air condition RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 391 of 431

13B-391

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

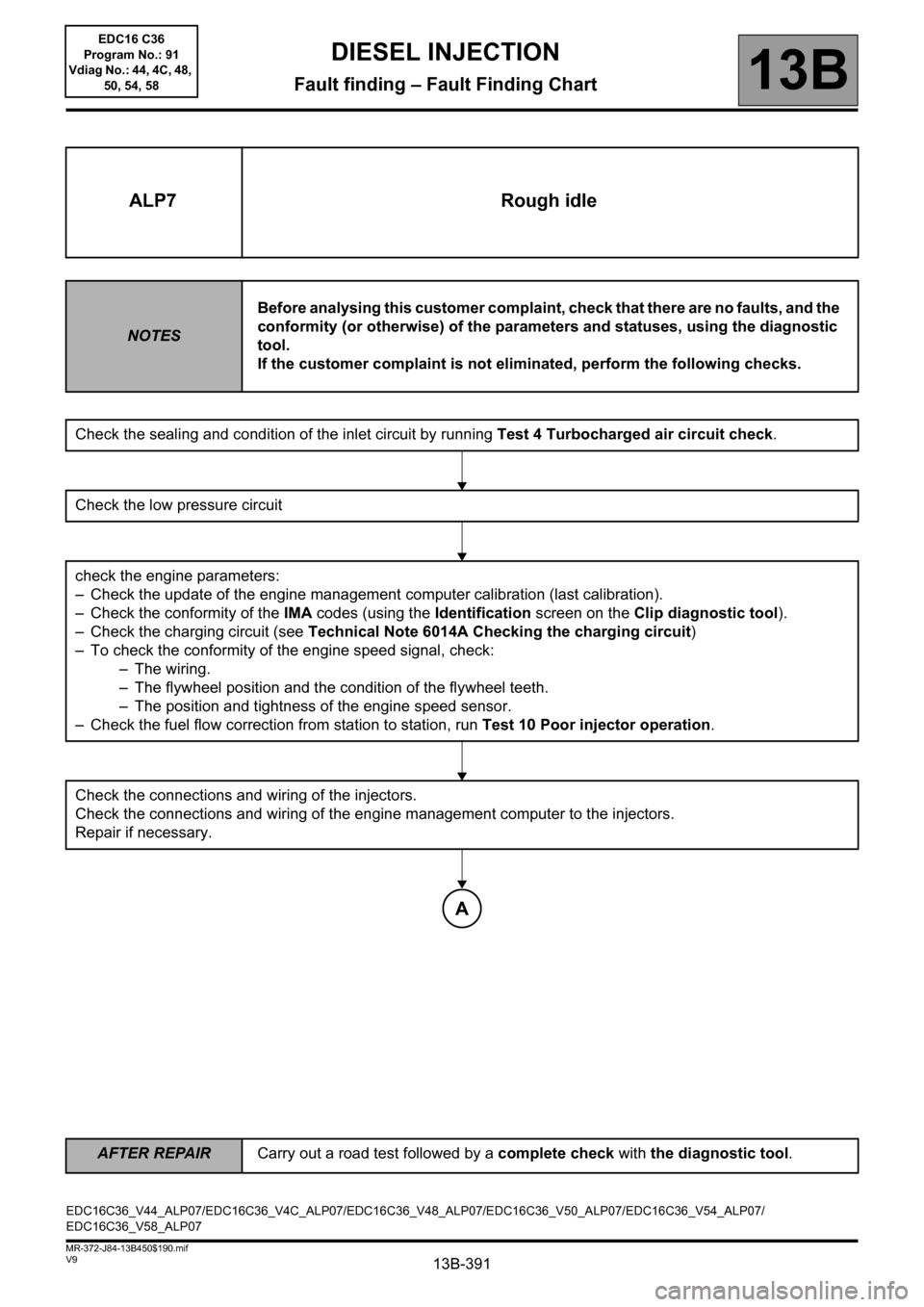

ALP7 Rough idle

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

Check the sealing and condition of the inlet circuit by running Test 4 Turbocharged air circuit check.

Check the low pressure circuit

check the engine parameters:

– Check the update of the engine management computer calibration (last calibration).

– Check the conformity of the IMA codes (using the Identification screen on the Clip diagnostic tool).

– Check the charging circuit (see Technical Note 6014A Checking the charging circuit)

– To check the conformity of the engine speed signal, check:

– The wiring.

– The flywheel position and the condition of the flywheel teeth.

– The position and tightness of the engine speed sensor.

– Check the fuel flow correction from station to station, run Test 10 Poor injector operation.

Check the connections and wiring of the injectors.

Check the connections and wiring of the engine management computer to the injectors.

Repair if necessary.

