rack RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 198, PDF Size: 0.85 MB

Page 2 of 198

13B-2V4 MR-372-J84-13B000$010.mif

13B

DDCR INJECTION

Vdiag No.: 44, 48

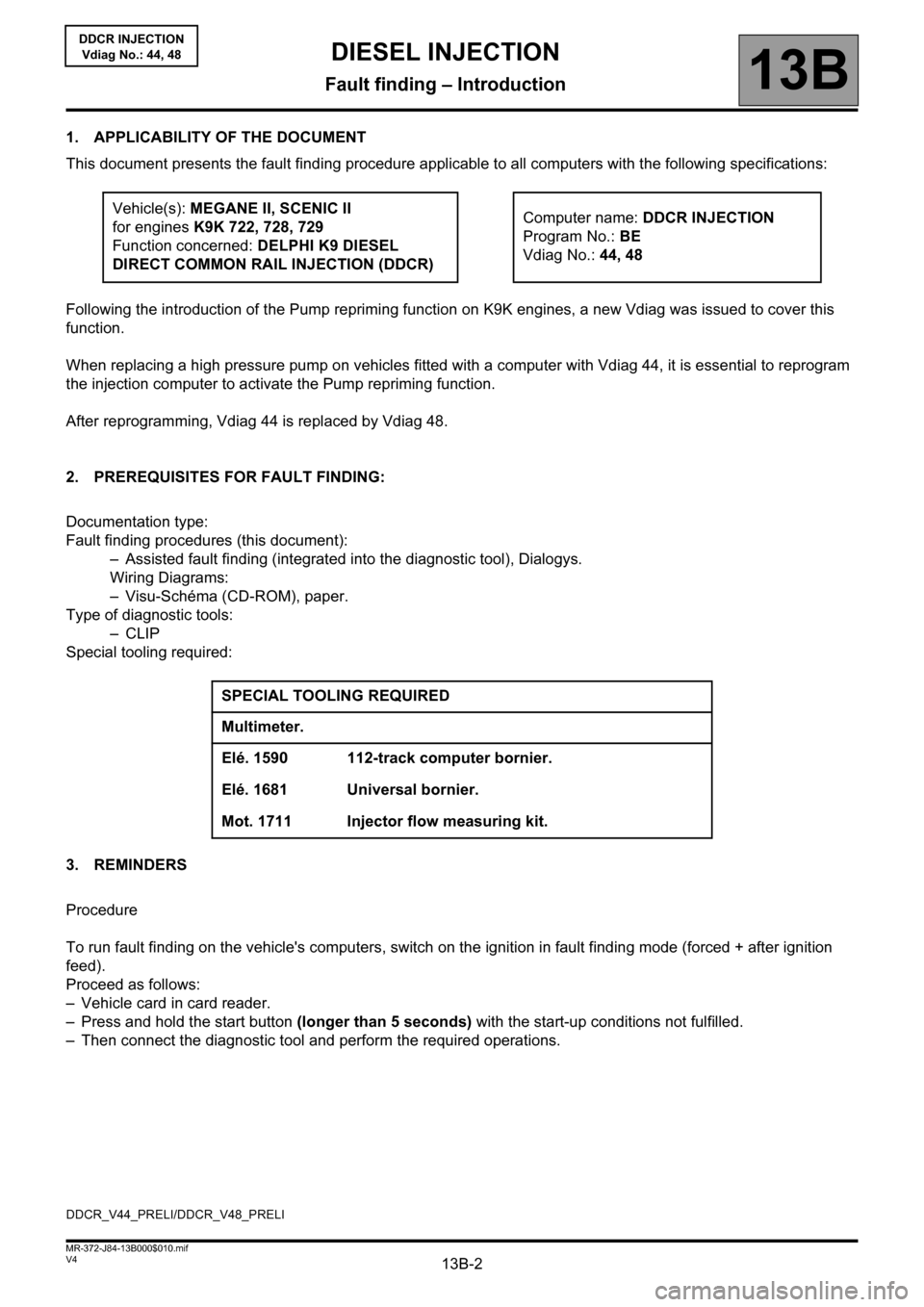

1. APPLICABILITY OF THE DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

Following the introduction of the Pump repriming function on K9K engines, a new Vdiag was issued to cover this

function.

When replacing a high pressure pump on vehicles fitted with a computer with Vdiag 44, it is essential to reprogram

the injection computer to activate the Pump repriming function.

After reprogramming, Vdiag 44 is replaced by Vdiag 48.

2. PREREQUISITES FOR FAULT FINDING:

Documentation type:

Fault finding procedures (this document):

– Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

– Visu-Schéma (CD-ROM), paper.

Type of diagnostic tools:

–CLIP

Special tooling required:

3. REMINDERS

Procedure

To run fault finding on the vehicle's computers, switch on the ignition in fault finding mode (forced + after ignition

feed).

Proceed as follows:

– Vehicle card in card reader.

– Press and hold the start button (longer than 5 seconds) with the start-up conditions not fulfilled.

– Then connect the diagnostic tool and perform the required operations.Vehicle(s): MEGANE II, SCENIC II

for engines K9K 722, 728, 729

Function concerned: DELPHI K9 DIESEL

DIRECT COMMON RAIL INJECTION (DDCR)Computer name: DDCR INJECTION

Program No.: BE

Vdiag No.: 44, 48

SPECIAL TOOLING REQUIRED

Multimeter.

