engine oil RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 8 of 431

13B-8V9 MR-372-J84-13B450$020.mif

13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

1. HAZARDS ASSOCIATED WITH CONTAMINATION

The high pressure direct injection system is highly sensitive to contamination. The risks caused by the introduction of

contamination are:

– damage to or destruction of the high pressure injection system,

– a component seizing up,

– a component losing its sealing.

All After-Sales operations must be performed under very clean conditions. This means that no impurities (particles

a few microns in size) should have penetrated the system during dismantling.

The cleanliness guidelines must be applied from the filter through to the injectors.

What are the sources of contamination?

– metal or plastic swarf,

– paint,

–fibres:

– from cardboard,

– from brushes,

– from paper,

– from clothing,

– from cloths,

– foreign bodies such as hair,

– the ambient atmosphere,

–etc.

2. INSTRUCTIONS TO BE FOLLOWED PRIOR TO ALL OPERATIONS

Check that you have plugs for the unions to be opened (set of plugs available from the Parts Department). The plugs

are single-use only. After use, they must be discarded (once used they are soiled and cleaning is not sufficient to

make them reusable). Unused plugs must be discarded.IMPORTANT

Cleaning the engine using a high pressure washer is prohibited because of the risk of damaging connections.

In addition, moisture may collect in the connectors and create faults in the electrical connections.

IMPORTANT

Before carrying out any work on the high pressure injection system, protect:

– the accessories and timing belts,

– the electrical accessories, (starter, alternator, electric power-assisted steering pump),

– the flywheel surface, to prevent any diesel from running onto the clutch friction plate.

DIESEL INJECTION

Fault finding – Cleanliness guidelines

Page 20 of 431

13B-20V9 MR-372-J84-13B450$050.mif

DIESEL INJECTION

Fault finding – Features13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Exhaust gas recirculation management:

The EGR (Exhaust Gas Recirculation) system involves removing exhaust gases and reintroducing them into the

inlet.

The exhaust gases are collected in the exhaust manifold (before the turbocharger), then directed to the EGR cooler

and the EGR valve.

EGR cooler

The EGR cooler bypass function cools the gases extracted from the exhaust via a gas-water exchanger and then

reintroduces the gases at the inlet. This cooler is equipped with an all-or-nothing solenoid valve, which enables

gases to be cooled or not cooled, depending on the emission control requirements.

EGR valve

The system comprises a direct current EGR valve and a potentiometer which reports the position of the valve.

A positive command controls its opening (0 → 100%).

The potentiometer serves to control and run fault finding on the valve.

The very first time the engine is started, then each subsequent engine start, the “valve closed” position is

programmed (offset). This value is compared to the very first offset or last programmed offset, for the purposes of

fault finding. It is also used to readjust the valve control function. This is why it is important to associate the EGR

valve to the computer which controls it.

Richness ratio sensor management (only on certain F9Q816 engines in VDiag 48):

The richness ratio sensor is mounted in the turbo outlet.

Its function is to reset the injection system drift.

The injection computer does not control the sensor immediately when the engine has just been started:

–ET300 Richness regulation is INACTIVE,

–PR779 Richness ratio sensor is equal to 1.

After a length of time that depends on the coolant temperature, with the engine running and in the absence of no

load conditions, the injection computer authorises the heating of the sensor:

–ET300 Richness regulation changes to ACTIVE,

– in about ten seconds, the PR778 Richness ratio sensor temperature increases to approximately 780°C,

– then the PR779 Richness ratio sensor displays a value of 0.3 ±0.1 at idle speed.

The turbocharger cooling pump:

Because of its high rotation speed, the turbocharger does not use ball bearings to ensure the pivot connection but

uses a bearing whose friction is reduced thanks to a pressurised film of oil.

When the engine is switched off, the oil is no longer under pressure and no longer provides the pivot connection. A

quantity of oil therefore remains, which collects around the bearing.

When the turbocharger is in operation, the bearing is subjected to high temperatures. After the engine is switched

off, the slow decrease in temperature heats the stagnant oil. This then modifies the viscosity of the oil and therefore

increases the risk of the turbocharger sticking.

To prevent this, a turbocharger coolant pump circulates coolant to lower the temperature of the turbocharger. It is

electrically activated for 5 mins if the engine coolant temperature exceeds 80°C. In addition, the coolant circulation

prevents deterioration of the liquid properties by stopping it collecting under the same temperature constraints as the

oil.