A

EDC16C36_V44_ALP07/EDC16C36_V4C_ALP07/EDC16C36_V48_ALP07/EDC16C36_V50_ALP07/EDC16C36_V54_ALP07/

EDC16C36_V58_ALP07EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 393 of 431

13B-393

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

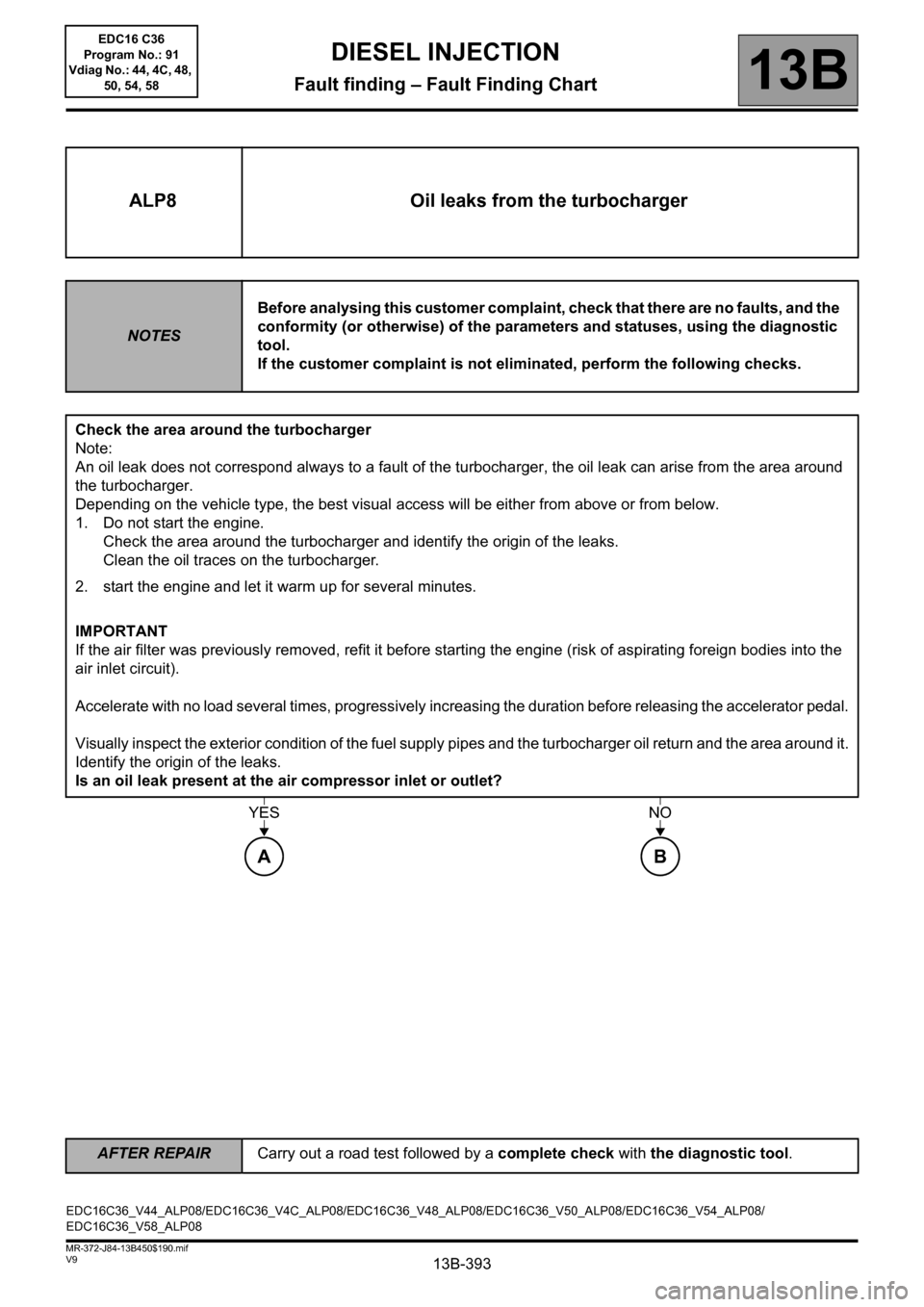

ALP8 Oil leaks from the turbocharger

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

Check the area around the turbocharger

Note:

An oil leak does not correspond always to a fault of the turbocharger, the oil leak can arise from the area around

the turbocharger.

Depending on the vehicle type, the best visual access will be either from above or from below.

1. Do not start the engine.

Check the area around the turbocharger and identify the origin of the leaks.

Clean the oil traces on the turbocharger.

2. start the engine and let it warm up for several minutes.

IMPORTANT

If the air filter was previously removed, refit it before starting the engine (risk of aspirating foreign bodies into the

air inlet circuit).

Accelerate with no load several times, progressively increasing the duration before releasing the accelerator pedal.

Visually inspect the exterior condition of the fuel supply pipes and the turbocharger oil return and the area around it.

Identify the origin of the leaks.

Is an oil leak present at the air compressor inlet or outlet?

YESNO

AB

EDC16C36_V44_ALP08/EDC16C36_V4C_ALP08/EDC16C36_V48_ALP08/EDC16C36_V50_ALP08/EDC16C36_V54_ALP08/

EDC16C36_V58_ALP08EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 403 of 431

