programming RENAULT SCENIC 2014 J95 / 3.G Petrol Injection - Sagem3000 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2014, Model line: SCENIC, Model: RENAULT SCENIC 2014 J95 / 3.GPages: 181

Page 1 of 181

1Engine and peripherals

V12 MR-372-J84-17B000$TOC.mif

V12

17B

"The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories from

which his vehicles are constructed."

V12

All rights reserved by Renault s.a.s.

Edition Anglaise

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault s.a.s.

© Renault s.a.s. 2014

PETROL INJECTION

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

Fault finding – Introduction 17B - 2

Fault finding – System operation 17B - 7

Fault finding – Allocation of computer tracks 17B - 12

Fault finding – Replacement of components 17B - 15

Fault finding – Configurations and programming 17B - 16

Fault finding – Fault summary table 17B - 17

Fault finding – Interpretation of faults 17B - 21

Fault finding – Conformity check 17B - 90

Fault finding – Status summary table 17B - 132

Fault finding – Interpretation of statuses 17B - 134

Fault finding – Parameter summary table 17B - 156

Fault finding – Interpretation of parameters 17B - 158

Fault finding – Command summary table 17B - 166

Fault finding – Interpretation of commands 17B - 167

Fault finding – Help 17B - 173

Fault finding – Customer complaints 17B - 175

Fault finding – Fault Finding Chart 17B - 176

Page 12 of 181

PETROL INJECTION

Fault finding – Allocation of computer tracks17B

17B - 12V12 MR-372-J84-17B000$135.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Allocation of computer tracks

