cruise control RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 46 of 329

13B-46

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

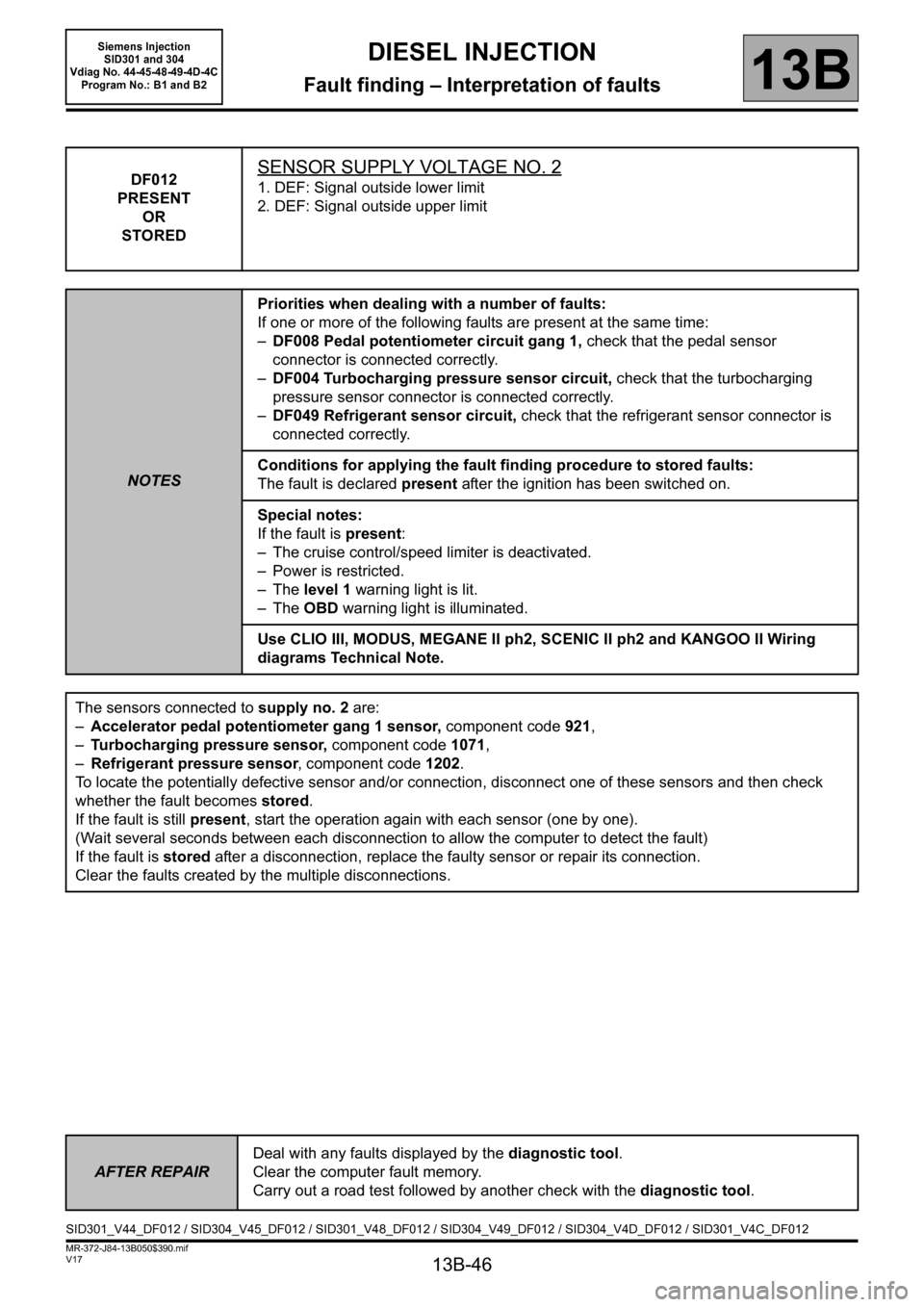

DF012

PRESENT

OR

STOREDSENSOR SUPPLY VOLTAGE NO. 2

1. DEF: Signal outside lower limit

2. DEF: Signal outside upper limit

NOTESPriorities when dealing with a number of faults:

If one or more of the following faults are present at the same time:

–DF008 Pedal potentiometer circuit gang 1, check that the pedal sensor

connector is connected correctly.

