EGR VALVE RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 450 of 510

13B-450V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC103EGR BY-PASS

NOTESCarry out this fault finding procedure when the interpretation of fault DF304 EGR

bypass circuit has not been resolved.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

Measure the resistance between connections 3FB and 3TP of component 1301.

If the resistance of the solenoid valve is not between:

•43 Ω and 49 Ω at + 25 °C,

•32 Ω and 37 Ω at - 40 °C, replace the EGR bypass solenoid valve.

Check the continuity and the absence of interference resistance on the following connection:

•3TP between components 120 and 1301.

Check the + 12 V after relay supply to the EGR bypass solenoid valve of the following connection:

•3FB of component 1301.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If you notice no valve movement when running command AC103, ensure that the computer output stage is

functioning:

Vehicle under + after ignition feed, clear the faults displayed by the diagnostic tool.

EDC16CP33_V18_AC103 / EDC16CP33_V1C_AC103 / EDC16CP33_V54_AC103 / EDC16CP33_V20_AC103 / EDC16CP33_V58_AC103 /

EDC16CP33_V5C_AC103 / EDC16CP33_V24_AC103 / EDC16CP33_V04_AC103 / EDC16CP33_V08_AC103 / EDC16CP33_V44_AC103 /

EDC16CP33_V4C_AC103 / EDC16CP33_V34_AC103 / EDC16CP33_V38_AC103 / EDC16CP33_V74_AC103 / EDC16CP33_V28_AC103 /

EDC16CP33_V62_AC103 / EDC16CP33_V26_AC103 / EDC16CP33_V60_AC103

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 451 of 510

13B-451V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC103

CONTINUED

With the voltmeter in the direct current position:

With the EGR BYPASS solenoid valve connected, connect the voltmeter earth lead to connection3TP of

component1301 and the positive lead to connection3FB of component1301. Run command AC103, the

voltmeter should display four successive readings which are approximately equal to the 12 V battery voltage.

If the voltmeter indicates no control or a continuous voltage, contact the Techline.

If activation has run correctly, check the control vacuum:

– Disconnect the solenoid valve inlet hose and connect it to a pressure gauge.

– Start the engine and run it at a stable idle speed.

– If the vacuum does not reach a value between 0.250 bar and 0.550 bar, check the vacuum circuit from the

vacuum pump.

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 459 of 510

13B-459V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

MT001TURBOCHARGING FUNCTION

NOTESPerform this fault finding procedure:

– following the interpretation of a fault concerning the air line which cannot be rectified,

– following an inconsistency found in the parameters concerning the air line

(turbocharging pressure or inlet air flow),

– following a customer complaint (starting faults, engine speed instability, lack of

power).

NOTESThis fault finding mode allows you to check dynamically certain mechanical components

on the engine.

To do this, the engine will run a 4-phase cycle which will enable the entire air line to be

checked: air filter, air flowmeter, duct (hoses), air refrigerant, turbocharging pressure

sensor, turbocharger, inlet manifold, exhaust manifold and exhaust pipe.

This test lasts for approximately 50 seconds.

Interpretation of test results:

The data recorded during this test is displayed in the DATA section.

- Identify any data which is outside the tolerance range and apply the different Monitool fault finding procedures

if necessary.

Introduction:

Engine parameters used during this test:

