start RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 198, PDF Size: 0.85 MB

Page 157 of 198

13B-157V4 MR-372-J84-13B000$120.mif

DIESEL INJECTION

Fault finding – Tests13B

DDCR INJECTION

Vdiag No.: 44, 48

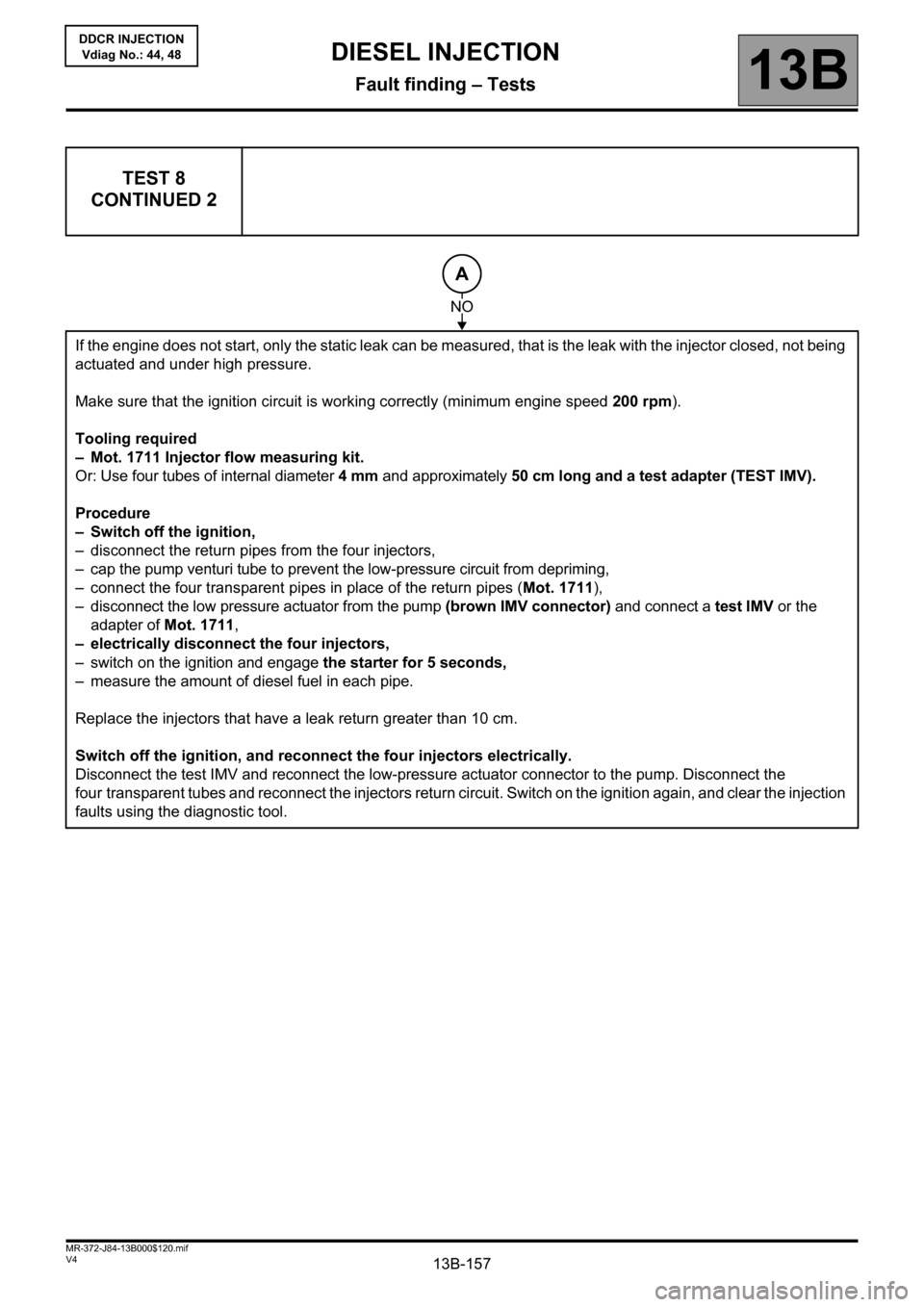

TEST 8

CONTINUED 2

If the engine does not start, only the static leak can be measured, that is the leak with the injector closed, not being

actuated and under high pressure.

Make sure that the ignition circuit is working correctly (minimum engine speed 200 rpm).

Tooling required

– Mot. 1711 Injector flow measuring kit.

Or: Use four tubes of internal diameter 4 mm and approximately 50 cm long and a test adapter (TEST IMV).