–DF004 Turbocharging pressure sensor circuit, check that the turbocharging

pressure sensor connector is connected correctly.

–DF049 Refrigerant sensor circuit, check that the refrigerant sensor connector is

connected correctly.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition has been switched on.

Special notes:

If the fault is present:

– The cruise control/speed limiter is deactivated.

– Power is restricted.

–The level 1 warning light is lit.

–The OBD warning light is illuminated.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

The sensors connected to supply no. 2 are:

–Accelerator pedal potentiometer gang 1 sensor, component code 921,

–Turbocharging pressure sensor, component code 1071,

–Refrigerant pressure sensor, component code 1202.

To locate the potentially defective sensor and/or connection, disconnect one of these sensors and then check

whether the fault becomes stored.

If the fault is still present, start the operation again with each sensor (one by one).

(Wait several seconds between each disconnection to allow the computer to detect the fault)

If the fault is stored after a disconnection, replace the faulty sensor or repair its connection.

Clear the faults created by the multiple disconnections.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF012 / SID304_V45_DF012 / SID301_V48_DF012 / SID304_V49_DF012 / SID304_V4D_DF012 / SID301_V4C_DF012

Page 61 of 329

13B-61

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

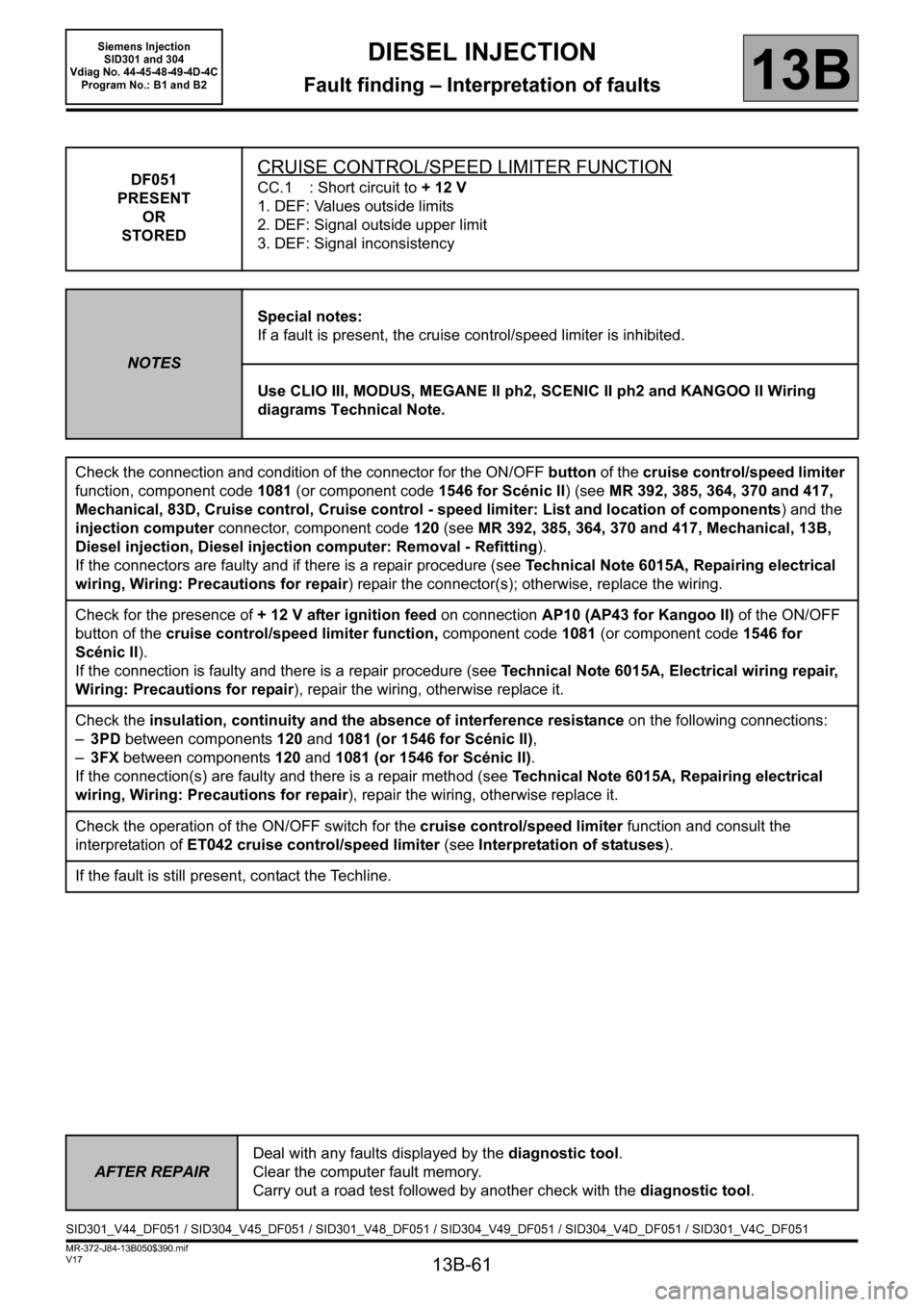

DF051

PRESENT

OR

STOREDCRUISE CONTROL/SPEED LIMITER FUNCTION

CC.1 : Short circuit to + 12 V

1. DEF: Values outside limits

2. DEF: Signal outside upper limit

3. DEF: Signal inconsistency

NOTESSpecial notes:

If a fault is present, the cruise control/speed limiter is inhibited.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Check the connection and condition of the connector for the ON/OFF button of the cruise control/speed limiter

function, component code1081 (or component code1546 for Scénic II) (see MR 392, 385, 364, 370 and 417,

Mechanical, 83D, Cruise control, Cruise control - speed limiter: List and location of components) and the

injection computer connector, component code120 (see MR 392, 385, 364, 370 and 417, Mechanical, 13B,