– PR055 Engine speed

– PR035 Atmospheric pressure

– PR059 Inlet air temperature

– PR064 Coolant temperature

–PR132 Air flow

– PR041 Turbocharging pressure

– PR051 EGR valve position feedback

EDC16CP33_V04_MT001 / EDC16CP33_V44_MT001

EDC16CP33

Program No.: C4

Vdiag No.: 04, 44

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 461 of 510

13B-461V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

MT001

CONTINUED 2

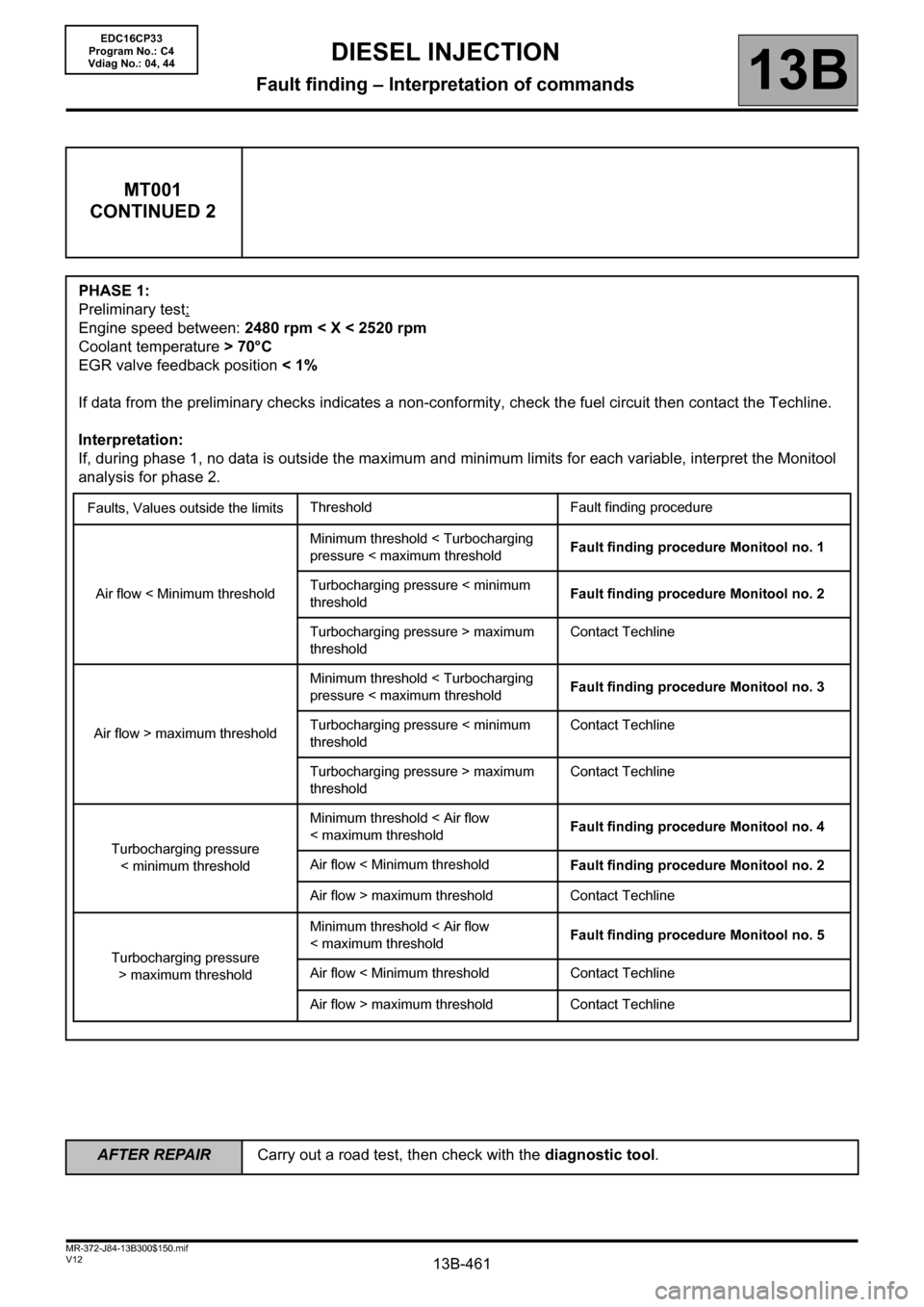

PHASE 1:

Preliminary test:

Engine speed between: 2480 rpm < X < 2520 rpm

Coolant temperature > 70°C

EGR valve feedback position < 1%

If data from the preliminary checks indicates a non-conformity, check the fuel circuit then contact the Techline.

Interpretation:

If, during phase 1, no data is outside the maximum and minimum limits for each variable, interpret the Monitool

analysis for phase 2.