Procedure

– Switch off the ignition,

– disconnect the return pipes from the four injectors,

– cap the pump venturi tube to prevent the low-pressure circuit from depriming,

– connect the four transparent pipes in place of the return pipes (Mot. 1711),

– disconnect the low pressure actuator from the pump (brown IMV connector) and connect a test IMV or the

adapter of Mot. 1711,

– electrically disconnect the four injectors,

– switch on the ignition and engage the starter for 5 seconds,

– measure the amount of diesel fuel in each pipe.

Replace the injectors that have a leak return greater than 10 cm.

Switch off the ignition, and reconnect the four injectors electrically.

Disconnect the test IMV and reconnect the low-pressure actuator connector to the pump. Disconnect the

four transparent tubes and reconnect the injectors return circuit. Switch on the ignition again, and clear the injection

faults using the diagnostic tool.

A

NO

Page 158 of 198

13B-158V4 MR-372-J84-13B000$120.mif

DIESEL INJECTION

Fault finding – Tests13B

DDCR INJECTION

Vdiag No.: 44, 48

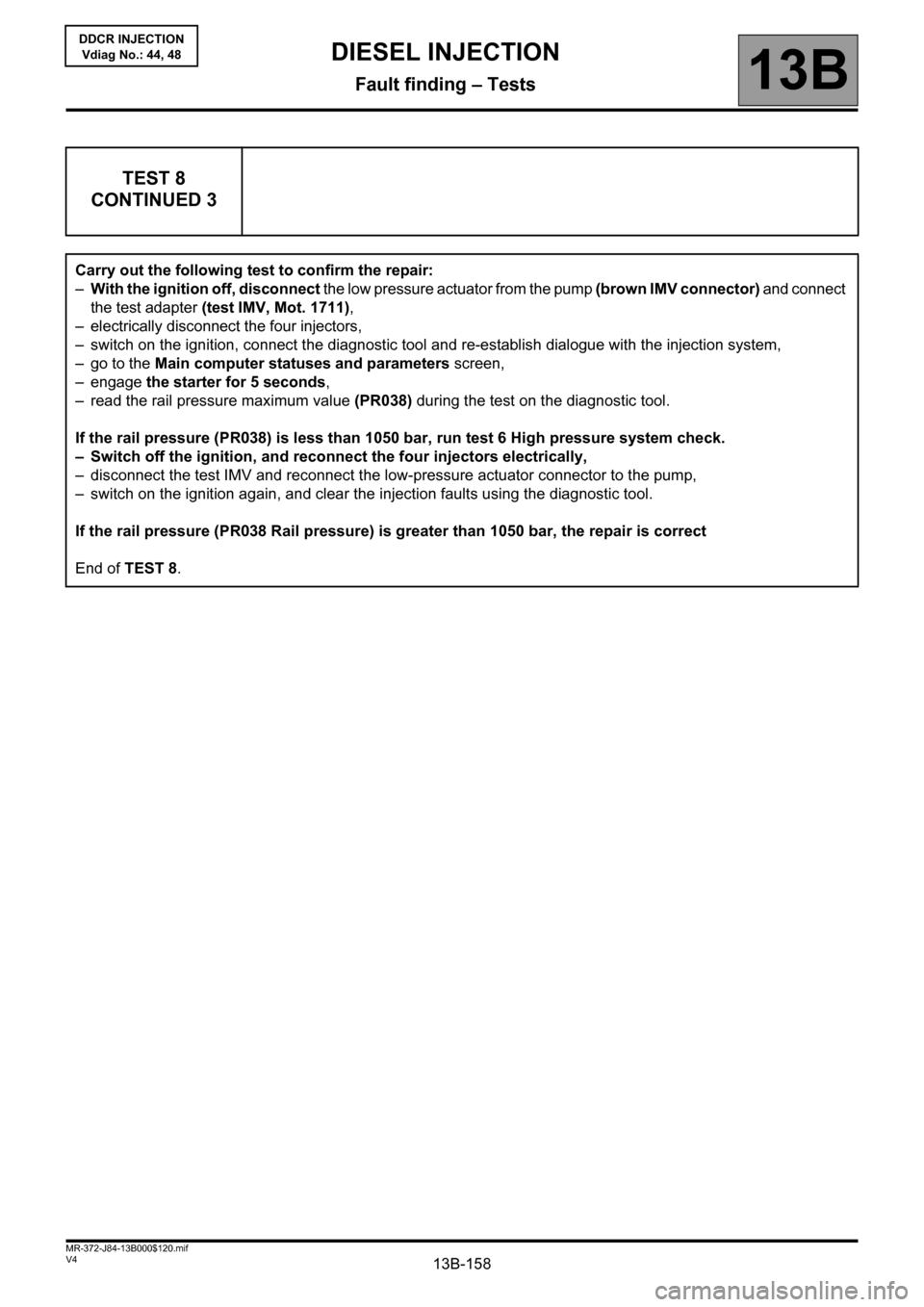

TEST 8

CONTINUED 3

Carry out the following test to confirm the repair:

–With the ignition off, disconnect the low pressure actuator from the pump (brown IMV connector) and connect

the test adapter (test IMV, Mot. 1711),

– electrically disconnect the four injectors,

– switch on the ignition, connect the diagnostic tool and re-establish dialogue with the injection system,

– go to the Main computer statuses and parameters screen,

– engage the starter for 5 seconds,

– read the rail pressure maximum value (PR038) during the test on the diagnostic tool.

