wiring RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 198, PDF Size: 0.85 MB

Page 139 of 198

13B-139

AFTER REPAIRCarry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$090.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DDCR INJECTION

Vdiag No.: 44, 48

ET703

CONTINUED 2

SUSPEND

Status ET703 becomes SUSPEND when the cruise control / speed limiter 0 button is

pressed. This button is located on the steering wheel, to the right.

To remove the driver's airbag to perform the checks in complete safety.

(see 88C, Airbag and pretensioners)

If status ET703 does not become SUSPEND, check the condition of the cruise control

- speed limiter R/0 button and the condition of its connector.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Measure the resistance of the following connection whilst pressing the 0 button

(on the button tracks):

• Connection code 86G of component 331.

• Connection code 86M of component 331.

If the resistance is not approximately 0 Ω, replace the R/0 control button.

If there is continuity, replace the R/0 control button (see MR 364 (Mégane II), MR 370

(Scénic II), Mechanical, 83D, Cruise control, Steering wheel switch: Removal -

Refitting).

Page 140 of 198

13B-140

AFTER REPAIRCarry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$090.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DDCR INJECTION

Vdiag No.: 44, 48

ET703

CONTINUED 3

RESUME

Status ET703 becomes RESUME when the R button of the cruise control/speed

limiter is pressed. This button is located on the steering wheel, to the right.

To remove the driver's airbag to perform the checks in complete safety.

(see 88C, Airbag and pretensioners)

If status ET703 does not change to RESUME, check the condition of the cruise

control / speed limiter R/0 button, and the condition of its connector. Repair if

necessary.

If there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Measure the resistance on the following connection while pressing

the R button (on the button tracks):

• Connection code 86G of component 331.

• Connection code 86M of component 331.

If the resistance is not approximately 900 Ω, check the continuity of the connection

when the button is not pressed. If there is continuity, replace the R/0 control button

(see MR 364 (Mégane II), MR 370 (Scénic II), Mechanical, 83D, Cruise control,

Steering wheel switch: Removal - Refitting).

Page 142 of 198

13B-142

AFTER REPAIRCarry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$090.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DDCR INJECTION