Faults, Values outside the limitsThreshold Fault finding procedure

Air flow < Minimum thresholdMinimum threshold < Turbocharging

pressure < maximum thresholdFault finding procedure Monitool no. 1

Turbocharging pressure < minimum

thresholdFault finding procedure Monitool no. 2

Turbocharging pressure > maximum

thresholdContact Techline

Air flow > maximum thresholdMinimum threshold < Turbocharging

pressure < maximum thresholdFault finding procedure Monitool no. 3

Turbocharging pressure < minimum

thresholdContact Techline

Turbocharging pressure > maximum

thresholdContact Techline

Turbocharging pressure

< minimum thresholdMinimum threshold < Air flow

< maximum thresholdFault finding procedure Monitool no. 4

Air flow < Minimum threshold

Fault finding procedure Monitool no. 2

Air flow > maximum threshold Contact Techline

Turbocharging pressure

> maximum thresholdMinimum threshold < Air flow

< maximum thresholdFault finding procedure Monitool no. 5

Air flow < Minimum threshold Contact Techline

Air flow > maximum threshold Contact Techline

EDC16CP33

Program No.: C4

Vdiag No.: 04, 44

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 464 of 510

13B-464V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

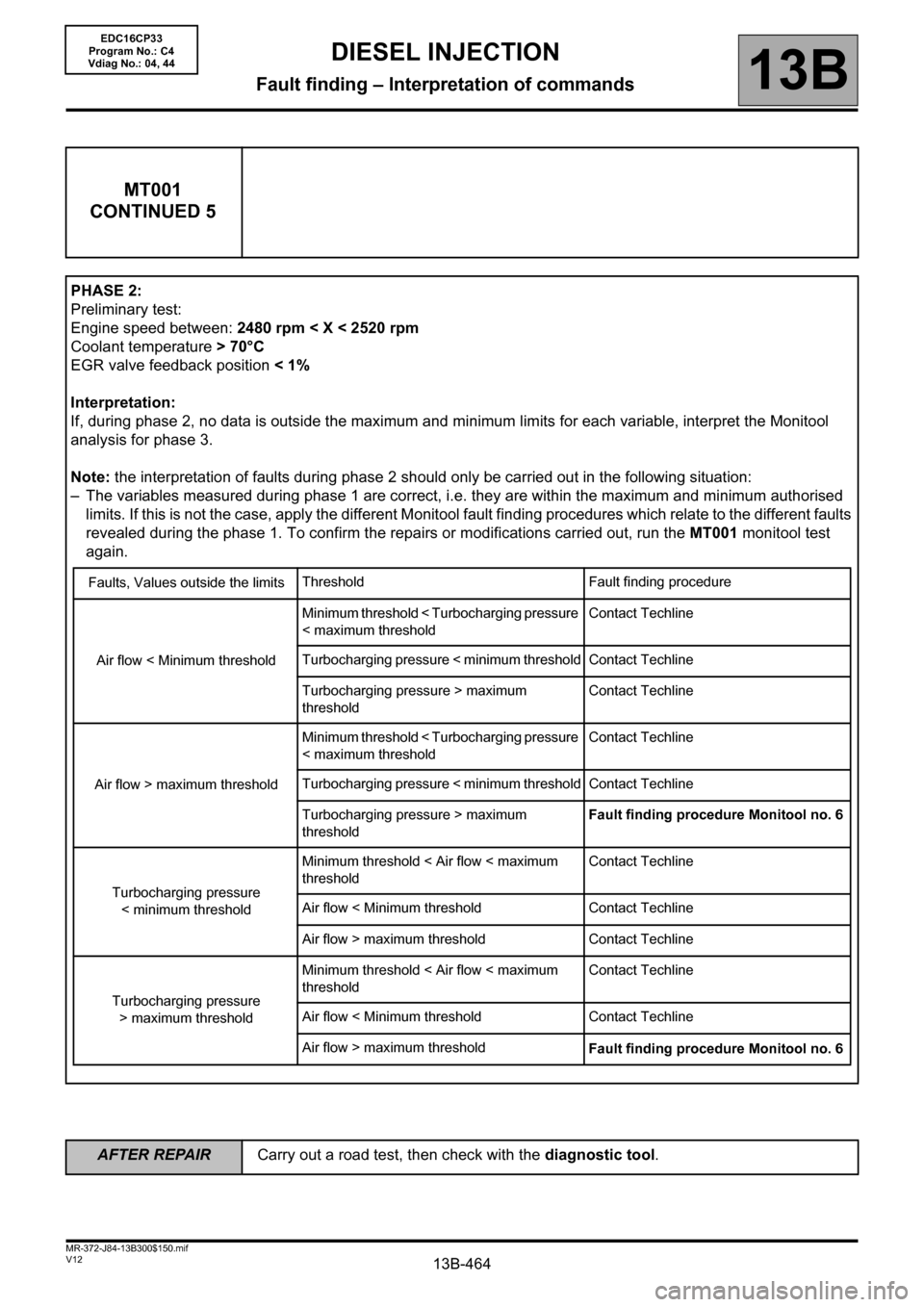

MT001

CONTINUED 5

PHASE 2:

Preliminary test:

Engine speed between: 2480 rpm < X < 2520 rpm

Coolant temperature > 70°C

EGR valve feedback position < 1%

Interpretation:

If, during phase 2, no data is outside the maximum and minimum limits for each variable, interpret the Monitool

analysis for phase 3.