Elé. 1590 112-track computer bornier.

Elé. 1681 Universal bornier.

Mot. 1711 Injector flow measuring kit.

DDCR_V44_PRELI/DDCR_V48_PRELI

DIESEL INJECTION

Fault finding – Introduction

Page 5 of 198

13B-5V4 MR-372-J84-13B000$010.mif

DIESEL INJECTION

Fault finding – Introduction13B

DDCR INJECTION

Vdiag No.: 44, 48

4. FAULT FINDING PROCEDURE (continued)

Wiring check

Fault finding problems

Disconnecting the connectors and/or manipulating the wiring may temporarily clear the cause of a fault.

The electrical measurements of the voltage, resistance, and insulation are generally correct, especially if the fault is

not present when the measurements are being taken (stored fault).

Visual inspection

Look for damage under the bonnet and in the passenger compartment.

Carefully check the fuses, insulators and wiring harness routing.

Look for signs of oxidation.

Physical inspection

When handling the wiring, use the diagnostic tool to detect any change in the status of the fault from stored to

present.

Make sure that the connectors are firmly locked.

Apply light pressure to the connectors.

Twist the wiring harness.

If there is a change in status, try to locate the source of the fault.

Inspection of each component

Disconnect the connectors and check the appearance of the clips and tabs as well as their crimping (no crimping on

the insulation). Check that the clips and the tabs are correctly locked in the sockets.

Check that no clips or tabs have been dislodged during connection.

Check the clip contact pressure using an appropriate model of tab.

Resistance check

Check the continuity of entire lines, then section by section.

Look for a short circuit to earth, to + 12 V or with another wire.

If a fault is detected, repair or replace the wiring harness.

5. FAULT FINDING LOG

IMPORTANTIMPORTANT

Any fault on a complex system requires thorough fault finding with the appropriate tools.

The FAULT FINDING LOG, which should be completed during the procedure, enables you to

keep track of the procedure which is carried out. It is an essential document when consulting

the manufacturer.

