alternator RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 236, PDF Size: 1.32 MB

Page 8 of 236

13B - 8

DIESEL INJECTION

Fault finding - Introduction13B

V10 MR-372-J84-13B150$047.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

Instructions to be followed before any work is carried out on the injection system:

Protect the accessories and timing belts, the electrical accessories (starter, alternator, electric power-assisted

steering pump) and the mating face to prevent diesel fuel spilling onto the clutch friction plate.

Check that you have plugs for the unions to be opened (set of plugs available from the Parts Department). The plugs

are single-use only. After use, they must be discarded (once used they are soiled and cleaning is not sufficient to

make them reusable). Unused plugs must be discarded.

Ensure that you have hermetically resealable plastic bags for storing removed parts. There is less risk of parts

stored in this way being exposed to contamination. These are single-use bags; after use they must be discarded.

Use lint-free cleaning cloths (part no. 77 11 211 707). Using normal cloth or paper is prohibited. They are not lint-free

and could contaminate the fuel circuit. Each cloth should only be used once.

Use fresh cleaning agent for each operation (used cleaning agent is contaminated). Pour it into an uncontaminated

container.

For each operation, use a clean brush in good condition (the brush must not shed its bristles).

Use a brush and cleaning agent to clean the unions to be opened.

Blast compressed air over the cleaned parts (tools, workbench, and the parts, unions and injection system area).

Check that no bristles remain.

Wash your hands before and during the operation if necessary.

When wearing leather protective gloves cover them with latex gloves to prevent contamination.

Instructions to be followed during the operation

As soon as the circuit is open, all openings must be plugged to prevent impurities from entering the system. The

plugs to be used are available from the Parts Department. They must not be reused under any circumstances.

Close the hermetically sealed bag, even if it has to be reopened shortly afterwards. Ambient air carries impurities.

All components removed from the injection system must be stored in a hermetically sealed plastic bag once they

have been plugged.

Using a brush, thinner, air gun, rifle-type brush or normal rag is strictly prohibited once the circuit has been opened.

These items are likely to allow impurities to enter the system.

If a component is being replaced with a new component, do not remove the packaging until it is ready to be fitted to

the vehicle.

Page 51 of 236

DIESEL INJECTION

Fault finding - Interpretation of faults13B

13B-51V10 MR-372-J84-13B150$282.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