Note: the interpretation of faults during phase 2 should only be carried out in the following situation:

– The variables measured during phase 1 are correct, i.e. they are within the maximum and minimum authorised

limits. If this is not the case, apply the different Monitool fault finding procedures which relate to the different faults

revealed during the phase 1. To confirm the repairs or modifications carried out, run the MT001 monitool test

again.

Faults, Values outside the limitsThreshold Fault finding procedure

Air flow < Minimum thresholdMinimum threshold < Turbocharging pressure

< maximum thresholdContact Techline

Turbocharging pressure < minimum threshold Contact Techline

Turbocharging pressure > maximum

thresholdContact Techline

Air flow > maximum thresholdMinimum threshold < Turbocharging pressure

< maximum thresholdContact Techline

Turbocharging pressure < minimum threshold Contact Techline

Turbocharging pressure > maximum

thresholdFault finding procedure Monitool no. 6

Turbocharging pressure

< minimum thresholdMinimum threshold < Air flow < maximum

thresholdContact Techline

Air flow < Minimum threshold Contact Techline

Air flow > maximum threshold Contact Techline

Turbocharging pressure

> maximum thresholdMinimum threshold < Air flow < maximum

thresholdContact Techline

Air flow < Minimum threshold Contact Techline

Air flow > maximum threshold

Fault finding procedure Monitool no. 6

EDC16CP33

Program No.: C4

Vdiag No.: 04, 44

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 466 of 510

13B-466V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

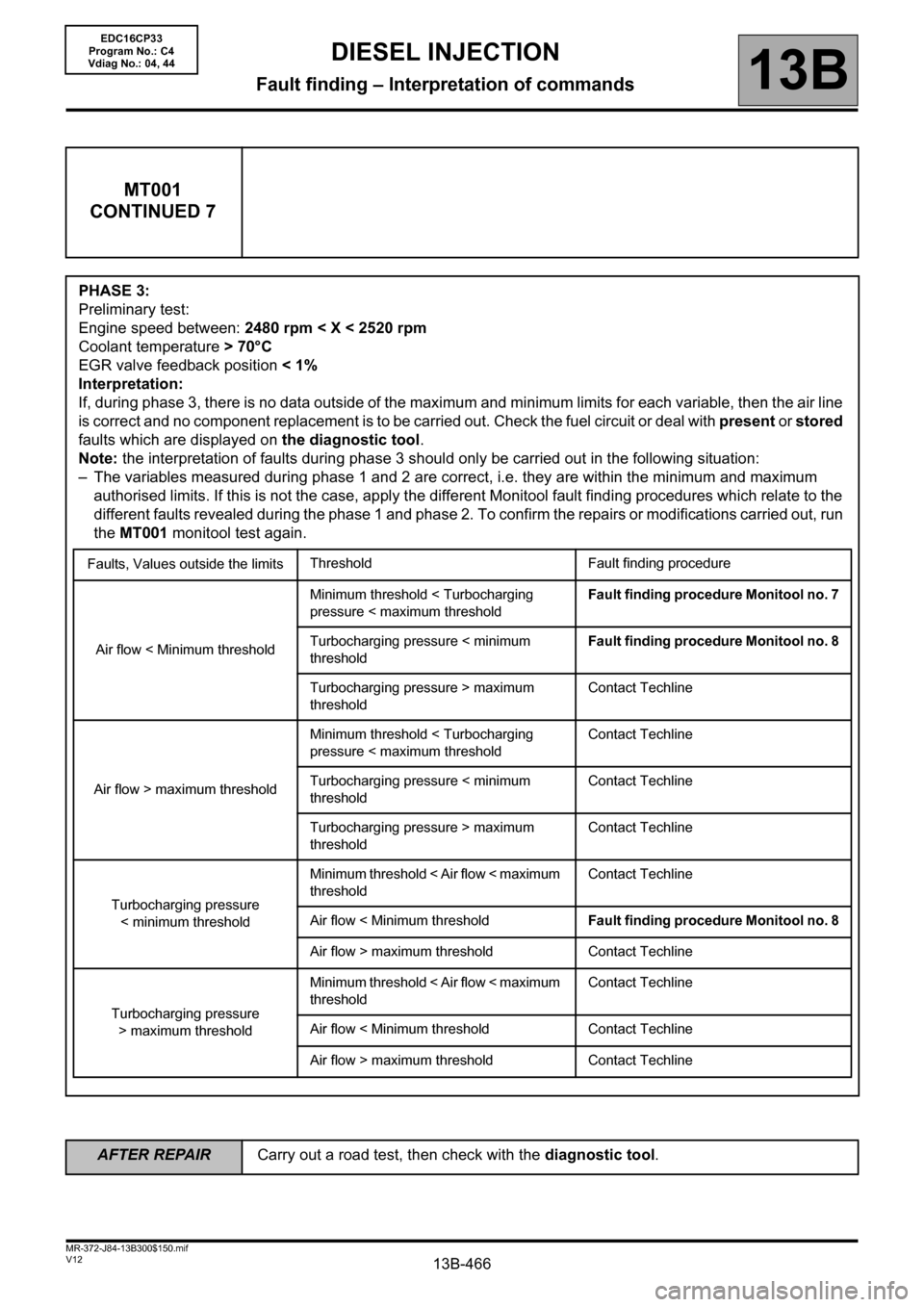

MT001

CONTINUED 7

PHASE 3:

Preliminary test:

Engine speed between: 2480 rpm < X < 2520 rpm

Coolant temperature > 70°C

EGR valve feedback position < 1%

Interpretation:

If, during phase 3, there is no data outside of the maximum and minimum limits for each variable, then the air line

is correct and no component replacement is to be carried out. Check the fuel circuit or deal with present or stored

faults which are displayed on the diagnostic tool.

Note: the interpretation of faults during phase 3 should only be carried out in the following situation:

– The variables measured during phase 1 and 2 are correct, i.e. they are within the minimum and maximum

authorised limits. If this is not the case, apply the different Monitool fault finding procedures which relate to the

different faults revealed during the phase 1 and phase 2. To confirm the repairs or modifications carried out, run

the MT001 monitool test again.

