brake sensor RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 29 of 365

13B-29

MR-372-J84-13B200$216.mif

V13

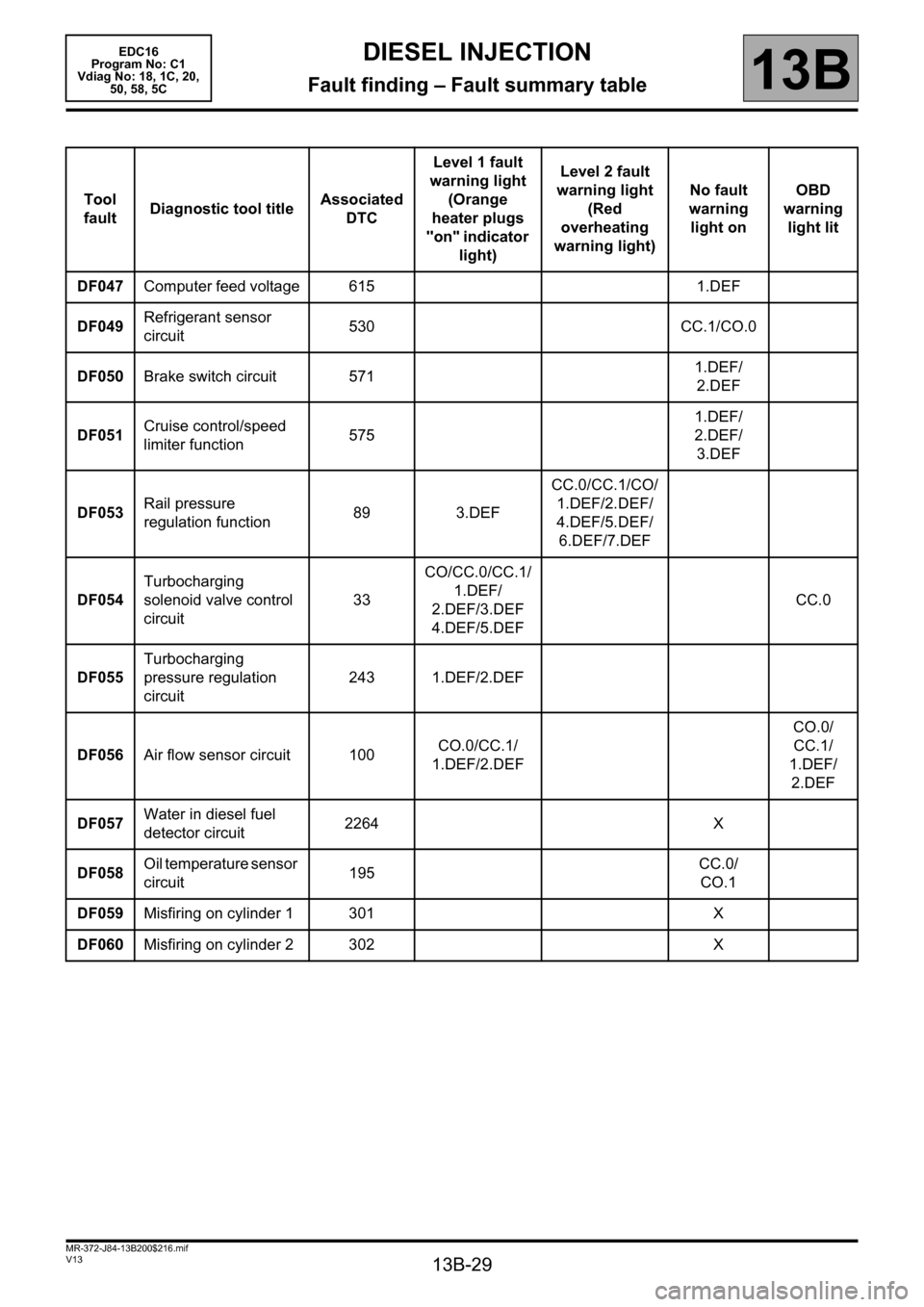

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF047Computer feed voltage 615 1.DEF

