air condition RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 359 of 431

13B-359

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC031OPERATIONAL FAULT FINDING OF CYLINDERS

NOTESThis command is used to run fault finding on the performance of each cylinder and

each injector.

To run this command, select scenario SC031 on the diagnostic tool.

Reminder: cylinder no. 1 is located at the timing end.

Procedure to be followed:

– select scenario SC031,

– once the conditions have been met, press the confirm button; the test will take approximately 5 minutes,

– the tool displays “cylinder no. 1 cut-off” and there will be a perceptible engine speed variation when the

cylinder is cut off; then the same procedure for the other three cylinders,

–the diagnostic tool displays the results,

– end of test.

Interpretation of correct results:

– If the displayed results are “VALID”, it means that the entire cylinder and injector assembly is in order. There is

no need for any operation.

Results Interpretation of results

Cylinder 1 VALID No operation

Cylinder 2 VALID No operation

Cylinder 3 VALID No operation

Cylinder 4 VALID No operation

– If a displayed result is “INVALID”, it means the cylinder or injector is not correct.

Difference compared to average Results Interpretation of results

Cylinder XNegative number or

Positive numberINVALIDCarry out the checks

described below.

EDC16C36_V4C_SC031/EDC16C36_V48_SC031/EDC16C36_V50_SC031/EDC16C36_V54_SC031/EDC16C36_V58_SC031 EDC16 C36

Program No.: 91

Vdiag No.: 4C, 48, 50,

54, 58

Page 365 of 431

13B-365

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

RZ005PROGRAMMING

NOTESThis command enables you to reinitialise the entire computer configuration according

to the vehicle.

Ignition on and engine stopped.

Command RZ005 reconfigures the computer.

if the computer has no configuration data,

run command RZ005 to enter the options fitted on the vehicle:

– air conditioning,

– cruise control/speed limiter.

These options are detected by the computer even if command RZ005 is not used.

the computer is configured as soon as the one of the vehicle's optional system components is operated.

EDC16C36_V44_RZ005/EDC16C36_V4C_RZ005/EDC16C36_V48_RZ005/EDC16C36_V50_RZ005/EDC16C36_V54_RZ005/

EDC16C36_V58_RZ005EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 370 of 431

13B-370

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC011

CONTINUED

Step 2

In the event of rail overpressure:

Check that there are no air bubbles in the diesel fuel low pressure circuit.

Check that the rail pressure sensor is operating correctly.

Consult the interpretation of parameter PR038 Rail pressure.

If these checks reveal no irregularities, replace the regulator.

in the event of rail underpressure:

Check that the rail pressure sensor is operating correctly.

Consult the interpretation of parameter PR038 Rail pressure.

Check the low pressure diesel circuit priming.

Check the conformity of the diesel filter connections.

Check the condition of the filter (clogging and water saturation).

Check that there are no air bubbles between the filter and the high pressure pump.

Check the sealing of the low and high pressure diesel fuel systems: use ALP6 Fuel circuit leaks (visual

inspections, touch tests, odours, etc.) on:

pump body, pressure release valve, pipes, rail and injectors unions, injector wells, etc.

Check the conformity of the seal fitting on the pressure regulator.

Check the operation of the injectors, run Test 10 Poor injector operation.

Carry out the necessary repairs.

If the engine starts:

Clear any faults.

Check the pressure regulator by applying (see ALP7 Rough idle).

With the engine warm, leave it to idle for a few minutes (3 to 5 minutes):

– If it stalls and the fault reappears, replace the regulator.

– If it does not stall, stabilise the engine speed at 2000 rpm(1 minute) then accelerate at full load until it cuts out.

If the engine stalls, contact the Techline

If the engine does not startor there is no timing:

first, replace the regulator and if the fault is still present, contact the Techline.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 372 of 431

13B-372

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC037PREHEATING RELAY

NOTESThis command is only run if fault DF025 Preheating unit diagnostic connection or

DF017 Preheating unit control circuit is present or stored and if no other fault is

present.

Ignition on and engine stopped.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Before applying the following fault finding procedure, check that the battery voltage is not below 12 V.

Otherwise, recharge the battery.