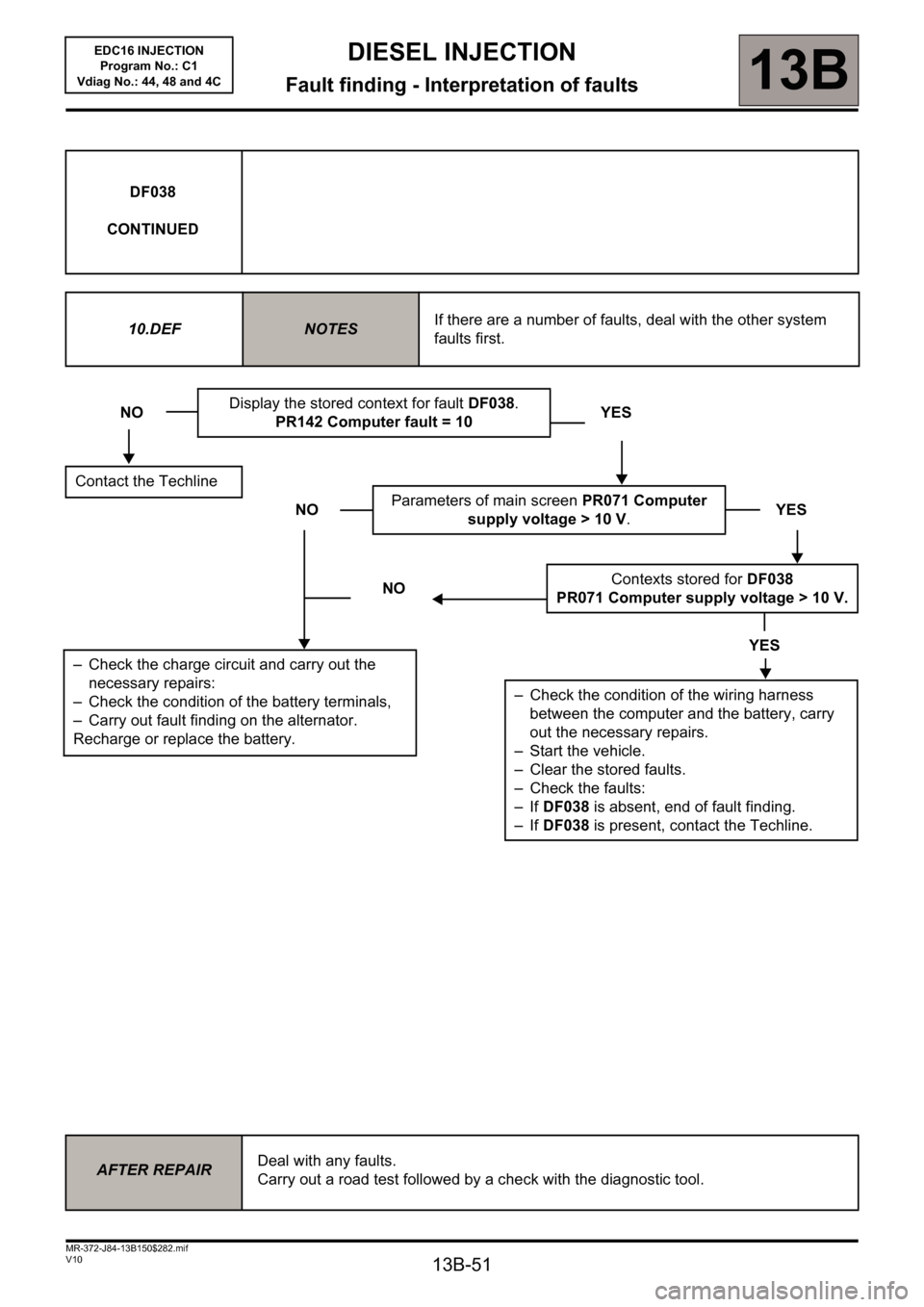

DF038

CONTINUED

10.DEF

NOTESIf there are a number of faults, deal with the other system

faults first.

NODisplay the stored context for fault DF038.

PR142 Computer fault = 10YES

Contact the Techline

NOParameters of main screen PR071 Computer

supply voltage > 10 V.YES

NOContexts stored for DF038

PR071 Computer supply voltage > 10 V.

YES

– Check the condition of the wiring harness

between the computer and the battery, carry

out the necessary repairs.

– Start the vehicle.

– Clear the stored faults.

– Check the faults:

– If DF038 is absent, end of fault finding.

– If DF038 is present, contact the Techline.

– Check the charge circuit and carry out the

necessary repairs:

– Check the condition of the battery terminals,

– Carry out fault finding on the alternator.

Recharge or replace the battery.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by a check with the diagnostic tool.

Page 59 of 236

13B-59

DIESEL INJECTION

Fault finding - Interpretation of faults13B

V10 MR-372-J84-13B150$329.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4C