Vdiag No.: 44, 48

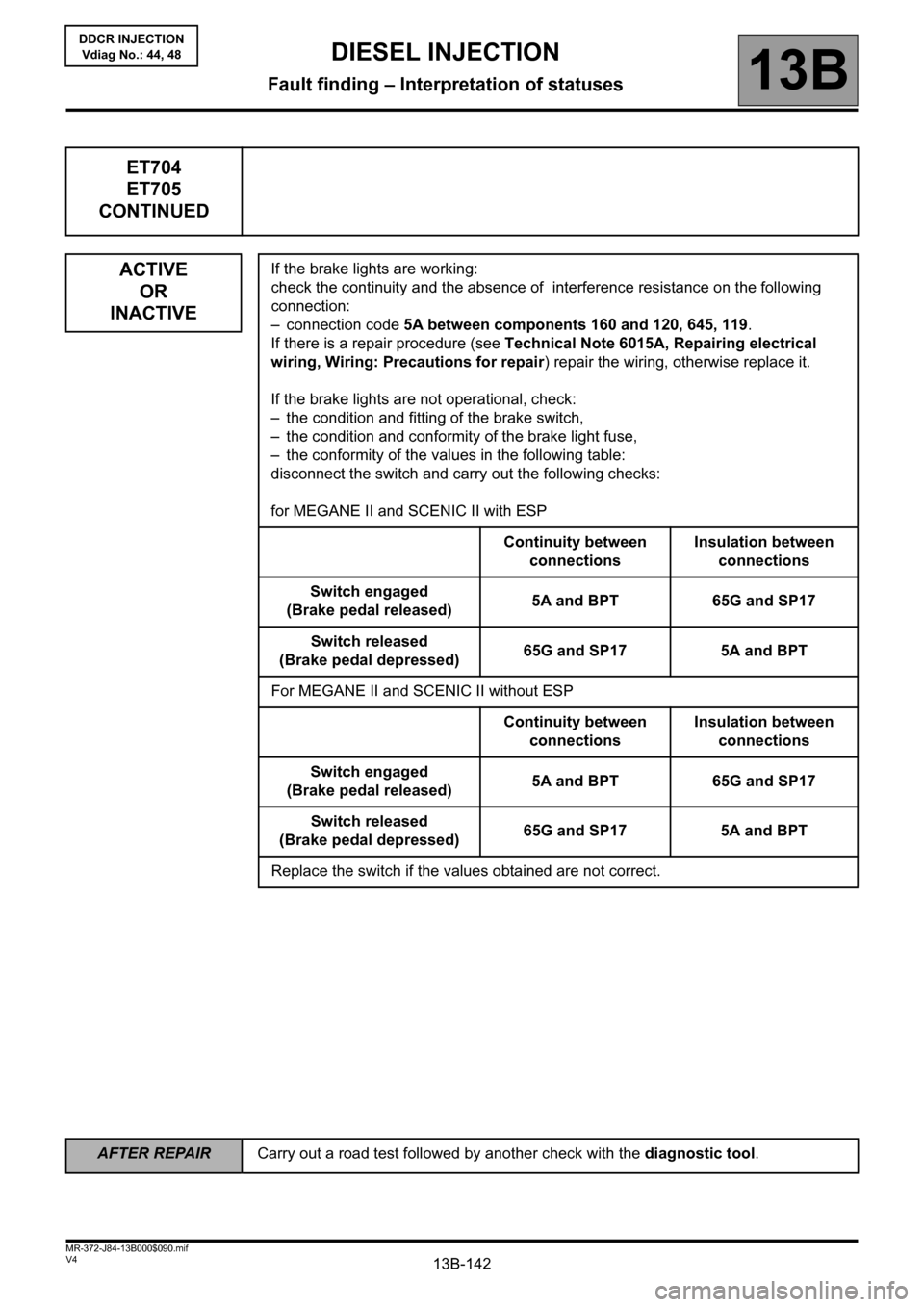

ET704

ET705

CONTINUED

ACTIVE

OR

INACTIVE

If the brake lights are working:

check the continuity and the absence of interference resistance on the following

connection:

– connection code 5A between components 160 and 120, 645, 119.

If there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair) repair the wiring, otherwise replace it.

If the brake lights are not operational, check:

– the condition and fitting of the brake switch,

– the condition and conformity of the brake light fuse,

– the conformity of the values in the following table:

disconnect the switch and carry out the following checks:

for MEGANE II and SCENIC II with ESP

Continuity between

connectionsInsulation between

connections

Switch engaged

(Brake pedal released)5A and BPT 65G and SP17

Switch released

(Brake pedal depressed)65G and SP17 5A and BPT

For MEGANE II and SCENIC II without ESP

Continuity between

connectionsInsulation between

connections

Switch engaged

(Brake pedal released)5A and BPT 65G and SP17

Switch released

(Brake pedal depressed)65G and SP17 5A and BPT

Replace the switch if the values obtained are not correct.