If the rail pressure (PR038) is less than 1050 bar, run test 6 High pressure system check.

– Switch off the ignition, and reconnect the four injectors electrically,

– disconnect the test IMV and reconnect the low-pressure actuator connector to the pump,

– switch on the ignition again, and clear the injection faults using the diagnostic tool.

If the rail pressure (PR038 Rail pressure) is greater than 1050 bar, the repair is correct

End of TEST 8.

Page 165 of 198

13B-165V4 MR-372-J84-13B000$130.mif

13B

DDCR INJECTION

Vdiag No.: 44, 48

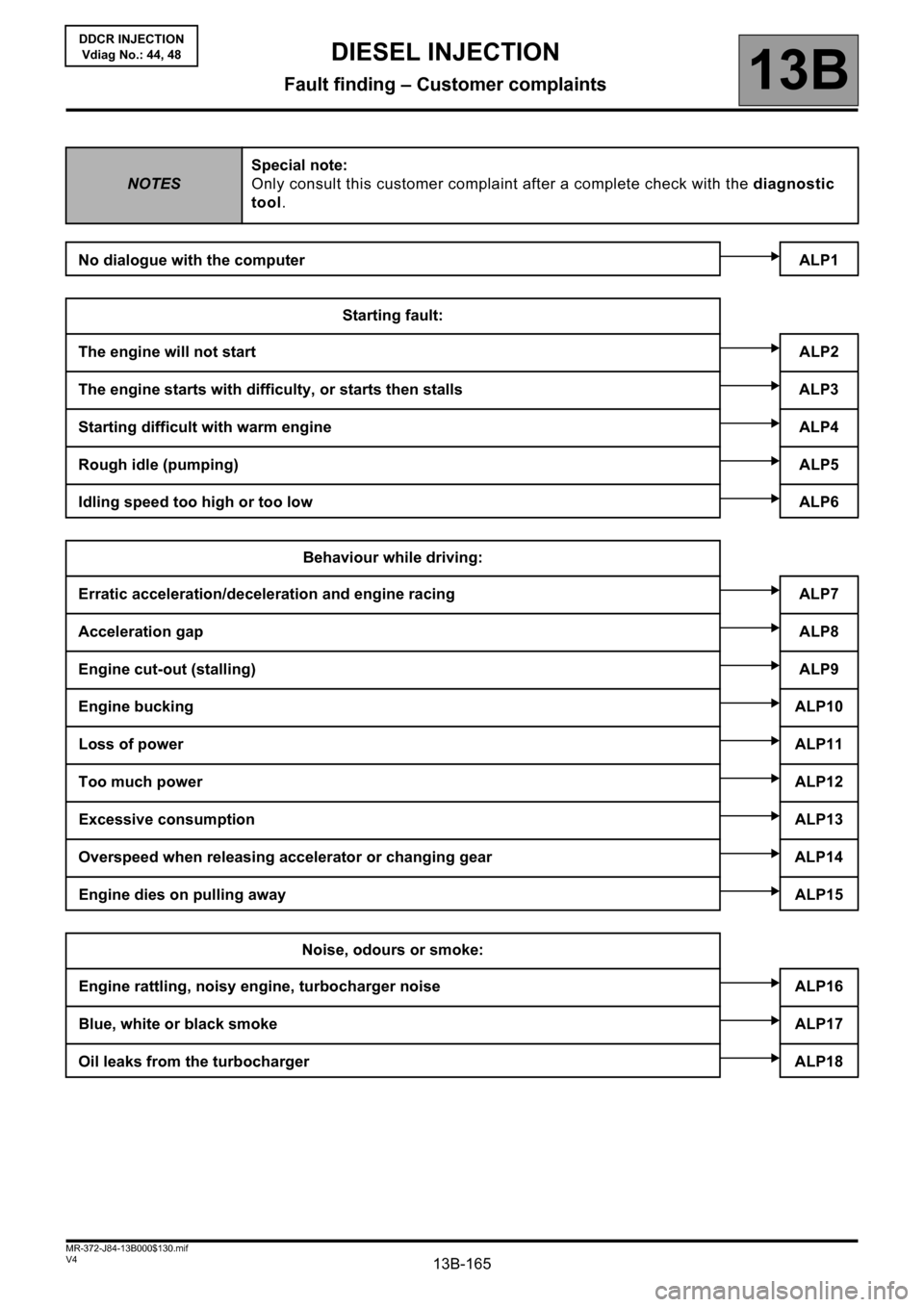

NOTESSpecial note:

Only consult this customer complaint after a complete check with the diagnostic

tool.