IT IS THEREFORE COMPULSORY TO COMPLETE A FAULT FINDING LOG EVERY TIME A FAULT FINDING

PROCEDURE IS PERFORMED

Page 15 of 198

13B-15V4 MR-372-J84-13B000$020.mif

DIESEL INJECTION

Fault finding – System operation13B

DDCR INJECTION

Vdiag No.: 44, 48

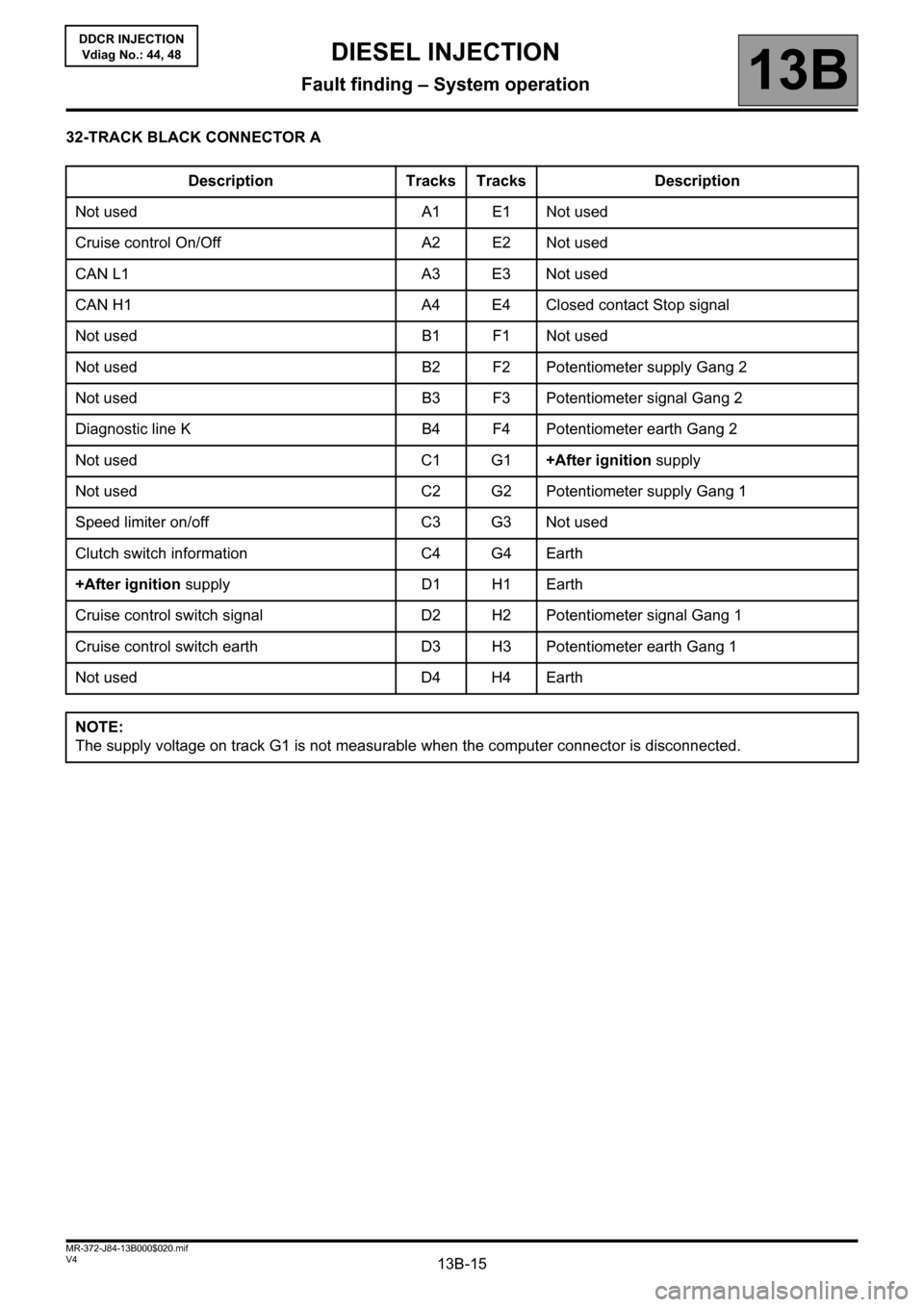

32-TRACK BLACK CONNECTOR A

Description Tracks Tracks Description

Not used A1 E1 Not used

Cruise control On/Off A2 E2 Not used

CAN L1 A3 E3 Not used

CAN H1 A4 E4 Closed contact Stop signal

Not used B1 F1 Not used

Not used B2 F2 Potentiometer supply Gang 2

Not used B3 F3 Potentiometer signal Gang 2

Diagnostic line K B4 F4 Potentiometer earth Gang 2

Not used C1 G1+After ignition supply

Not used C2 G2 Potentiometer supply Gang 1

Speed limiter on/off C3 G3 Not used

Clutch switch information C4 G4 Earth

+After ignition supply D1 H1 Earth

Cruise control switch signal D2H2 Potentiometer signal Gang 1

Cruise control switch earth D3H3 Potentiometer earth Gang 1

Not used D4 H4 Earth

NOTE:

The supply voltage on track G1 is not measurable when the computer connector is disconnected.