Diesel injection, Diesel injection computer: Removal - Refitting).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair) repair the connector(s); otherwise, replace the wiring.

Check for the presence of + 12 V after ignition feed on connection AP10 (AP43 for Kangoo II) of the ON/OFF

button of the cruise control/speed limiter function, component code 1081 (or component code 1546 for

Scénic II).

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3PD between components120 and 1081 (or 1546 for Scénic II),

–3FX between components120 and 1081 (or 1546 for Scénic II).

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the operation of the ON/OFF switch for the cruise control/speed limiter function and consult the

interpretation of ET042 cruise control/speed limiter (see Interpretation of statuses).

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF051 / SID304_V45_DF051 / SID301_V48_DF051 / SID304_V49_DF051 / SID304_V4D_DF051 / SID301_V4C_DF051

Page 89 of 329

13B-89

MR-372-J84-13B050$429.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF582

PRESENT

OR

STOREDPRESSURE CONSISTENCY

1. DEF: Signal outside lower limit

2. DEF: Signal outside upper limit

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault becomes present after starting the engine.

If the fault is present:

–The level 1 and OBD fault warning lights are lit on the instrument panel.

–The cruise control/speed limiter is inhibited.

– Loss of performance, torque setpoint restricted.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Check the condition and connection of the turbocharging pressure sensor connector, component code 1071.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the connection and condition of the injection computer connector, component code 120 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

With the ignition on, check for + 5 V on connection 3LQ and earth on connection 3LN of the turbocharging

pressure sensor.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3LQ between components 1071 and 120,

–3LN between components 1071 and 120,

–3LP between components 1071 and 120.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the consistency between the atmospheric pressure and the turbocharging pressure (PR035

Atmospheric pressure = PR041 Turbocharging pressure

).

Engine stopped (cold), the pressure read by the two sensors must be nearly the same.

