coolant temperature RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Injection Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 236, PDF Size: 1.32 MB

Page 181 of 236

13B - 181

DIESEL INJECTION

Fault finding - Parameter summary table13B

V10 MR-372-J84-13B150$611.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

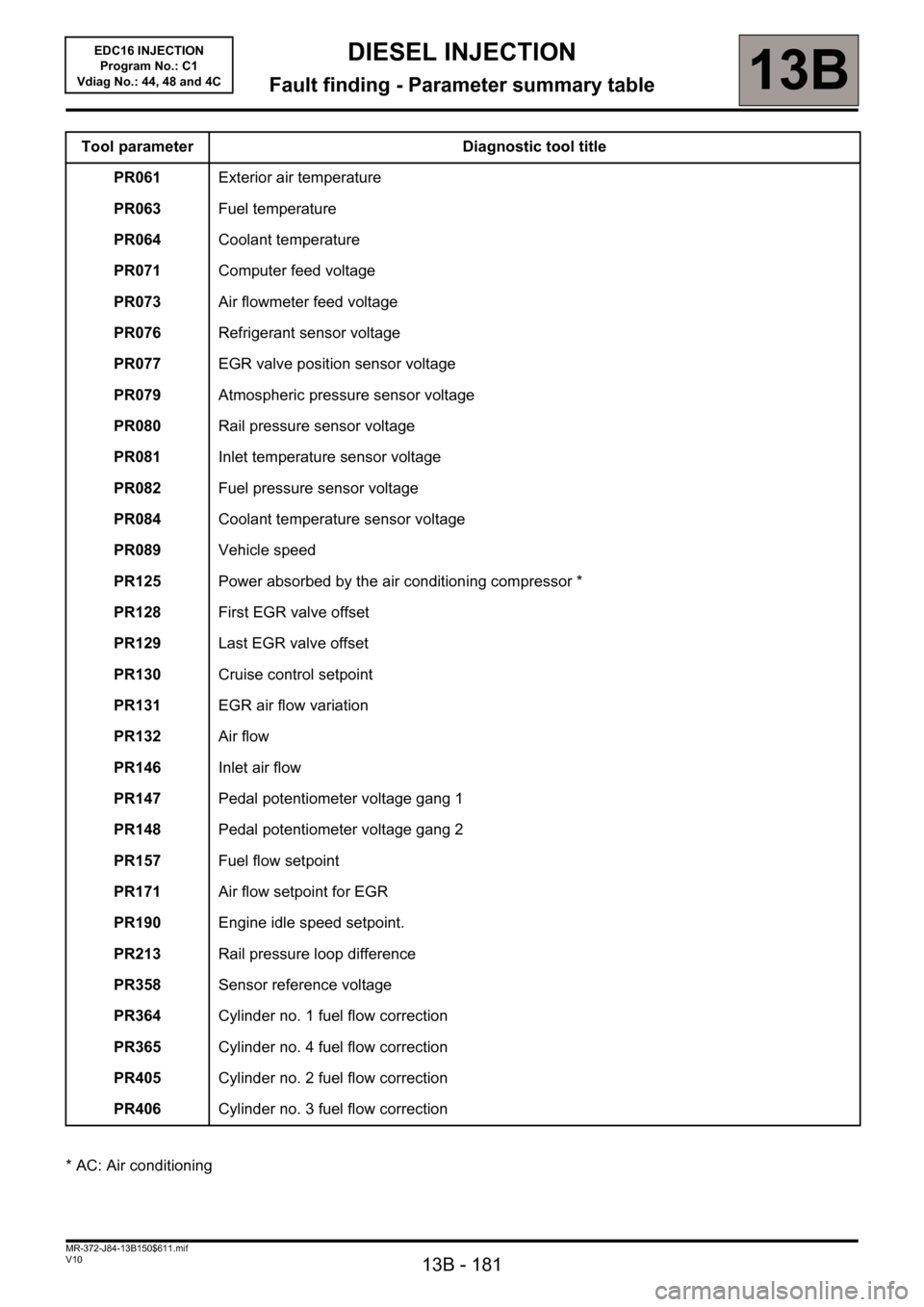

Tool parameter Diagnostic tool title

PR061Exterior air temperature

PR063Fuel temperature

PR064Coolant temperature

PR071Computer feed voltage

PR073Air flowmeter feed voltage

PR076Refrigerant sensor voltage

PR077EGR valve position sensor voltage

PR079Atmospheric pressure sensor voltage

PR080Rail pressure sensor voltage

PR081Inlet temperature sensor voltage

PR082Fuel pressure sensor voltage

PR084Coolant temperature sensor voltage

PR089Vehicle speed

PR125Power absorbed by the air conditioning compressor *

PR128First EGR valve offset

PR129Last EGR valve offset

PR130Cruise control setpoint

PR131EGR air flow variation

PR132Air flow

PR146Inlet air flow

PR147Pedal potentiometer voltage gang 1

PR148Pedal potentiometer voltage gang 2

PR157Fuel flow setpoint

PR171Air flow setpoint for EGR

PR190Engine idle speed setpoint.