Page 167 of 198

13B-167

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

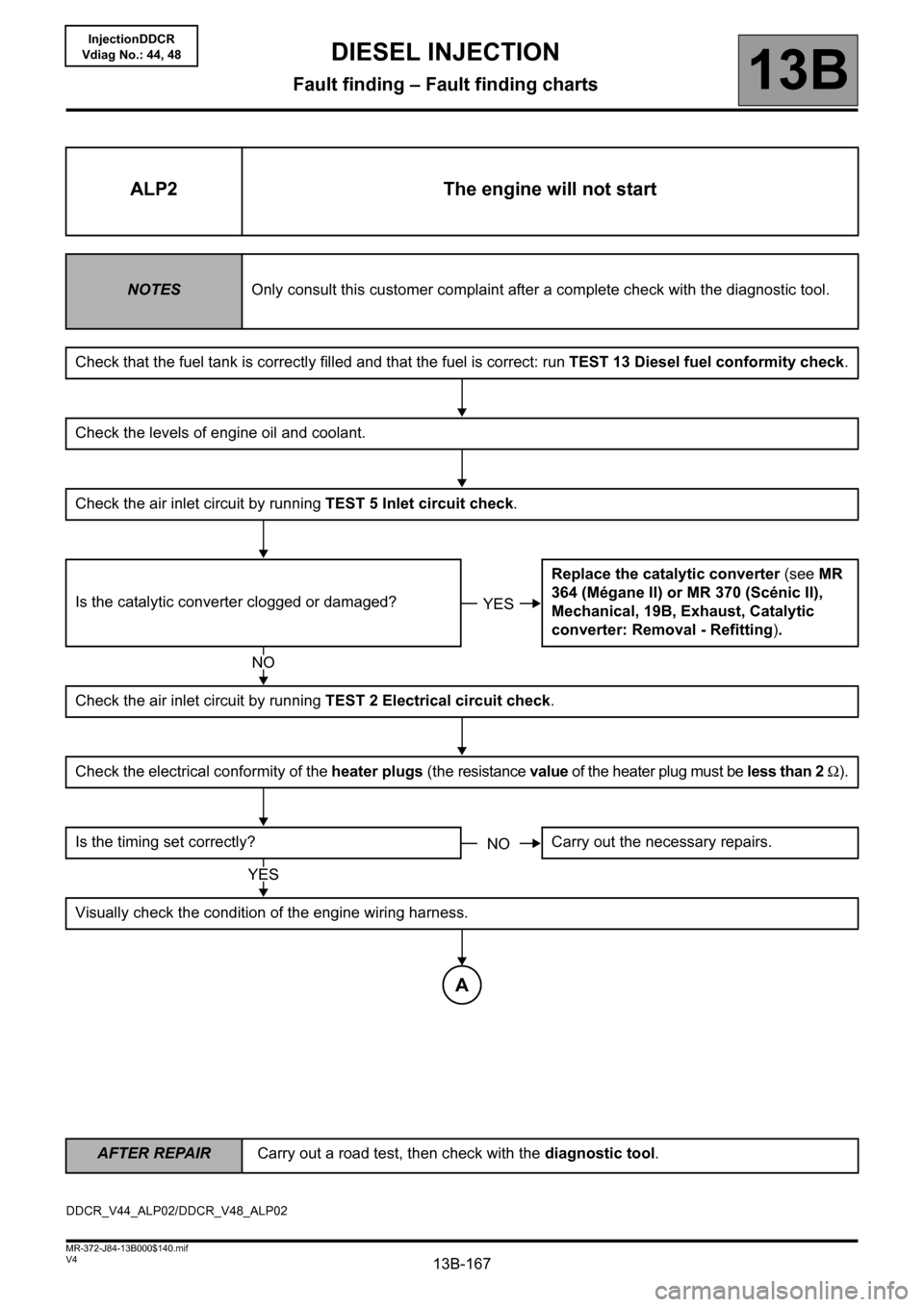

ALP2 The engine will not start

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Check the air inlet circuit by running TEST 5 Inlet circuit check.

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see MR

364 (Mégane II) or MR 370 (Scénic II),

Mechanical, 19B, Exhaust, Catalytic

converter: Removal - Refitting).

Check the air inlet circuit by running TEST 2 Electrical circuit check.

Check the electrical conformity of the heater plugs (the resistance value of the heater plug must be less than 2 Ω).

Is the timing set correctly? Carry out the necessary repairs.

Visually check the condition of the engine wiring harness.

