lock RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 198, PDF Size: 0.85 MB

Page 151 of 198

13B-151V4 MR-372-J84-13B000$120.mif

DIESEL INJECTION

Fault finding – Tests13B

DDCR INJECTION

Vdiag No.: 44, 48

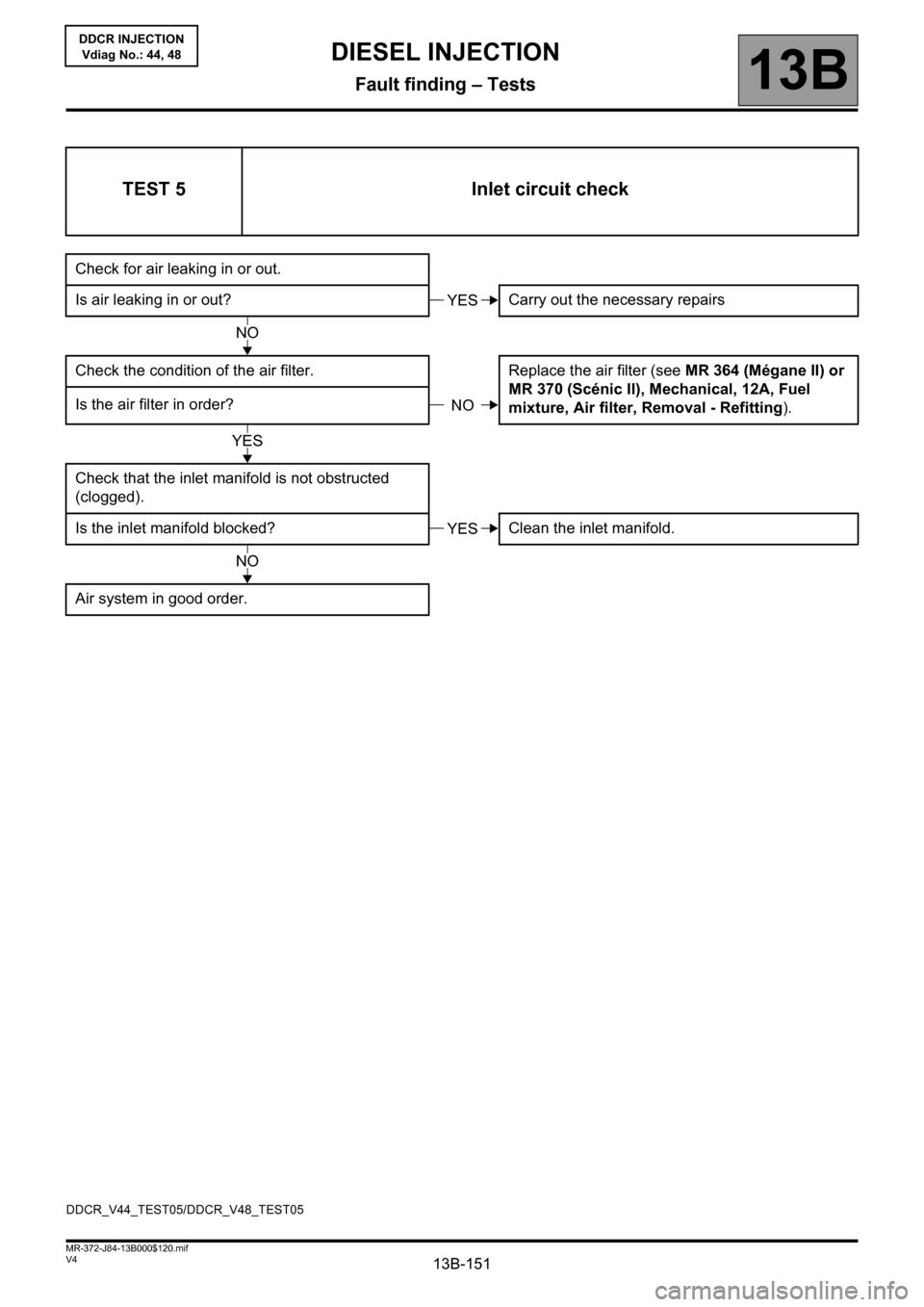

TEST 5 Inlet circuit check

Check for air leaking in or out.

Is air leaking in or out? Carry out the necessary repairs

Check the condition of the air filter. Replace the air filter (see MR 364 (Mégane II) or

MR 370 (Scénic II), Mechanical, 12A, Fuel

mixture, Air filter, Removal - Refitting). Is the air filter in order?

Check that the inlet manifold is not obstructed

(clogged).

Is the inlet manifold blocked? Clean the inlet manifold.

Air system in good order.