Page 22 of 431

13B-22V9 MR-372-J84-13B450$050.mif

DIESEL INJECTION

Fault finding – Features13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

If all the criteria are met, the computer enters regeneration mode. The injection programming is adjusted in order to

raise the target exhaust gas temperature between 550 and 650°C.

This temperature allows the particles accumulated in the filter to be partially or completely burnt (regenerated).

Regeneration efficiency depends on the particle filter inlet temperature and the time spent in regeneration mode.

Regeneration can be carried out automatically when driving if the weight of soot is less than 70 g and if the number

of regeneration attempts when driving is less than 11 (only for Vdiag 48).

If the weight of soot is greater than 70 g, the user will have to request an After-sales regeneration.

This regeneration is carried out in the workshop. Always follow the instructions written in the interpretation of

commands (SC017 Particle filter regeneration) to perform regeneration in complete safety.

After an After-sales regeneration, always reconfigure certain parameters in the computer using command SC036

Reinitialise programming (see "interpretation of commands").

Warning light management:

Instrument panel display

The computer displays certain information on the instrument panel relating to engine operation. This involves six

functions:

– the pre-postheating warning light,

– the coolant temperature warning message,

– the level 1 fault warning light (non-critical fault),

– the level 2 fault warning light (emergency stop),

– the OBD warning light (European On Board Diagnostic),

– the particle filter specific warning light (F9Q816 engine only).

These six functions are represented by 6 warning lights and/or messages displayed by the on-board computer.

In addition, certain warning lights are, when lit, accompanied by a spoken message on vehicles fitted with a voice

synthesiser (refer to the driver's handbook).

A 3 second visual inspection (automatic test procedure managed by the instrument panel) is carried out by the

injection computer when the ignition is switched on.IMPORTANT

The particle filter must be replaced after a period of time which largely depends on the grade of engine oil used -

this information is in the driver's handbook.

After replacing it, always reconfigure certain parameters in the computer using command SC036 Reinitialise

programming (see "interpretation of commands").

Page 29 of 431

13B-29V9 MR-372-J84-13B450$080.mif

13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

COMPUTER REPLACEMENT OR REPROGRAMMING

Two operations must be performed when replacing or reprogramming the computer:

SC003 Save computer data and SC001 Enter saved data.

–Run SC003 Save computer data before replacing or reprogramming the computer. This enables certain data

to be saved in the diagnostic tool so that the new computer* can be reconfigured like the old one. The saved data

are: injector codes, EGR programming, vehicle options.

–Run SC001 Enter saved data after replacing or reprogramming the computer. This enables the data (saved by

the command SC003 Save computer data) to be rewritten in the new computer*.

If you cannot establish dialogue with the computer being replaced: you will not be able to save anything.

After replacing the computer, write the IMA codes of each injector manually using command SC002 Enter injector

codes by reading the code on each injector (see Replacing the injectors).

Only on F9Q816 engines:

– Enter the data specific to particle filter operation by running SC036 Reinitialise programming and selecting after

replacing injection computer with no save option.

Exhaust gas recirculation valve data is programmed automatically the 1st time the new computer is turned on*.

* New computer or reprogrammed computer.

Specific to the cruise control/speed limiter operation to be carried out before reprogramming of the computer:

Before reprogramming the injection computer, move the main Cruise control/Speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational.

The procedure for resetting the function is as follows:

– Vehicle ignition on.

– Position the main switch in rest position (the computer then detects the rest position).

– Position the switch in Cruise control position to activate the Cruise control function.

– Position the switch in Speed limiter position to activate the Speed limiter function. IMPORTANT

– Switch on the diagnostic tool (mains or cigarette lighter supply).

– Connect a battery charger.

– Cut off all the electrical consumers (lights, interior lighting, air conditioning, radio CD, etc.).

– Wait for the engine to cool (engine coolant temperature < 60° and air temperature < 50°).

– During (re)programming, the instrument panel screen displays "Oil pressure fault".

Ignore this message and do not take any action in connection with it.