If the values are very different, replace the turbocharging pressure sensor.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF582 / SID304_V45_DF582 / SID301_V48_DF582 / SID304_V49_DF582 / SID304_V4D_DF582 / SID301_V4C_DF582

Page 125 of 329

13B-125

MR-372-J84-13B050$546.mif

V17

13B

DIESEL INJECTION

Fault finding – Status summary table

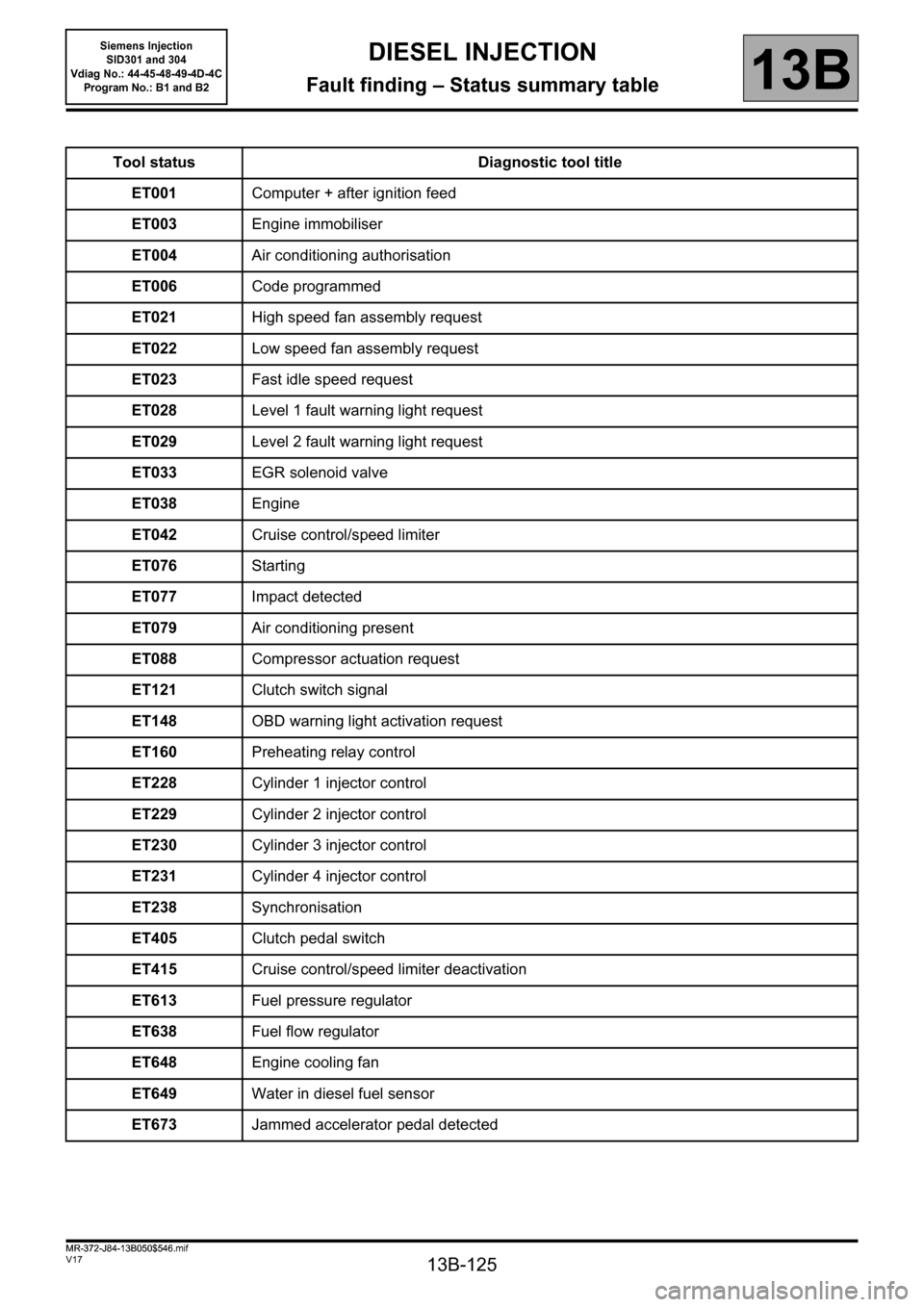

Tool status Diagnostic tool title

ET001Computer + after ignition feed

ET003Engine immobiliser

ET004 Air conditioning authorisation

ET006Code programmed

ET021High speed fan assembly request

ET022Low speed fan assembly request

ET023Fast idle speed request

ET028Level 1 fault warning light request

ET029Level 2 fault warning light request

ET033EGR solenoid valve

ET038Engine

ET042Cruise control/speed limiter

ET076Starting

ET077Impact detected

ET079Air conditioning present

ET088Compressor actuation request

ET121Clutch switch signal

ET148OBD warning light activation request

ET160Preheating relay control

ET228Cylinder 1 injector control

ET229Cylinder 2 injector control

ET230Cylinder 3 injector control

ET231Cylinder 4 injector control

ET238Synchronisation

ET405Clutch pedal switch

ET415Cruise control/speed limiter deactivation

ET613Fuel pressure regulator

ET638Fuel flow regulator

ET648Engine cooling fan

ET649Water in diesel fuel sensor

ET673Jammed accelerator pedal detected

MR-372-J84-13B050$546.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

Page 126 of 329

13B-126

MR-372-J84-13B050$546.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Status summary table13B