13B-403

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

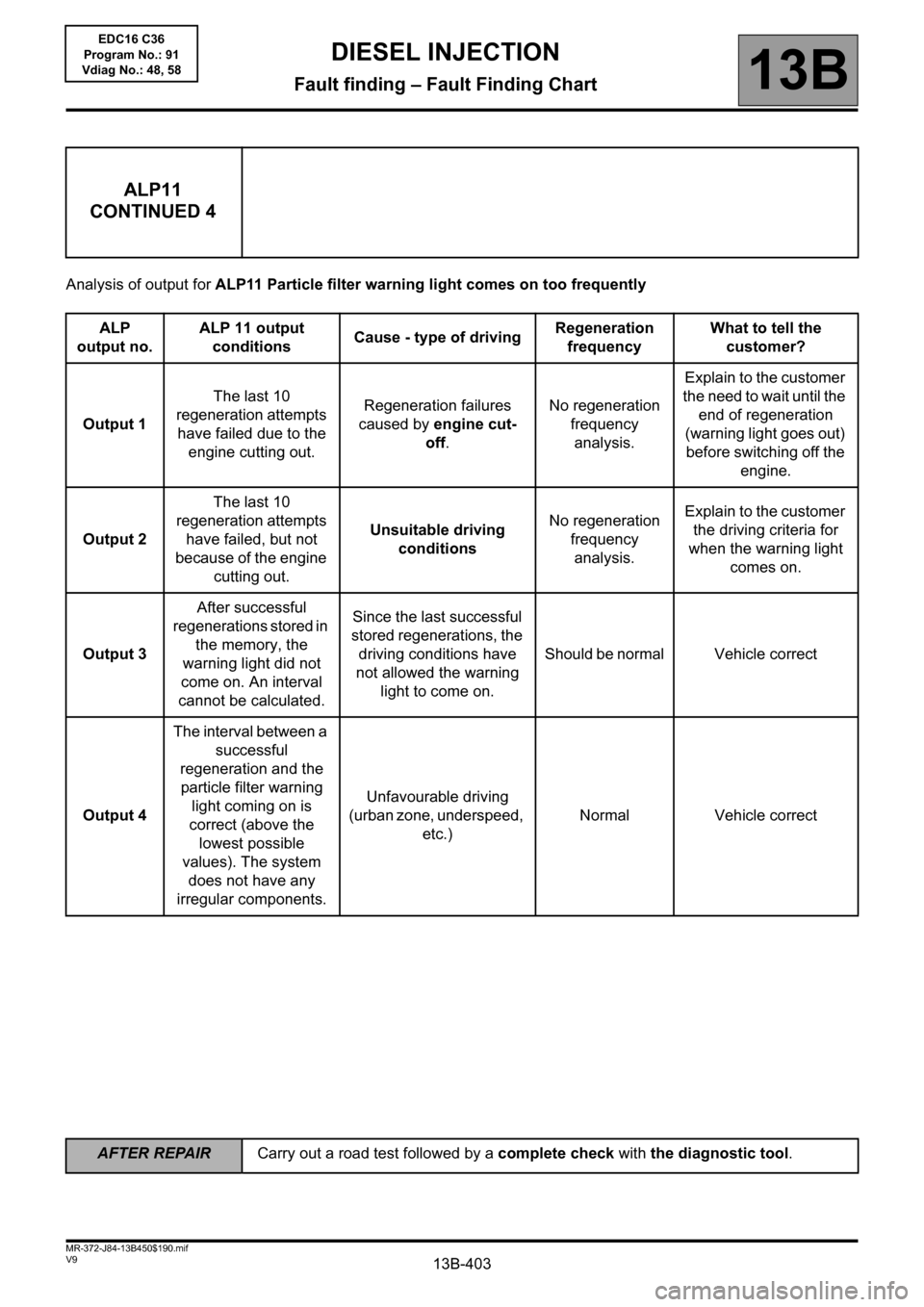

Analysis of output for ALP11 Particle filter warning light comes on too frequently

ALP11

CONTINUED 4

ALP

output no.ALP 11 output

conditionsCause - type of drivingRegeneration

frequencyWhat to tell the

customer?

Output 1The last 10

regeneration attempts

have failed due to the

engine cutting out.Regeneration failures

caused by engine cut-

off.No regeneration

frequency

analysis.Explain to the customer

the need to wait until the

end of regeneration

(warning light goes out)

before switching off the

engine.

Output 2The last 10

regeneration attempts

have failed, but not

because of the engine

cutting out.Unsuitable driving

conditionsNo regeneration

frequency

analysis.Explain to the customer

the driving criteria for

when the warning light

comes on.