YES

NO

NO

YES

A

DDCR_V44_ALP02/DDCR_V48_ALP02

Page 169 of 198

13B-169

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

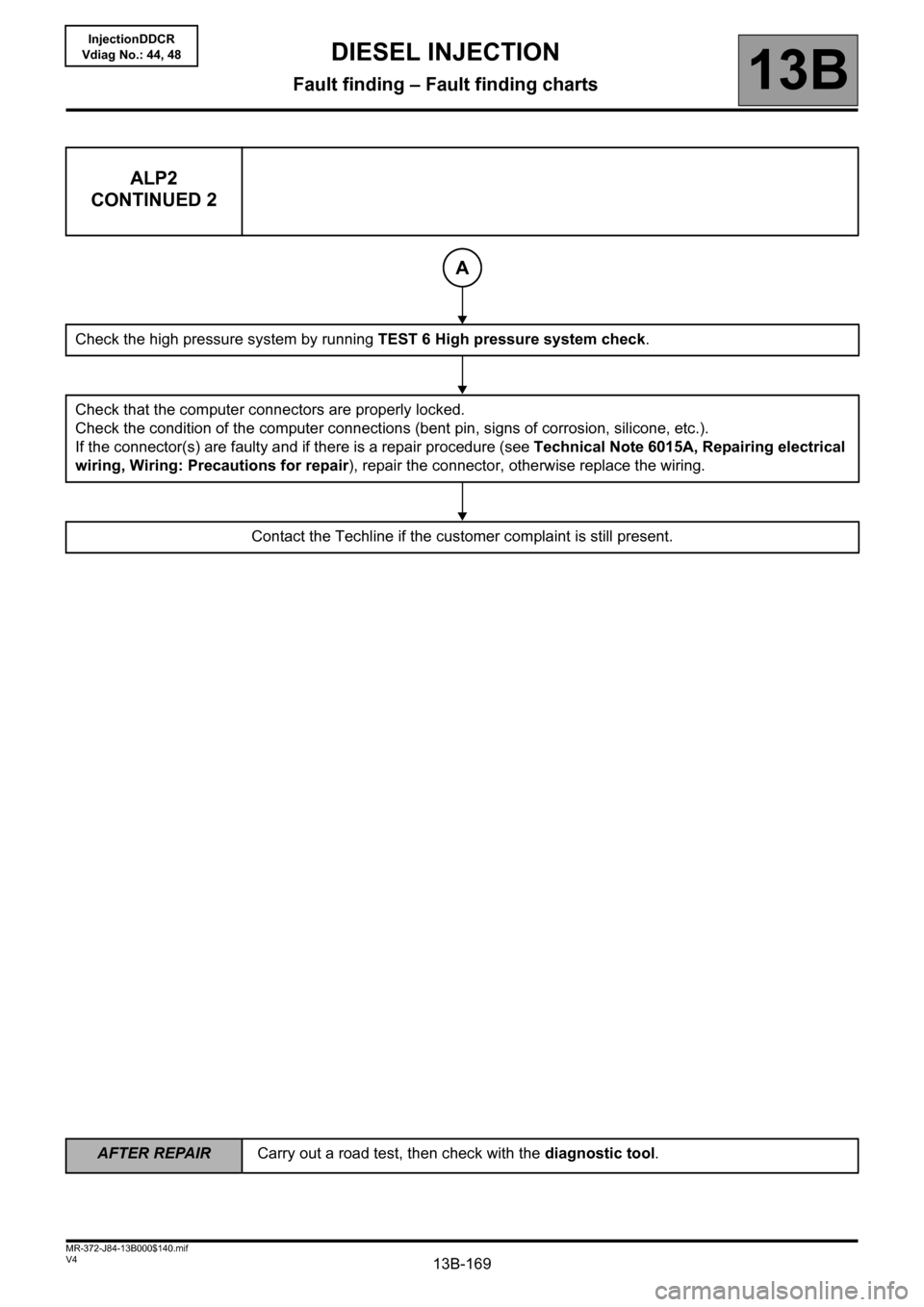

ALP2

CONTINUED 2

Check the high pressure system by running TEST 6 High pressure system check.

