Air condition RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 325 of 510

13B-325V12 MR-372-J84-13B300$110.mif

13B

EDC16CP33

Program No.: C4

VDiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

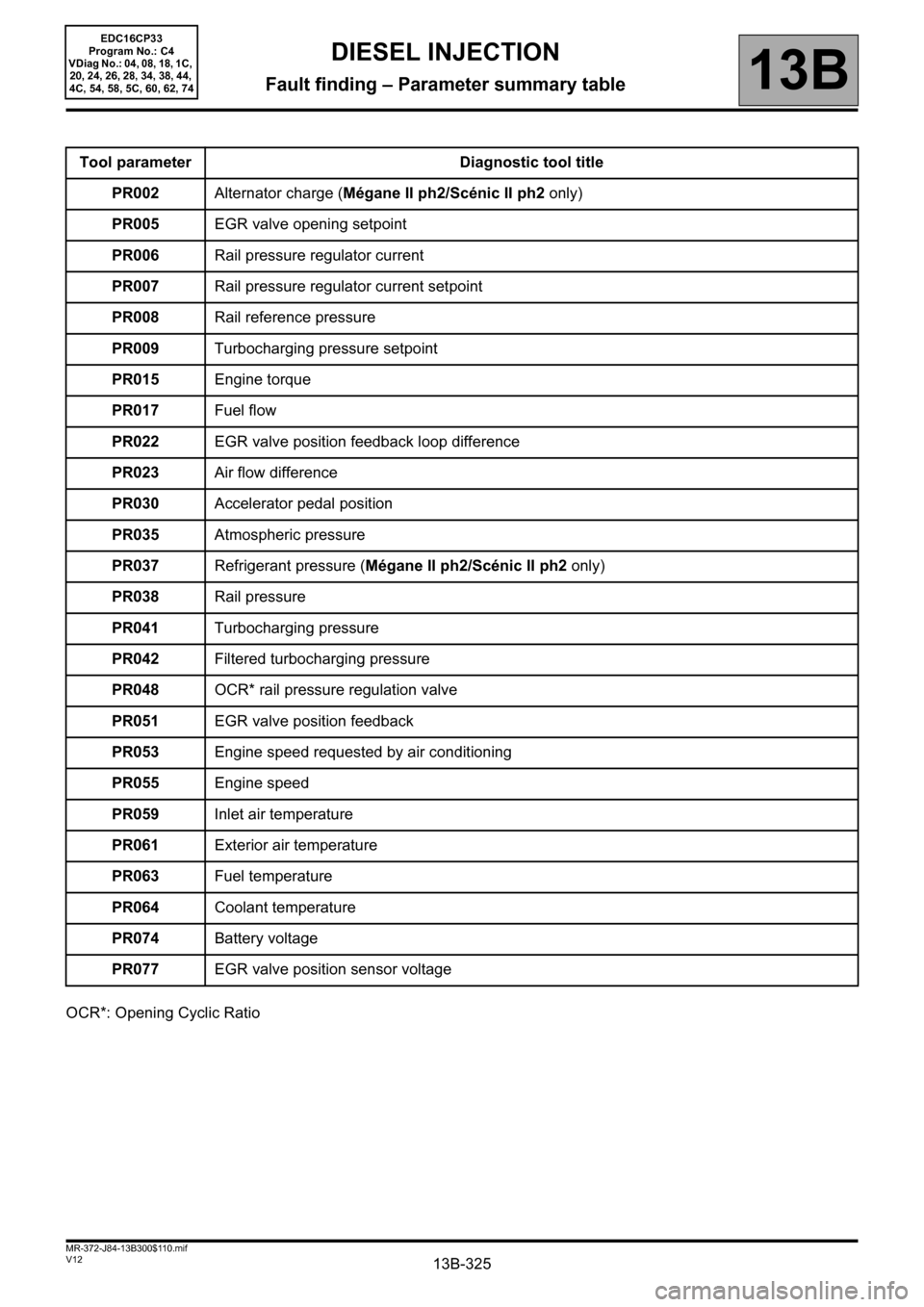

OCR*: Opening Cyclic RatioTool parameter Diagnostic tool title

PR002Alternator charge (Mégane II ph2/Scénic II ph2 only)