DIESEL INJECTION

Fault finding – Replacement of components

Page 39 of 431

13B-39V9 MR-372-J84-13B450$090.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

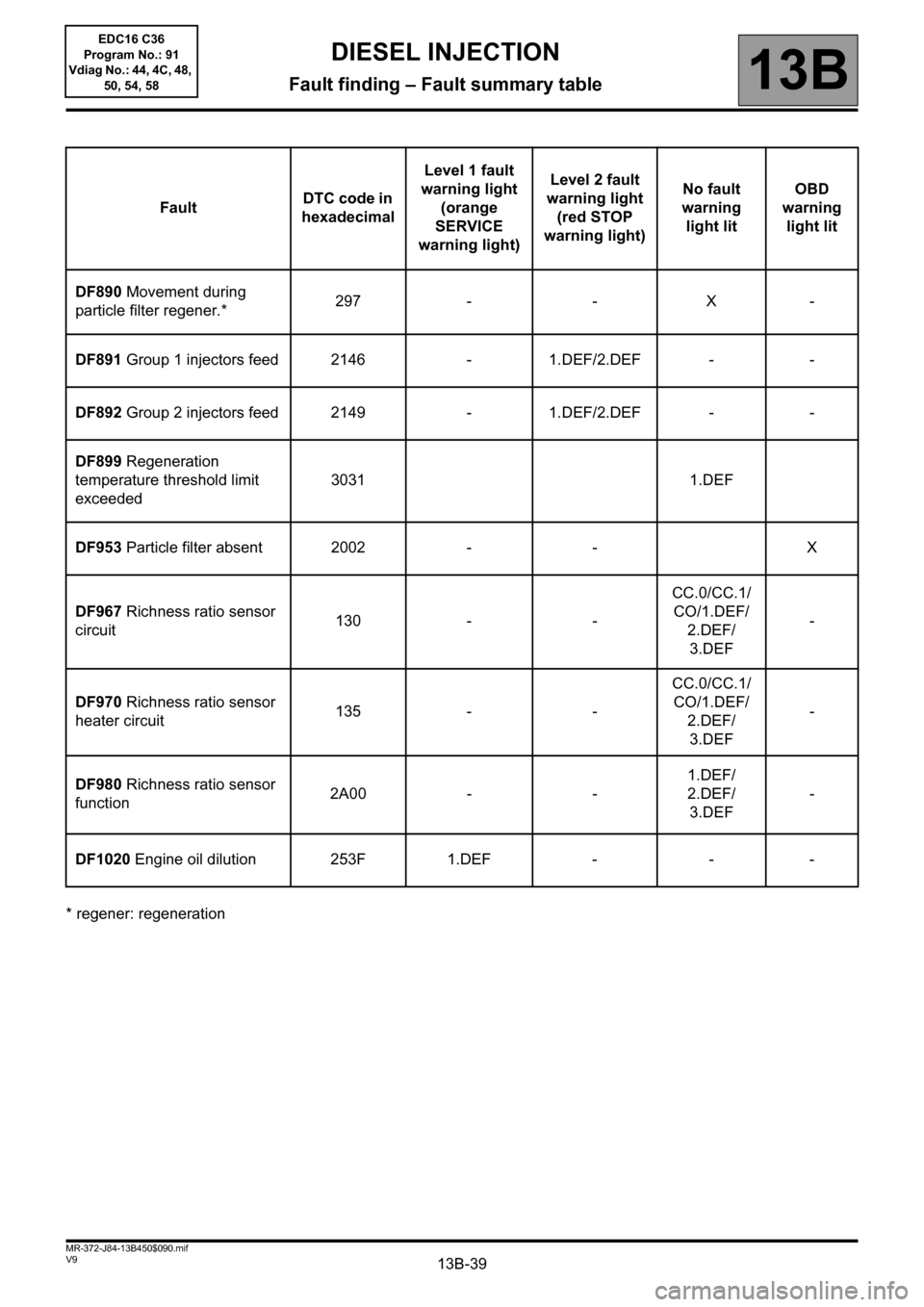

* regener: regenerationFaultDTC code in

hexadecimalLevel 1 fault

warning light

(orange

SERVICE

warning light)Level 2 fault

warning light

(red STOP

warning light)No fault

warning

light litOBD

warning

light lit

DF890 Movement during

particle filter regener.* 297 - - X -

DF891 Group 1 injectors feed 2146 - 1.DEF/2.DEF - -

DF892 Group 2 injectors feed 2149 - 1.DEF/2.DEF - -

DF899 Regeneration

temperature threshold limit

exceeded 3031 1.DEF

DF953 Particle filter absent 2002 - - X

DF967 Richness ratio sensor

circuit130 - -CC.0/CC.1/

CO/1.DEF/

2.DEF/

3.DEF-

DF970 Richness ratio sensor

heater circuit135 - -CC.0/CC.1/

CO/1.DEF/

2.DEF/

3.DEF-

DF980 Richness ratio sensor

function2A00 - -1.DEF/

2.DEF/

3.DEF-

DF1020 Engine oil dilution 253F 1.DEF - - -

Page 116 of 431

13B-116V9 MR-372-J84-13B450$102.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF107

CONTINUED

Only for F9Q816:

If the vehicle is not new (mileage greater than 10 km):

Check that there are no leaks or blockages in the exhaust pipe,

Repair if necessary

– Do an after-sales regeneration using the control SC017 Particle filter regeneration.

– Perform an oil change (see MR 364 (Mégane II) or MR 370 (Scénic II), Mechanical, 10A Engine and

peripherals, Engine oil: Draining – Filling).

If the fault is still present, contact the Techline.

Page 122 of 431

13B-122

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF151

STOREDMAIN RELAY CIRCUIT1.DEF: Relay cut off too soon

2.DEF: Relay cut off too late

NOTESSpecial notes:

The level 1 warning light is on.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

1.DEF

NOTESNone.

Check the condition of the injection feed relay mounting connector (see Wiring Diagram Technical Note, Mégane II