Faults, Values outside the limitsThreshold Fault finding procedure

Air flow < Minimum thresholdMinimum threshold < Turbocharging

pressure < maximum thresholdFault finding procedure Monitool no. 7

Turbocharging pressure < minimum

thresholdFault finding procedure Monitool no. 8

Turbocharging pressure > maximum

thresholdContact Techline

Air flow > maximum thresholdMinimum threshold < Turbocharging

pressure < maximum thresholdContact Techline

Turbocharging pressure < minimum

thresholdContact Techline

Turbocharging pressure > maximum

thresholdContact Techline

Turbocharging pressure

< minimum thresholdMinimum threshold < Air flow < maximum

thresholdContact Techline

Air flow < Minimum thresholdFault finding procedure Monitool no. 8

Air flow > maximum threshold Contact Techline

Turbocharging pressure

> maximum thresholdMinimum threshold < Air flow < maximum

thresholdContact Techline

Air flow < Minimum threshold Contact Techline

Air flow > maximum threshold Contact Techline

EDC16CP33

Program No.: C4

Vdiag No.: 04, 44

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 501 of 510

13B-501V12 MR-372-J84-13B300$180.mif

DIESEL INJECTION

Fault finding – Test13B

OCR*: Opening Cyclic Ratio

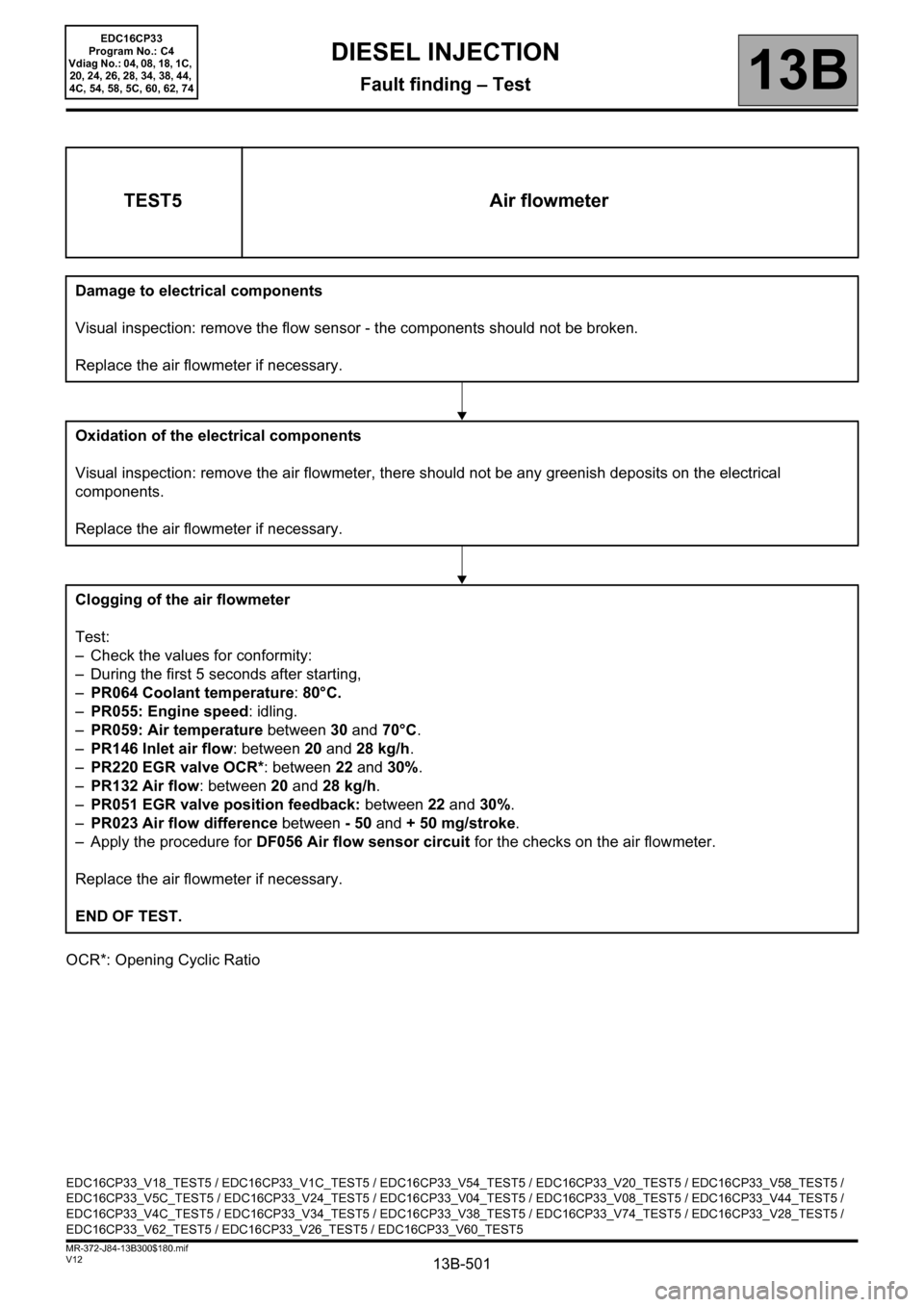

TEST5 Air flowmeter

Damage to electrical components

Visual inspection: remove the flow sensor - the components should not be broken.