PR005EGR valve opening setpoint

PR006Rail pressure regulator current

PR007Rail pressure regulator current setpoint

PR008Rail reference pressure

PR009Turbocharging pressure setpoint

PR015Engine torque

PR017Fuel flow

PR022EGR valve position feedback loop difference

PR023Air flow difference

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure (Mégane II ph2/Scénic II ph2 only)

PR038Rail pressure

PR041Turbocharging pressure

PR042Filtered turbocharging pressure

PR048OCR* rail pressure regulation valve

PR051EGR valve position feedback

PR053Engine speed requested by air conditioning

PR055Engine speed

PR059Inlet air temperature

PR061Exterior air temperature

PR063Fuel temperature

PR064Coolant temperature

PR074Battery voltage

PR077EGR valve position sensor voltage

DIESEL INJECTION

Fault finding – Parameter summary table

Page 345 of 510

13B-345

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$121.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

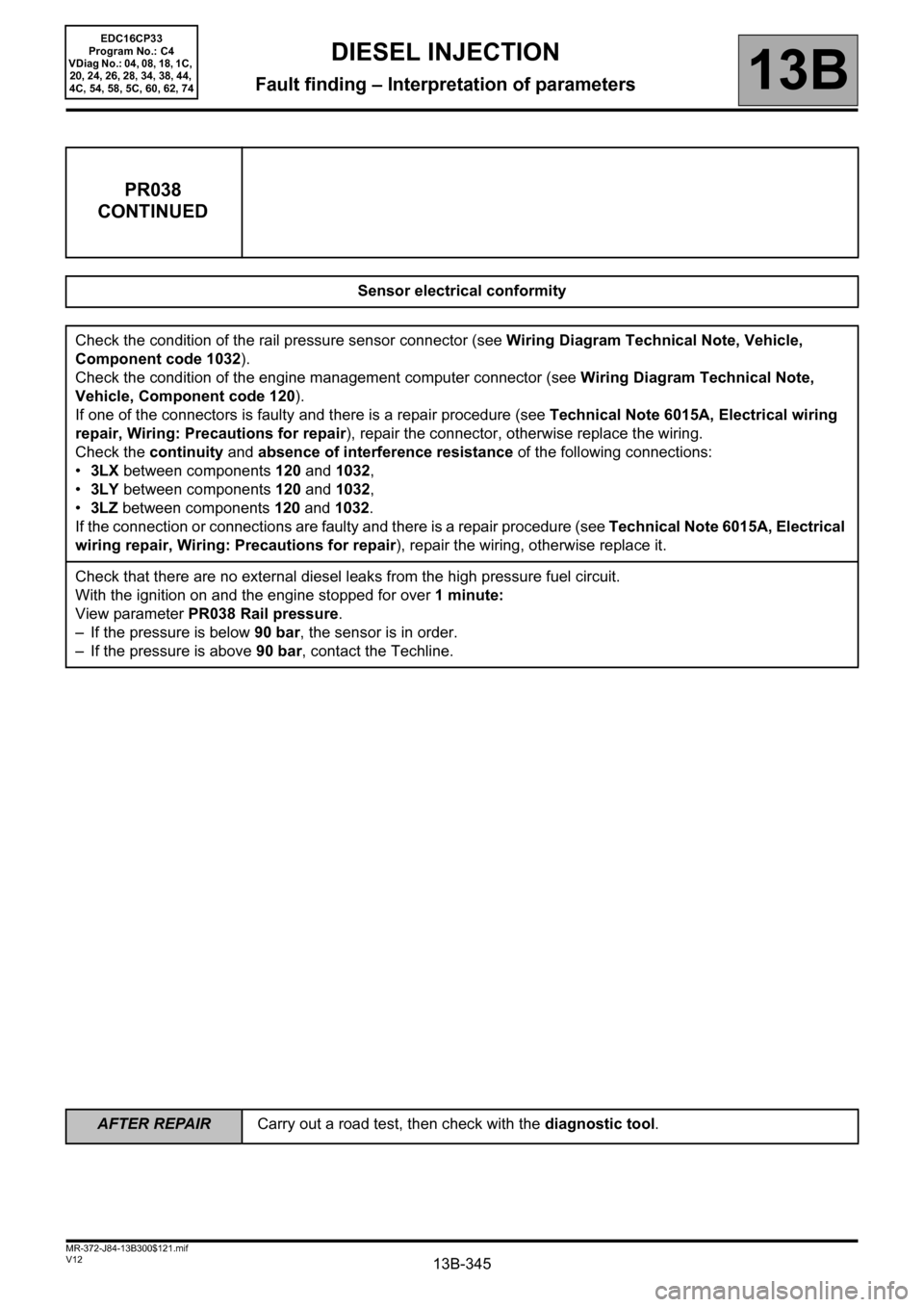

PR038

CONTINUED

Sensor electrical conformity

Check the condition of the rail pressure sensor connector (see Wiring Diagram Technical Note, Vehicle,

Component code 1032).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Vehicle, Component code 120).

If one of the connectors is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity and absence of interference resistance of the following connections:

•3LX between components 120 and 1032,

•3LY between components 120 and 1032,

•3LZ between components 120 and 1032.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check that there are no external diesel leaks from the high pressure fuel circuit.

With the ignition on and the engine stopped for over 1 minute:

View parameter PR038 Rail pressure.

– If the pressure is below 90 bar, the sensor is in order.

– If the pressure is above 90 bar, contact the Techline.

EDC16CP33

Program No.: C4

VDiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 351 of 510

13B-351

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$121.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