No dialogue with the computer ALP1

Starting fault:

The engine will not startALP2

The engine starts with difficulty, or starts then stalls ALP3

Starting difficult with warm engine ALP4

Rough idle (pumping)ALP5

Idling speed too high or too low ALP6

Behaviour while driving:

Erratic acceleration/deceleration and engine racing ALP7

Acceleration gapALP8

Engine cut-out (stalling)ALP9

Engine buckingALP10

Loss of powerALP11

Too much powerALP12

Excessive consumptionALP13

Overspeed when releasing accelerator or changing gear ALP14

Engine dies on pulling awayALP15

Noise, odours or smoke:

Engine rattling, noisy engine, turbocharger noise ALP16

Blue, white or black smokeALP17

Oil leaks from the turbocharger ALP18

DIESEL INJECTION

Fault finding – Customer complaints

Page 167 of 198

13B-167

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

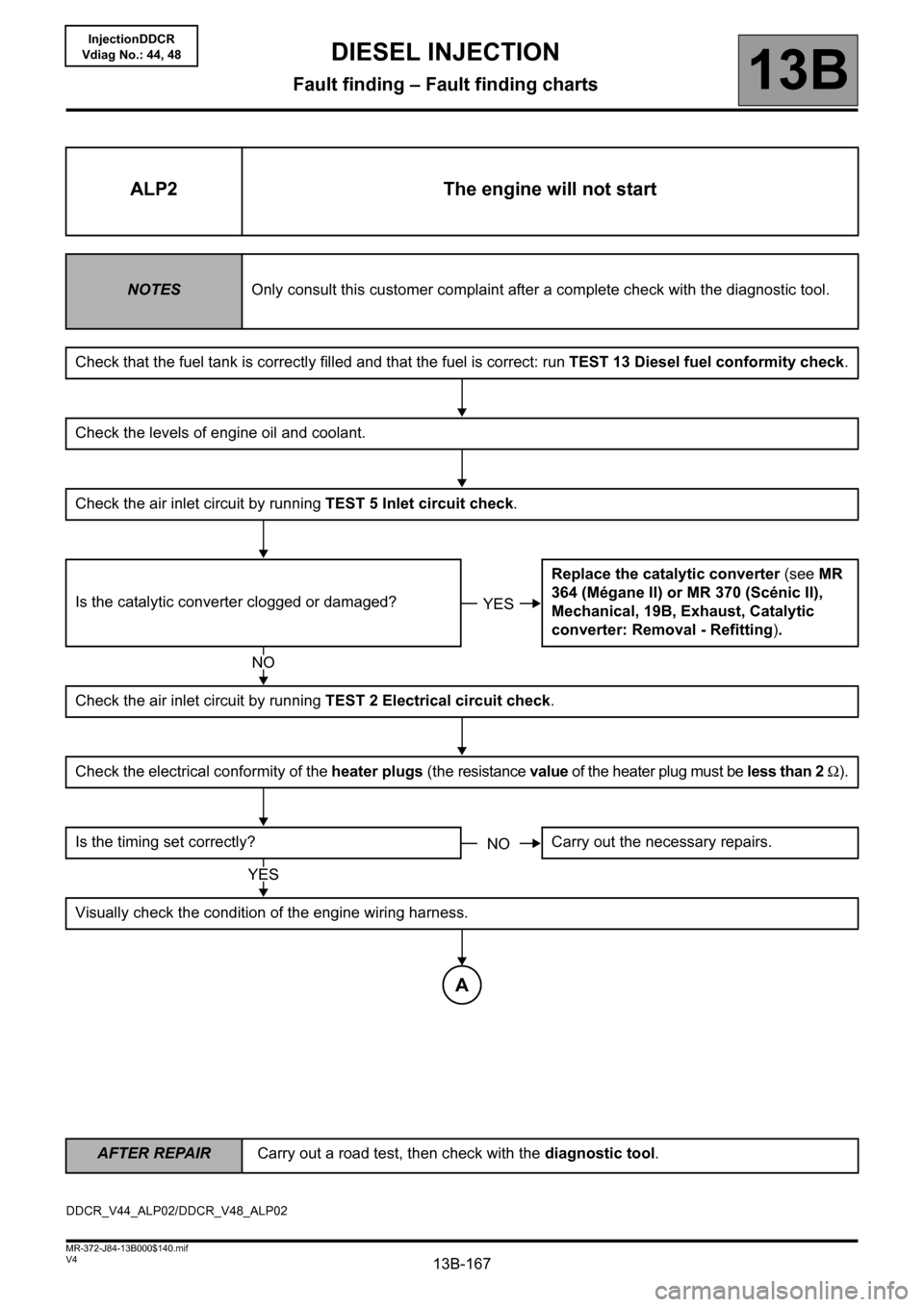

ALP2 The engine will not start

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Check the air inlet circuit by running TEST 5 Inlet circuit check.