Output 3After successful

regenerations stored in

the memory, the

warning light did not

come on. An interval

cannot be calculated.Since the last successful

stored regenerations, the

driving conditions have

not allowed the warning

light to come on.Should be normal Vehicle correct

Output 4The interval between a

successful

regeneration and the

particle filter warning

light coming on is

correct (above the

lowest possible

values). The system

does not have any

irregular components.Unfavourable driving

(urban zone, underspeed,

etc.)Normal Vehicle correct

EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 406 of 431

13B-406V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

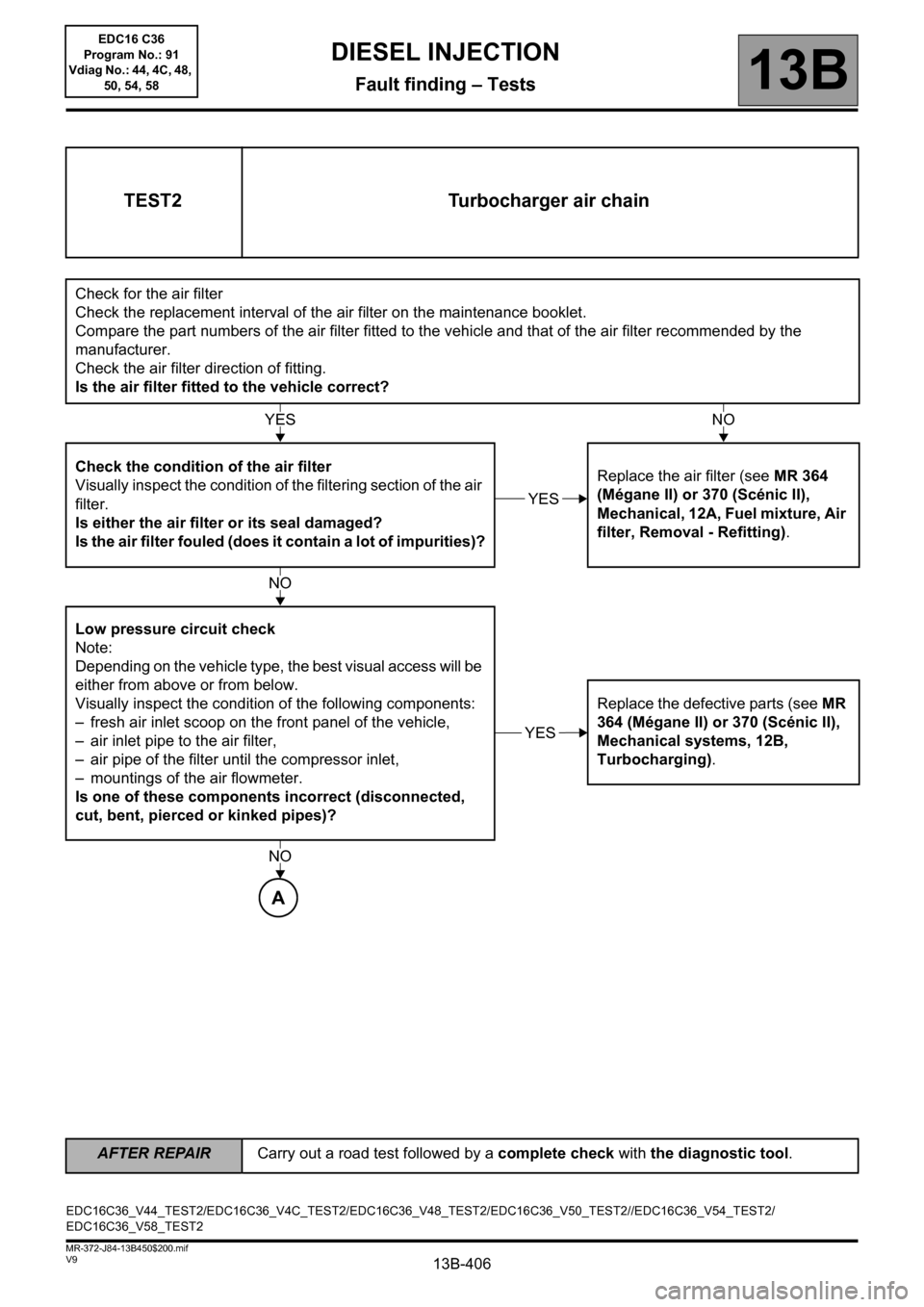

TEST2 Turbocharger air chain

Check for the air filter

Check the replacement interval of the air filter on the maintenance booklet.

Compare the part numbers of the air filter fitted to the vehicle and that of the air filter recommended by the

manufacturer.

Check the air filter direction of fitting.

Is the air filter fitted to the vehicle correct?

Check the condition of the air filter

Visually inspect the condition of the filtering section of the air

filter.

Is either the air filter or its seal damaged?

Is the air filter fouled (does it contain a lot of impurities)?Replace the air filter (see MR 364

(Mégane II) or 370 (Scénic II),

Mechanical, 12A, Fuel mixture, Air

filter, Removal - Refitting).

Low pressure circuit check

Note:

Depending on the vehicle type, the best visual access will be

either from above or from below.

Visually inspect the condition of the following components:

– fresh air inlet scoop on the front panel of the vehicle,

– air inlet pipe to the air filter,

– air pipe of the filter until the compressor inlet,

– mountings of the air flowmeter.

Is one of these components incorrect (disconnected,

cut, bent, pierced or kinked pipes)?Replace the defective parts (see MR

364 (Mégane II) or 370 (Scénic II),

Mechanical systems, 12B,

Turbocharging).