Page 16 of 198

13B-16V4 MR-372-J84-13B000$020.mif

DIESEL INJECTION

Fault finding – System operation13B

DDCR INJECTION

Vdiag No.: 44, 48

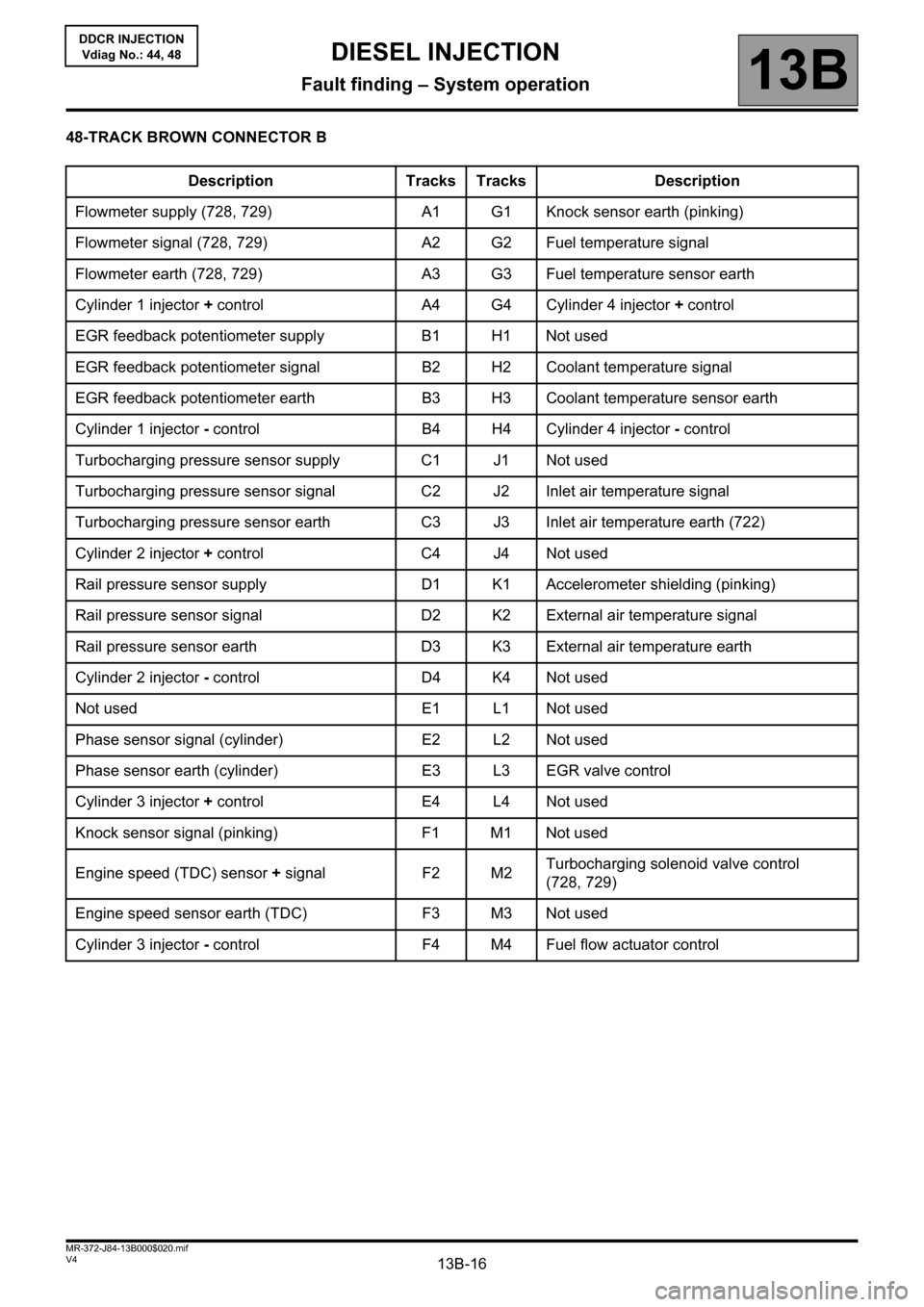

48-TRACK BROWN CONNECTOR B

Description Tracks Tracks Description

Flowmeter supply (728, 729) A1 G1 Knock sensor earth (pinking)

Flowmeter signal (728, 729) A2 G2 Fuel temperature signal

Flowmeter earth (728, 729) A3 G3 Fuel temperature sensor earth

Cylinder 1 injector + control A4 G4 Cylinder 4 injector + control

EGR feedback potentiometer supply B1 H1 Not used

EGR feedback potentiometer signal B2 H2 Coolant temperature signal

EGR feedback potentiometer earth B3 H3 Coolant temperature sensor earth

Cylinder 1 injector - control B4 H4 Cylinder 4 injector - control

Turbocharging pressure sensor supply C1 J1 Not used

Turbocharging pressure sensor signal C2 J2 Inlet air temperature signal

Turbocharging pressure sensor earth C3 J3 Inlet air temperature earth (722)

Cylinder 2 injector + control C4 J4 Not used

Rail pressure sensor supply D1 K1 Accelerometer shielding (pinking)

Rail pressure sensor signal D2 K2 External air temperature signal

Rail pressure sensor earth D3 K3 External air temperature earth

Cylinder 2 injector - control D4 K4 Not used

Not used E1 L1 Not used

Phase sensor signal (cylinder) E2 L2 Not used

Phase sensor earth (cylinder) E3 L3 EGR valve control

Cylinder 3 injector + control E4 L4 Not used

Knock sensor signal (pinking) F1 M1 Not used

Engine speed (TDC) sensor + signal F2 M2Turbocharging solenoid valve control

(728, 729)