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see MR

364 (Mégane II) or MR 370 (Scénic II),

Mechanical, 19B, Exhaust, Catalytic

converter: Removal - Refitting).

Check the air inlet circuit by running TEST 2 Electrical circuit check.

Check the electrical conformity of the heater plugs (the resistance value of the heater plug must be less than 2 Ω).

Is the timing set correctly? Carry out the necessary repairs.

Visually check the condition of the engine wiring harness.

YES

NO

NO

YES

A

DDCR_V44_ALP02/DDCR_V48_ALP02

Page 168 of 198

13B-168

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

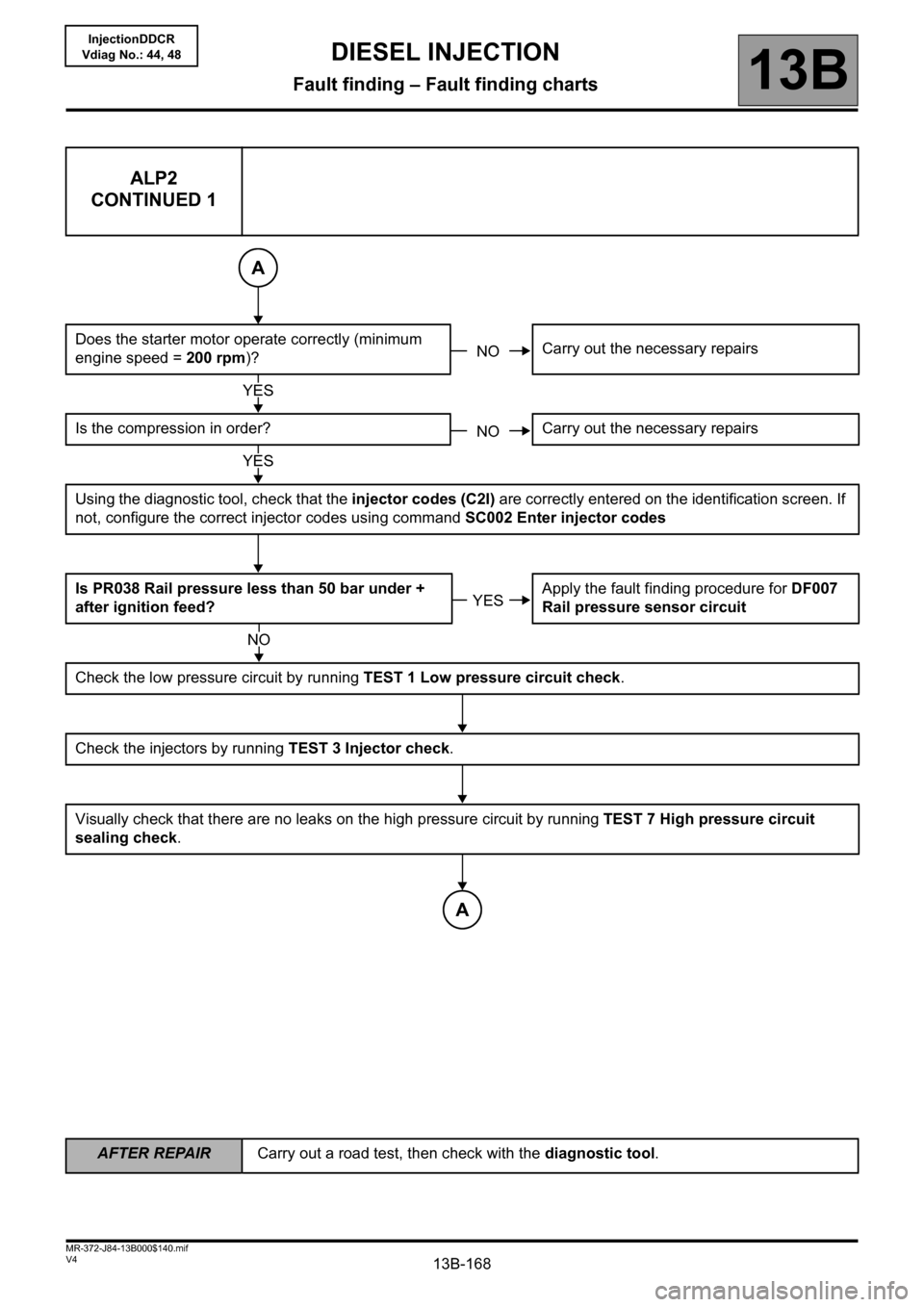

ALP2

CONTINUED 1

Does the starter motor operate correctly (minimum

engine speed = 200 rpm)?Carry out the necessary repairs

Is the compression in order? Carry out the necessary repairs

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes

Is PR038 Rail pressure less than 50 bar under +

after ignition feed?Apply the fault finding procedure for DF007

Rail pressure sensor circuit

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Check the injectors by running TEST 3 Injector check.