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

A

Page 171 of 198

13B-171

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

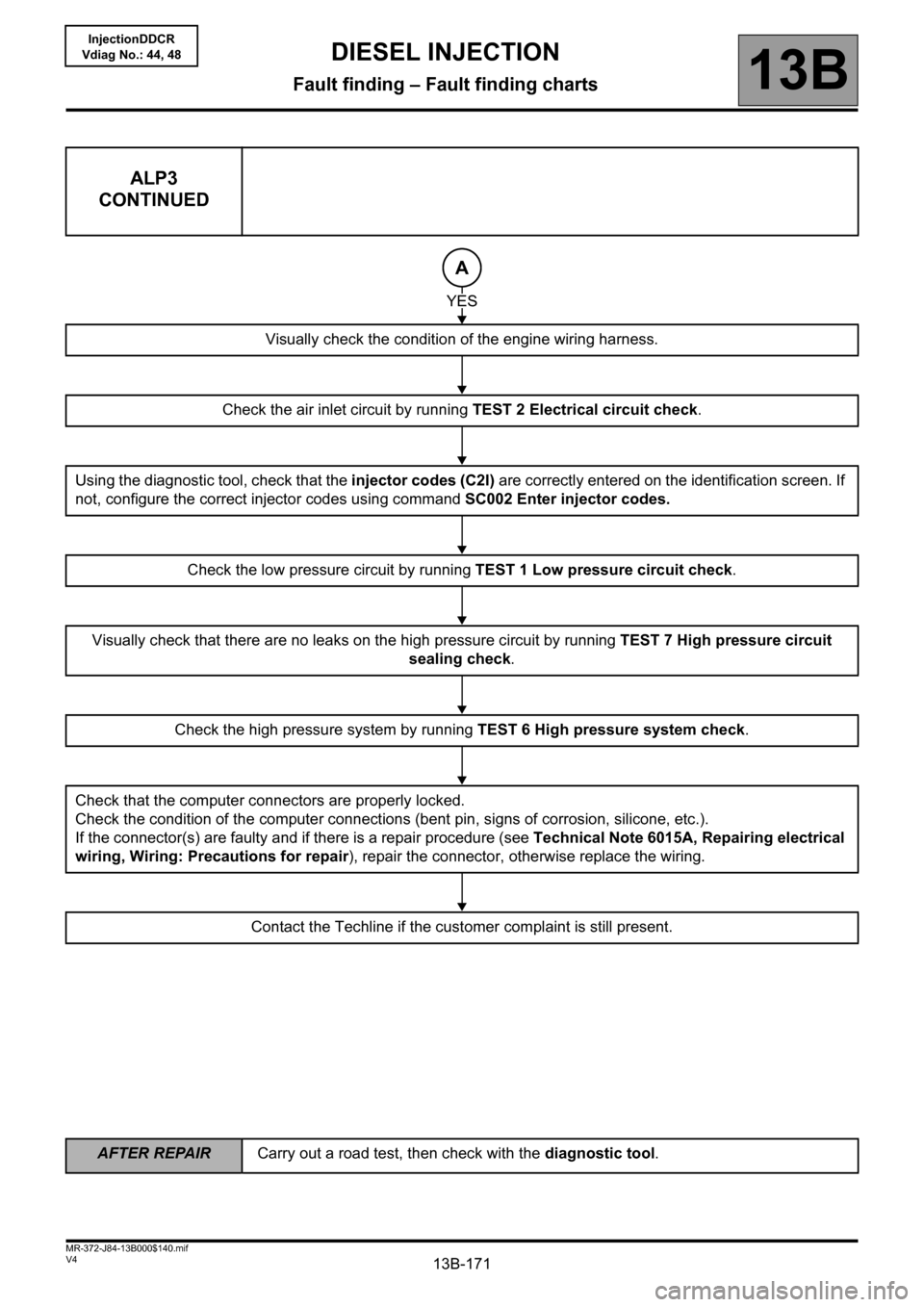

ALP3

CONTINUED

Visually check the condition of the engine wiring harness.

Check the air inlet circuit by running TEST 2 Electrical circuit check.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Visually check that there are no leaks on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

Check the high pressure system by running TEST 6 High pressure system check.

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

A

YES

Page 172 of 198

13B-172

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

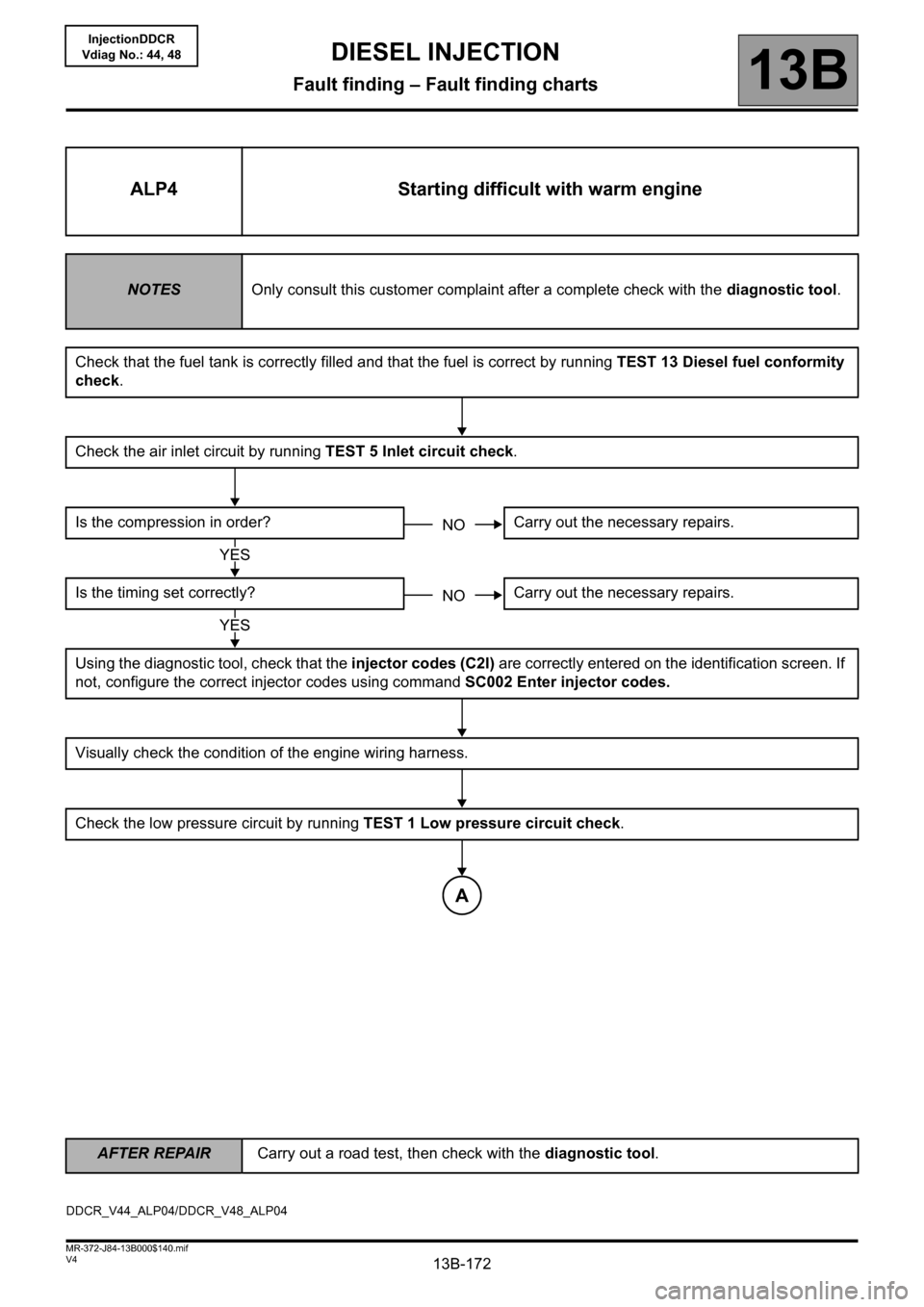

ALP4 Starting difficult with warm engine

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct by running TEST 13 Diesel fuel conformity

check.