Engine speed sensor earth (TDC) F3 M3 Not used

Cylinder 3 injector - control F4 M4 Fuel flow actuator control

Page 17 of 198

13B-17V4 MR-372-J84-13B000$020.mif

DIESEL INJECTION

Fault finding – System operation13B

DDCR INJECTION

Vdiag No.: 44, 48

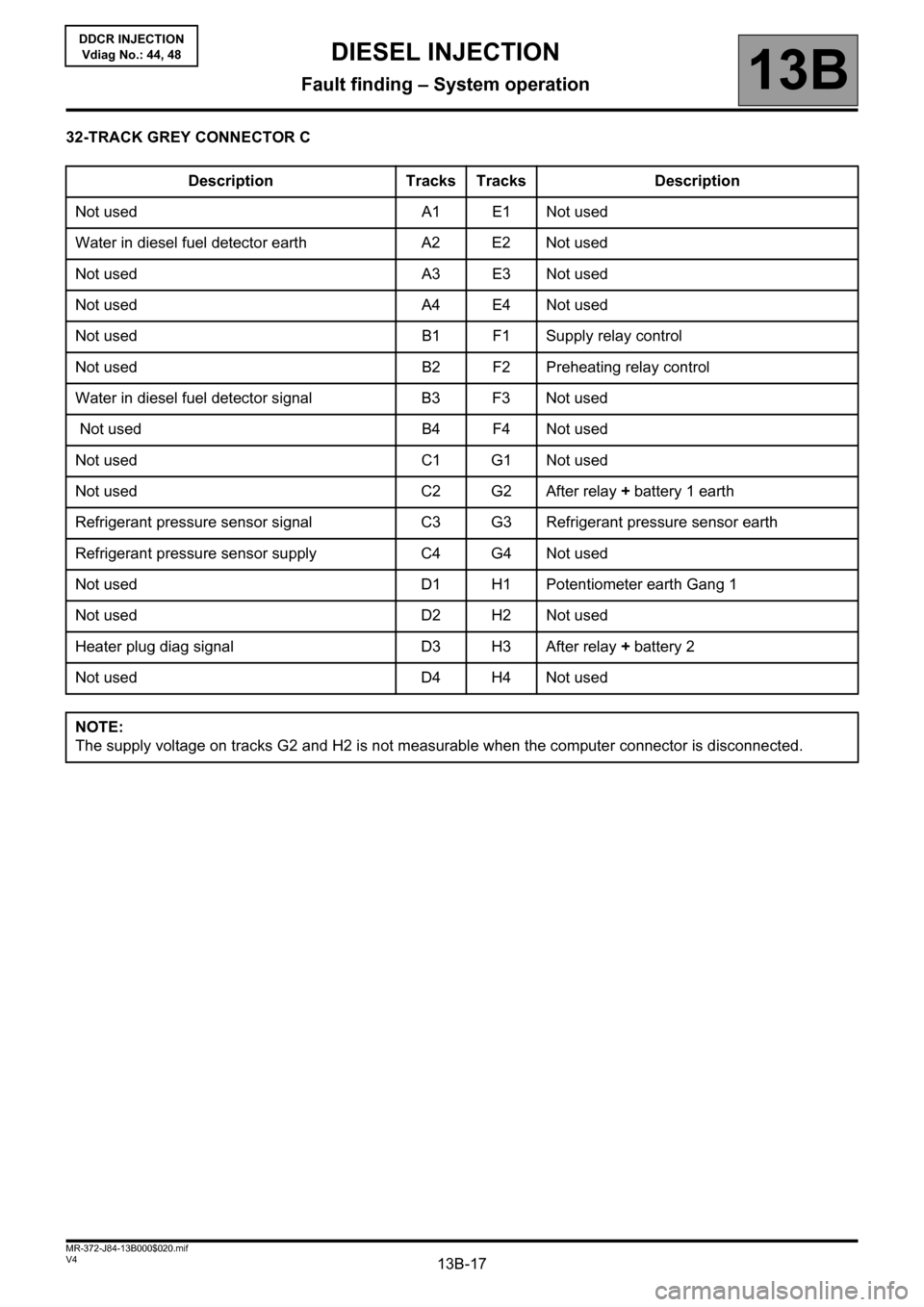

32-TRACK GREY CONNECTOR C

Description Tracks Tracks Description

Not used A1 E1 Not used

Water in diesel fuel detector earth A2 E2 Not used

Not used A3 E3 Not used

Not used A4 E4 Not used

Not used B1 F1 Supply relay control

Not used B2 F2 Preheating relay control

Water in diesel fuel detector signal B3 F3 Not used

Not used B4 F4 Not used

Not used C1 G1 Not used

Not used C2 G2 After relay + battery 1 earth

Refrigerant pressure sensor signal C3 G3 Refrigerant pressure sensor earth

Refrigerant pressure sensor supply C4 G4 Not used

Not used D1 H1 Potentiometer earth Gang 1

Not used D2 H2 Not used

Heater plug diag signal D3 H3 After relay + battery 2

Not used D4 H4 Not used

NOTE:

The supply voltage on tracks G2 and H2 is not measurable when the computer connector is disconnected.