Visually check that there are no leaks on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

A

NO

YES

NO

YES

YES

NO

A

Page 170 of 198

13B-170

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

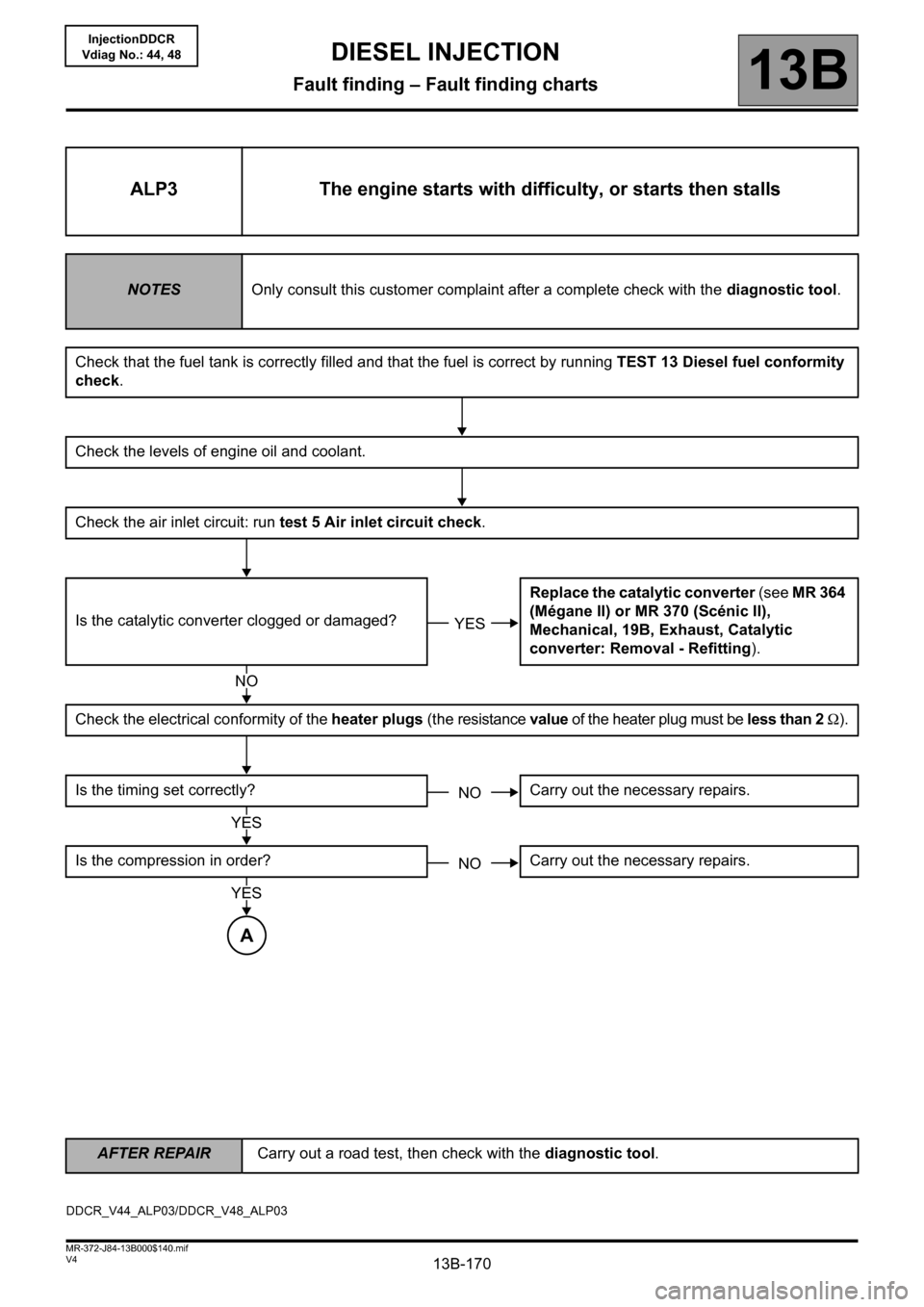

ALP3 The engine starts with difficulty, or starts then stalls

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct by running TEST 13 Diesel fuel conformity

check.

Check the levels of engine oil and coolant.

Check the air inlet circuit: run test 5 Air inlet circuit check.

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see MR 364

(Mégane II) or MR 370 (Scénic II),

Mechanical, 19B, Exhaust, Catalytic

converter: Removal - Refitting).