YES

NO

NO

YES

YES

NO

DDCR_V44_TEST05/DDCR_V48_TEST05

Page 159 of 198

13B-159V4 MR-372-J84-13B000$120.mif

DIESEL INJECTION

Fault finding – Tests13B

DDCR INJECTION

Vdiag No.: 44, 48

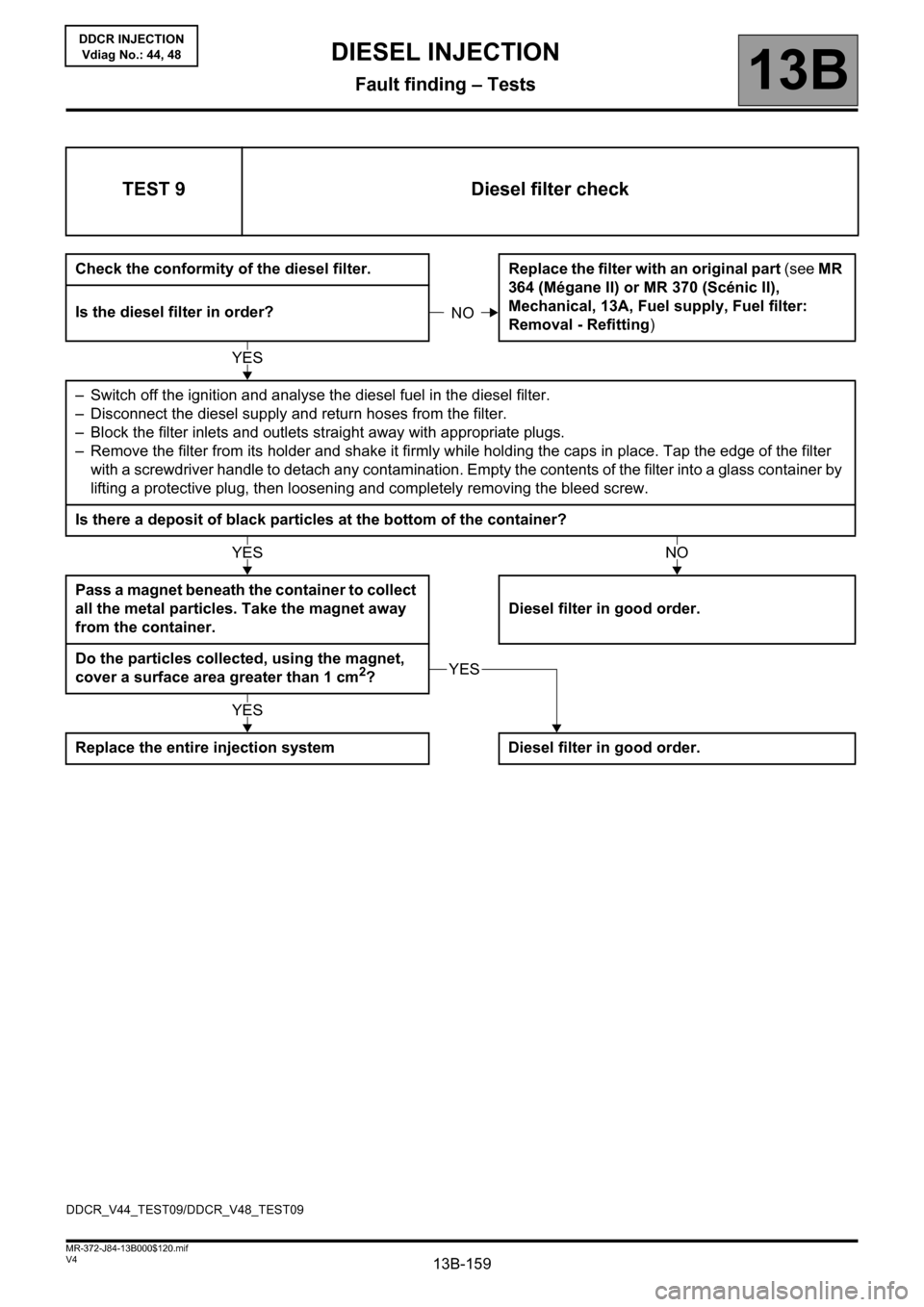

TEST 9 Diesel filter check

Check the conformity of the diesel filter. Replace the filter with an original part (see MR

364 (Mégane II) or MR 370 (Scénic II),

Mechanical, 13A, Fuel supply, Fuel filter:

Removal - Refitting) Is the diesel filter in order?

– Switch off the ignition and analyse the diesel fuel in the diesel filter.

– Disconnect the diesel supply and return hoses from the filter.

– Block the filter inlets and outlets straight away with appropriate plugs.

– Remove the filter from its holder and shake it firmly while holding the caps in place. Tap the edge of the filter

with a screwdriver handle to detach any contamination. Empty the contents of the filter into a glass container by

lifting a protective plug, then loosening and completely removing the bleed screw.

Is there a deposit of black particles at the bottom of the container?

Pass a magnet beneath the container to collect

all the metal particles. Take the magnet away

from the container.Diesel filter in good order.

Do the particles collected, using the magnet,

cover a surface area greater than 1 cm

2?

Replace the entire injection system Diesel filter in good order.