Replace the air flowmeter if necessary.

Oxidation of the electrical components

Visual inspection: remove the air flowmeter, there should not be any greenish deposits on the electrical

components.

Replace the air flowmeter if necessary.

Clogging of the air flowmeter

Test:

– Check the values for conformity:

– During the first 5 seconds after starting,

–PR064 Coolant temperature: 80°C.

–PR055: Engine speed: idling.

–PR059: Air temperature between 30 and 70°C.

–PR146 Inlet air flow: between 20 and 28 kg/h.

–PR220 EGR valve OCR*: between 22 and 30%.

–PR132 Air flow: between 20 and 28 kg/h.

–PR051 EGR valve position feedback: between 22 and 30%.

–PR023 Air flow difference between - 50 and + 50 mg/stroke.

– Apply the procedure for DF056 Air flow sensor circuit for the checks on the air flowmeter.

Replace the air flowmeter if necessary.

END OF TEST.

EDC16CP33_V18_TEST5 / EDC16CP33_V1C_TEST5 / EDC16CP33_V54_TEST5 / EDC16CP33_V20_TEST5 / EDC16CP33_V58_TEST5 /

EDC16CP33_V5C_TEST5 / EDC16CP33_V24_TEST5 / EDC16CP33_V04_TEST5 / EDC16CP33_V08_TEST5 / EDC16CP33_V44_TEST5 /

EDC16CP33_V4C_TEST5 / EDC16CP33_V34_TEST5 / EDC16CP33_V38_TEST5 / EDC16CP33_V74_TEST5 / EDC16CP33_V28_TEST5 /

EDC16CP33_V62_TEST5 / EDC16CP33_V26_TEST5 / EDC16CP33_V60_TEST5

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74