Check the air inlet circuit by running TEST 5 Inlet circuit check.

Is the compression in order? Carry out the necessary repairs.

Is the timing set correctly? Carry out the necessary repairs.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Visually check the condition of the engine wiring harness.

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

NO

YES

NO

YES

A

DDCR_V44_ALP04/DDCR_V48_ALP04

Page 173 of 198

13B-173

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

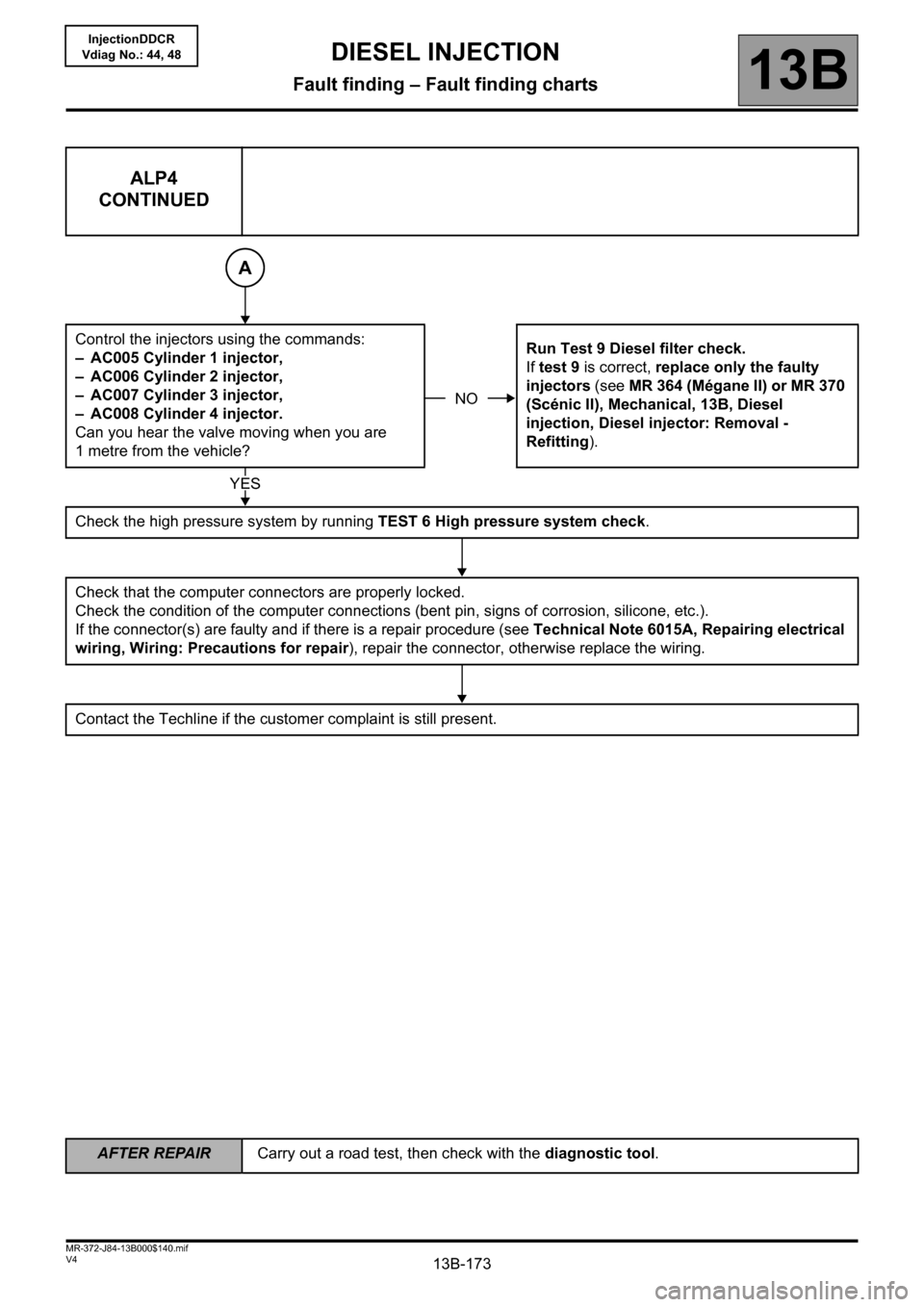

ALP4

CONTINUED

Control the injectors using the commands:

– AC005 Cylinder 1 injector,

– AC006 Cylinder 2 injector,

– AC007 Cylinder 3 injector,

– AC008 Cylinder 4 injector.