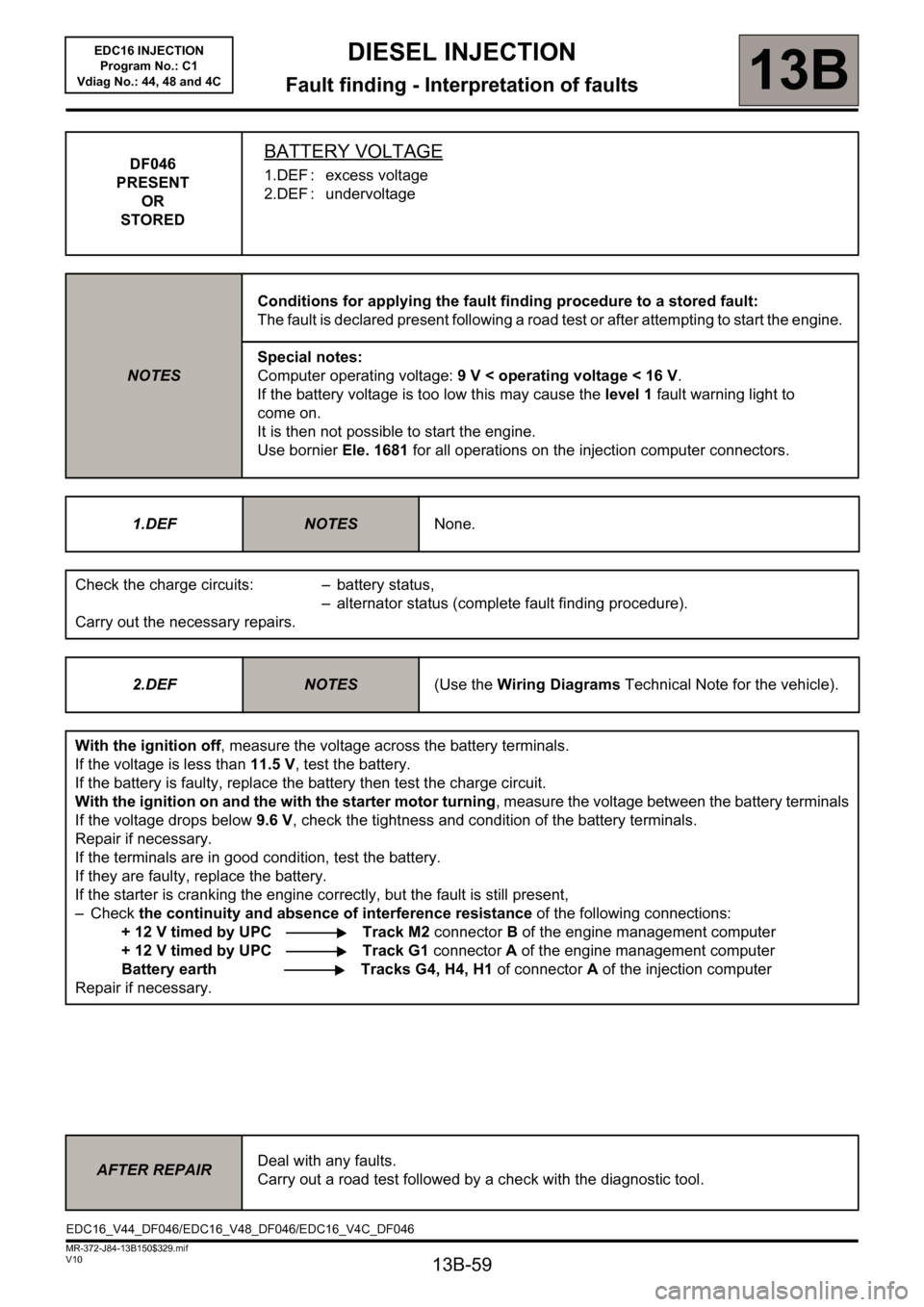

DF046

PRESENT

OR

STOREDBATTERY VOLTAGE

1.DEF : excess voltage

2.DEF : undervoltage

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present following a road test or after attempting to start the engine.

Special notes:

Computer operating voltage: 9 V < operating voltage < 16 V.

If the battery voltage is too low this may cause the level 1 fault warning light to

come on.

It is then not possible to start the engine.

Use bornier Ele. 1681 for all operations on the injection computer connectors.

1.DEF

NOTESNone.

Check the charge circuits: – battery status,

– alternator status (complete fault finding procedure).

Carry out the necessary repairs.

2.DEF

NOTES(Use the Wiring Diagrams Technical Note for the vehicle).

With the ignition off, measure the voltage across the battery terminals.

If the voltage is less than 11.5 V, test the battery.

If the battery is faulty, replace the battery then test the charge circuit.

With the ignition on and the with the starter motor turning, measure the voltage between the battery terminals

If the voltage drops below 9.6 V, check the tightness and condition of the battery terminals.

Repair if necessary.

If the terminals are in good condition, test the battery.

If they are faulty, replace the battery.