Check the electrical conformity of the heater plugs (the resistance value of the heater plug must be less than 2 Ω).

Is the timing set correctly? Carry out the necessary repairs.

Is the compression in order? Carry out the necessary repairs.

YES

NO

NO

YES

NO

YES

A

DDCR_V44_ALP03/DDCR_V48_ALP03

Page 172 of 198

13B-172

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

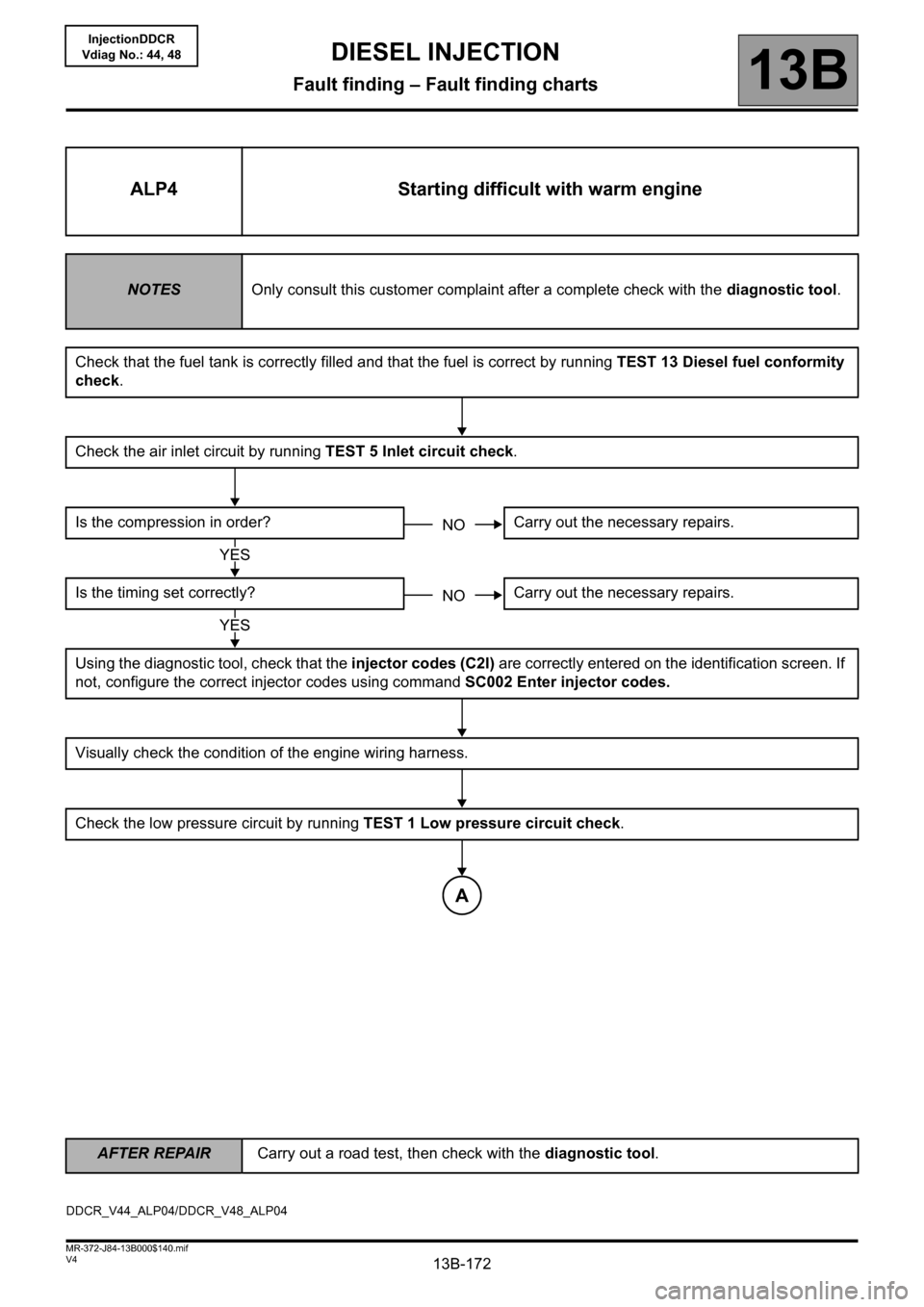

ALP4 Starting difficult with warm engine

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct by running TEST 13 Diesel fuel conformity

check.

Check the air inlet circuit by running TEST 5 Inlet circuit check.

Is the compression in order? Carry out the necessary repairs.

Is the timing set correctly? Carry out the necessary repairs.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Visually check the condition of the engine wiring harness.