Can you hear the valve moving when you are

1 metre from the vehicle?Run Test 9 Diesel filter check.

If test 9 is correct, replace only the faulty

injectors (see MR 364 (Mégane II) or MR 370

(Scénic II), Mechanical, 13B, Diesel

injection, Diesel injector: Removal -

Refitting).

Check the high pressure system by running TEST 6 High pressure system check.

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

A

NO

YES

Page 174 of 198

13B-174

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

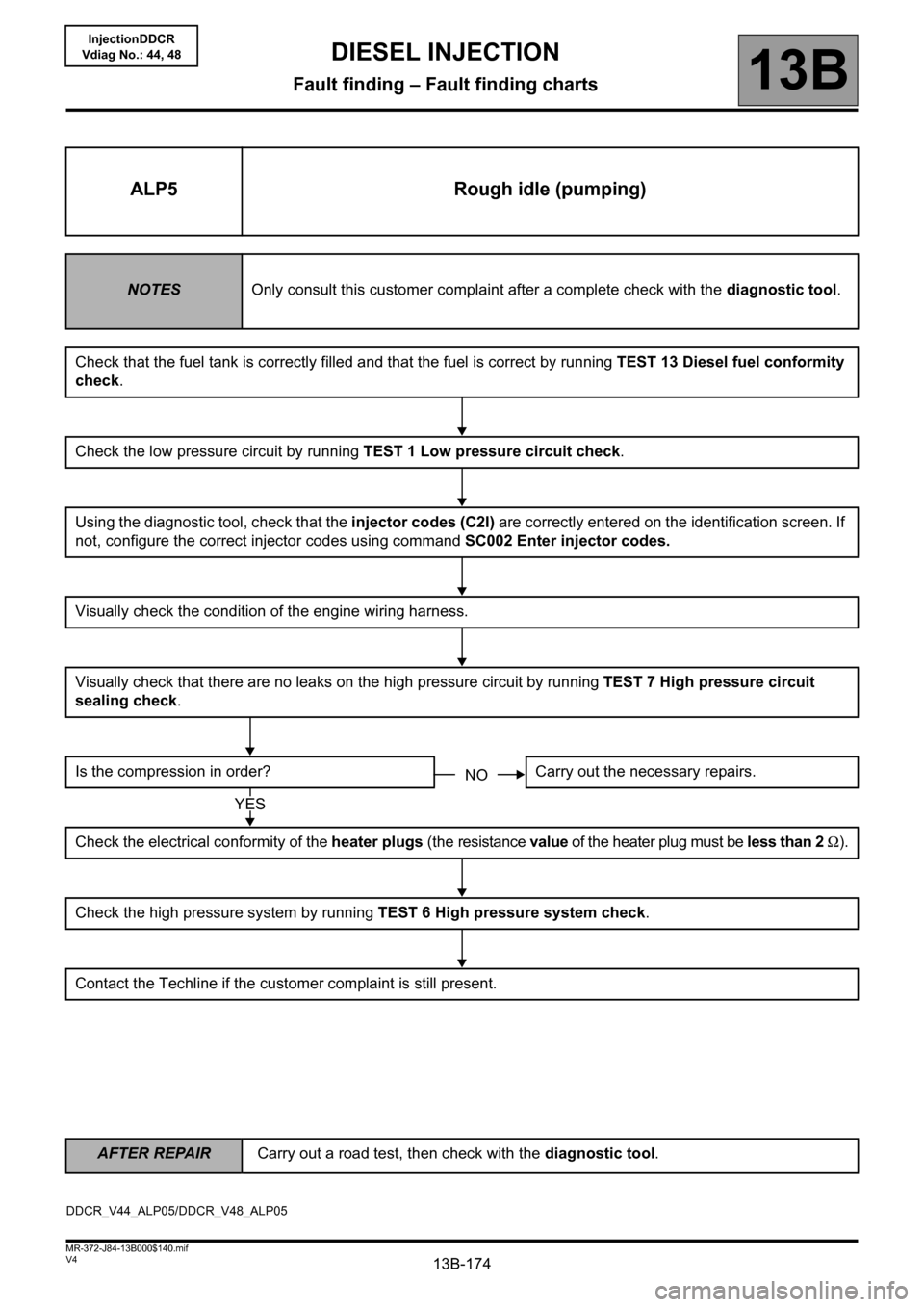

ALP5 Rough idle (pumping)

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct by running TEST 13 Diesel fuel conformity

check.

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Visually check the condition of the engine wiring harness.