Page 22 of 198

13B-22V4 MR-372-J84-13B000$050.mif

13B

DDCR INJECTION

Vdiag No.: 44, 48

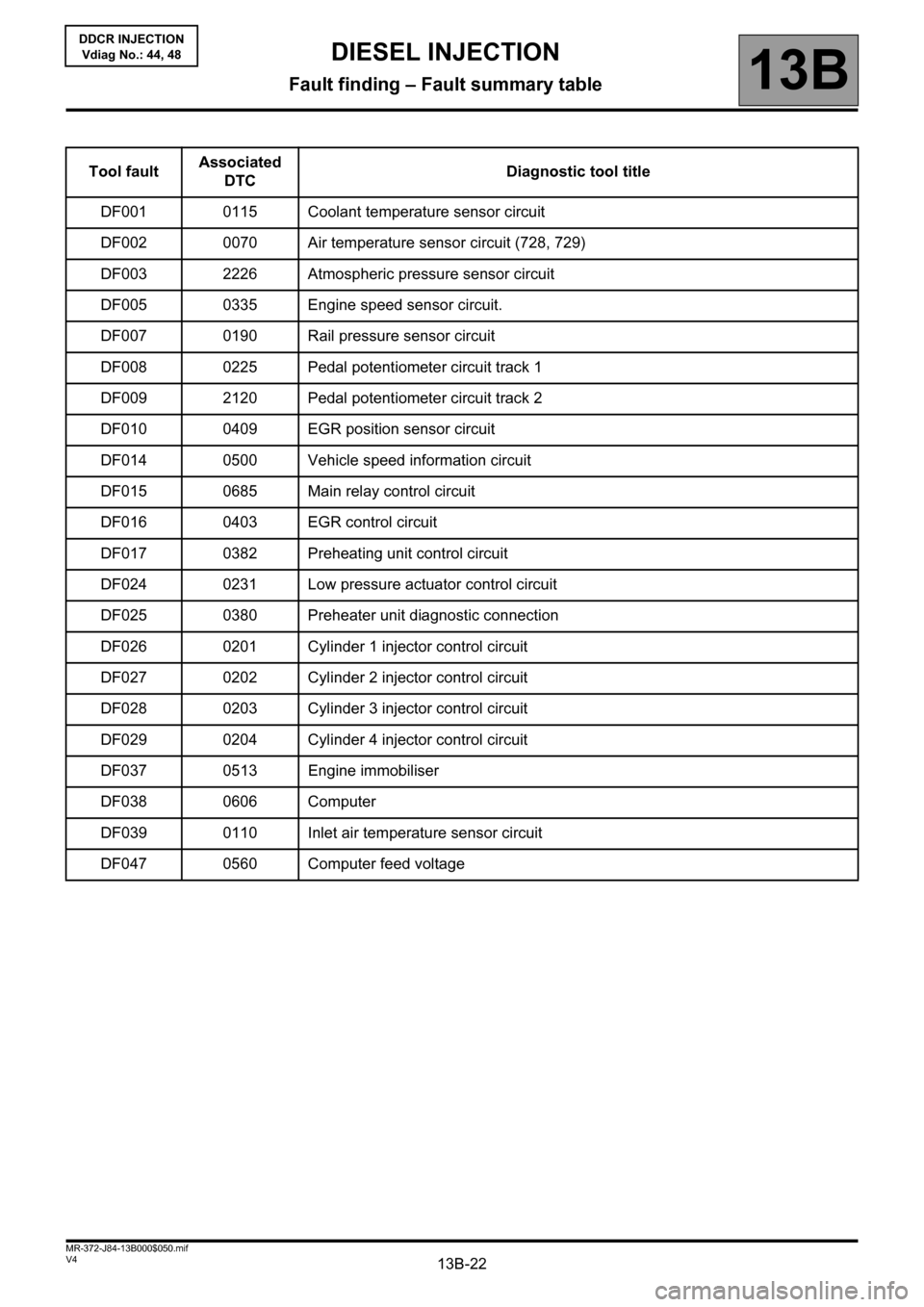

Tool faultAssociated

DTCDiagnostic tool title

DF001 0115 Coolant temperature sensor circuit

DF002 0070 Air temperature sensor circuit (728, 729)

DF003 2226 Atmospheric pressure sensor circuit

DF005 0335 Engine speed sensor circuit.