ph2, Scénic II ph2, component code 983).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the tightness and the condition of the "+ " and "-" battery terminals.

Check the conformity of the main relay (relay removed):

Insulation of the contacts between the following connections:

– Connection code 3FB of component 983.

– Connection codeBP37 of component983.

Resistance of the coil between the following connections:

– Connection code 3AA of component 983.

– Connection codeBP37 of component983.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Replace the relay if the resistance is less than 6 Ωor greater than 1 kΩ.

EDC16C36_V44_DF151M/EDC16C36_V4C_DF151M/EDC16C36_V48_DF151M/EDC16C36_V50_DF151M/EDC16C36_V54_DF151M/

EDC16C36_V58_DF151MEDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 124 of 431

13B-124

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF151

CONTINUED 2

2.DEFNOTESNone.

Check the condition of the injection supply relay mounting connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 983).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the conformity of the main relay (relay removed):

Insulation of the contacts between the following connections:

– Connection code 3FB of component 983.

– Connection code BP37 of component 983.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Resistance of the coil between the following connections:

– Connection code 3AA of component 983.

– Connection codeBP37 of component983.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Replace the relay if the resistance is less than 6 Ωor greater than 1 kΩ.

Check the continuity and absence of any interference resistance on the following connection:

– Connection code 3AA between components 983 and 120.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the injection supply relay.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 201 of 431