PR213Rail pressure loop difference

PR358Sensor reference voltage

PR364Cylinder no. 1 fuel flow correction

PR365Cylinder no. 4 fuel flow correction

PR405Cylinder no. 2 fuel flow correction

PR406Cylinder no. 3 fuel flow correction

* AC: Air conditioning

Page 185 of 236

13B - 185

DIESEL INJECTION

Fault finding - Interpretation of parameters13B

V10 MR-372-J84-13B150$658.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

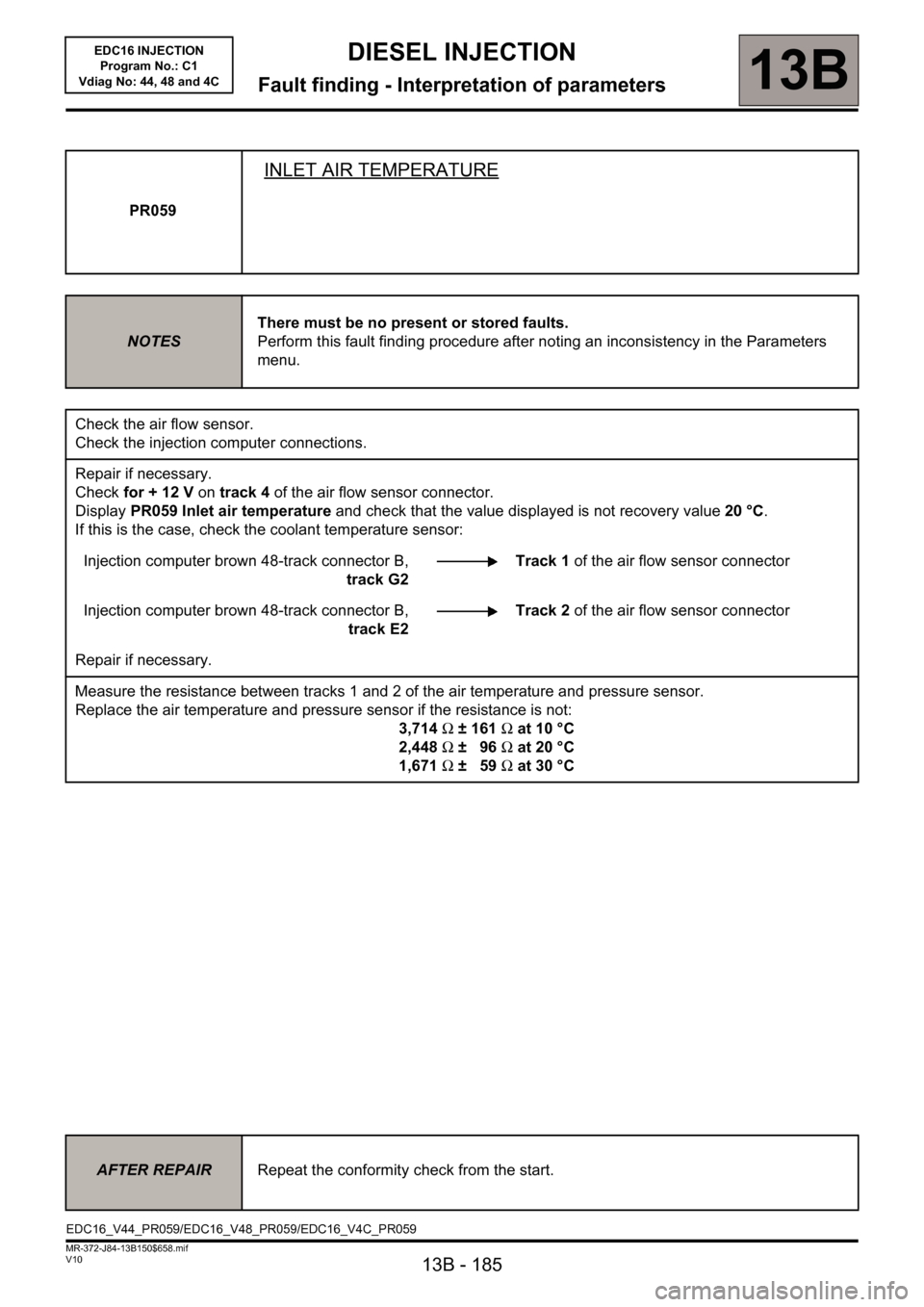

PR059

INLET AIR TEMPERATURE

NOTESThere must be no present or stored faults.

Perform this fault finding procedure after noting an inconsistency in the Parameters

menu.

Check the air flow sensor.

Check the injection computer connections.

Repair if necessary.

Check for + 12 V on track 4 of the air flow sensor connector.

Display PR059 Inlet air temperature and check that the value displayed is not recovery value 20 °C.

If this is the case, check the coolant temperature sensor:

Injection computer brown 48-track connector B,

track G2Track 1 of the air flow sensor connector

Injection computer brown 48-track connector B,

track E2Track 2 of the air flow sensor connector

Repair if necessary.

Measure the resistance between tracks 1 and 2 of the air temperature and pressure sensor.

Replace the air temperature and pressure sensor if the resistance is not:

3,714Ω ±161Ω at 10 °C

2,448Ω ±96Ω at 20 °C

1,671Ω ±59Ω at 30 °C

AFTER REPAIRRepeat the conformity check from the start.