NO

YES

YESNO

YES

YES

DDCR_V44_TEST09/DDCR_V48_TEST09

Page 169 of 198

13B-169

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

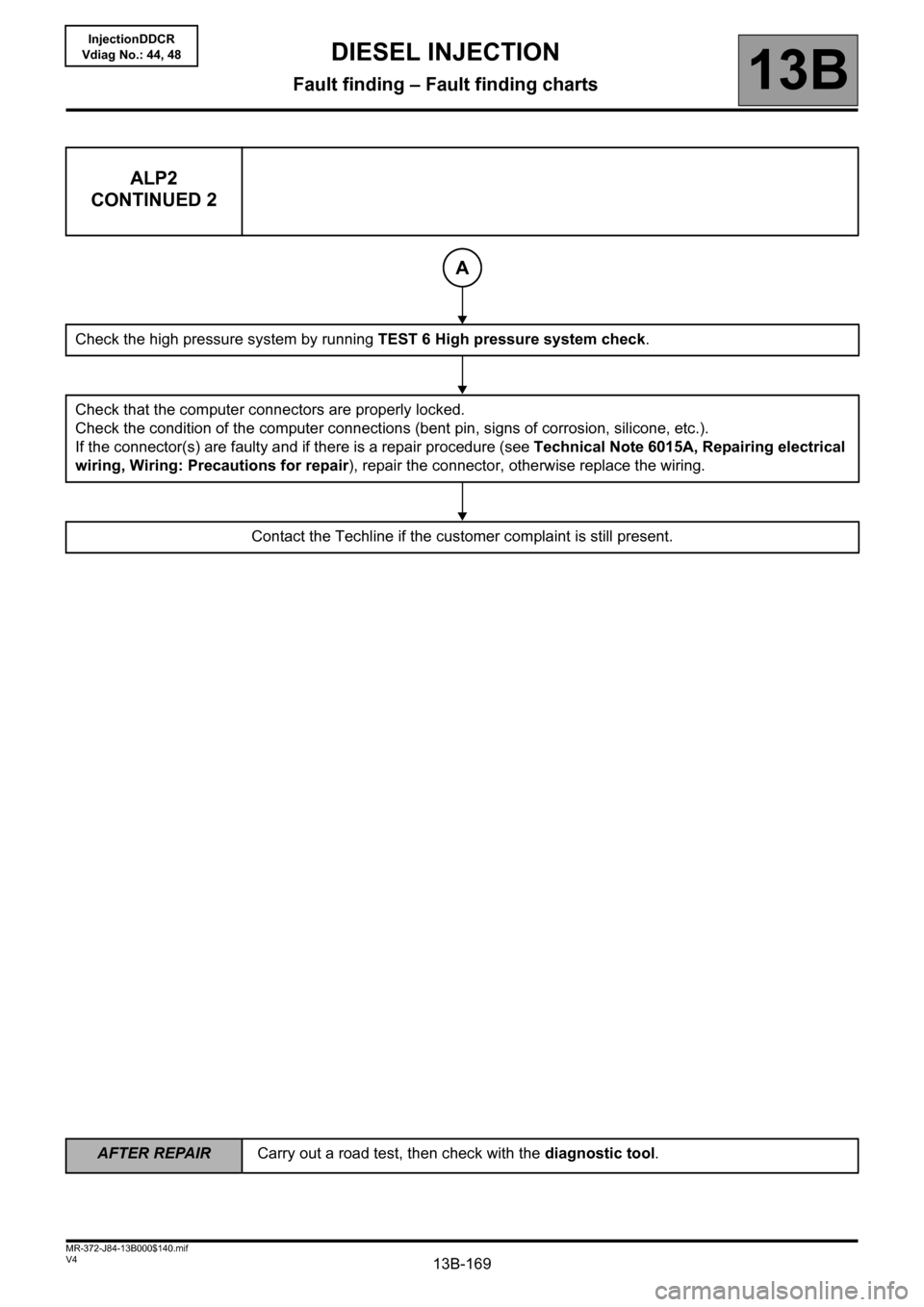

ALP2

CONTINUED 2

Check the high pressure system by running TEST 6 High pressure system check.