DF049Refrigerant sensor

circuit530 CC.1/CO.0

DF050Brake switch circuit 5711.DEF/

2.DEF

DF051Cruise control/speed

limiter function5751.DEF/

2.DEF/

3.DEF

DF053Rail pressure

regulation function89 3.DEFCC.0/CC.1/CO/

1.DEF/2.DEF/

4.DEF/5.DEF/

6.DEF/7.DEF

DF054Turbocharging

solenoid valve control

circuit33CO/CC.0/CC.1/

1.DEF/

2.DEF/3.DEF

4.DEF/5.DEFCC.0

DF055Turbocharging

pressure regulation

circuit243 1.DEF/2.DEF

DF056Air flow sensor circuit 100CO.0/CC.1/

1.DEF/2.DEFCO.0/

CC.1/

1.DEF/

2.DEF

DF057Water in diesel fuel

detector circuit2264 X

DF058Oil temperature sensor

circuit195CC.0/

CO.1

DF059Misfiring on cylinder 1 301 X

DF060Misfiring on cylinder 2 302 X

Page 323 of 365

13B-323

MR-372-J84-13B200$828.mif

V13

DIESEL INJECTION

Fault finding – Fault Finding Chart

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

ALP 4

CONTINUED

Check the injector operation: run test 9.

If the fault is still present

Check the conformity of the accelerator pedal position sensor, the brake pedal sensor, the atmospheric pressure

sensor, the exhaust gas recirculation valve and the damper valve.

Check the consistency of the signal: of the air flowmeter, of the engine coolant temperature sensor, of the fuel

temperature sensor and of the engine speed.

Check the connections, continuity and absence of interference resistance on the air flow sensor (run DF056 Air

flow sensor circuit, 2.DEF), the engine coolant temperature sensor (run DF001 Coolant circuit, 1.DEF), and

the engine speed (run DF195 Engine speed / camshaft sensor consistency, 2.DEF).

Check:

– That the diesel filter is not clogged (for the test, see DF053 Rail pressure regulation function 2.def).

– That there are no leaks on the high and low pressure diesel circuits, run Test 4 Turbocharged air inlet circuit

check.

– That the oil vapour rebreathing system is connected.

– The flow regulator (jammed / seized), apply the interpretation of command AC011 Rail pressure regulator.

– Check the timing setting (and the position of the high pressure pump pinion)

– Check the engine compressions (cylinder compression balance with the Compression test function on the

CLIP Technic tool).

– Measure the engine compressions with the special tool

– If the fault is still present, contact the techline.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 324 of 365

13B-324

MR-372-J84-13B200$828.mif

V13

DIESEL INJECTION

Fault finding – Fault Finding Chart

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

ALP 5 Irregular engine operation

NOTESBefore dealing with this customer complaint, check that there are no faults, and

the conformity (or otherwise) of the parameters and statuses using the

diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

If the engine races during gear changes, check, if there is a floor carpet, that this is not blocking the accelerator

pedal, the brake pedal or the clutch pedal, then check the conformity of the clutch switch and the conformity of the

accelerator pedal sensor when the pedal is released. Measure the resistance of the engine speed sensor

between connections 3BG and 3BL of component 149:

Replace the sensor if its resistance is not 510 Ω < X < 850 Ω at 20°C.

Check the continuity of the following connections:

– connection code 3BG,

– connection code 3BL.

between components 120 and 149.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the conformity of the engine earths (oxidation, tightness, etc.).

Check the mounting, air gap (check that the engine speed sensor – flywheel gap is correct: 0.5 < X < 1.8 mm)

and the condition of the sensor (heating).

Replace if necessary.

Low pressure circuit check.

– Check the pressure regulating solenoid valve using part B of ALP7 Rough idle.

~ 1600 bar with full load on the accelerator.

– Apply the procedure used for checking the air flow (see “conformity check”).

– Check the turbocharger:

–Run Test 2 Air line at the turbocharger.

–Run Test 6 Turbocharger control solenoid valve check.

–Run Test 7 Turbocharger.

– Apply the procedure used for checking the hydraulic circuit (see conformity check).

If the fault is still present:

Check the balance of the cylinders using the CLIP Technic function, Compression test physical measurements

icon.

Check the engine compressions with the special tool, if necessary.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V50_ALP5/EDC16_V58_ALP5/EDC16_V5C_ALP5/EDC16_V18_ALP5/EDC16_V1C_ALP5/EDC16_V20_ALP5