If the starter is cranking the engine correctly, but the fault is still present,

–Check the continuity and absence of interference resistance of the following connections:

+ 12 V timed by UPC Track M2 connector B of the engine management computer

+ 12 V timed by UPC Track G1 connector A of the engine management computer

Battery earth Tracks G4, H4, H1 of connectorA of the injection computer

Repair if necessary.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by a check with the diagnostic tool.

EDC16_V44_DF046/EDC16_V48_DF046/EDC16_V4C_DF046

Page 110 of 236

13B-110

DIESEL INJECTION

Fault finding - Conformity check13B

V10 MR-372-J84-13B150$423.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

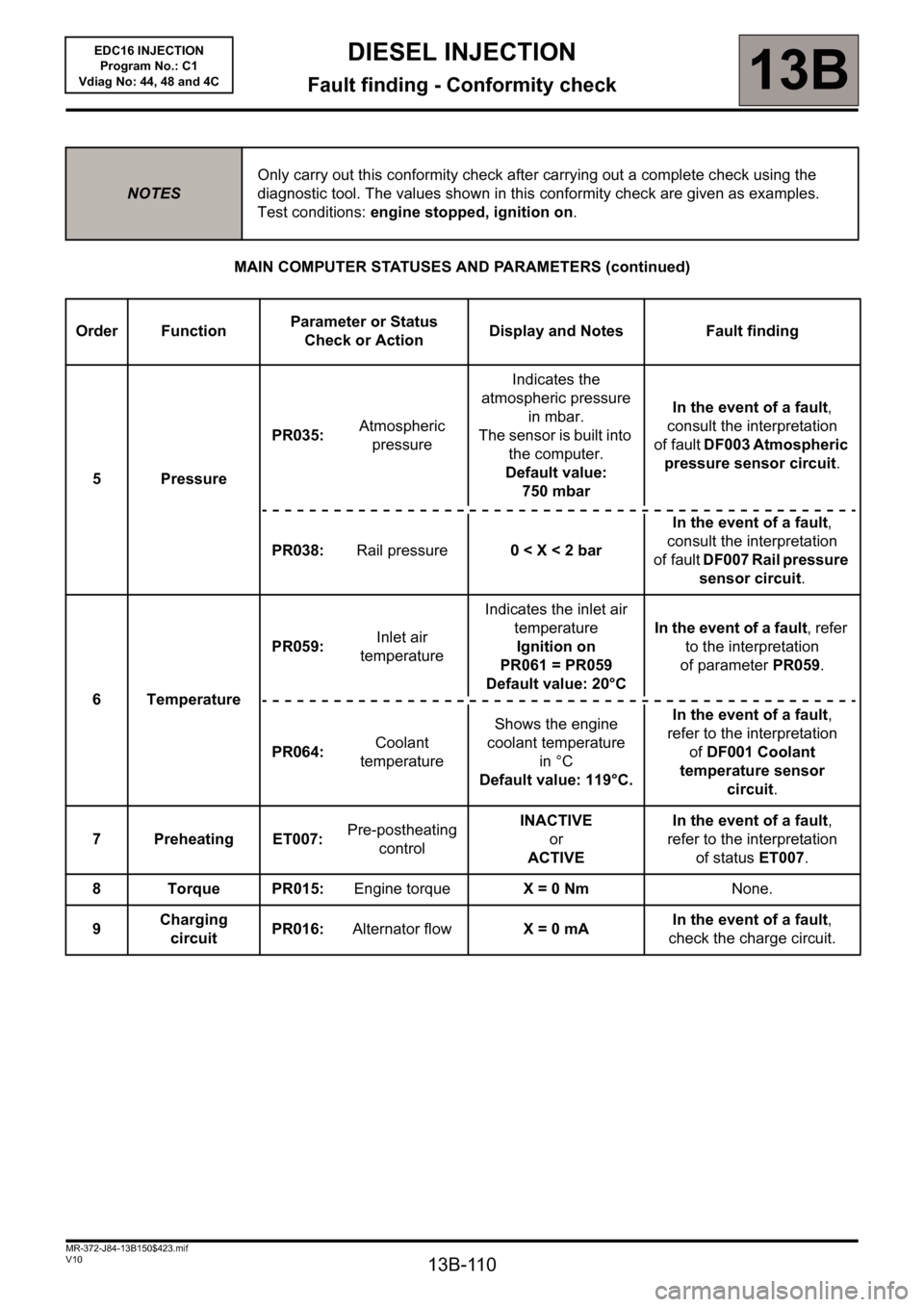

MAIN COMPUTER STATUSES AND PARAMETERS (continued)

NOTESOnly carry out this conformity check after carrying out a complete check using the

diagnostic tool. The values shown in this conformity check are given as examples.