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

A

Page 171 of 198

13B-171

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

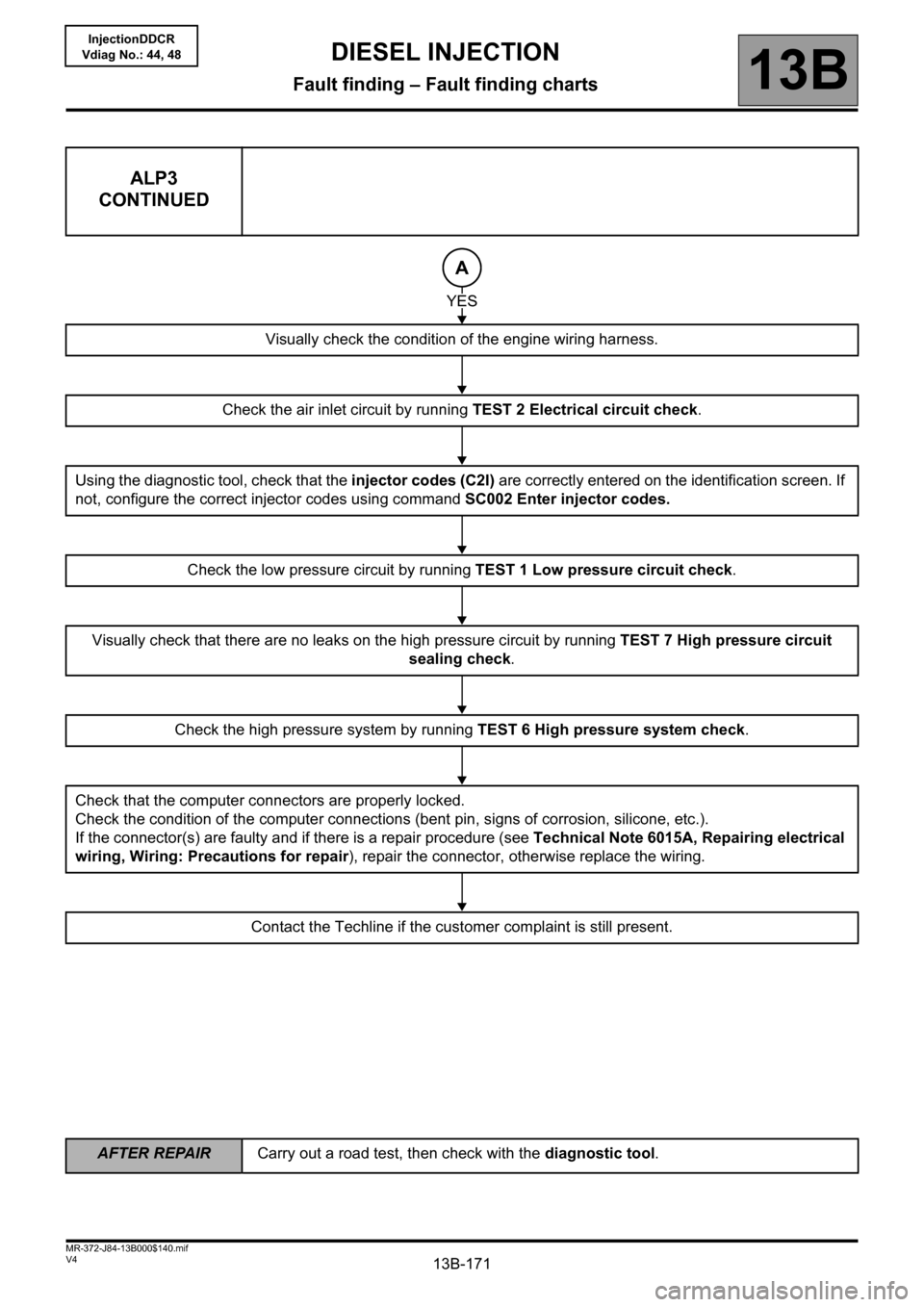

ALP3

CONTINUED

Visually check the condition of the engine wiring harness.

Check the air inlet circuit by running TEST 2 Electrical circuit check.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Visually check that there are no leaks on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

Check the high pressure system by running TEST 6 High pressure system check.