YESNO

YES

NO

YES

NO

A

EDC16C36_V44_TEST2/EDC16C36_V4C_TEST2/EDC16C36_V48_TEST2/EDC16C36_V50_TEST2//EDC16C36_V54_TEST2/

EDC16C36_V58_TEST2

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 407 of 431

13B-407V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

TEST2

CONTINUED 1

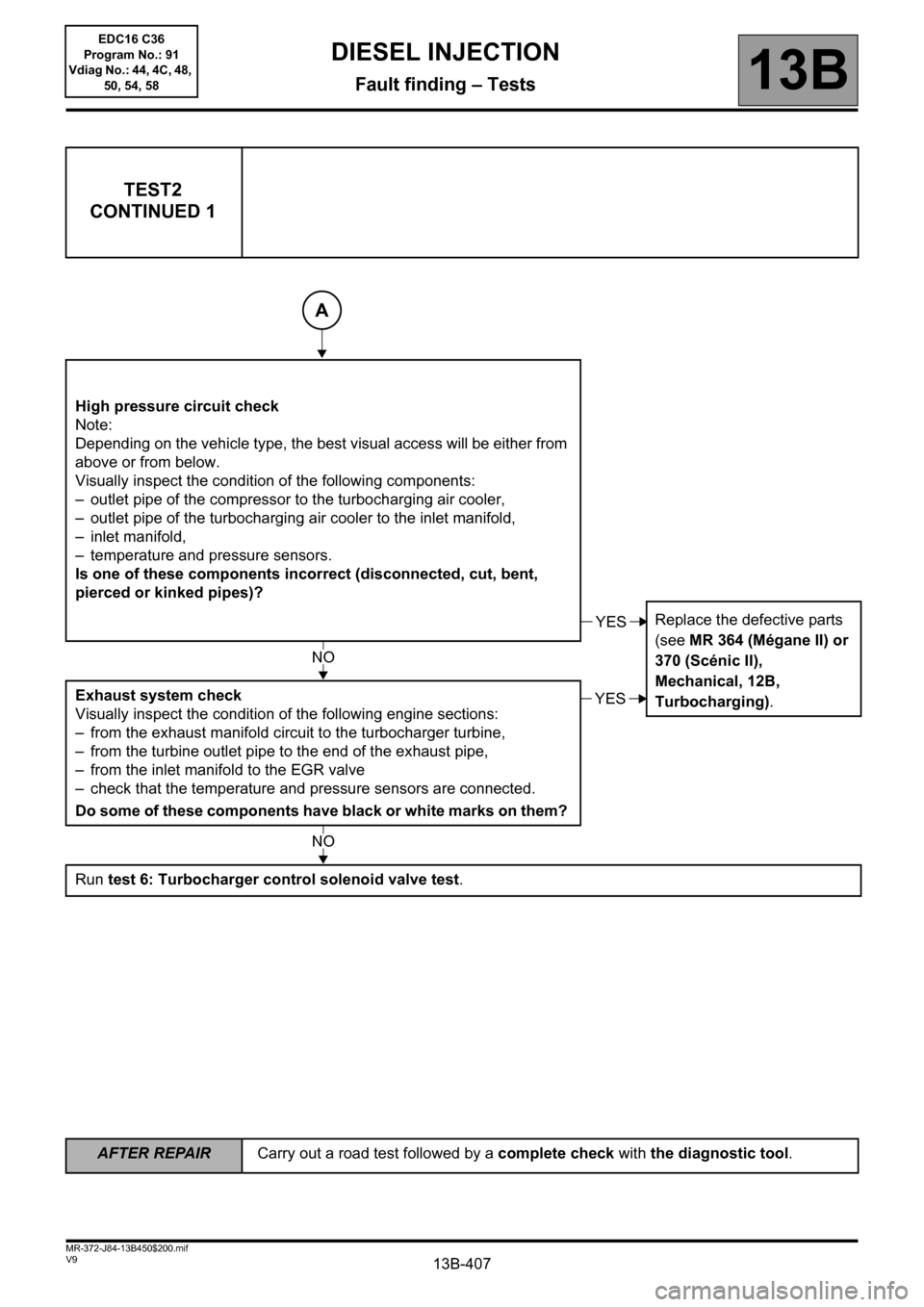

High pressure circuit check

Note:

Depending on the vehicle type, the best visual access will be either from

above or from below.

Visually inspect the condition of the following components:

– outlet pipe of the compressor to the turbocharging air cooler,

– outlet pipe of the turbocharging air cooler to the inlet manifold,

– inlet manifold,

– temperature and pressure sensors.

Is one of these components incorrect (disconnected, cut, bent,

pierced or kinked pipes)?

Replace the defective parts

(see MR 364 (Mégane II) or

370 (Scénic II),

Mechanical, 12B,

Turbocharging). Exhaust system check

Visually inspect the condition of the following engine sections:

– from the exhaust manifold circuit to the turbocharger turbine,

– from the turbine outlet pipe to the end of the exhaust pipe,

– from the inlet manifold to the EGR valve

– check that the temperature and pressure sensors are connected.

Do some of these components have black or white marks on them?

Run test 6: Turbocharger control solenoid valve test.

