detector circuit,

–DF067 Damper control circuit,

Check the conformity of the + 12 V after relay supply line,

from track 2 of the UPC PPM1 connector.

(Use the Wiring Diagrams Technical Note for the vehicle).

Check the camshaft sensor connectors,

Check the injection computer connections.

Check that the camshaft sensor is correctly positioned and mounted.

Also check the general condition (damaged housing, heating up, etc.).

Carry out the necessary repairs.

Check the continuity and absence of interference resistance of the following connections:

Injection computer brown 48-track connector B, track D1 Track 2 Camshaft sensor

Injection computer brown 48-track connector B, track A1 Track 1 Camshaft sensor

Repair if necessary.

Check the camshaft sensor resistance between tracks 2 and 3.

If the resistance is not 10250Ω ±500 at 20°C, replace the sensor.

AFTER REPAIRDeal with any faults.

Carry out a road test, then check with the diagnostic tool.

EDC16_V44_DF097/EDC16_V48_DF097/EDC16_V4C_DF097

Page 100 of 236

13B-100

DIESEL INJECTION

Fault finding - Interpretation of faults

13B

V10 MR-372-J84-13B150$376.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

DF272

CONTINUED 1

CC.0

CO

NOTESSpecial notes:

If fault DF209 EGR valve position sensor circuit CO.0 is

present at the same time, check that the EGR valve

connector is properly connected.

Check the EGR valve connections.

Check the injection computer connections.

Repair if necessary.

Measure the resistance of the EGR solenoid valve between tracks 1 and 5.

If the resistance measured is not 8Ω ± 0.5 at 20°C, replace the EGR valve.

Check the continuity and insulation against earth of the following connections:

Injection computer brown 48-track connector B, track L2 Track 5 of the EGR valve

UPC black PPM1 connector track 1 Track 1 of the EGR valve

Check for + 12 V after relay (UPC) on track 1 of the EGR valve.

If there is not + 12 V on track 1, refer to the UPC fault finding note.

If the fault is still present, replace the EGR valve

AFTER REPAIRDeal with any faults.

Carry out a road test, then check with the diagnostic tool.