EDC16_V44_PR059/EDC16_V48_PR059/EDC16_V4C_PR059

Page 187 of 236

13B - 187

DIESEL INJECTION

Fault finding - Interpretation of parameters13B

V10 MR-372-J84-13B150$658.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

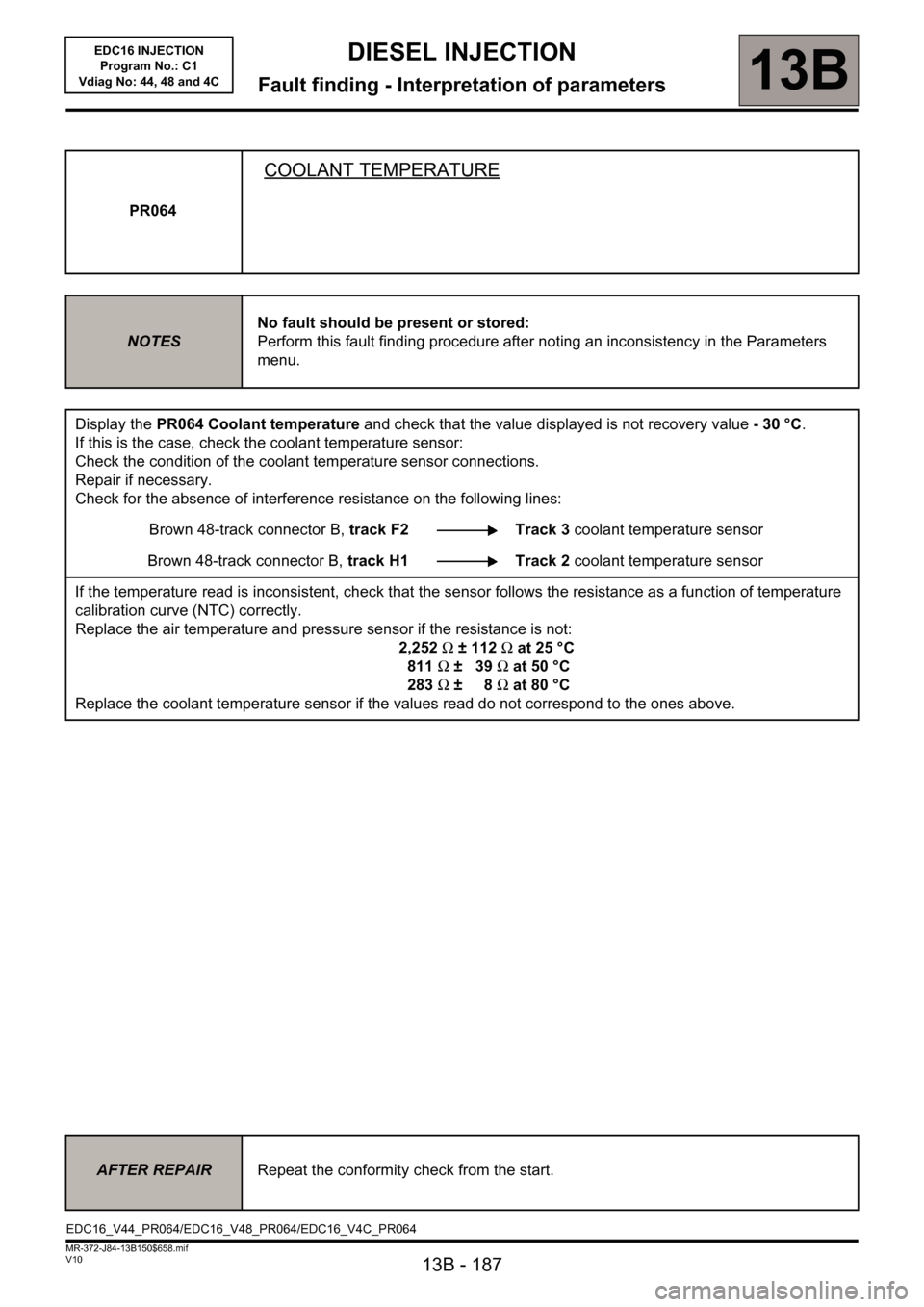

PR064

COOLANT TEMPERATURE

NOTESNo fault should be present or stored:

Perform this fault finding procedure after noting an inconsistency in the Parameters

menu.

Display the PR064 Coolant temperature and check that the value displayed is not recovery value -30°C.

If this is the case, check the coolant temperature sensor:

Check the condition of the coolant temperature sensor connections.

Repair if necessary.

Check for the absence of interference resistance on the following lines:

Brown 48-track connector B, track F2 Track 3 coolant temperature sensor

Brown 48-track connector B, track H1 Track 2 coolant temperature sensor

If the temperature read is inconsistent, check that the sensor follows the resistance as a function of temperature

calibration curve (NTC) correctly.

Replace the air temperature and pressure sensor if the resistance is not:

2,252Ω ± 112Ω at 25 °C

811Ω ±39Ω at 50 °C

283Ω ±8Ω at 80 °C

Replace the coolant temperature sensor if the values read do not correspond to the ones above.

AFTER REPAIRRepeat the conformity check from the start.