13B-201

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

*ADAC: Trip Computer

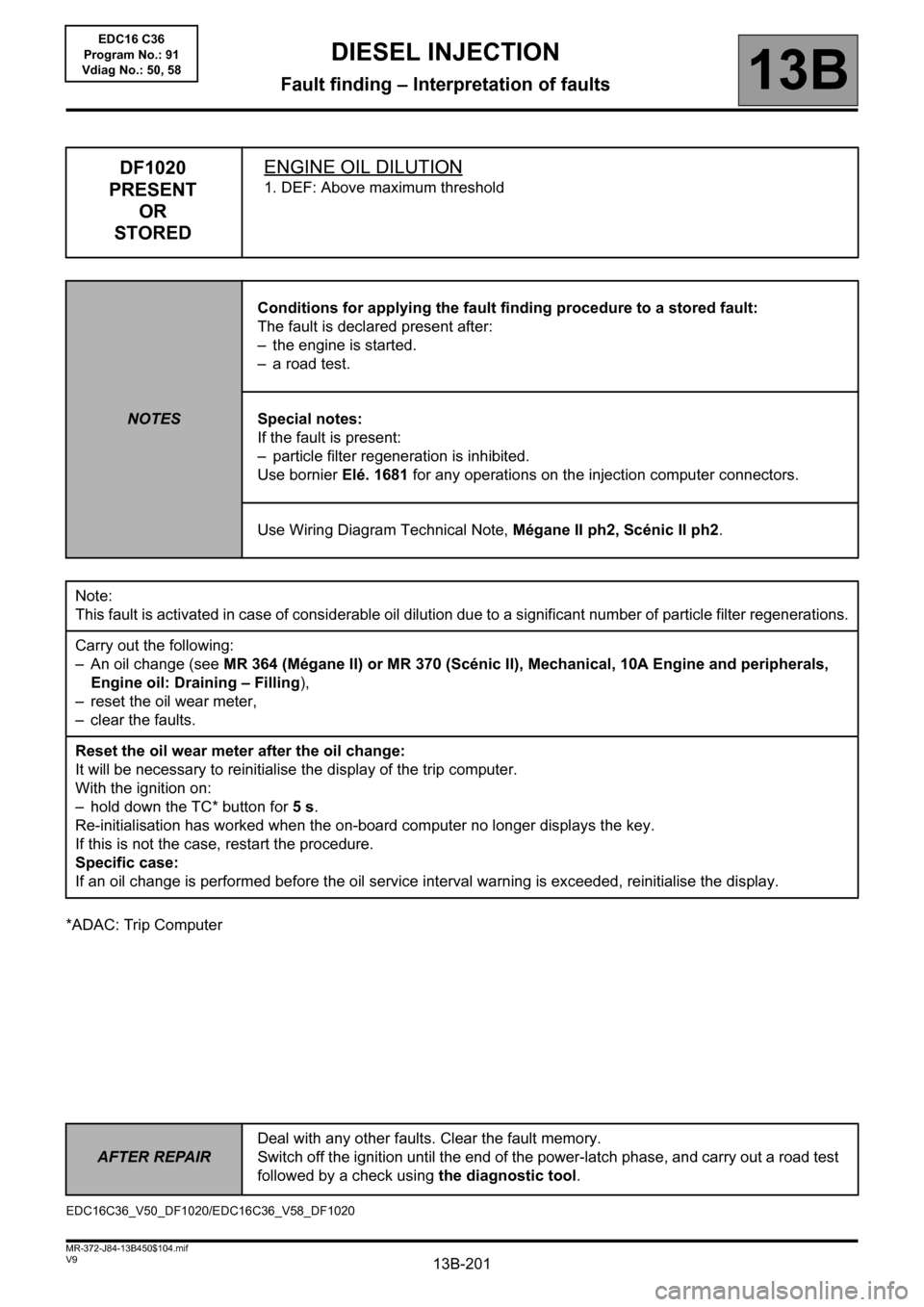

DF1020

PRESENT

OR

STOREDENGINE OIL DILUTION

1. DEF: Above maximum threshold

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the engine is started.

– a road test.

Special notes:

If the fault is present:

– particle filter regeneration is inhibited.

Use bornier Elé. 1681 for any operations on the injection computer connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Note:

This fault is activated in case of considerable oil dilution due to a significant number of particle filter regenerations.

Carry out the following:

– An oil change (see MR 364 (Mégane II) or MR 370 (Scénic II), Mechanical, 10A Engine and peripherals,

Engine oil: Draining – Filling),

– reset the oil wear meter,

– clear the faults.

Reset the oil wear meter after the oil change:

It will be necessary to reinitialise the display of the trip computer.

With the ignition on:

– hold down the TC* button for 5 s.

Re-initialisation has worked when the on-board computer no longer displays the key.

If this is not the case, restart the procedure.

Specific case:

If an oil change is performed before the oil service interval warning is exceeded, reinitialise the display.