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

NO

YES

NO

YES

A

DDCR_V44_ALP04/DDCR_V48_ALP04

Page 195 of 198

13B-195

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

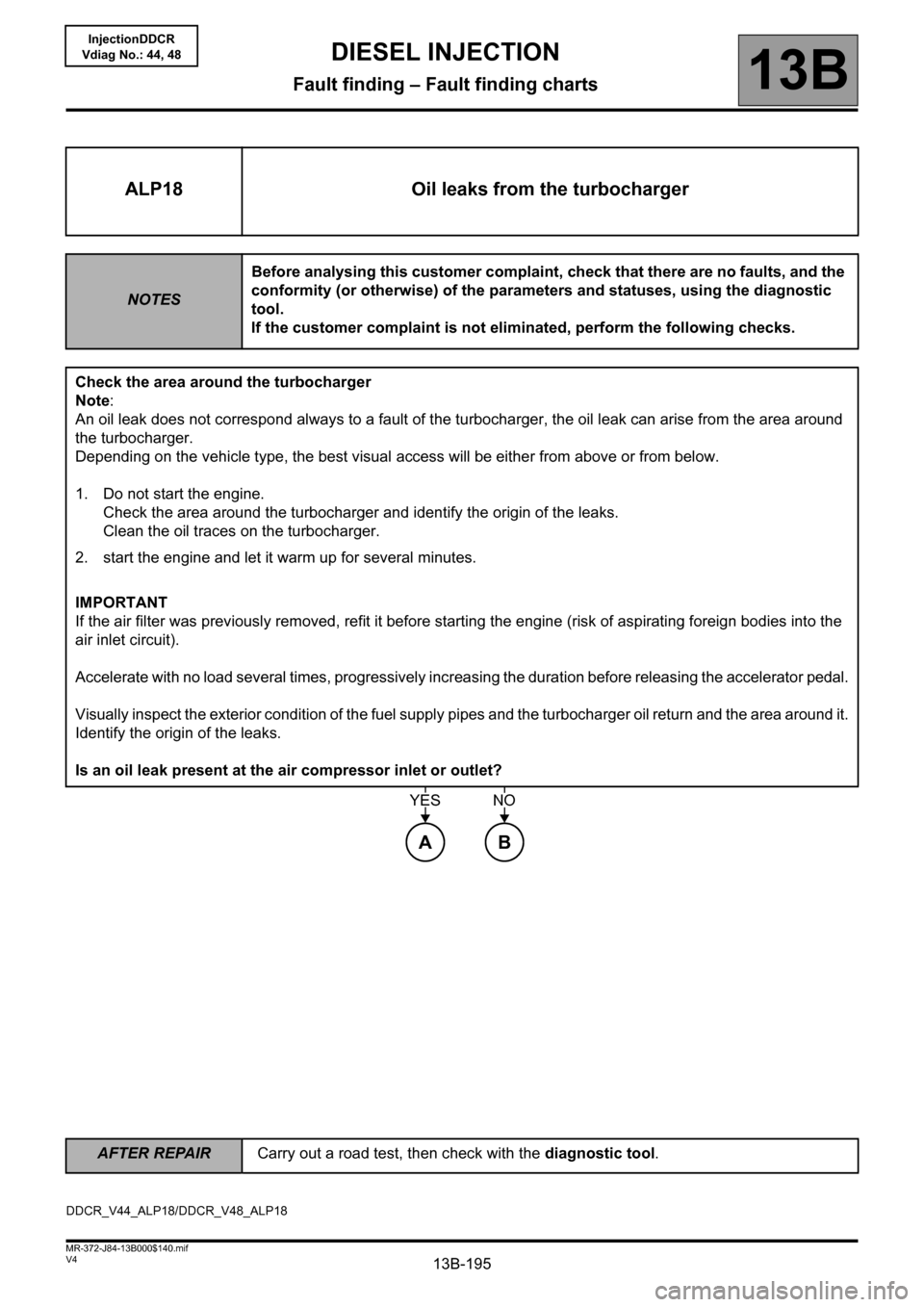

ALP18 Oil leaks from the turbocharger

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

Check the area around the turbocharger

Note:

An oil leak does not correspond always to a fault of the turbocharger, the oil leak can arise from the area around

the turbocharger.

Depending on the vehicle type, the best visual access will be either from above or from below.

1. Do not start the engine.

Check the area around the turbocharger and identify the origin of the leaks.

Clean the oil traces on the turbocharger.

2. start the engine and let it warm up for several minutes.

IMPORTANT

If the air filter was previously removed, refit it before starting the engine (risk of aspirating foreign bodies into the

air inlet circuit).

Accelerate with no load several times, progressively increasing the duration before releasing the accelerator pedal.

Visually inspect the exterior condition of the fuel supply pipes and the turbocharger oil return and the area around it.

Identify the origin of the leaks.

Is an oil leak present at the air compressor inlet or outlet?

AB

YESNO

DDCR_V44_ALP18/DDCR_V48_ALP18