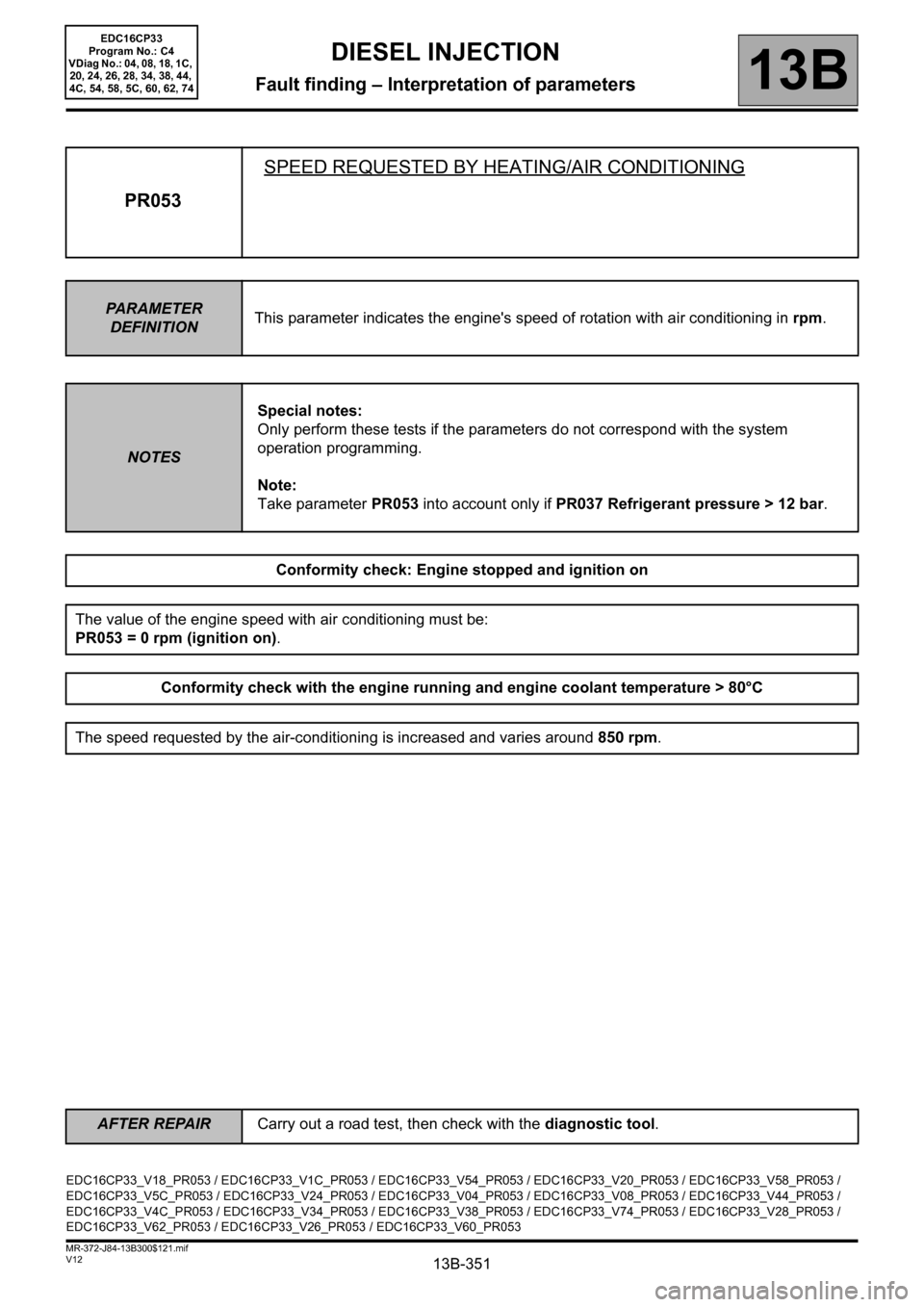

PR053SPEED REQUESTED BY HEATING/AIR CONDITIONING

PARAMETER

DEFINITIONThis parameter indicates the engine's speed of rotation with air conditioning in rpm.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

Note:

Take parameter PR053 into account only if PR037 Refrigerant pressure > 12 bar.

Conformity check: Engine stopped and ignition on

The value of the engine speed with air conditioning must be:

PR053 = 0 rpm (ignition on).

Conformity check with the engine running and engine coolant temperature > 80°C

The speed requested by the air-conditioning is increased and varies around 850 rpm.