EDC16_V44_PR064/EDC16_V48_PR064/EDC16_V4C_PR064

Page 205 of 236

13B-205

MR-372-J84-13B150$846.mif

V10

DIESEL INJECTION

Fault finding - Fault finding chart13B

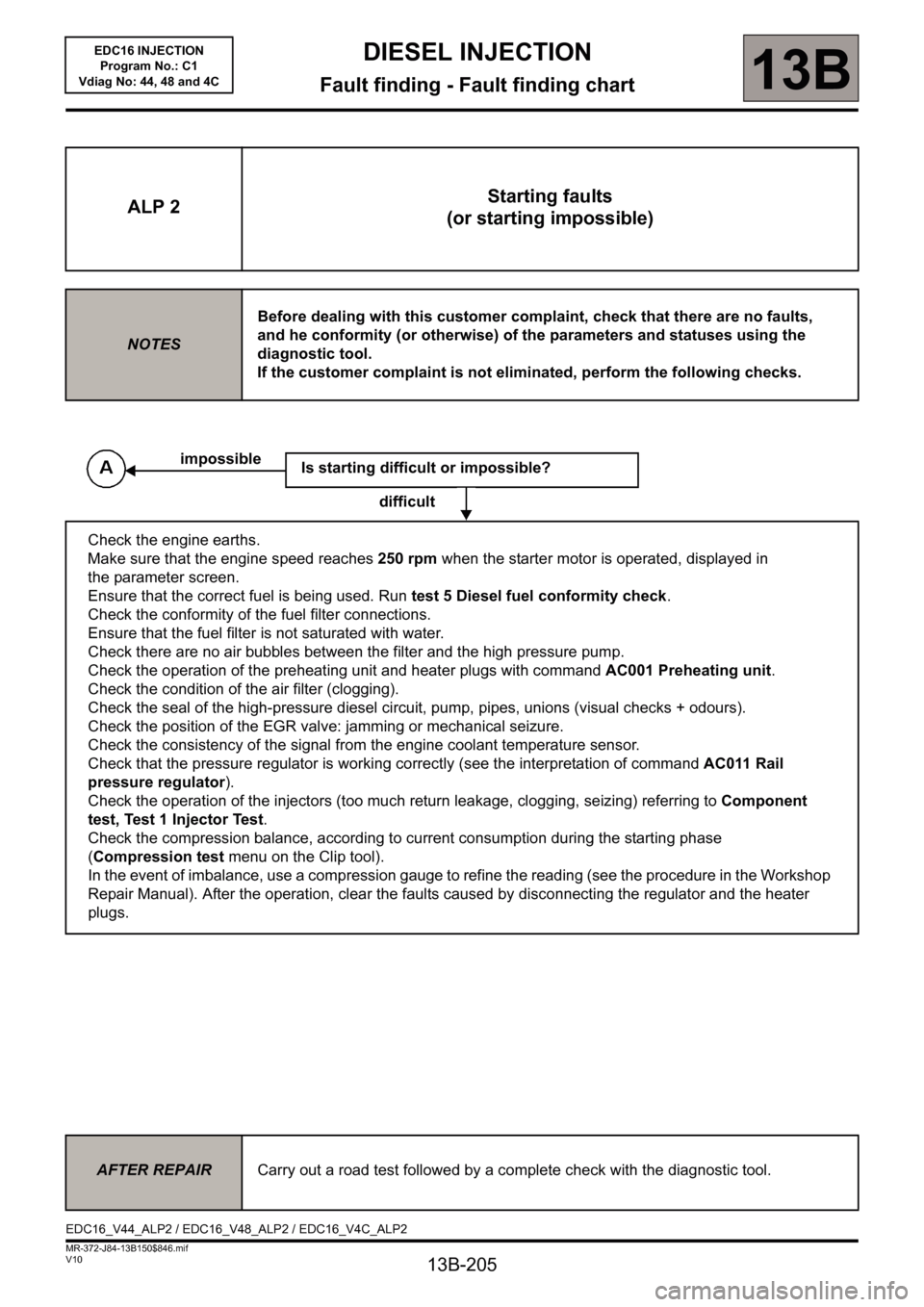

ALP 2Starting faults

(or starting impossible)

NOTESBefore dealing with this customer complaint, check that there are no faults,

and he conformity (or otherwise) of the parameters and statuses using the

diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

Is starting difficult or impossible?

difficult

Check the engine earths.

Make sure that the engine speed reaches 250 rpm when the starter motor is operated, displayed in

the parameter screen.

Ensure that the correct fuel is being used. Run test 5 Diesel fuel conformity check.

Check the conformity of the fuel filter connections.

Ensure that the fuel filter is not saturated with water.

Check there are no air bubbles between the filter and the high pressure pump.

Check the operation of the preheating unit and heater plugs with command AC001 Preheating unit.

Check the condition of the air filter (clogging).

Check the seal of the high-pressure diesel circuit, pump, pipes, unions (visual checks + odours).

Check the position of the EGR valve: jamming or mechanical seizure.

Check the consistency of the signal from the engine coolant temperature sensor.

Check that the pressure regulator is working correctly (see the interpretation of command AC011 Rail

pressure regulator).

Check the operation of the injectors (too much return leakage, clogging, seizing) referring to Component

test, Test 1 Injector Test.

Check the compression balance, according to current consumption during the starting phase

(Compression test menu on the Clip tool).