Test conditions: engine stopped, ignition on.

Order FunctionParameter or Status

Check or ActionDisplay and Notes Fault finding

5 PressurePR035:Atmospheric

pressureIndicates the

atmospheric pressure

in mbar.

The sensor is built into

the computer.

Default value:

750 mbarIn the event of a fault,

consult the interpretation

of fault DF003 Atmospheric

pressure sensor circuit.

PR038:Rail pressure0

of fault DF007 Rail pressure

sensor circuit.

6 TemperaturePR059: Inlet air

temperatureIndicates the inlet air

temperature

Ignition on

PR061 = PR059

Default value: 20°C In the event of a fault, refer

to the interpretation

of parameter PR059.

PR064: Coolant

temperatureShows the engine

coolant temperature

in °C

Default value: 119°C.In the event of a fault,

refer to the interpretation

ofDF001 Coolant

temperature sensor

circuit.

7 Preheating ET007: Pre-postheating

controlINACTIVE

or

ACTIVEIn the event of a fault,

refer to the interpretation

of statusET007.

8 Torque PR015: Engine torqueX = 0 NmNone.

9Charging

circuit PR016:Alternator flow X = 0 mAIn the event of a fault,

check the charge circuit.

Page 129 of 236

13B-129

DIESEL INJECTION

Fault finding - Conformity check13B

V10 MR-372-J84-13B150$423.mif

EDC16 INJECTION

Program No.: C1

Vdiag No: 44, 48 and 4C

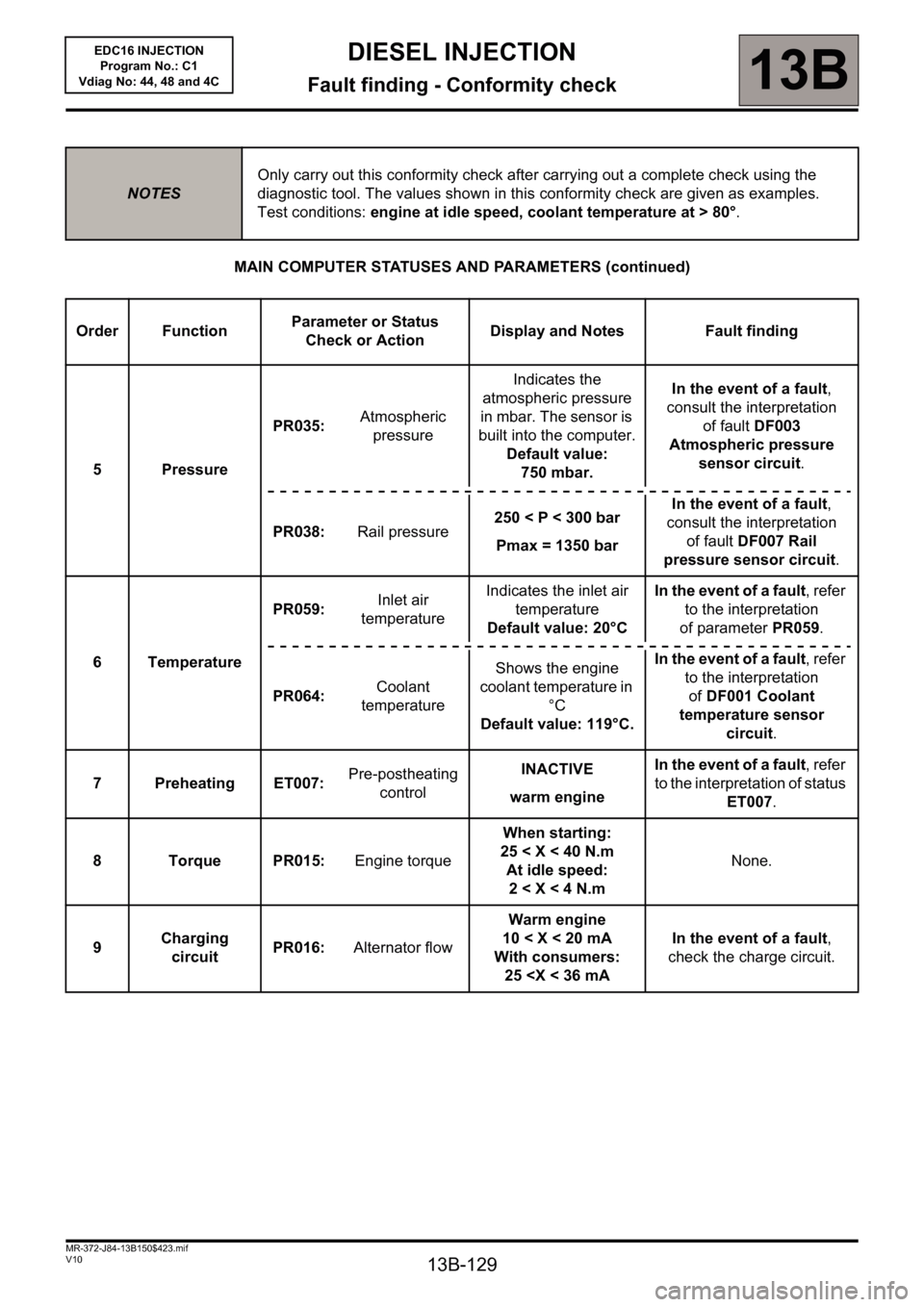

MAIN COMPUTER STATUSES AND PARAMETERS (continued)