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

A

YES

Page 173 of 198

13B-173

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

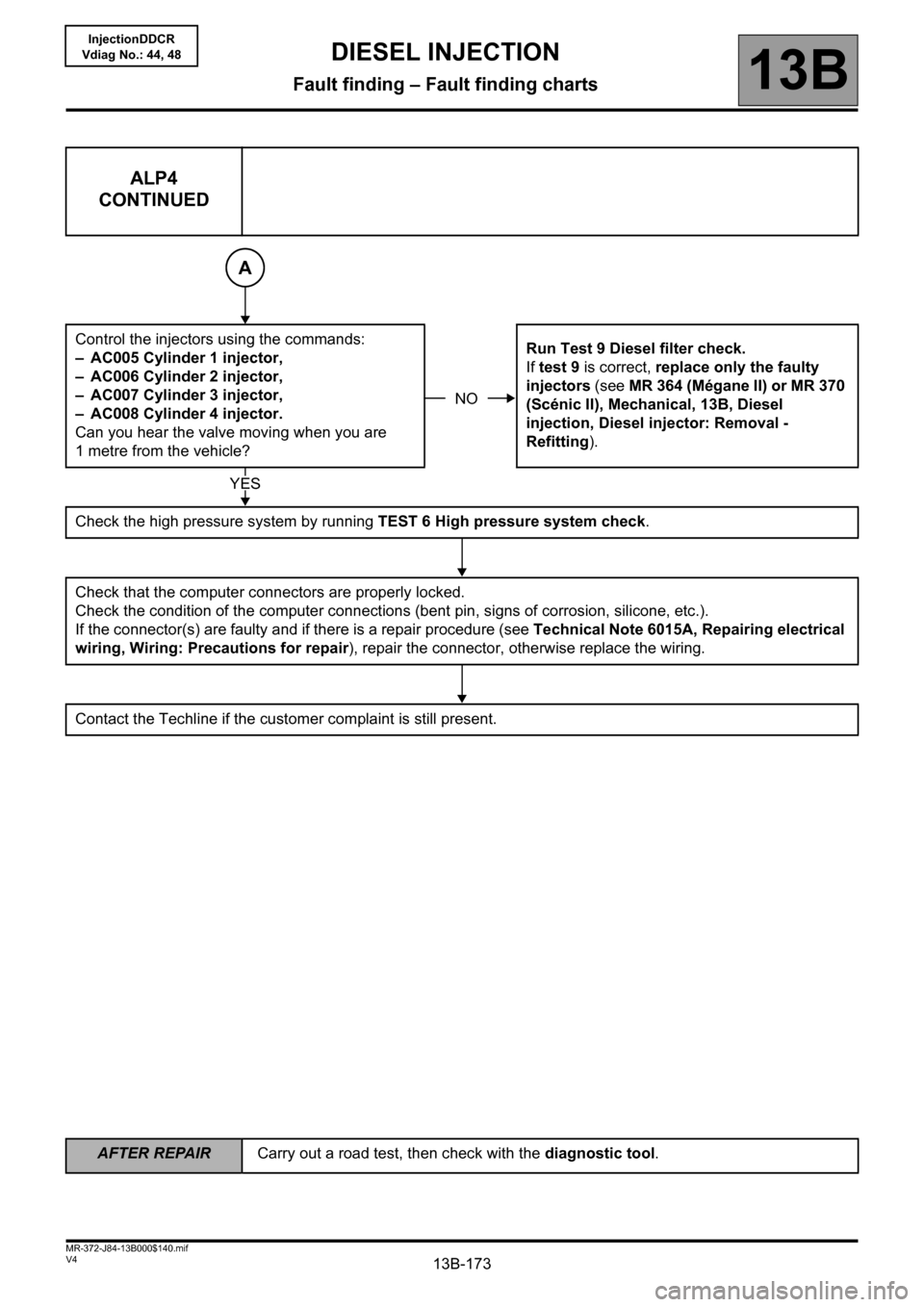

ALP4

CONTINUED

Control the injectors using the commands:

– AC005 Cylinder 1 injector,

– AC006 Cylinder 2 injector,

– AC007 Cylinder 3 injector,

– AC008 Cylinder 4 injector.

Can you hear the valve moving when you are

1 metre from the vehicle?Run Test 9 Diesel filter check.

If test 9 is correct, replace only the faulty

injectors (see MR 364 (Mégane II) or MR 370

(Scénic II), Mechanical, 13B, Diesel

injection, Diesel injector: Removal -

Refitting).

Check the high pressure system by running TEST 6 High pressure system check.