In the event of imbalance, use a compression gauge to refine the reading (see the procedure in the Workshop

Repair Manual). After the operation, clear the faults caused by disconnecting the regulator and the heater

plugs.

impossible

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V44_ALP2 / EDC16_V48_ALP2 / EDC16_V4C_ALP2

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

Page 208 of 236

13B-208

MR-372-J84-13B150$846.mif

V10

DIESEL INJECTION

Fault finding - Fault finding chart13B

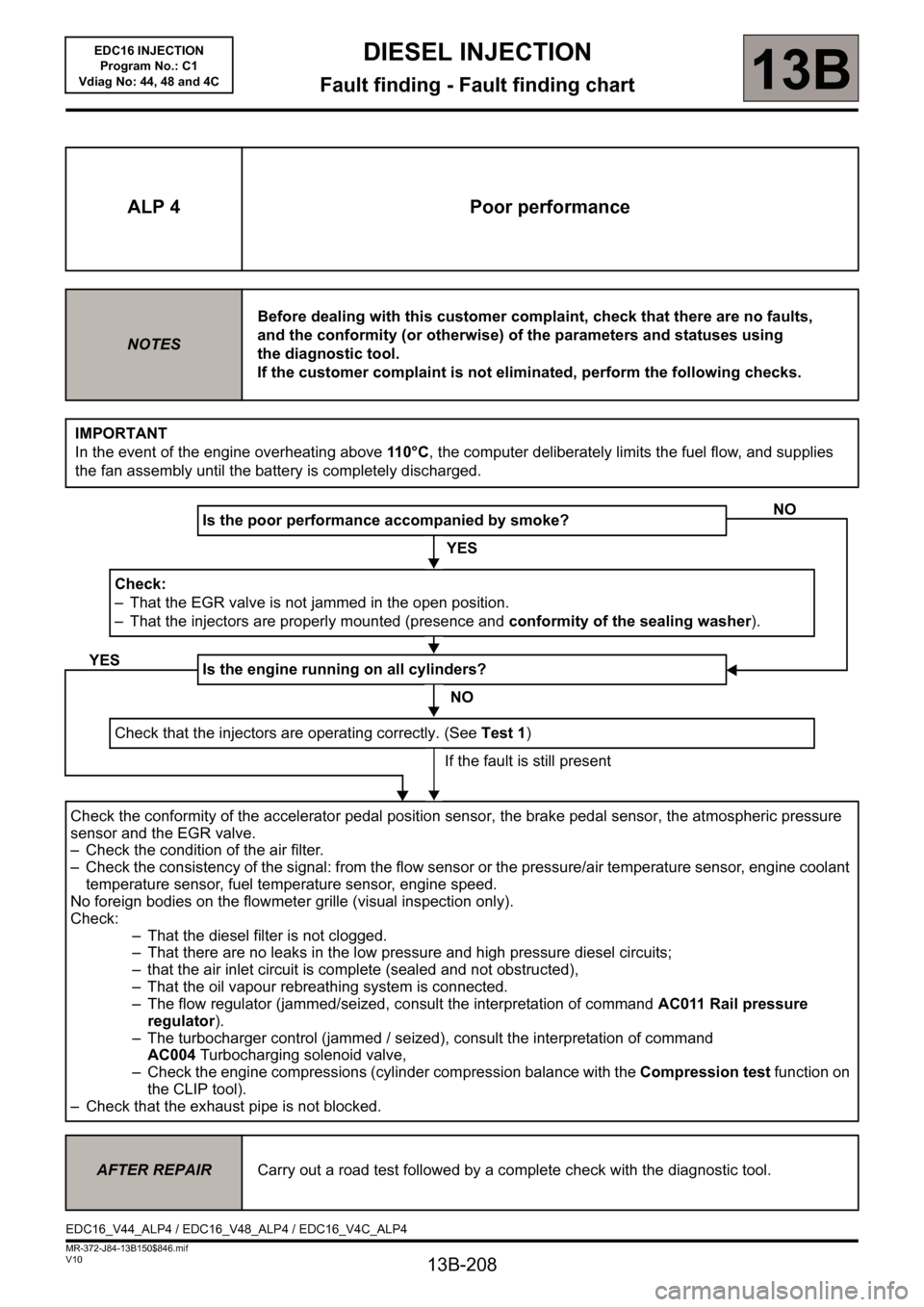

ALP 4 Poor performance

NOTESBefore dealing with this customer complaint, check that there are no faults,

and the conformity (or otherwise) of the parameters and statuses using

the diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT

In the event of the engine overheating above 11 0 ° C, the computer deliberately limits the fuel flow, and supplies

the fan assembly until the battery is completely discharged.