A

YES

NO

YES

NO

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 408 of 431

13B-408V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

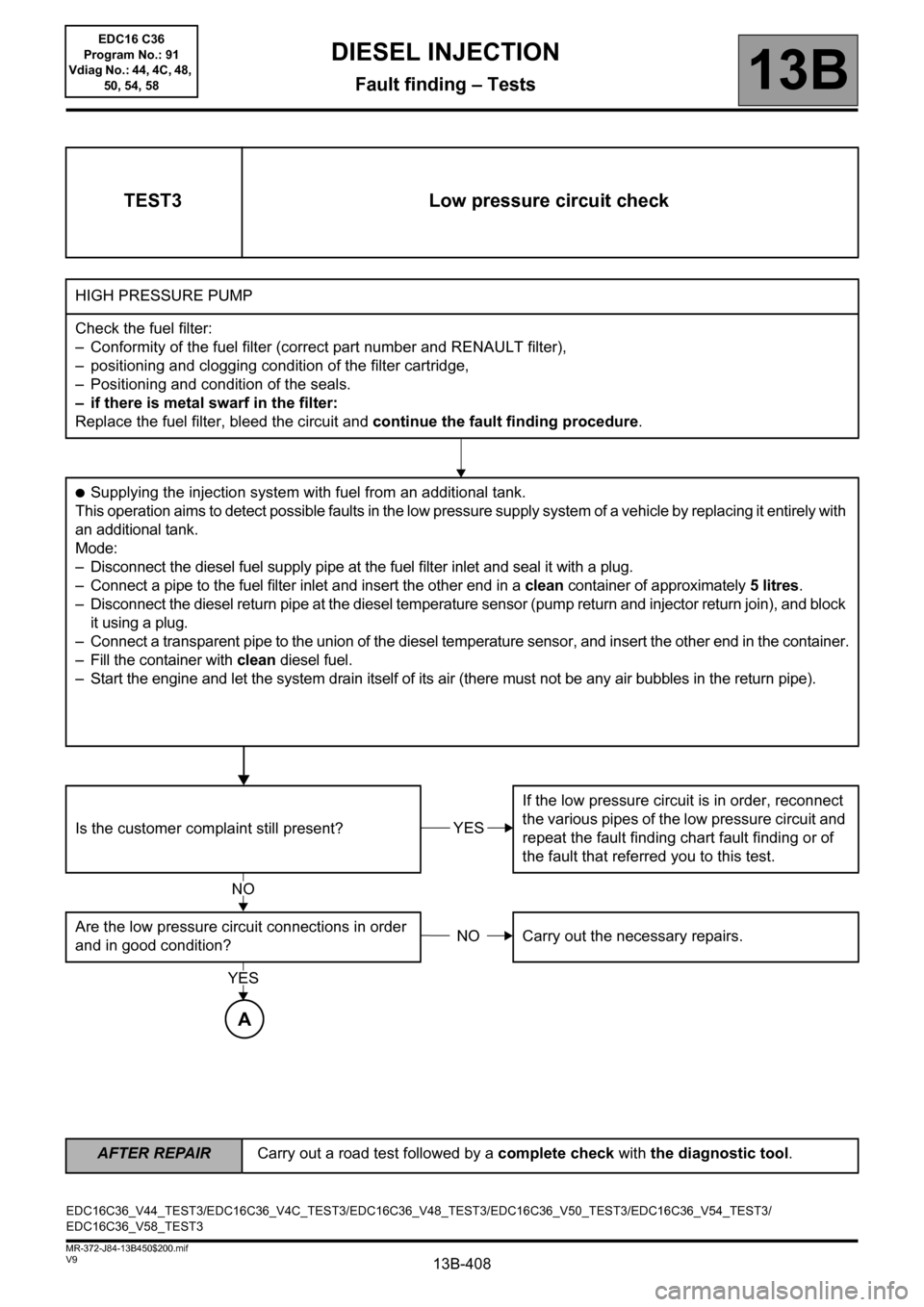

TEST3 Low pressure circuit check

HIGH PRESSURE PUMP

Check the fuel filter:

– Conformity of the fuel filter (correct part number and RENAULT filter),

– positioning and clogging condition of the filter cartridge,

– Positioning and condition of the seals.

– if there is metal swarf in the filter:

Replace the fuel filter, bleed the circuit and continue the fault finding procedure.

●Supplying the injection system with fuel from an additional tank.

This operation aims to detect possible faults in the low pressure supply system of a vehicle by replacing it entirely with

an additional tank.

Mode:

– Disconnect the diesel fuel supply pipe at the fuel filter inlet and seal it with a plug.

– Connect a pipe to the fuel filter inlet and insert the other end in a clean container of approximately 5litres.

– Disconnect the diesel return pipe at the diesel temperature sensor (pump return and injector return join), and block

it using a plug.

– Connect a transparent pipe to the union of the diesel temperature sensor, and insert the other end in the container.

– Fill the container with clean diesel fuel.

– Start the engine and let the system drain itself of its air (there must not be any air bubbles in the return pipe).

Is the customer complaint still present?If the low pressure circuit is in order, reconnect

the various pipes of the low pressure circuit and

repeat the fault finding chart fault finding or of

the fault that referred you to this test.

Are the low pressure circuit connections in order

and in good condition?Carry out the necessary repairs.