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

A

NO

YES

Page 175 of 198

13B-175

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

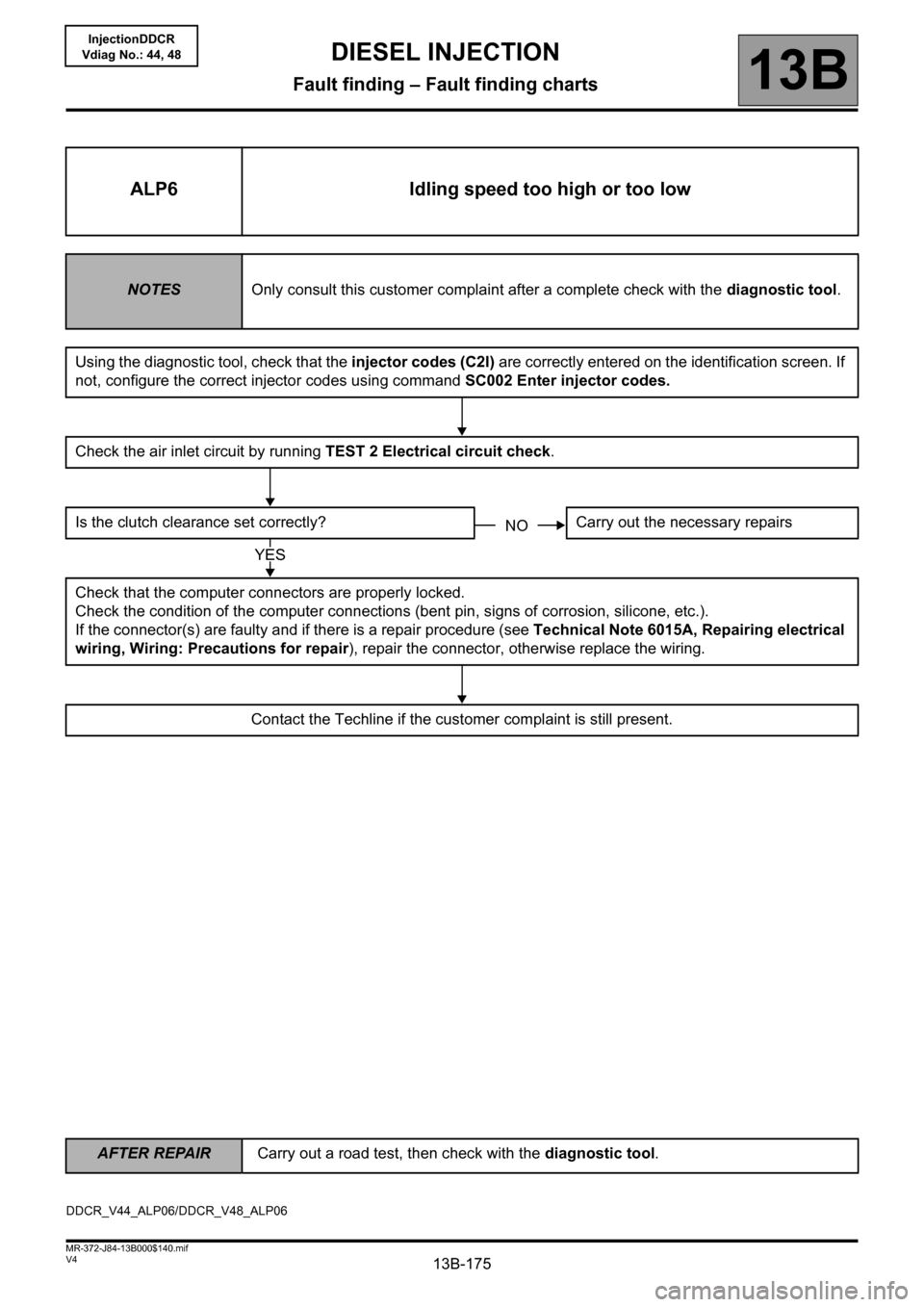

ALP6 Idling speed too high or too low

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Check the air inlet circuit by running TEST 2 Electrical circuit check.

Is the clutch clearance set correctly? Carry out the necessary repairs

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

NO

YES

DDCR_V44_ALP06/DDCR_V48_ALP06

Page 176 of 198

13B-176

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

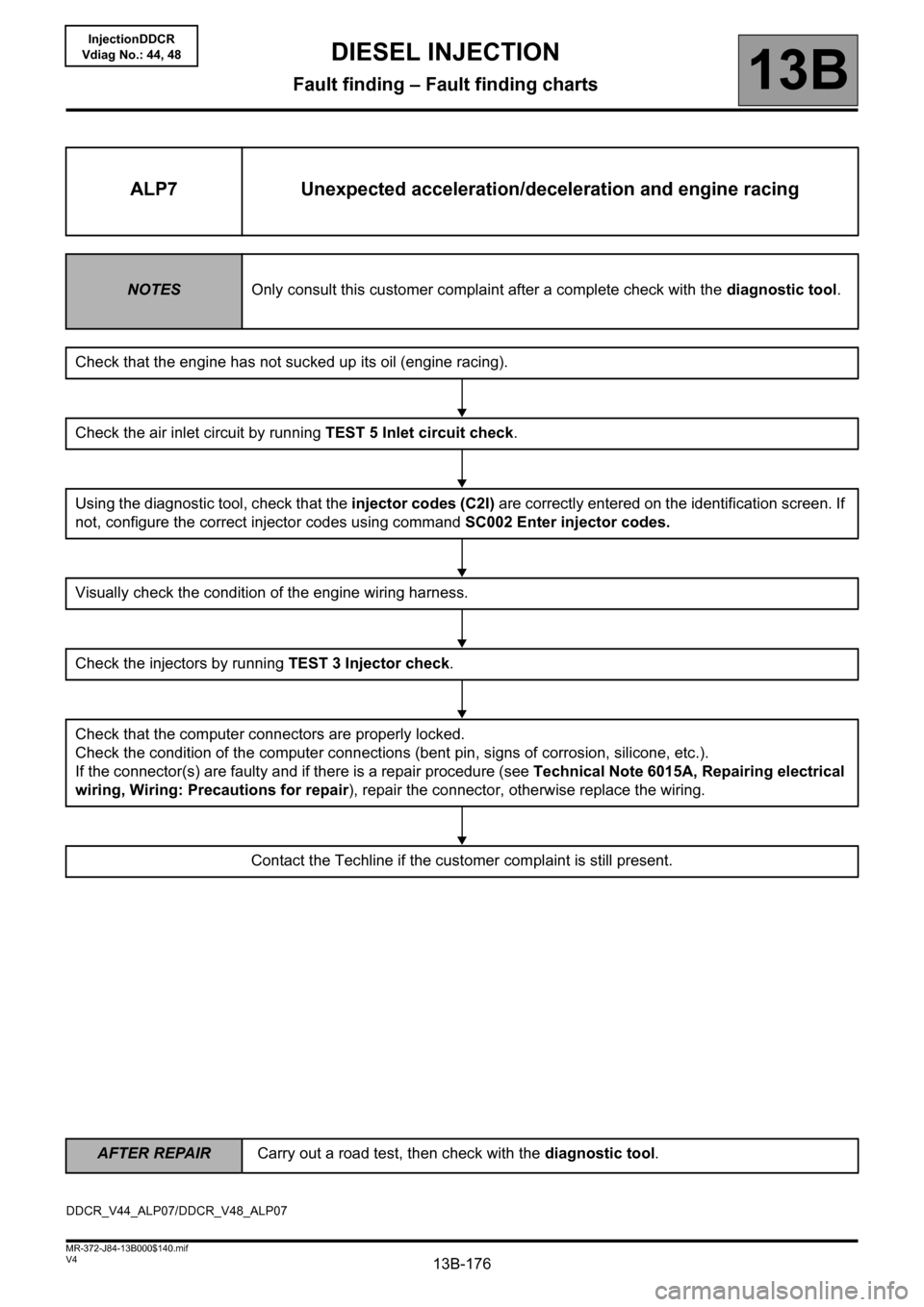

ALP7 Unexpected acceleration/deceleration and engine racing

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Check that the engine has not sucked up its oil (engine racing).