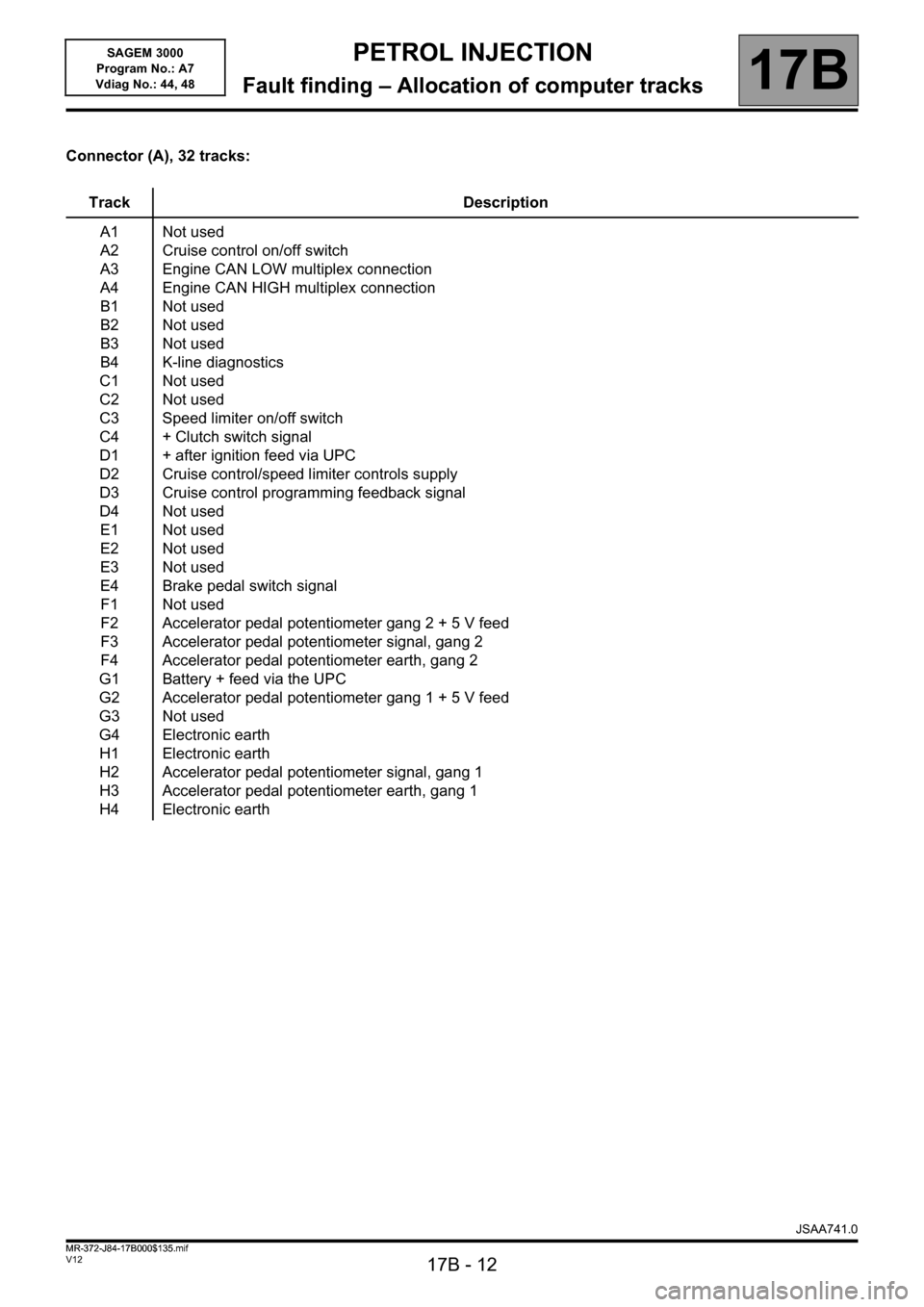

Connector (A), 32 tracks:

Track Description

A1

A2

A3

A4

B1

B2

B3

B4

C1

C2

C3

C4

D1

D2

D3

D4

E1

E2

E3

E4

F1

F2

F3

F4

G1

G2

G3

G4

H1

H2

H3

H4Not used

Cruise control on/off switch

Engine CAN LOW multiplex connection

Engine CAN HIGH multiplex connection

Not used

Not used

Not used

K-line diagnostics

Not used

Not used

Speed limiter on/off switch

+ Clutch switch signal

+ after ignition feed via UPC

Cruise control/speed limiter controls supply

Cruise control programming feedback signal

Not used

Not used

Not used

Not used

Brake pedal switch signal

Not used

Accelerator pedal potentiometer gang 2 + 5 V feed

Accelerator pedal potentiometer signal, gang 2

Accelerator pedal potentiometer earth, gang 2

Battery + feed via the UPC

Accelerator pedal potentiometer gang 1 + 5 V feed

Not used

Electronic earth

Electronic earth

Accelerator pedal potentiometer signal, gang 1

Accelerator pedal potentiometer earth, gang 1

Electronic earth

JSAA741.0

MR-372-J84-17B000$135.mif

Page 15 of 181

PETROL INJECTION

Fault finding – Replacement of components17B

17B - 15V12 MR-372-J84-17B000$180.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Replacement of components

1. PROGRAMMING, REPROGRAMMING OR REPLACING THE COMPUTER

The system can be programmed and reprogrammed via the diagnostic socket using the RENAULT CLIP diagnostic

tool (Consult Technical Note 3585A or follow the instructions provided by the diagnostic tool).

Whenever the computer has been programmed, reprogrammed or replaced:

–switch off the ignition;

–start and then stop the engine (to initialise the computer) and wait for 30 seconds,

–switch on the ignition again and use the diagnostic tool to carry out the following steps:

– run command VP010 Enter VIN,

– deal with any faults declared by the diagnostic tool. Clear the computer memory.

– program the flywheel sensor target and throttle stops,

– carry out a road test followed by another check with the diagnostic tool.

2. REPLACING OR REMOVING THE TDC SENSOR

When the TDC sensor is replaced or removed, the flywheel target has to be programmed.

3. REPLACING THE MOTORISED THROTTLE VALVE

When the throttle valve is replaced, the throttle stops must be programmed.IMPORTANT

–switch on the diagnostic tool (mains or cigarette lighter supply),

–connect a battery charger (during the entire computer (re)programming procedure, the motor-driven fan

assemblies are triggered automatically),

–observe the engine temperature instructions of the diagnostic tool before (re)programming.

IMPORTANT

It is not possible to test an injection computer from the Parts Department because it can no longer be fitted on any

other vehicle.

IMPORTANT

Never drive the vehicle without having programmed the throttle stops.

JSAA741.0

MR-372-J84-17B000$180.mif

Page 16 of 181

PETROL INJECTION

Fault finding – Configurations and programming17B

17B - 16V12 MR-372-J84-17B000$225.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Configurations and programming

1. CONFIGURATION

Computer configuration by automatic detection

The computer can automatically configure itself based on the sensors or vehicle options it detects.

2. PROGRAMMING

Programming the flywheel target

Accelerate up to 4000 rpm in 3rd gear then decelerate to power take-up* speed. Then repeat immediately.

Check the programming with ET089.

Programming the throttle end stops

After replacing the computer or motorised throttle valve, after switching on the ignition, wait 30 seconds for the

computer to memorise the MAXIMUM and MINIMUM stops.

Check the programming with ET051.

* This is the moment when, during deceleration with no load, the engine drops to idle speed and recovers torque.