NOTESOnly carry out this conformity check after carrying out a complete check using the

diagnostic tool. The values shown in this conformity check are given as examples.

Test conditions: engine at idle speed, coolant temperature at > 80°.

Order FunctionParameter or Status

Check or ActionDisplay and Notes Fault finding

5PressurePR035: Atmospheric

pressureIndicates the

atmospheric pressure

in mbar. The sensor is

built into the computer.

Default value:

750 mbar.In the event of a fault,

consult the interpretation

of fault DF003

Atmospheric pressure

sensor circuit.

PR038: Rail pressure250< P< 300bar

Pmax = 1350 barIn the event of a fault,

consult the interpretation

of fault DF007 Rail

pressure sensor circuit.

6 TemperaturePR059: Inlet air

temperatureIndicates the inlet air

temperature

Default value: 20°CIn the event of a fault, refer

to the interpretation

of parameter PR059.

PR064: Coolant

temperatureShows the engine

coolant temperature in

°C

Default value: 119°C.In the event of a fault, refer

to the interpretation

ofDF001 Coolant

temperature sensor

circuit.

7 Preheating ET007: Pre-postheating

controlINACTIVE

warm engineIn the event of a fault, refer

to the interpretation of status

ET007.

8 Torque PR015: Engine torqueWhen starting:

25 < X < 40 N.m

At idle speed:

2

circuitPR016: Alternator flowWarm engine

10 < X < 20 mA

With consumers:

