key RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 2 of 329

13B-2

MR-372-J84-13B050$039.mif

V17

13B

DIESEL INJECTION

Fault finding – Introduction

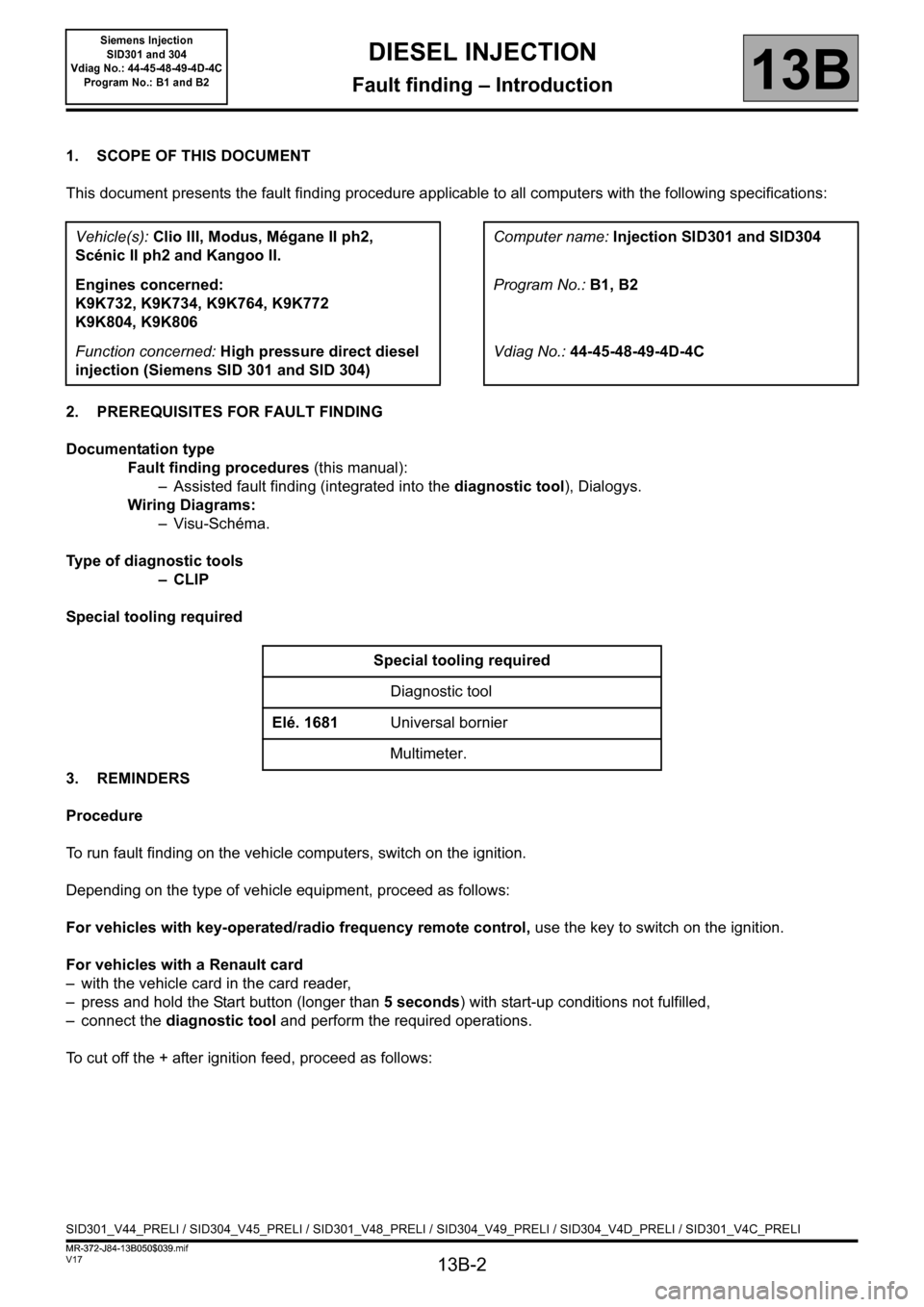

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this manual):

– Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu-Schéma.