EDC16CP33_V18_PR053 / EDC16CP33_V1C_PR053 / EDC16CP33_V54_PR053 / EDC16CP33_V20_PR053 / EDC16CP33_V58_PR053 /

EDC16CP33_V5C_PR053 / EDC16CP33_V24_PR053 / EDC16CP33_V04_PR053 / EDC16CP33_V08_PR053 / EDC16CP33_V44_PR053 /

EDC16CP33_V4C_PR053 / EDC16CP33_V34_PR053 / EDC16CP33_V38_PR053 / EDC16CP33_V74_PR053 / EDC16CP33_V28_PR053 /

EDC16CP33_V62_PR053 / EDC16CP33_V26_PR053 / EDC16CP33_V60_PR053

EDC16CP33

Program No.: C4

VDiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 418 of 510

13B-418

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$130.mif

13B

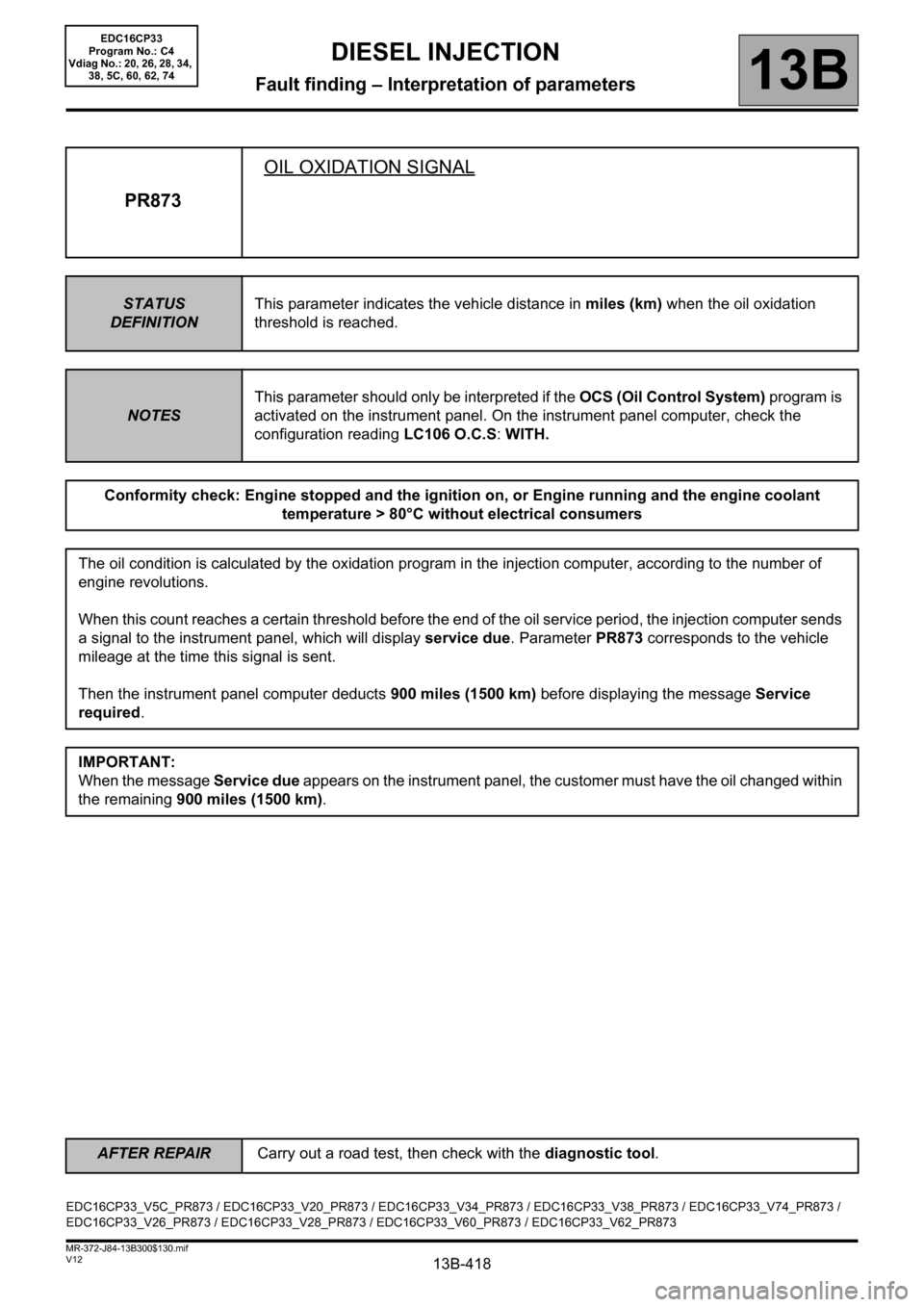

PR873OIL OXIDATION SIGNAL

STATUS

DEFINITIONThis parameter indicates the vehicle distance in miles (km) when the oil oxidation

threshold is reached.

NOTESThis parameter should only be interpreted if the OCS (Oil Control System) program is

activated on the instrument panel. On the instrument panel computer, check the

configuration reading LC106 O.C.S: WITH.