Is the poor performance accompanied by smoke?

YES

Check:

– That the EGR valve is not jammed in the open position.

– That the injectors are properly mounted (presence and conformity of the sealing washer).

Is the engine running on all cylinders?

NO

Check that the injectors are operating correctly. (See Test 1)

If the fault is still present

Check the conformity of the accelerator pedal position sensor, the brake pedal sensor, the atmospheric pressure

sensor and the EGR valve.

– Check the condition of the air filter.

– Check the consistency of the signal: from the flow sensor or the pressure/air temperature sensor, engine coolant

temperature sensor, fuel temperature sensor, engine speed.

No foreign bodies on the flowmeter grille (visual inspection only).

Check:

– That the diesel filter is not clogged.

– That there are no leaks in the low pressure and high pressure diesel circuits;

– that the air inlet circuit is complete (sealed and not obstructed),

– That the oil vapour rebreathing system is connected.

– The flow regulator (jammed/seized, consult the interpretation of command AC011 Rail pressure

regulator).

– The turbocharger control (jammed / seized), consult the interpretation of command

AC004Turbocharging solenoid valve,

– Check the engine compressions (cylinder compression balance with the Compression test function on

the CLIP tool).

– Check that the exhaust pipe is not blocked.

NO

YES

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V44_ALP4 / EDC16_V48_ALP4 / EDC16_V4C_ALP4

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

Page 236 of 236

13B-236

DIESEL INJECTION

Fault finding - Glossary13B

V10 MR-372-J84-13B150$940.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4CDIESEL INJECTION