DF007 0190 Rail pressure sensor circuit

DF008 0225 Pedal potentiometer circuit track 1

DF009 2120 Pedal potentiometer circuit track 2

DF010 0409 EGR position sensor circuit

DF014 0500 Vehicle speed information circuit

DF015 0685 Main relay control circuit

DF016 0403 EGR control circuit

DF017 0382 Preheating unit control circuit

DF024 0231 Low pressure actuator control circuit

DF025 0380 Preheater unit diagnostic connection

DF026 0201 Cylinder 1 injector control circuit

DF027 0202 Cylinder 2 injector control circuit

DF028 0203 Cylinder 3 injector control circuit

DF029 0204 Cylinder 4 injector control circuit

DF037 0513 Engine immobiliser

DF038 0606 Computer

DF039 0110 Inlet air temperature sensor circuit

DF047 0560 Computer feed voltage

DIESEL INJECTION

Fault finding – Fault summary table

Page 24 of 198

13B-24

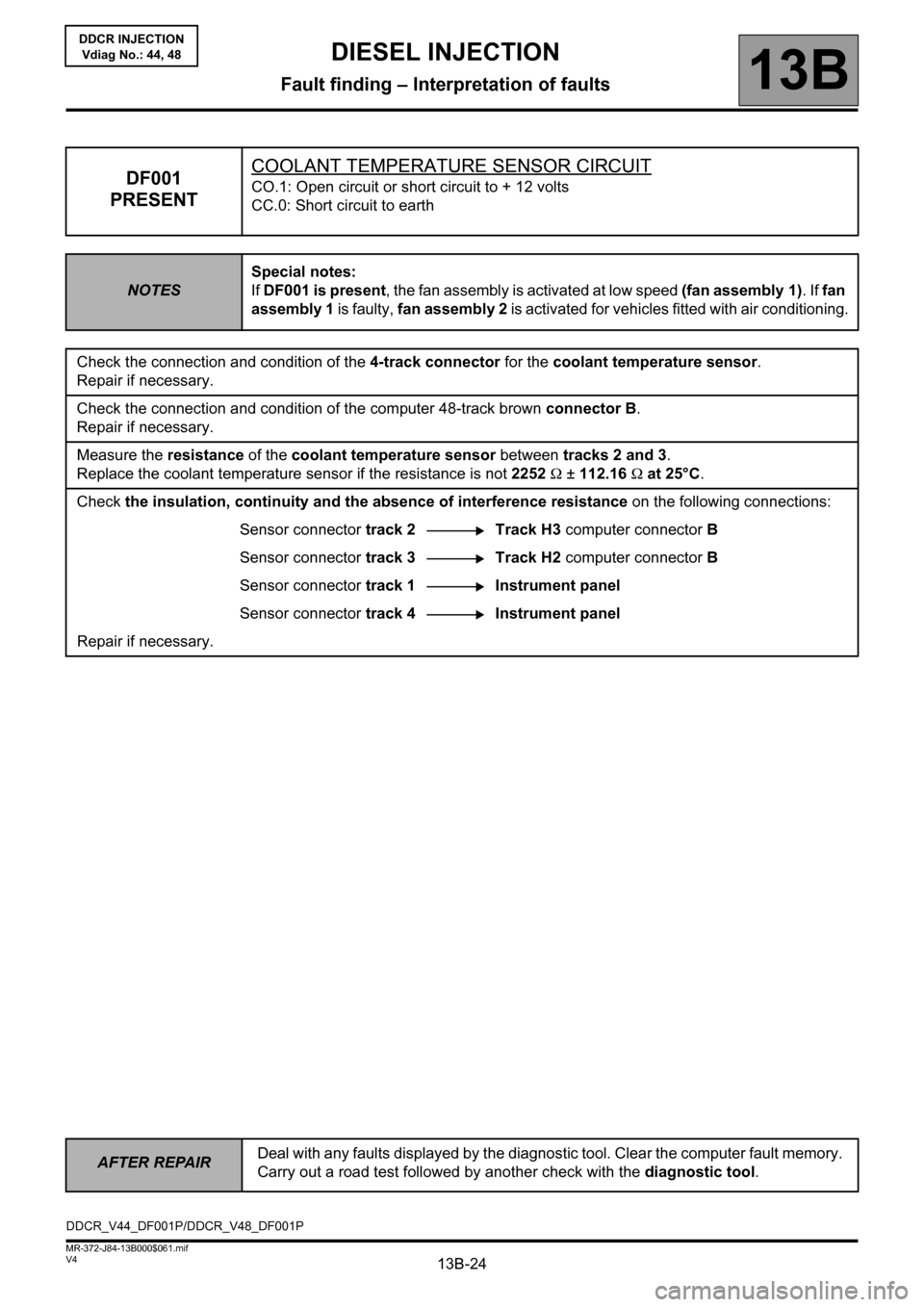

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$061.mif

13B

DDCR INJECTION

Vdiag No.: 44, 48

DF001

PRESENTCOOLANT TEMPERATURE SENSOR CIRCUITCO.1: Open circuit or short circuit to + 12 volts

CC.0: Short circuit to earth

NOTESSpecial notes:

If DF001 is present, the fan assembly is activated at low speed (fan assembly 1). If fan

assembly 1 is faulty, fan assembly 2 is activated for vehicles fitted with air conditioning.

Check the connection and condition of the 4-track connector for the coolant temperature sensor.

Repair if necessary.

Check the connection and condition of the computer 48-track brown connector B.

Repair if necessary.

Measure the resistance of the coolant temperature sensor between tracks 2 and 3.

Replace the coolant temperature sensor if the resistance is not 2252 Ω ± 112.16 Ω at 25°C.

Check the insulation, continuity and the absence of interference resistance on the following connections:

Sensor connector track 2 Track H3 computer connector B

Sensor connector track 3 Track H2 computer connector B

Sensor connector track 1 Instrument panel

Sensor connector track 4 Instrument panel

Repair if necessary.