Conformity check: Engine stopped and the ignition on, or Engine running and the engine coolant

temperature > 80°C without electrical consumers

The oil condition is calculated by the oxidation program in the injection computer, according to the number of

engine revolutions.

When this count reaches a certain threshold before the end of the oil service period, the injection computer sends

a signal to the instrument panel, which will display service due. Parameter PR873 corresponds to the vehicle

mileage at the time this signal is sent.

Then the instrument panel computer deducts 900 miles (1500 km) before displaying the message Service

required.

IMPORTANT:

When the message Service due appears on the instrument panel, the customer must have the oil changed within

the remaining 900 miles (1500 km).

EDC16CP33_V5C_PR873 / EDC16CP33_V20_PR873 / EDC16CP33_V34_PR873 / EDC16CP33_V38_PR873 / EDC16CP33_V74_PR873 /

EDC16CP33_V26_PR873 / EDC16CP33_V28_PR873 / EDC16CP33_V60_PR873 / EDC16CP33_V62_PR873

DIESEL INJECTION

Fault finding – Interpretation of parameters

EDC16CP33

Program No.: C4

Vdiag No.: 20, 26, 28, 34,

38, 5C, 60, 62, 74

Page 427 of 510

13B-427V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC017PARTICLE FILTER REGENERATION

NOTESOnly run this command after interpretation of the following faults:

– DF308 Clogged particle filter,

– DF311 Failed regenerations limit exceeded,

– df312: speed request.

WARNING:

– It is essential to observe the health and safety guidelines (see MR364 (Mégane II ph2), MR370 (Scénic II ph2),

MR 395 (Laguna II ph2), 402 (Vel Satis ph2), 405 (Espace IV ph2) Mechanical, 19B, Exhaust, Particle

filter: Cleaning) and follow the procedure below.

SAFETY INSTRUCTIONS TO BE FOLLOWED:

The regeneration causes exhaust fumes and high temperatures.

It is strongly recommended that you put the vehicle outside during regeneration.

If it is not possible to carry out regeneration outside, use an extractor fan that can withstand the very high

regeneration temperatures (400°C at the exhaust outlet).

Perform regeneration on a surface free from fire risks (oil, dry leaves, etc.).

Nothing should be left in the vicinity of the exhaust pipe.

Check that there are no leaks or blockages in the exhaust pipe,

Repair if necessary.

WARNING:

Check the engine oil level before running the command to avoid any engine racing. The oil level must be

between the minimum level and the middle level on the oil dipstick.

Before performing a particle filter regeneration, it is essential to deactivate the air conditioning

compressor (risk of engine damage) and all the electrical consumers.

IF NECESSARY:

Regeneration can be stopped by pressing the engine start button twice briefly (less than 3 seconds).

Switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes) Communication

lost with computer: EDC16 C33, check the tool connection and the computer power supply before

switching the ignition back on.

EDC16CP33_V1C_SC017 / EDC16CP33_V54_SC017 / EDC16CP33_V20_SC017 / EDC16CP33_V58_SC017 / EDC16CP33_V5C_SC017 /

EDC16CP33_V24_SC017 / EDC16CP33_V28_SC017 / EDC16CP33_V62_SC017/ EDC16CP33_V26_SC017 / EDC16CP33_V60_SC017

EDC16CP33

Program No.: C4

Vdiag No.: 1C, 20, 24, 26,

28, 54, 58, 5C, 60, 62

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 431 of 510

13B-431V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC031OPERATIONAL FAULT FINDING OF CYLINDERS

NOTESThis command allows fault finding to be carried out on the output of each cylinder and

each injector and applies to all the Vdiags except Vdiag 18, 04 and 44.

Note:

For Vdiags 18, 04 and 44, check that the fuel flow correction value of parameters

PR364 Cylinder no. 1 fuel flow correction, PR365 Cylinder no. 4 fuel flow

correction, PR405 Cylinder no. 2 fuel flow correction and PR406 Cylinder no. 3

fuel flow correction is between: -5 mg/st < X < 5 mg/st.