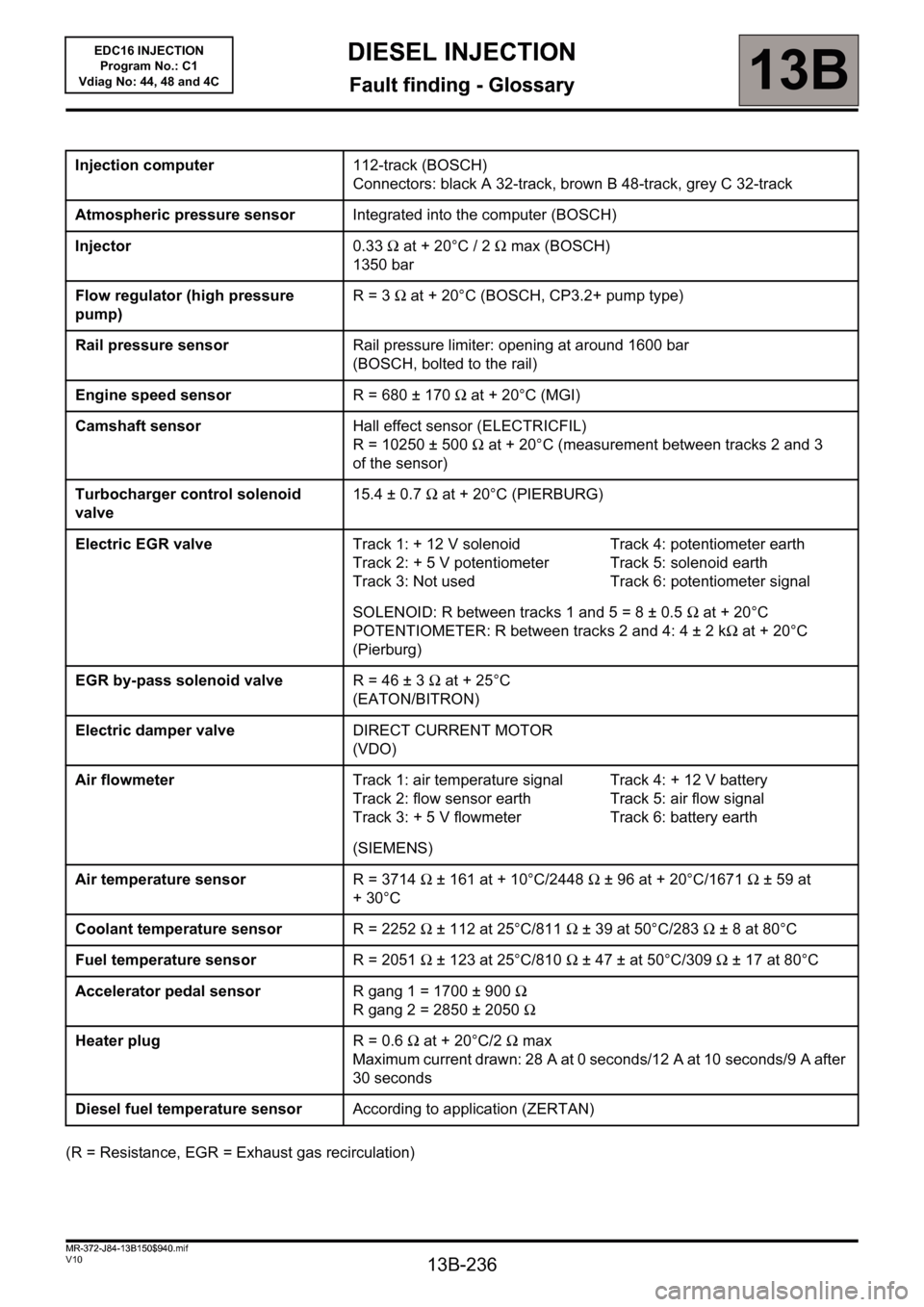

Fault finding - Glossary

(R = Resistance, EGR = Exhaust gas recirculation)Injection computer112-track (BOSCH)

Connectors: black A 32-track, brown B 48-track, grey C 32-track

Atmospheric pressure sensorIntegrated into the computer (BOSCH)

Injector0.33Ω at + 20°C / 2Ω max (BOSCH)

1350 bar

Flow regulator (high pressure

pump)R= 3Ω at + 20°C (BOSCH, CP3.2+ pump type)

Rail pressure sensorRail pressure limiter: opening at around 1600 bar

(BOSCH, bolted to the rail)

Engine speed sensorR = 680 ± 170Ω at + 20°C (MGI)

Camshaft sensorHall effect sensor (ELECTRICFIL)

R = 10250 ± 500Ω at + 20°C (measurement between tracks 2 and 3

of the sensor)

Turbocharger control solenoid

valve15.4 ± 0.7Ω at + 20°C (PIERBURG)

Electric EGR valveTrack 1: + 12 V solenoid

Track 2: + 5 V potentiometer

Track 3: Not usedTrack 4: potentiometer earth

Track 5: solenoid earth

Track 6: potentiometer signal