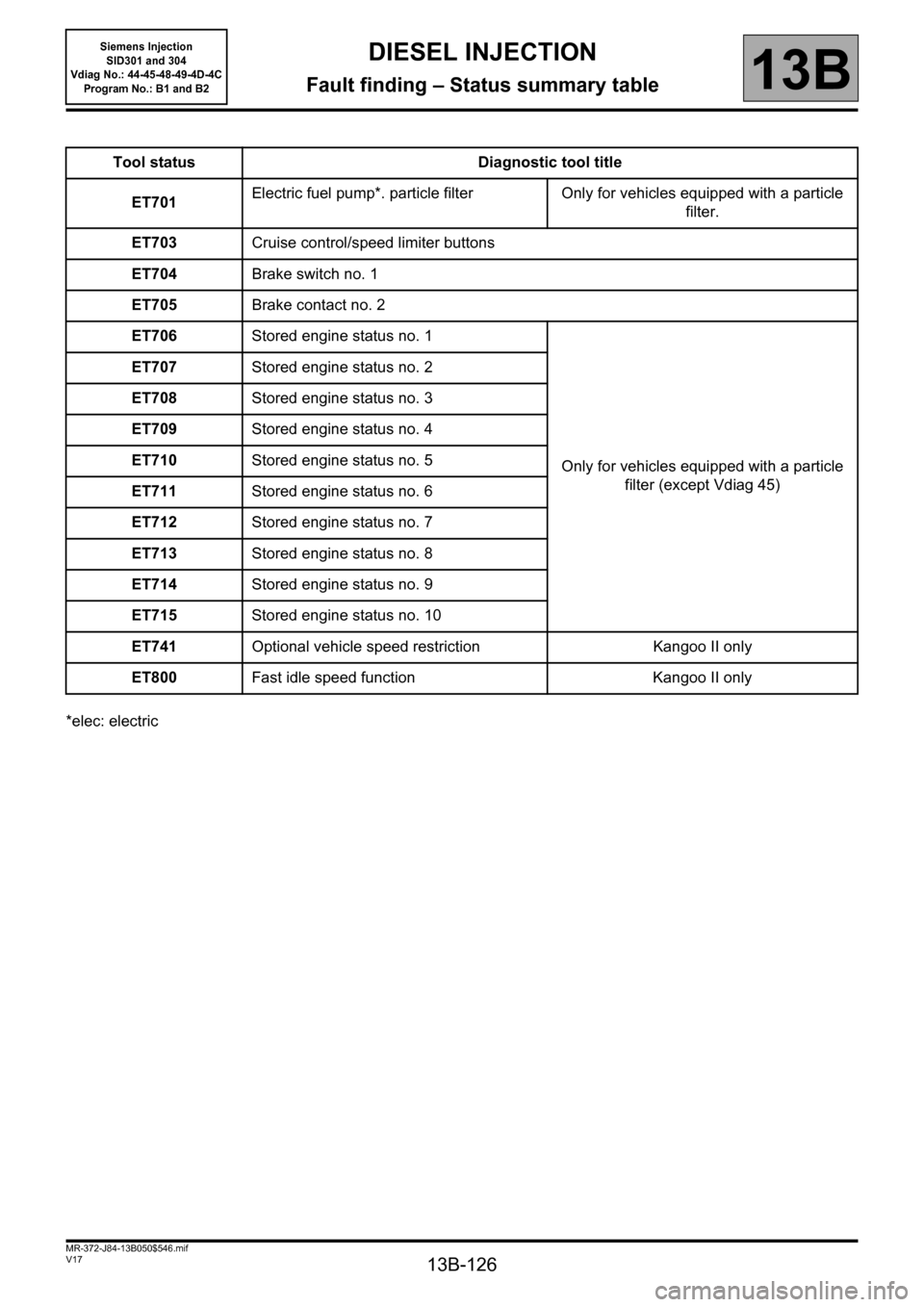

*elec: electricTool status Diagnostic tool title

ET701Electric fuel pump*. particle filter Only for vehicles equipped with a particle

filter.

ET703Cruise control/speed limiter buttons

ET704Brake switch no. 1

ET705Brake contact no. 2

ET706Stored engine status no. 1

Only for vehicles equipped with a particle

filter (except Vdiag 45) ET707Stored engine status no. 2

ET708Stored engine status no. 3

ET709Stored engine status no. 4

ET710Stored engine status no. 5

ET711Stored engine status no. 6

ET712Stored engine status no. 7

ET713Stored engine status no. 8

ET714Stored engine status no. 9

ET715Stored engine status no. 10

ET741Optional vehicle speed restriction Kangoo II only

ET800Fast idle speed function Kangoo II only

Page 139 of 329

13B-139

MR-372-J84-13B050$585.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

ET042

CRUISE CONTROL/SPEED LIMITER

STATUS DEFINITION"NOT DETECTED": This status indicates that the cruise control or speed limiter

function is not present on the vehicle.

"INACTIVE": This status indicates that the cruise control/speed limiter main On/Off

switch is in the rest position.

"LIMITER": This status indicates that the driver has used the main switch to select the

speed limiter.

"CRUISE CONTROL": This status indicates that the driver has used the main switch to

select the cruise control.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

NOT DETECTED

If the vehicle does not have buttons for the cruise control or speed limiter functions,

status ET042 is permanently NOT DETECTED. This confirms that the cruise control/

speed limiter function is not present on the vehicle.