Check the air inlet circuit by running TEST 5 Inlet circuit check.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Visually check the condition of the engine wiring harness.

Check the injectors by running TEST 3 Injector check.

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

DDCR_V44_ALP07/DDCR_V48_ALP07

Page 178 of 198

13B-178

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

ALP8

CONTINUED

Visually check that there are no leaks on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

A

Page 180 of 198

13B-180

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

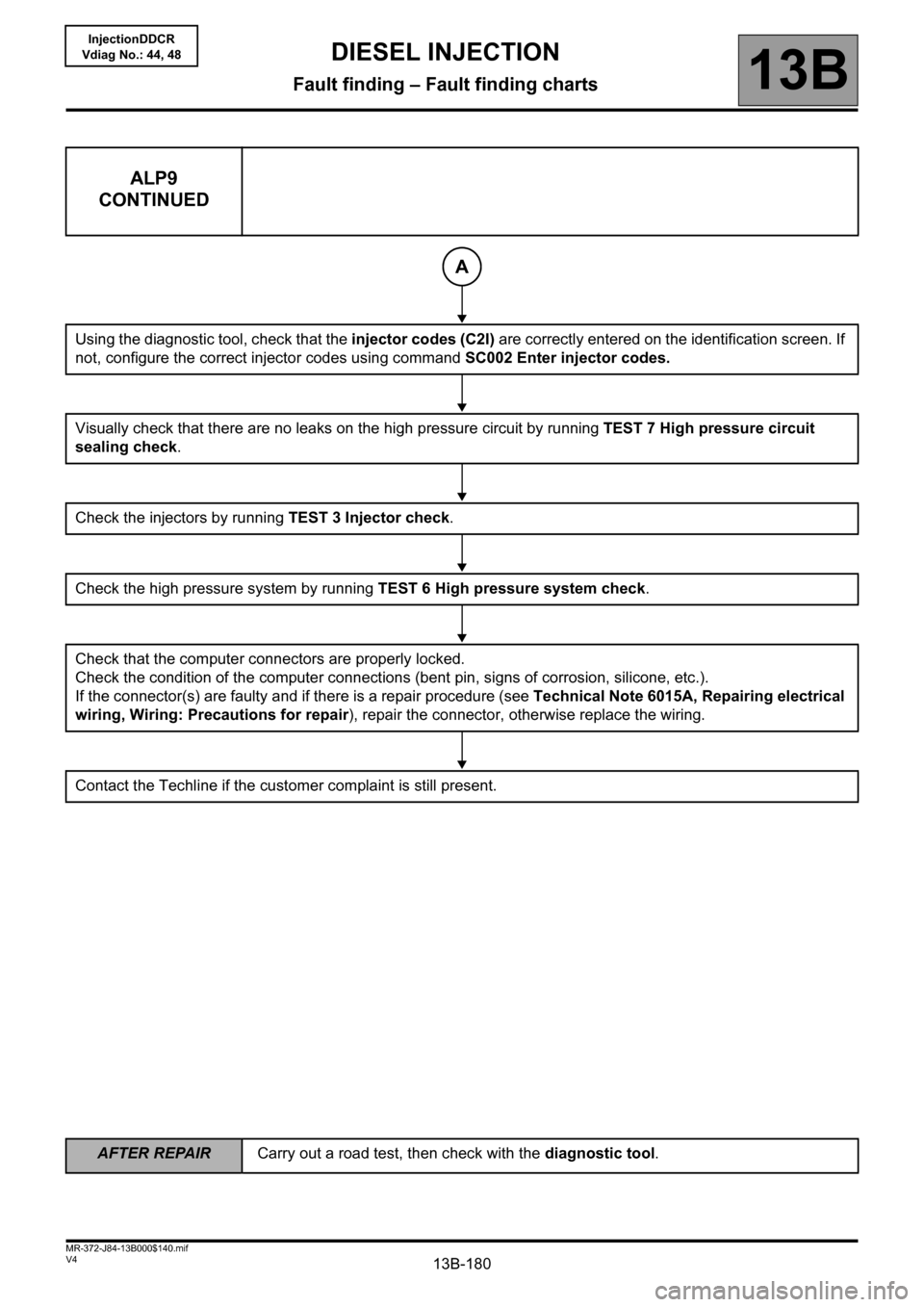

ALP9

CONTINUED

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Visually check that there are no leaks on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

Check the injectors by running TEST 3 Injector check.