Reminder: cylinder no. 1 is located at the timing end.

Procedure to be followed:

– select scenario SC031,

– once the conditions have been met, press the confirm button; the test will take approximately 5 minutes,

– the tool displays cylinder no. 1 cut-off and there will be a perceptible engine speed variation when the cylinder

is cut off; then the same procedure for the other three cylinders,

–the diagnostic tool displays the results,

– end of test.

Interpretation of correct results:

– If the displayed results are “VALID”, it means that the entire cylinder and injector assembly is in order. There

is no need for any operation.

Results Interpretation of results

Cylinder 1 VALID No operation

Cylinder 2 VALID No operation

Cylinder 3 VALID No operation

Cylinder 4 VALID No operation

EDC16CP33_V1C_SC031 / EDC16CP33_V54_SC031 / EDC16CP33_V20_SC031 / EDC16CP33_V58_SC031 / EDC16CP33_V5C_SC031 /

EDC16CP33_V24_SC031 / EDC16CP33_V08_SC003 / EDC16CP33_V4C_SC031 / EDC16CP33_V34_SC031 / EDC16CP33_V38_SC031 /

EDC16CP33_V74_SC031 / EDC16CP33_V28_SC031 / EDC16CP33_V62_SC031 / EDC16CP33_V26_SC031 / EDC16CP33_V60_SC031

EDC16CP33

Program No.: C4

Vdiag No.: 08, 1C, 20, 24,

26, 28, 34, 38, 4C, 54, 58,

5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 437 of 510

13B-437V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

RZ005PROGRAMMING

NOTESSpecial notes:

this command enables you to reinitialise the entire computer configuration according to

the vehicle.

Command RZ005 reconfigures the computer.

If the computer does not have any configuration data, use command RZ005 to enter the vehicle options:

– air conditioning,

– Passenger compartment heating resistor,

– cruise control/speed limiter.

These options are detected by the computer even if command RZ005 is not used.

The computer is configured as soon as the one of the vehicle's optional system components is operated.

EDC16CP33_V18_RZ005 / EDC16CP33_V1C_RZ005 / EDC16CP33_V54_RZ005 / EDC16CP33_V20_RZ005 / EDC16CP33_V58_RZ005 /

EDC16CP33_V5C_RZ005 / EDC16CP33_V24_RZ005 / EDC16CP33_V04_RZ005 / EDC16CP33_V08_RZ005 / EDC16CP33_V44_RZ005 /

EDC16CP33_V4C_RZ005 / EDC16CP33_V34_RZ005 / EDC16CP33_V38_RZ005 / EDC16CP33_V74_RZ005 / EDC16CP33_V28_RZ005 /

EDC16CP33_V62_RZ005 / EDC16CP33_V26_RZ005 / EDC16CP33_V60_RZ005

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 442 of 510

13B-442V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC031THERMOPLUNGER No. 3 RELAY

NOTESCheck that the computer is correctly configured using command LC056

Thermoplungers

There must be no present or stored faults:

Perform this fault finding procedure if there is a fault with the passenger compartment

heating - demisting.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

If the Thermoplunger no. 3 relay or the additional heater interface unit does not function when command

AC031 is run.

Check the condition of the thermoplunger 3 relay mounting on the engine fuse box or the additional heater

interface unit (see Wiring Diagram Technical Note, Vehicle, component code 1069 or 1550).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Vehicle, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

if the fault is still present, check as follows that this relay is controlled by the engine management computer:

Disconnect the thermoplunger no. 3 relay and fit a 50 Ω to 100Ω resistor on its mounting instead of the coil and

connect a voltmeter as follows:

– positive terminal to + 12 V battery,

– negative terminal to connection 3JAB of component 1069 or 1550.

Run command AC031.

If the voltmeter indicates the battery voltage (4 ON-OFF cycles of 10 seconds), replace the thermoplunger no. 3

relay.