If the vehicle is fitted with cruise control or speed limiter function buttons, the main

switch is in rest (or neutral) position and the injection computer has just been

programmed or reprogrammed, then status ET042 is NOT DETECTED.

To activate the cruise control or speed limiter function, press the main switch in the

cruise control position and then in the speed limiter position.

Return to rest position.

The tool displays status ET042: "INACTIVE".

If not, several steps must be checked:

1. return to the page on testing the multiplex network with the CLIP program. Repeat

the multiplex network test. Re-establish dialogue with the injection computer.

Check status ET042. If ET042 is "INACTIVE", the injection computer has detected

the various positions of the main switch. The cruise control/speed limiter is active.

2. If status ET042 is still NOT DETECTED, check that the owner of the vehicle has

not, sometime in the past, asked for the cruise control/speed limiter function to be

deactivated. Contact the Techline.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID301_V44_ET042/SID304_V45_ET042/SID301_V48_ET042/SID304_V49_ET042/SID304_V4D_ET042/SID301_V4C_ET042

Page 140 of 329

13B-140

MR-372-J84-13B050$585.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

ET042

CONTINUED 1

INACTIVE

Method to be applied for Clio III and Modus:

When the main switch is in the rest (or neutral) position, status ET042 is INACTIVE.

If CRUISE CONTROL or SPEED LIMITER appears despite the main button being in

the rest (or neutral) position, carry out the following operations:

Check the connections of the cruise control/speed limiter main switch.

Check for + 12 V APC on the main switch connector.