Check the high pressure system by running TEST 6 High pressure system check.

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

A

Page 182 of 198

13B-182

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

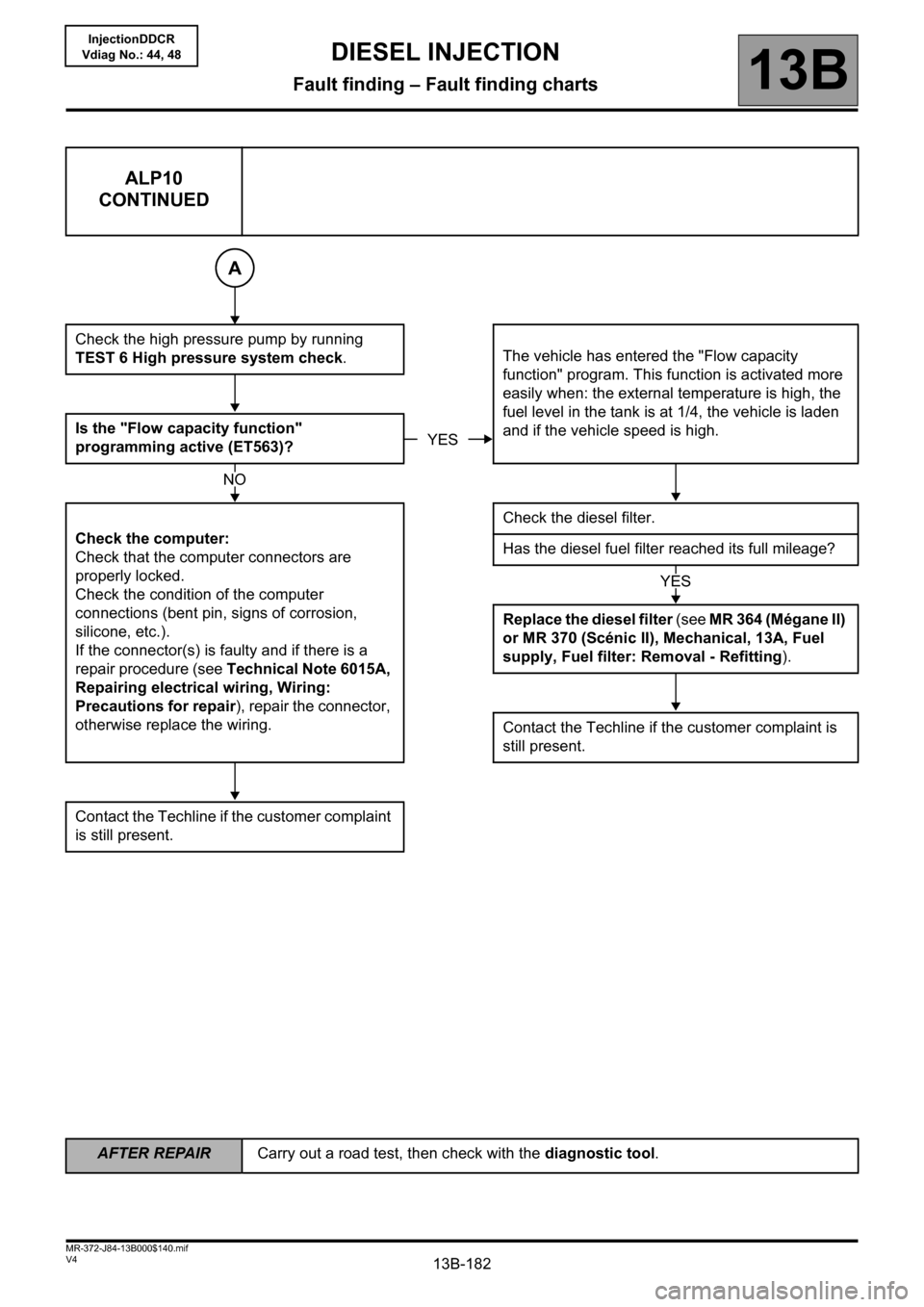

ALP10

CONTINUED

Check the high pressure pump by running

TEST 6 High pressure system check.The vehicle has entered the "Flow capacity

function" program. This function is activated more

easily when: the external temperature is high, the

fuel level in the tank is at 1/4, the vehicle is laden

and if the vehicle speed is high. Is the "Flow capacity function"

programming active (ET563)?

Check the computer:

Check that the computer connectors are

properly locked.

Check the condition of the computer

connections (bent pin, signs of corrosion,

silicone, etc.).

If the connector(s) is faulty and if there is a

repair procedure (see Technical Note 6015A,

Repairing electrical wiring, Wiring:

Precautions for repair), repair the connector,

otherwise replace the wiring.Check the diesel filter.

Has the diesel fuel filter reached its full mileage?

Replace the diesel filter (see MR 364 (Mégane II)

or MR 370 (Scénic II), Mechanical, 13A, Fuel

supply, Fuel filter: Removal - Refitting).

Contact the Techline if the customer complaint is

still present.

Contact the Techline if the customer complaint

is still present.

A

YES

NO

YES