EDC16C36_V50_DF1020/EDC16C36_V58_DF1020EDC16 C36

Program No.: 91

Vdiag No.: 50, 58

Page 259 of 431

13B-259V9 MR-372-J84-13B450$140.mif

13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

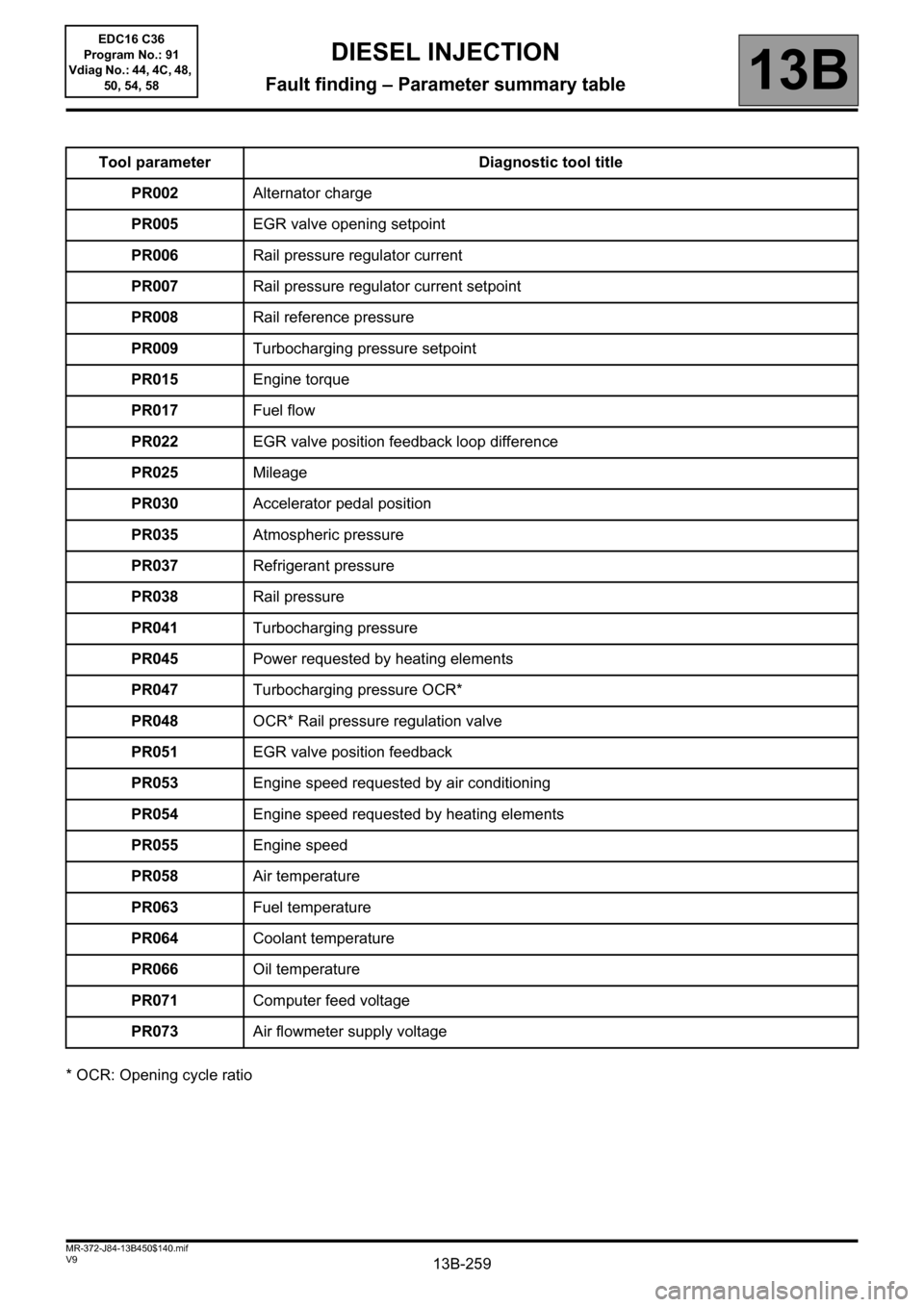

* OCR: Opening cycle ratioTool parameter Diagnostic tool title

PR002Alternator charge

PR005EGR valve opening setpoint

PR006Rail pressure regulator current

PR007Rail pressure regulator current setpoint

PR008Rail reference pressure

PR009Turbocharging pressure setpoint

PR015Engine torque

PR017Fuel flow

PR022EGR valve position feedback loop difference

PR025Mileage

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR041Turbocharging pressure

PR045Power requested by heating elements

PR047Turbocharging pressure OCR*

PR048OCR* Rail pressure regulation valve

PR051EGR valve position feedback

PR053Engine speed requested by air conditioning

PR054Engine speed requested by heating elements

PR055Engine speed

PR058Air temperature

PR063Fuel temperature

PR064Coolant temperature

PR066Oil temperature

PR071Computer feed voltage

PR073Air flowmeter supply voltage

DIESEL INJECTION

Fault finding – Parameter summary table