Check the connections on the preheating unit, heater plugs and injection computer.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Measure the resistance of the heater plugs. If this resistance is > 2 Ω, replace the defective plug(s).

Check the continuity and the absence of interference resistance on the following connections:

– Connection code 37AA between components257 and 681.

– Connection code 37AB between components 257 and 682.

– Connection code 37AC between components 257 and 683.

– Connection code 37AZ between components 257 and 680.

Check the condition of fuse FM12 (70 A) of the preheating unit supply. Replace it if necessary.

Then check for +12 V on connection BP35 of component 257.

Check the continuity, insulation, and the absence of interference resistance of the following connections:

– Connection code 3FF,

– Connection code 3FY,

Between components 257 and 120.

If the fault is still present, replace the pre-postheating unit.

EDC16C36_V44_AC037/EDC16C36_V4C_AC037/EDC16C36_V48_AC037/EDC16C36_V50_AC037/EDC16C36_V54_AC037/

EDC16C36_V58_AC037EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 373 of 431

13B-373

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC038LOW-SPEED FAN ASSEMBLY RELAY

NOTESThere must be no present or stored faults.

Perform this fault finding after an engine cooling fault or air conditioning fault.

Refer to the Wiring Diagram Technical Notes for the vehicle to locate the fuses and

relays concerned.

Ignition on and engine stopped.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

If the low speed fan assembly relay does not operate when command AC038 is run:

Check the low-speed fan assembly relay mounting and the connections of the engine management computer.

Check the fan assembly connections.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

If the fault is still present, check that the relay is actuated by the engine management computer as follows:

Disconnect the low-speed fan assembly relay, and fit a 50 to 100 Ω resistor on the relay mounting in place of the

coil, and connect a voltmeter as follows:

– positive terminal to +12 V battery,

– negative terminal to connection 3JN of component 336.

Run command AC038

If the voltmeter shows the battery voltage (4 ON-OFF cycles of 10 seconds), replace the relay.

If the low speed fan assembly relay is supplied using command AC038, but there is still a fan assembly activation

fault, check using the wiring diagram.

The conformity of the fan assembly FM15 maxi-fuse.

EDC16C36_V44_AC038/EDC16C36_V4C_AC038/EDC16C36_V48_AC038/EDC16C36_V50_AC038/EDC16C36_V54_AC038/

EDC16C36_V58_AC038EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 383 of 431

13B-383

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP2 Starting difficult (or impossible)

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

Is it difficult or impossible to start the engine?

PART A:

Check the engine earths.

If the engine speed is less than 200 rpm, refer to Technical Note 6014A, Checking the charging circuit, Starter

fault finding, Starter.

If an engine speed of 200 rpm is achieved with starter motor in operation, PR055 Engine speed.

If the engine speed shown on CLIP is zero and the engine is running, check the resistance of the engine speed

sensor between the following connections:

– Connection code 3BG,

– Connection code 3BL,

of component 149.

Replace the sensor if the resistance is not between 200 Ω and 270 Ω at 20°C.

Check the continuity and insulation of the following connections:

– Connection code 3BG,

– Connection code 3BL,

between components 120 and 149.

If any of the connections are faulty and there is a repair method (see Technical Note 6015A, Electrical wiring

repair, Wiring: precautions for repairs), repair the wiring; otherwise replace the wiring.

Check the conformity of the engine earths (oxidation, tightness, etc.).

Check the mounting and condition (overheating) of the sensor.

Replace if necessary.

Check the synchronisation of the camshaft sensors and the engine speed sensors with the display of ET238

Synchronisation. If synchronisation is not active, refer to the checks described in DF195 Camshaft/engine

speed consistency.

Check the fuel circuit for leaks using test 3 Low pressure circuit check.

If test 3: Low pressure circuit check is correct.

PART

B

Impossible

Difficult

EDC16C36_V44_ALP02/EDC16C36_V4C_ALP02/EDC16C36_V48_ALP02/EDC16C36_V50_ALP02/EDC16C36_V54_ALP02/

EDC16C36_V58_ALP02EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 384 of 431

13B-384

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP2

CONTINUED 1

Test the high pressure fuel circuit:

Run the scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

Check that the heater plugs are actuated using the AC037 Preheating relay command.