If the voltmeter does not show the battery voltage (4 ON-OFF cycles of 10 seconds), contact the Techline.

EDC16CP33_V18_AC031 / EDC16CP33_V1C_AC031 / EDC16CP33_V54_AC031 / EDC16CP33_V20_AC031 / EDC16CP33_V58_AC031 /

EDC16CP33_V5C_AC031 / EDC16CP33_V24_AC031 / EDC16CP33_V04_AC031 / EDC16CP33_V08_AC031 / EDC16CP33_V44_AC031 /

EDC16CP33_V4C_AC031 / EDC16CP33_V34_AC031 / EDC16CP33_V38_AC031 / EDC16CP33_V74_AC031 / EDC16CP33_V28_AC031 /

EDC16CP33_V62_AC031 / EDC16CP33_V26_AC031 / EDC16CP33_V60_AC031

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 445 of 510

13B-445V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC037

CONTINUED

STEP 2:

Check the connections of the preheating unit, component code 257, the heater plugs, component codes 680, 681,

682 and 683 and the injection computer, component code 120.

Measure the resistance of the heater plugs. If the resistance value is > 2 Ω, replace the faulty plug or plugs,

making sure that the correct plug type, slow or fast, is fitted on the vehicle.

Check the continuity and absence of interference resistance of the following connections:

•37AB between components 257 and 683,

•37AA between components 257 and 680,

•37Z between components 257 and 681,

•37AC between components 257 and 682.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the condition of the preheating unit supply fuse (70 A) (see MR 364 (Mégane II ph2), MR 370 (Scénic II

ph2), MR 395 (Laguna II ph2), 402 (Vel Satis ph2), 405 (Espace IV ph2) Mechanical, 81C, Fuses, Fuses: List

and location of components).

Check the + 12 V battery supply to the preheating unit on the following connection:

•BP35 of component 257.

Check the continuity and absence of interference resistance of the following connections:

•3FY between components120 and 257,

•3FF between components120 and 257.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the preheating unit.

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 446 of 510

13B-446V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC063THERMOPLUNGER No. 1 RELAY

NOTESThere must be no present or stored faults:

Perform this fault finding procedure if there is a fault with the passenger compartment

heating - demisting.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

If the Thermoplunger no. 1 relay or the additional heater interface unit does not function when command

AC063 is run.

Check the condition of the thermoplunger no. 1 relay mounting connector on the engine fuse box (see Wiring

Diagram Technical Note, Vehicle, component code 1067 or 1550).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Vehicle, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

if the fault is still present, check as follows that this relay is controlled by the engine management computer:

Disconnect thermoplunger no. 1 relay, and fit a 50 Ω to 100 Ω resistor on the mounting instead of the coil and

connect a voltmeter as follows:

– positive terminal to + 12 V battery,

– negative terminal to connection 3JA of component 1067 or 1550.

Run command AC063.

If the voltmeter shows the battery voltage (4 ON-OFF cycles of 10 seconds), replace the thermoplunger no. 1

relay.

If the voltmeter does not show the battery voltage (4 ON-OFF cycles of 10 seconds), contact the Techline.

EDC16CP33_V18_AC063 / EDC16CP33_V1C_AC063 / EDC16CP33_V54_AC063 / EDC16CP33_V20_AC063 / EDC16CP33_V58_AC063 /

EDC16CP33_V5C_AC063 / EDC16CP33_V24_AC063 / EDC16CP33_V04_AC063 / EDC16CP33_V08_AC063 / EDC16CP33_V44_AC063 /

EDC16CP33_V4C_AC063 / EDC16CP33_V34_AC063 / EDC16CP33_V38_AC063 / EDC16CP33_V74_AC063 / EDC16CP33_V28_AC063 /

EDC16CP33_V62_AC063 / EDC16CP33_V26_AC063 / EDC16CP33_V60_AC063

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.