YES

NO

NO

YES

A

EDC16C36_V44_TEST3/EDC16C36_V4C_TEST3/EDC16C36_V48_TEST3/EDC16C36_V50_TEST3/EDC16C36_V54_TEST3/

EDC16C36_V58_TEST3

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 409 of 431

13B-409V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

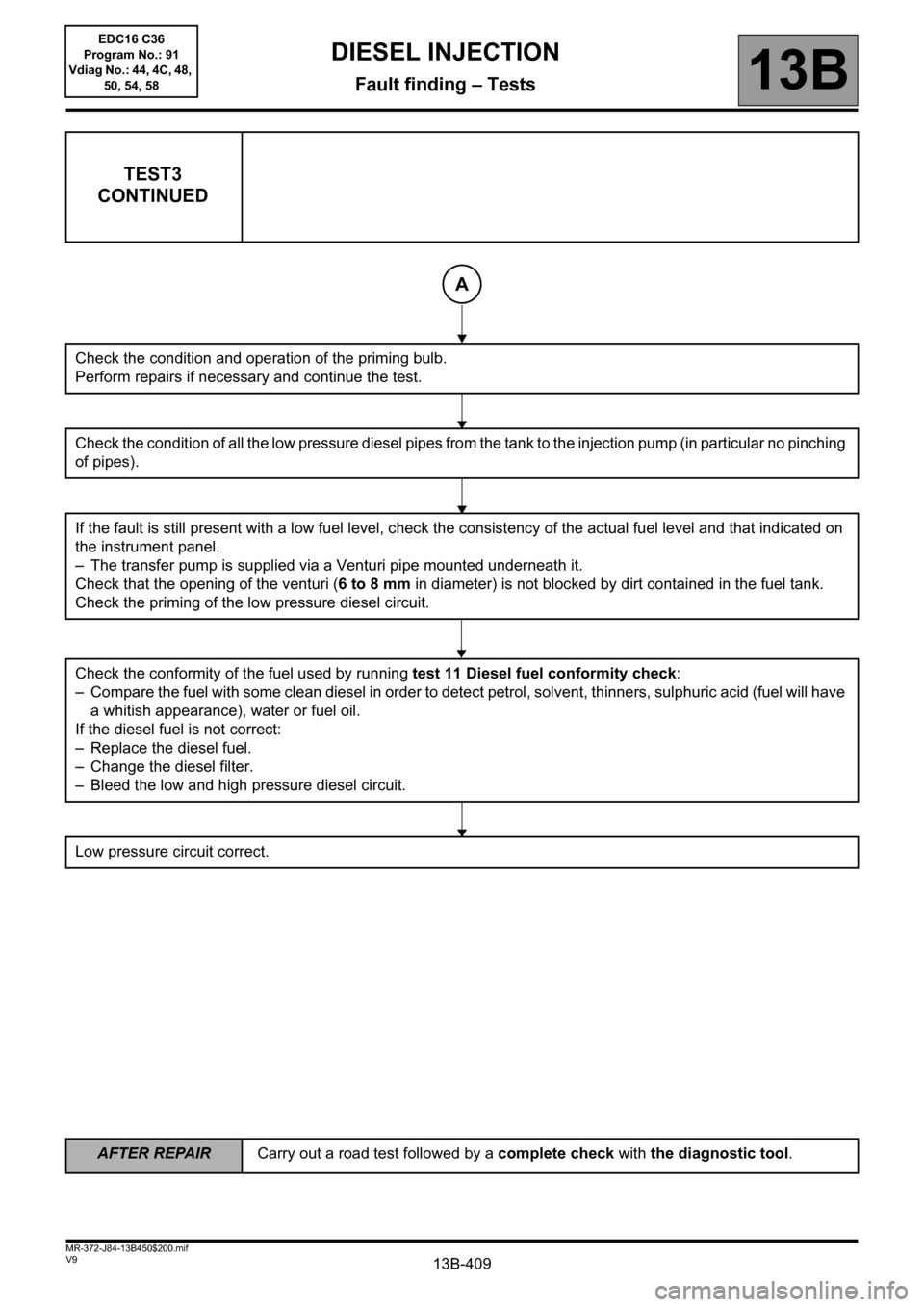

TEST3

CONTINUED

Check the condition and operation of the priming bulb.

Perform repairs if necessary and continue the test.

Check the condition of all the low pressure diesel pipes from the tank to the injection pump (in particular no pinching

of pipes).

If the fault is still present with a low fuel level, check the consistency of the actual fuel level and that indicated on

the instrument panel.

– The transfer pump is supplied via a Venturi pipe mounted underneath it.

Check that the opening of the venturi (6 to 8 mm in diameter) is not blocked by dirt contained in the fuel tank.

Check the priming of the low pressure diesel circuit.

Check the conformity of the fuel used by running test 11 Diesel fuel conformity check:

– Compare the fuel with some clean diesel in order to detect petrol, solvent, thinners, sulphuric acid (fuel will have

a whitish appearance), water or fuel oil.

If the diesel fuel is not correct:

– Replace the diesel fuel.

– Change the diesel filter.

– Bleed the low and high pressure diesel circuit.

Low pressure circuit correct.