Check the tightness and the condition of the inlet circuit: run test 4: Turbocharged air inlet circuit check and

follow the procedure.

Check that the exhaust is not blocked, run test 1 Exhaust system check and follow the procedure.

Check the consistency of the signal from the engine coolant temperature sensor.

Check the operation of the rail pressure regulator (DRV) using command AC011 Rail pressure regulator.

Check the timing setting.

End of part A

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 386 of 431

13B-386

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

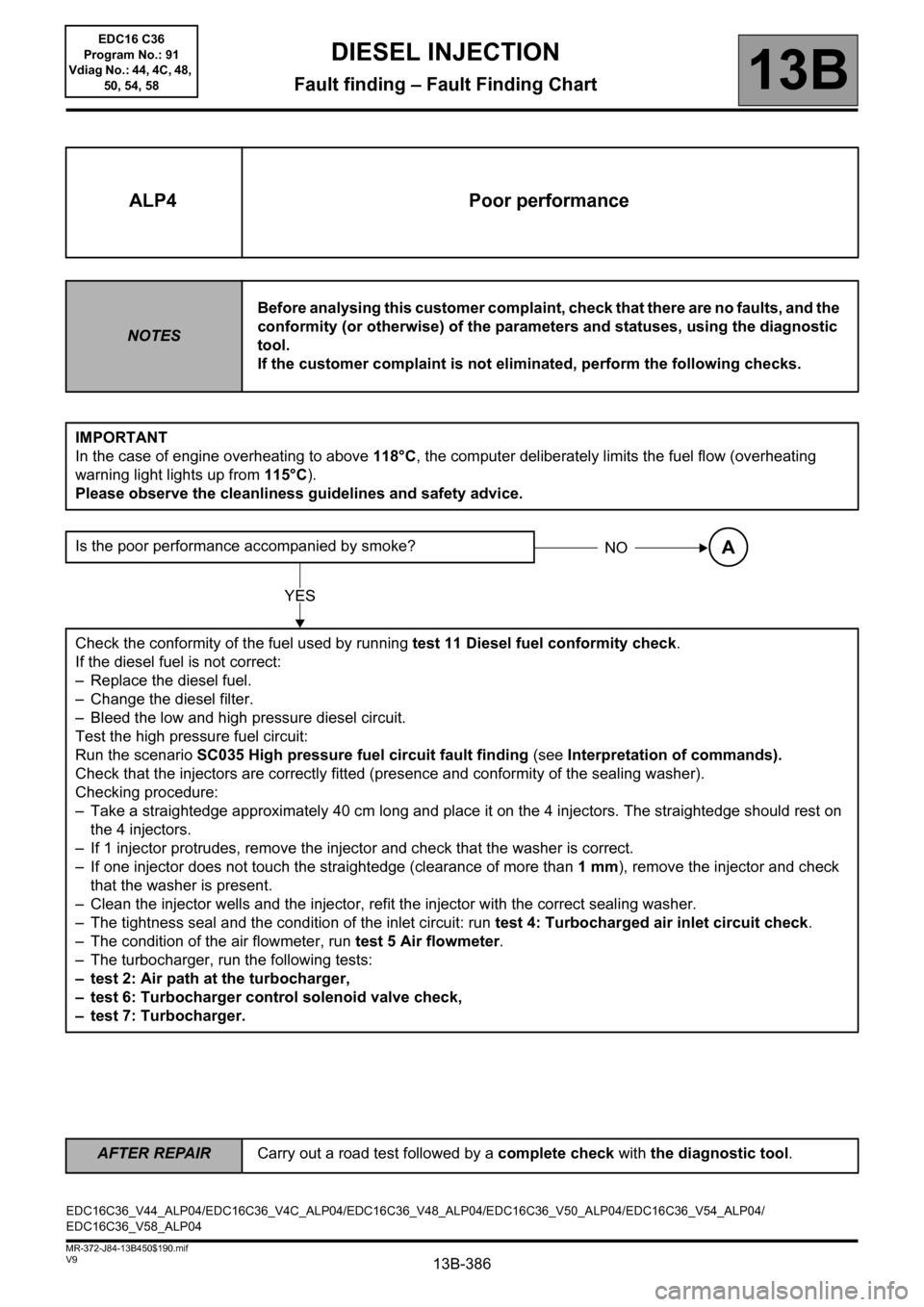

ALP4 Poor performance

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT

In the case of engine overheating to above 118°C, the computer deliberately limits the fuel flow (overheating

warning light lights up from 115°C).