●Connection code AP10 of component 1081.

Disconnect the main switch and with it in the rest position, check the insulation

between:

●Connection code AP10 and 3FX of component 1081.

●Connection code AP10 and 3PD of component 1081.

– Check the continuity between connections AP10 and 3PD of component 1081 in

the speed limiter position.

– Check the continuity between connections AP10 and 3FX of component 1081 in

the cruise control position.

If these checks are not in order, replace the switch.

Check the insulation, continuity and the absence of interference resistance on the

following connections:

●Connection code 3FX,

●Connection code 3PD,

between components 1081 and 120.

Also check the engine management computer connectors.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A,

Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 141 of 329

13B-141

MR-372-J84-13B050$585.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

ET042

CONTINUED 2

INACTIVE

CONTINUED 1

Method to be applied for Mégane II ph2 and Kangoo II:

When the main switch is in the rest (or neutral) position, status ET042 is INACTIVE.

If CRUISE CONTROL or SPEED LIMITER appears despite the main button being in

the rest (or neutral) position, carry out the following operations:

Check the connections of the cruise control/speed limiter main switch.

Check for + 12 V APC on the main switch connector.

●Connection code AP43 of component 1081.

Disconnect the main switch and with it in the rest position, check the insulation

between:

●Connection code AP43 and 3FX for component 1081.

●Connection code AP43 and 3PD for component 1081.

– Check the continuity between connections AP43 and 3PD of component 1081 in

the speed limiter position.

– Check the continuity between connections AP43 and 3FX of component 1081 in

the cruise control position.

If these checks are not in order, replace the switch.

Check the insulation, continuity and the absence of interference resistance on the

following connections:

●Connection code 3FX,

●Connection code 3PD,

between components 1081 and 120.

Also check the engine management computer connectors.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A,

Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 142 of 329

13B-142

MR-372-J84-13B050$585.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

ET042

CONTINUED 3

INACTIVE

CONTINUED 2

Method to be applied for Scenic II ph2:

When the main switch is in the rest (or neutral) position, status ET042 is INACTIVE.

If CRUISE CONTROL or SPEED LIMITER appears despite the main button being in

the rest (or neutral) position, carry out the following operations:

Check the connections of the cruise control/speed limiter main switch.

Check for + 12 V APC on the main switch connector.

●Connection code AP43 of component 1546.

Disconnect the main switch and with it in the rest position, check the insulation

between:

●Connection code AP43 and 3FX of component 1546.

●Connection code AP43 and 3PD of component 1546.

– Check the continuity between connections AP43 and 3PD of component 1546 in

the speed limiter position.

– Check the continuity between connections AP43 and 3FX of component 1546 in

the cruise control position.

If these checks are not in order, replace the switch.

Check the insulation, continuity and the absence of interference resistance on the

following connections:

●Connection code 3FX,

●Connection code 3PD,

between components 1546 and 120.

Also check the engine management computer connectors.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A,

Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 143 of 329

13B-143

MR-372-J84-13B050$585.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

ET042

CONTINUED 4

SPEED LIMITER

Method to be applied for Clio III, Modus:

When the driver presses the main switch in the speed limiter position, status ET042

becomes SPEED LIMITER.

If CRUISE CONTROL or INACTIVE appears although the switch was pressed in the

speed limiter position, carry out the following operations:

Check the connections of the cruise control/speed limiter main switch.

Check for + 12 V APC on the main switch connector.

●Connection code AP10 of component 1081.

Disconnect the main switch and with it in the rest position, check the insulation

between:

●Connection codes AP10 and 3FX, of component 1081.

●Connection codes AP10 and 3PD, of component 1081.

– Check the continuity between connections AP10 and 3PD of component 1081 in

the speed limiter position.

– Check the continuity between connections AP10 and 3FX of component 1081 in

the cruise control position.

If these checks show incorrect values, replace the main switch.

Check the insulation, continuity and the absence of interference resistance on the

following connections:

●Connection code 3FX,

●Connection code 3PD,

between components 1081 and 120.

Also check the engine management computer connectors.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A,

Repairing electrical wiring, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.