A

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 410 of 431

13B-410V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

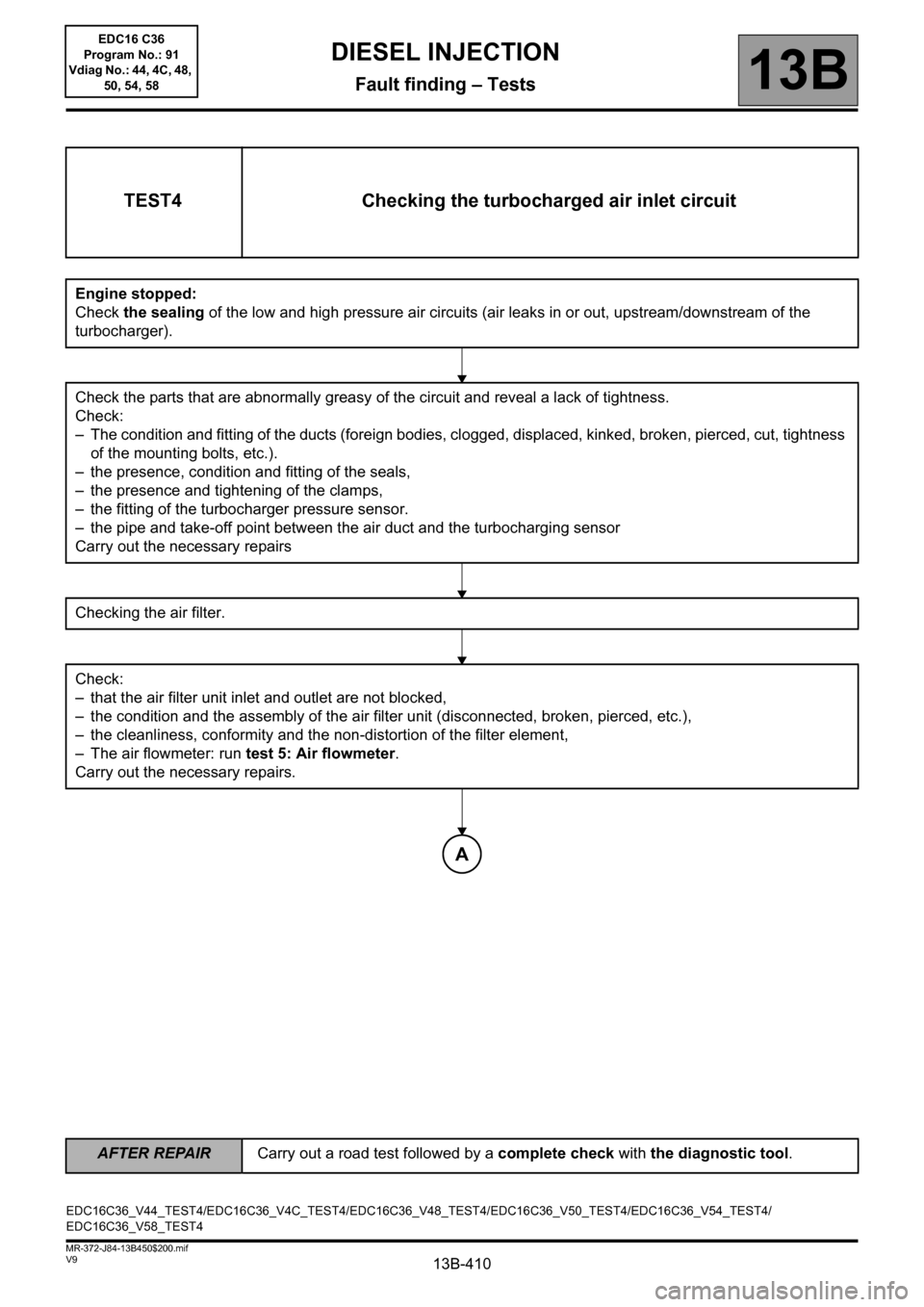

TEST4 Checking the turbocharged air inlet circuit

Engine stopped:

Check the sealing of the low and high pressure air circuits (air leaks in or out, upstream/downstream of the

turbocharger).

Check the parts that are abnormally greasy of the circuit and reveal a lack of tightness.

Check:

– The condition and fitting of the ducts (foreign bodies, clogged, displaced, kinked, broken, pierced, cut, tightness

of the mounting bolts, etc.).

– the presence, condition and fitting of the seals,

– the presence and tightening of the clamps,

– the fitting of the turbocharger pressure sensor.

– the pipe and take-off point between the air duct and the turbocharging sensor

Carry out the necessary repairs

Checking the air filter.

Check:

– that the air filter unit inlet and outlet are not blocked,

– the condition and the assembly of the air filter unit (disconnected, broken, pierced, etc.),

– the cleanliness, conformity and the non-distortion of the filter element,

– The air flowmeter: run test 5: Air flowmeter.

Carry out the necessary repairs.

A

EDC16C36_V44_TEST4/EDC16C36_V4C_TEST4/EDC16C36_V48_TEST4/EDC16C36_V50_TEST4/EDC16C36_V54_TEST4/

EDC16C36_V58_TEST4

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 411 of 431

13B-411V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

TEST4

CONTINUED

Check:

– the condition of the damper valve,

– the tightening of the mounting bolts,

– cracks in the damper valve.

Carry out the necessary repairs.

Replace if necessary.

Check that there is no leak at the exhaust manifold, in particular at the exhaust manifold/turbocharger connection.

Check the exhaust system: run test 1 Exhaust pipe check in ALP2.

Carry out the necessary repairs.

Carry out a visual inspection of the EGR circuit sealing.

Note: the operating play in the EGR heat exchanger valve shaft produces small black marks due to a slight leak

of no importance. Do not replace this part.

Replace if necessary.

Check the condition of the intercooler:

– clogging,

– leaks (vehicle stationary, stabilise the engine speed between 3500 rpm and 4000 rpm and check that there are

no leaks).

Replace if necessary.

Check that the take-off point for the turbocharging pressure sensor is not blocked.

Replace if necessary.

END OF TEST.

A

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 417 of 431

13B-417V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

TEST10

CONTINUED 1

CASE No. 2: If at least one of the values is less than or equal to - 5 mg/st

– Check the valve clearance.

– Check the level and condition of the engine oil.

– Remove the injector with the largest adjustment.

– If there is contamination via the diesel, check the condition of the cylinder concerned (cylinder, piston, valves).

Use an endoscope if possible.

– Replace only the removed injector, and modify the IMA code using the command SC002 Enter injector codes

(see Interpretation of commands).

–Apply Part B Confirmation of flow correction fault finding for each injector (individual correction) to

confirm the fault finding.

CASE No. 3: If at least one of these values does not stabilise (20 seconds after starting)

– Check the low pressure circuit with test 3: Low pressure circuit check.

– Check the conformity of the fuel by running test 11 Diesel fuel conformity check.

Apply Part B Confirmation of flow correction fault finding for each injector (individual correction) to confirm

the fault finding.

CASE No. 4: If the fuel flow correction values are all correct (between - 5 mg/st and + 5 mg/st)

Apply Part C Measure return fuel flow.

IMPORTANT

When removing/refitting an injector, follow the cleanliness guidelines and safety advice (see MR 364 (Mégane II)

or 370 (Scénic II), Mechanical systems 13B, Diesel injector: Removal - Refitting).

Section B: Confirmation of flow correction fault finding for each injector (individual correction):

Clear the faults and perform a test with the engine idling during at least 5 min, fuel temperature> 50°C.

Check that no fault appears on the CLIP diagnostic tool and that the correction values do not reach ±5 mg/st to

confirm the repair.

If the customer complaint is still present and the fuel flow correction values are between -5 mg/st and +5 mg/st,

apply part A Fuel regulation balance check for each injector (individual), CASE No. 4.

If one or more cylinders has a flow correction value per injector that reaches ±5 mg/st, apply Part A Fuel

regulation balance check for each injector (individual) because one or more injectors might be defective.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58