Please observe the cleanliness guidelines and safety advice.

Is the poor performance accompanied by smoke?

Check the conformity of the fuel used by running test 11 Diesel fuel conformity check.

If the diesel fuel is not correct:

– Replace the diesel fuel.

– Change the diesel filter.

– Bleed the low and high pressure diesel circuit.

Test the high pressure fuel circuit:

Run the scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

Check that the injectors are correctly fitted (presence and conformity of the sealing washer).

Checking procedure:

– Take a straightedge approximately 40 cm long and place it on the 4 injectors. The straightedge should rest on

the 4 injectors.

– If 1 injector protrudes, remove the injector and check that the washer is correct.

– If one injector does not touch the straightedge (clearance of more than 1 mm), remove the injector and check

that the washer is present.

– Clean the injector wells and the injector, refit the injector with the correct sealing washer.

– The tightness seal and the condition of the inlet circuit: run test 4: Turbocharged air inlet circuit check.

– The condition of the air flowmeter, run test 5 Air flowmeter.

– The turbocharger, run the following tests:

– test 2: Air path at the turbocharger,

– test 6: Turbocharger control solenoid valve check,

– test 7: Turbocharger.

NOA

YES

EDC16C36_V44_ALP04/EDC16C36_V4C_ALP04/EDC16C36_V48_ALP04/EDC16C36_V50_ALP04/EDC16C36_V54_ALP04/

EDC16C36_V58_ALP04EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 388 of 431

13B-388

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP5 Irregular engine operation

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

If the engine races during gear changes, if there is a floor carpet, check that this is not blocking the accelerator

pedal, the brake pedal and the clutch pedal, then check the conformity of the clutch switch and the conformity of

the accelerator pedal sensor when the pedal is released.

Measure the resistance of the engine speed sensor between the following connections:

– Connection code 3BG,

– Connection code 3BL,

of component 149.

Replace the sensor if the resistance is not 200 Ω to 270 Ω at +20°C

Check the continuity of the following connections:

– Connection code 3BG,

– Connection code 3BL,

between components120 and 149.

Check the conformity of the engine earths (oxidation, tightness, etc.).

Check the mounting and condition (overheating) of the sensor.

Replace if necessary.

Check the low pressure circuit, run test 3 Low pressure circuit check.

Apply the air flow test procedure (see Interpretation of statuses and Interpretation of parameters).

Check the turbocharger, apply the following tests:

– test 2: Air path at the turbocharger,

– test 6: Turbocharger control solenoid valve check,

– test 7: Turbocharger.

Test the high pressure fuel circuit:

Run scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

If the customer complaint is still present, contact Techline.

EDC16C36_V44_ALP05/EDC16C36_V4C_ALP05/EDC16C36_V48_ALP05/EDC16C36_V50_ALP05/EDC16C36_V54_ALP05/

EDC16C36_V58_ALP05EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 389 of 431