Type of diagnostic tools

–CLIP

Special tooling required

3. REMINDERS

Procedure

To run fault finding on the vehicle computers, switch on the ignition.

Depending on the type of vehicle equipment, proceed as follows:

For vehicles with key-operated/radio frequency remote control, use the key to switch on the ignition.

For vehicles with a Renault card

– with the vehicle card in the card reader,

– press and hold the Start button (longer than 5 seconds) with start-up conditions not fulfilled,

– connect the diagnostic tool and perform the required operations.

To cut off the + after ignition feed, proceed as follows:Vehicle(s): Clio III, Modus, Mégane II ph2,

Scénic II ph2 and Kangoo II.Computer name: Injection SID301 and SID304

Engines concerned:

K9K732, K9K734, K9K764, K9K772

K9K804, K9K806Program No.: B1, B2

Function concerned: High pressure direct diesel

injection (Siemens SID 301 and SID 304)Vdiag No.: 44-45-48-49-4D-4C

Special tooling required

Diagnostic tool

Elé. 1681Universal bornier

Multimeter.

SID301_V44_PRELI / SID304_V45_PRELI / SID301_V48_PRELI / SID304_V49_PRELI / SID304_V4D_PRELI / SID301_V4C_PRELI

MR-372-J84-13B050$039.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

Page 3 of 329

13B-3

MR-372-J84-13B050$039.mif

V17

DIESEL INJECTION

Fault finding – Introduction

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

For vehicles with key/radio frequency remote control, use the key to switch off the ignition.

For vehicles with a Renault card:

– press the Start button twice briefly (less than 3 seconds),

– ensure that the + after ignition feed has been cut off by checking that the computer warning lights on the

instrument panel have gone out.

Faults

Faults are declared present or stored (depending on whether they appeared in a certain context and have

disappeared since, or whether they remain present but are not diagnosed within the current context).

The present or stored status of faults should be considered when using the diagnostic tool after the + after ignition

feed is switched on (without any action on the system components).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the instructions in the Notes section.

If the fault is confirmed when the instructions are applied, the fault is present. Deal with the fault.

If the fault is not confirmed, check:

– the electrical lines which correspond to the fault,

– the connectors on these lines (corrosion, bent pins, etc.),

– the resistance of the faulty component,

– the condition of the wires (melted or split insulation, wear).

Conformity check

The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool when the

data is inconsistent. Therefore, this stage is used to:

– carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint,

– check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the test with the diagnostic tool is OK but the customer complaint is still present, the fault should be processed

bycustomer complaints.

A synopsis of the general procedure to follow is provided on the following page in the

form of a flow chart.