DDCR_V44_DF001P/DDCR_V48_DF001P

DIESEL INJECTION

Fault finding – Interpretation of faults

Page 25 of 198

13B-25

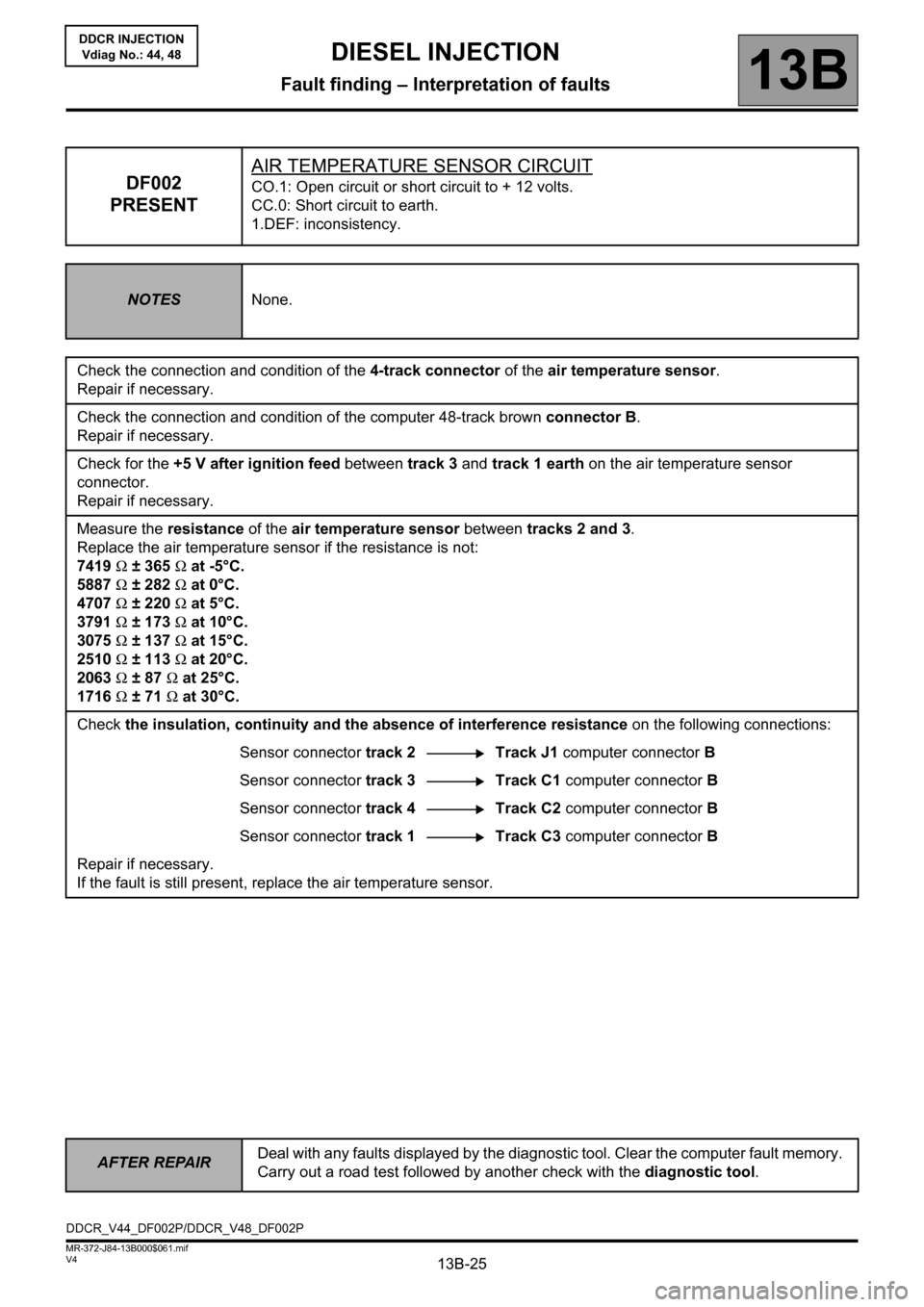

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$061.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DDCR INJECTION

Vdiag No.: 44, 48

DF002

PRESENTAIR TEMPERATURE SENSOR CIRCUITCO.1: Open circuit or short circuit to + 12 volts.

CC.0: Short circuit to earth.

1.DEF: inconsistency.

NOTESNone.

Check the connection and condition of the 4-track connector of the air temperature sensor.

Repair if necessary.

Check the connection and condition of the computer 48-track brown connector B.

Repair if necessary.

Check for the +5 V after ignition feed between track 3 and track 1 earth on the air temperature sensor

connector.

Repair if necessary.

Measure the resistance of the air temperature sensor between tracks 2 and 3.

Replace the air temperature sensor if the resistance is not:

7419 Ω ± 365 Ω at -5°C.

5887 Ω ± 282 Ω at 0°C.

4707 Ω ± 220 Ω at 5°C.

3791 Ω ± 173 Ω at 10°C.

3075 Ω ± 137 Ω at 15°C.

2510 Ω ± 113 Ω at 20°C.

2063 Ω ± 87 Ω at 25°C.

1716 Ω ± 71 Ω at 30°C.

Check the insulation, continuity and the absence of interference resistance on the following connections:

Sensor connector track 2 Track J1 computer connector B

Sensor connector track 3 Track C1 computer connector B

Sensor connector track 4 Track C2 computer connector B

Sensor connector track 1 Track C3 computer connector B

Repair if necessary.

If the fault is still present, replace the air temperature sensor.

DDCR_V44_DF002P/DDCR_V48_DF002P

Page 27 of 198

13B-27

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$061.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DDCR INJECTION

Vdiag No.: 44, 48

DF005

PRESENT

OR

STOREDENGINE SPEED SENSOR CIRCUIT1.DEF: Inconsistency.

2.DEF: No signal.

3.DEF: Too many additional teeth.

4.DEF: Teeth missing.

5.DEF: Additional teeth.

6.DEF: Too many teeth missing.

NOTESSpecial notes:

If 1.DEF, 2.DEF, 3.DEF, 6.DEF present: the engine stops and the level 1 warning

light illuminates along with the message Faulty injection.

If 4.DEF, 5.DEF, the engine performance is 75%, no warning light illuminates.

Conditions for applying the fault finding procedure to a stored fault:

the fault is present with the engine under the starter or idling.

Check the connection and condition of the 2-track connector of the engine speed sensor. Repair if necessary.

Ensure the sensor is correctly fitted on the engine.

Check the connection and condition of the computer 48-track brown connector B.

Repair if necessary.

Measure the resistance at the engine speed sensor terminals.

Replace the engine speed sensor if the resistance is not:

– for 80hp versions (K9K 722): 800 Ω ± 80 Ω at 20°C

– for 100hp versions (K9K 728/729): 680 Ω ± 68 Ω at 20°C

Check the insulation, continuity and the absence of interference resistance on the following connections:

Sensor connector track A Track F2 computer connector B

Sensor connector track BTrack F3 computer connector B

Repair if necessary.

Check that the flywheel ring gear is not defective (missing teeth).

DDCR_V44_DF005P/DDCR_V48_DF005P

Page 28 of 198

13B-28

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$061.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DDCR INJECTION

Vdiag No.: 44, 48

DF007

STOREDRAIL PRESSURE SENSOR CIRCUIT

CC.0: Short circuit to earth.

CO.1: Open circuit or short circuit to + 12 volts.

1.DEF: inconsistency.

2.DEF: Below minimum threshold.

3.DEF: Above maximum threshold.

NOTESPriority when dealing with a number of faults:

– Deal with fault DF113 Sensor supply voltage first.

Conditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the engine is started.

Special notes: if DF007, the engine stops and cannot be restarted, and the level 1

warning light illuminates along with the message Faulty injection.

Check the connection and condition of the 3-track connector of the rail pressure sensor.

Repair if necessary.

Check the connection and condition of the computer 48-track brown connector B.

Repair if necessary.

Check the insulation, continuity and the absence of interference resistance on the following connections:

Sensor connector track 2 Track D3 computer connector B

Sensor connector track 1Track D2 computer connector B

Sensor connector track 3 Track D1 computer connector B

Repair if necessary.

If the fault is still present, there is a rail pressure sensor fault, replace the rail.

DDCR_V44_DF007M/DDCR_V48_DF007M