13B-389

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

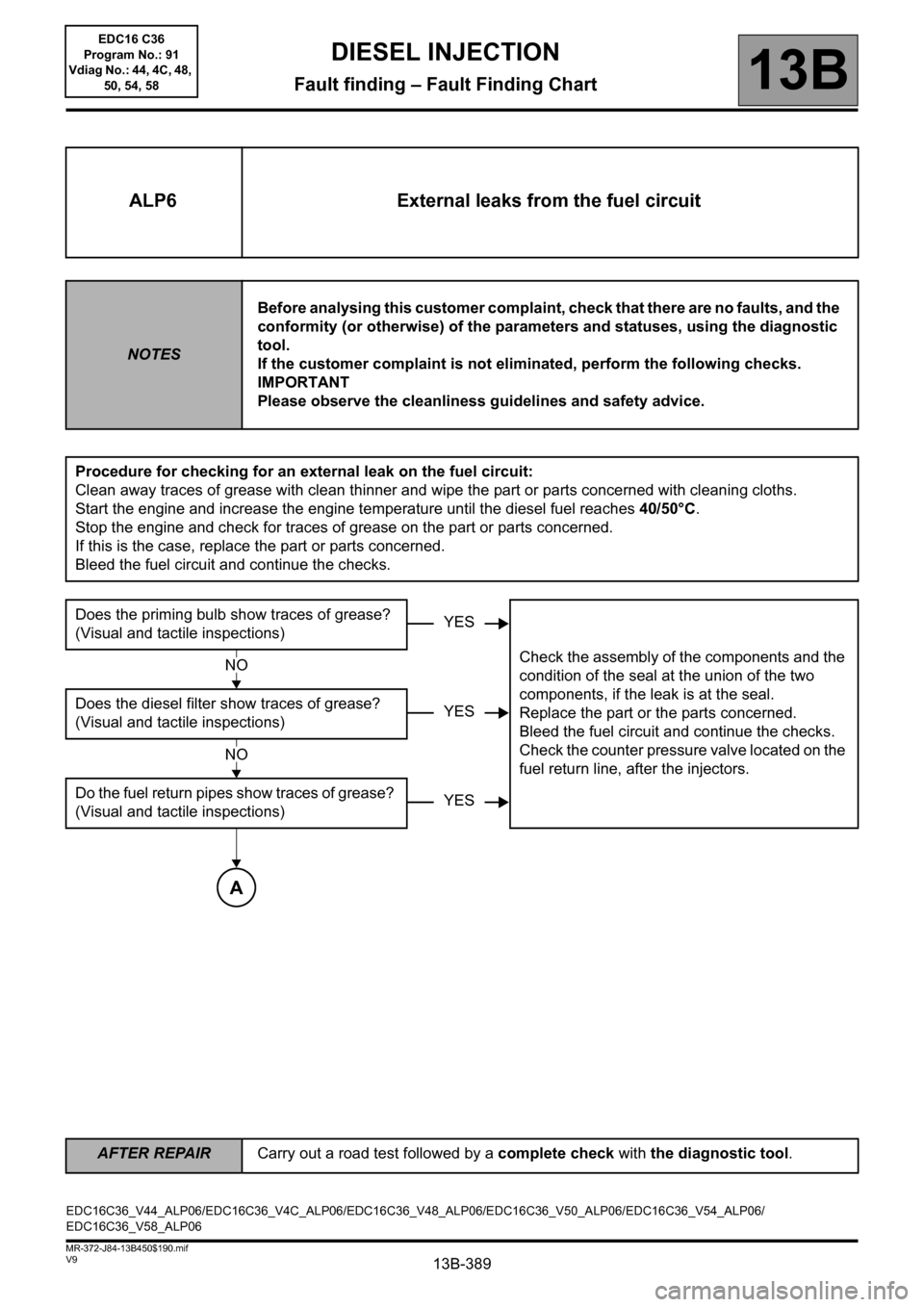

ALP6 External leaks from the fuel circuit

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT

Please observe the cleanliness guidelines and safety advice.

Procedure for checking for an external leak on the fuel circuit:

Clean away traces of grease with clean thinner and wipe the part or parts concerned with cleaning cloths.

Start the engine and increase the engine temperature until the diesel fuel reaches 40/50°C.

Stop the engine and check for traces of grease on the part or parts concerned.

If this is the case, replace the part or parts concerned.

Bleed the fuel circuit and continue the checks.

Does the priming bulb show traces of grease?

(Visual and tactile inspections)

Check the assembly of the components and the

condition of the seal at the union of the two

components, if the leak is at the seal.

Replace the part or the parts concerned.

Bleed the fuel circuit and continue the checks.

Check the counter pressure valve located on the

fuel return line, after the injectors. Does the diesel filter show traces of grease?

(Visual and tactile inspections)

Do the fuel return pipes show traces of grease?

(Visual and tactile inspections)

YES

NO

YES

NO

YES

A

EDC16C36_V44_ALP06/EDC16C36_V4C_ALP06/EDC16C36_V48_ALP06/EDC16C36_V50_ALP06/EDC16C36_V54_ALP06/

EDC16C36_V58_ALP06EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58