Page 131 of 329

13B-131

MR-372-J84-13B050$585.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

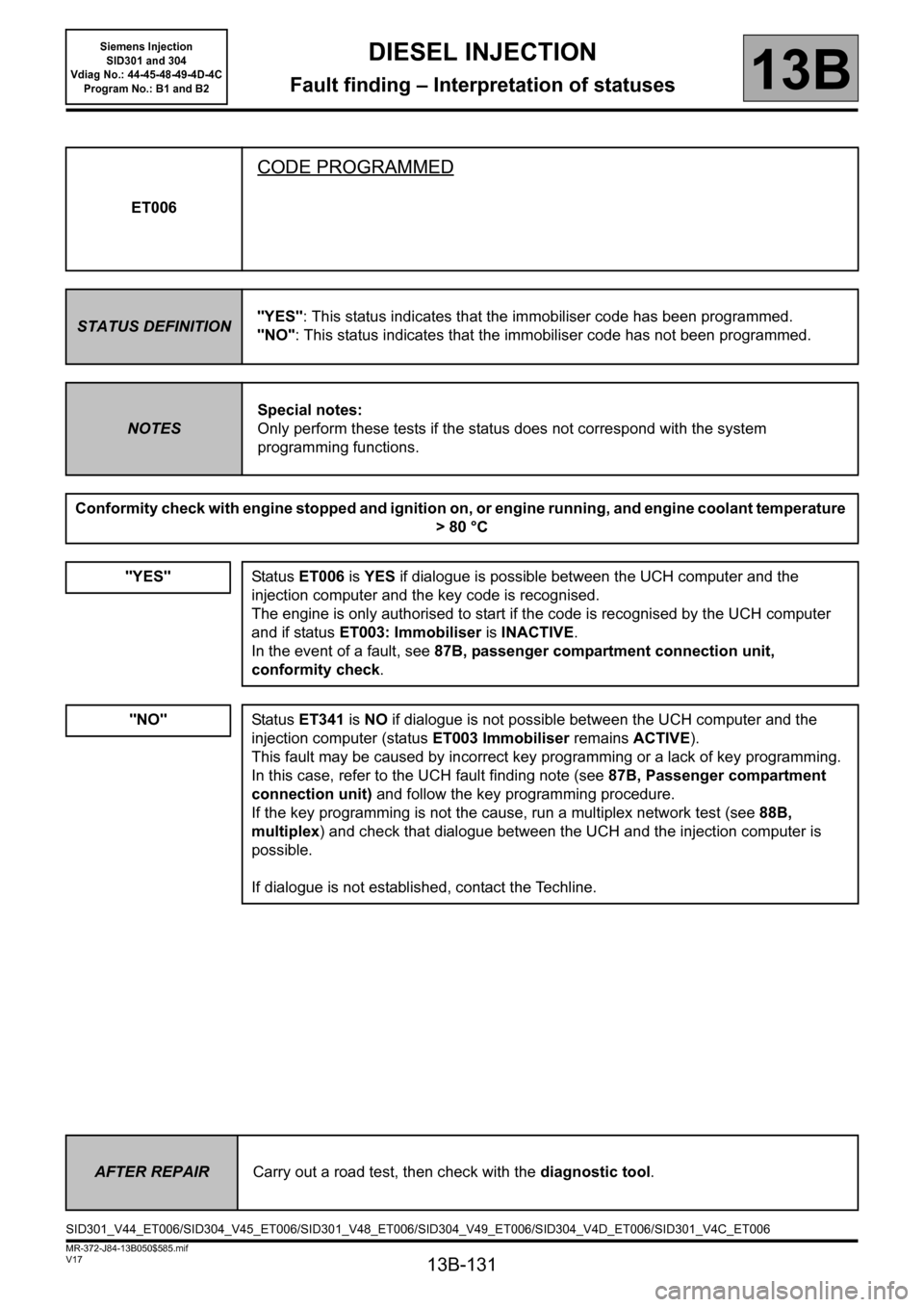

ET006

CODE PROGRAMMED

STATUS DEFINITION"YES": This status indicates that the immobiliser code has been programmed.

"NO": This status indicates that the immobiliser code has not been programmed.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C

"YES"

Status ET006 is YES if dialogue is possible between the UCH computer and the

injection computer and the key code is recognised.

The engine is only authorised to start if the code is recognised by the UCH computer

and if status ET003: Immobiliser is INACTIVE.

In the event of a fault, see87B, passenger compartment connection unit,

conformity check.

"NO"Status ET341 is NO if dialogue is not possible between the UCH computer and the

injection computer (status ET003 Immobiliser remains ACTIVE).

This fault may be caused by incorrect key programming or a lack of key programming.

In this case, refer to the UCH fault finding note (see87B, Passenger compartment

connection unit) and follow the key programming procedure.

If the key programming is not the cause, run a multiplex network test (see88B,

multiplex) and check that dialogue between the UCH and the injection computer is

possible.

If dialogue is not established, contact the Techline.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID301_V44_ET006/SID304_V45_ET006/SID301_V48_ET006/SID304_V49_ET006/SID304_V4D_ET006/SID301_V4C_ET006