25

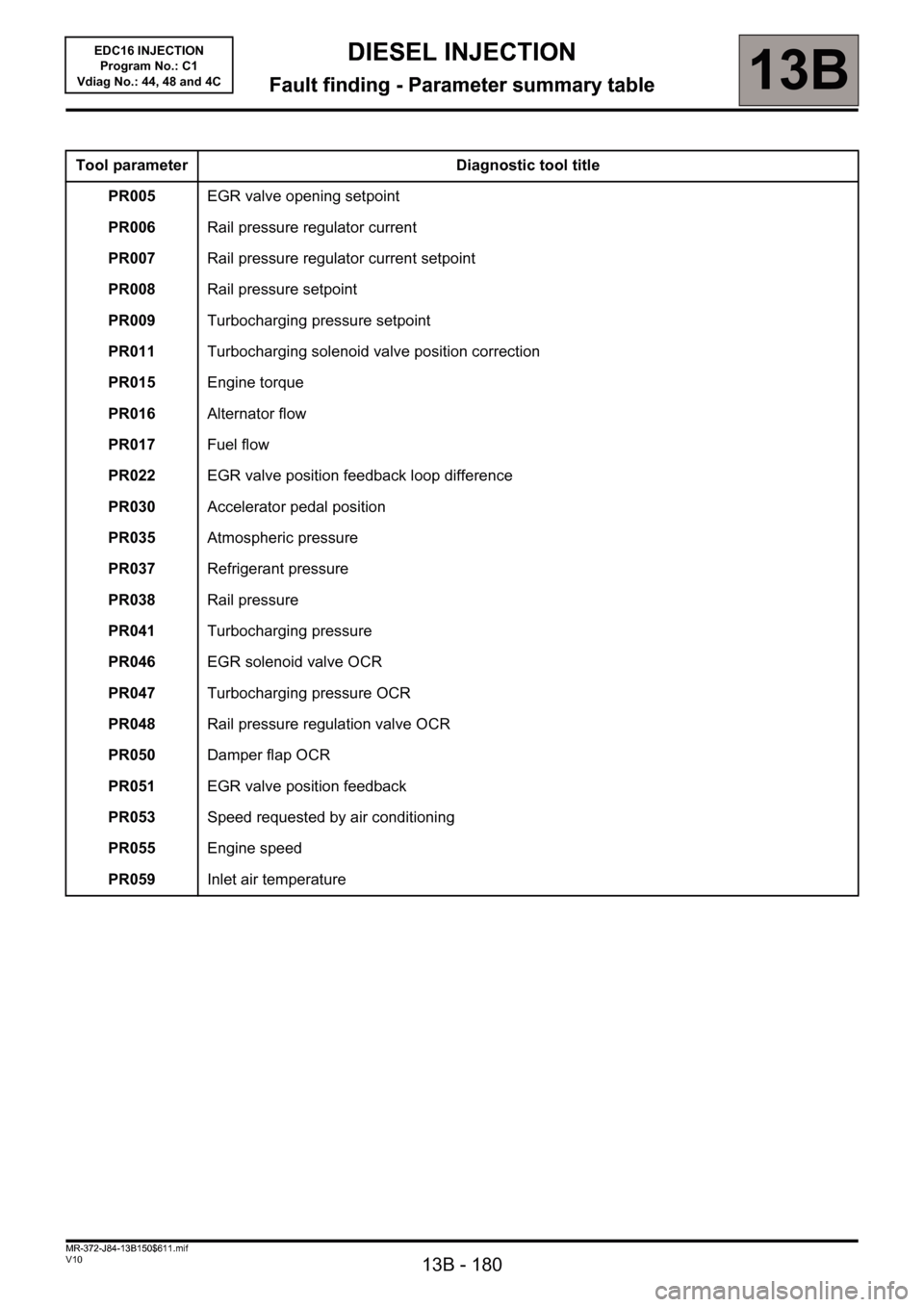

Page 180 of 236

13B - 180

DIESEL INJECTION

Fault finding - Parameter summary table13B

V10 MR-372-J84-13B150$611.mif

EDC16 INJECTION

Program No.: C1

Vdiag No.: 44, 48 and 4CDIESEL INJECTION

Fault finding - Parameter summary table

Tool parameter Diagnostic tool title

PR005EGR valve opening setpoint

PR006Rail pressure regulator current

PR007Rail pressure regulator current setpoint

PR008Rail pressure setpoint

PR009Turbocharging pressure setpoint

PR011Turbocharging solenoid valve position correction

PR015Engine torque

PR016Alternator flow

PR017Fuel flow

PR022EGR valve position feedback loop difference

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR041Turbocharging pressure

PR046EGR solenoid valve OCR

PR047Turbocharging pressure OCR

PR048Rail pressure regulation valve OCR

PR050Damper flap OCR

PR051EGR valve position feedback

PR053Speed requested by air conditioning

PR055Engine speed

PR059Inlet air temperature

MR-372-J84-13B150$611.mif