SOLENOID: R between tracks 1 and 5 = 8 ± 0.5Ω at + 20°C

POTENTIOMETER: R between tracks 2 and 4: 4 ± 2 kΩ at + 20°C

(Pierburg)

EGR by-pass solenoid valveR= 46 ±3Ω at + 25°C

(EATON/BITRON)

Electric damper valveDIRECT CURRENT MOTOR

(VDO)

Air flowmeterTrack 1: air temperature signal

Track 2: flow sensor earth

Track 3: + 5 V flowmeterTrack 4: + 12 V battery

Track 5: air flow signal

Track 6: battery earth

(SIEMENS)

Air temperature sensorR = 3714Ω ± 161 at + 10°C/2448Ω ± 96 at + 20°C/1671Ω ± 59 at

+30°C

Coolant temperature sensorR = 2252Ω ± 112 at 25°C/811Ω ± 39 at 50°C/283Ω ±8 at 80°C

Fuel temperature sensorR = 2051Ω ± 123 at 25°C/810Ω ± 47 ± at 50°C/309Ω ± 17 at 80°C

Accelerator pedal sensorR gang 1 = 1700 ± 900Ω

R gang 2 = 2850 ± 2050Ω

Heater plugR= 0.6Ω at + 20°C/2Ω max

Maximum current drawn: 28 A at 0 seconds/12 A at 10 seconds/9 A after

30 seconds

Diesel fuel temperature sensorAccording to application (ZERTAN)

MR-372-J84-13B150$940.mif