Visually check that there are no leaks on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

Is the compression in order? Carry out the necessary repairs.

Check the electrical conformity of the heater plugs (the resistance value of the heater plug must be less than 2 Ω).

Check the high pressure system by running TEST 6 High pressure system check.

Contact the Techline if the customer complaint is still present.

NO

YES

DDCR_V44_ALP05/DDCR_V48_ALP05

Page 175 of 198

13B-175

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

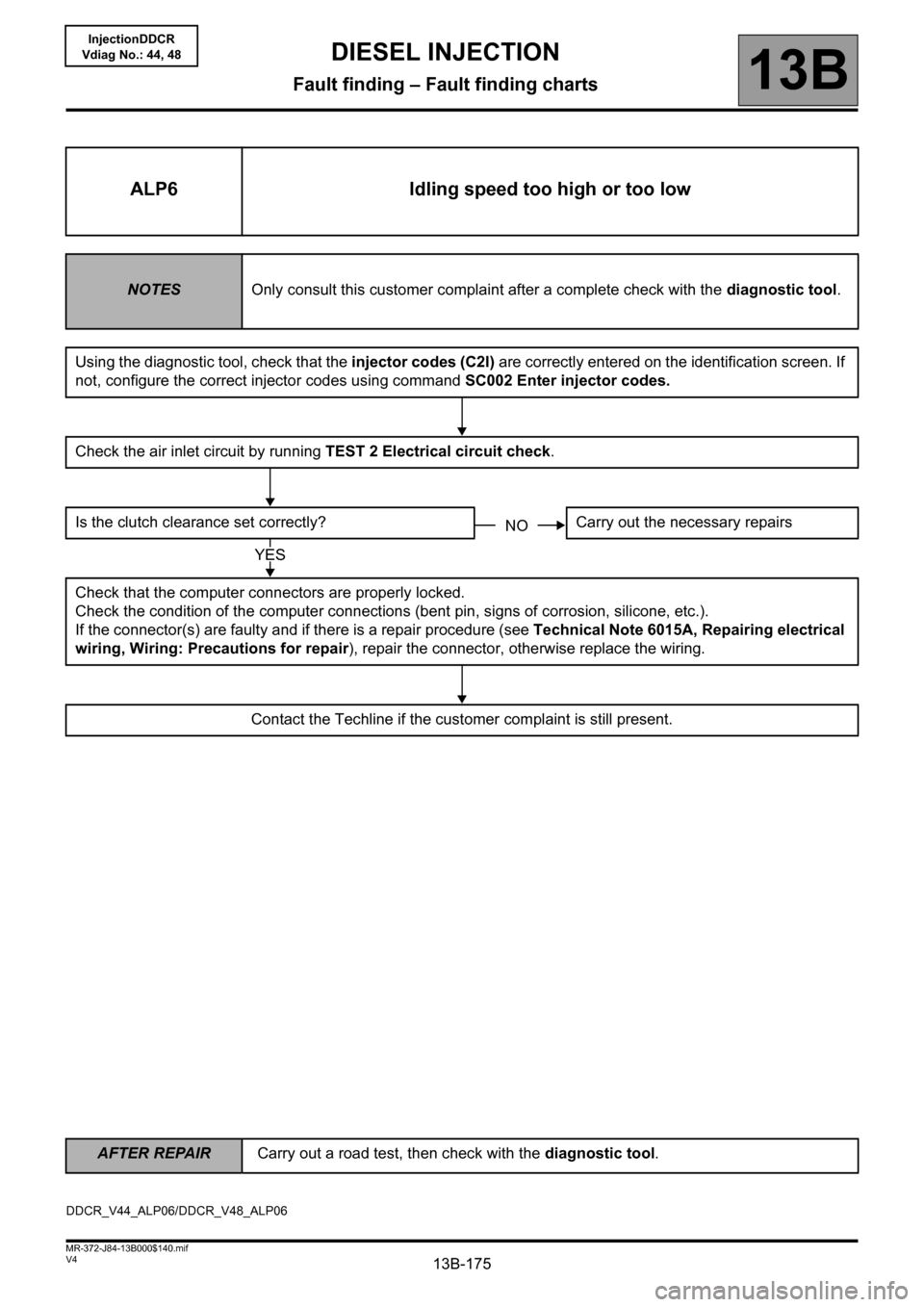

ALP6 Idling speed too high or too low

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Check the air inlet circuit by running TEST 2 Electrical circuit check.

Is the clutch clearance set correctly? Carry out the necessary repairs

Check that the computer connectors are properly locked.

Check the condition of the computer connections (bent pin, signs of corrosion, silicone, etc.).

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Contact the Techline if the customer complaint is still present.

NO

YES

DDCR_V44_ALP06/DDCR_V48_ALP06