JSAA741.0

MR-372-J84-17B000$225.mif

Page 20 of 181

PETROL INJECTION

Fault finding – Fault summary table17B

17B - 20V12 MR-372-J84-17B000$270.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

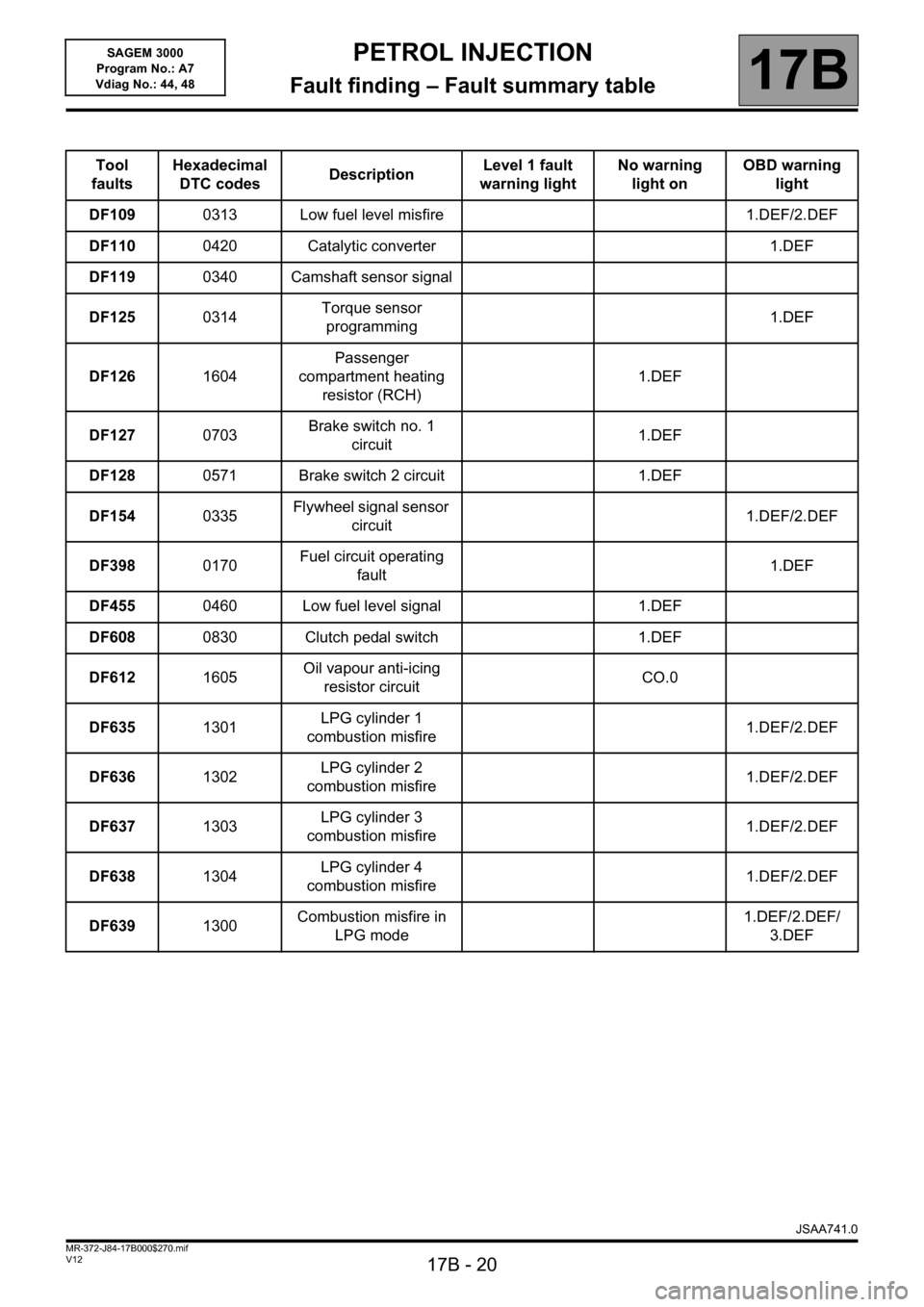

Tool

faultsHexadecimal

DTC codesDescriptionLevel 1 fault

warning lightNo warning

light onOBD warning

light

DF1090313 Low fuel level misfire 1.DEF/2.DEF

DF1100420 Catalytic converter 1.DEF

DF1190340 Camshaft sensor signal

DF1250314Torque sensor

programming1.DEF

DF1261604Passenger

compartment heating

resistor (RCH)1.DEF

DF1270703Brake switch no. 1

circuit1.DEF

DF1280571 Brake switch 2 circuit 1.DEF

DF1540335Flywheel signal sensor

circuit1.DEF/2.DEF

DF3980170Fuel circuit operating

fault1.DEF

DF4550460 Low fuel level signal 1.DEF

DF6080830 Clutch pedal switch 1.DEF

DF6121605Oil vapour anti-icing

resistor circuitCO.0

DF6351301LPG cylinder 1

combustion misfire1.DEF/2.DEF

DF6361302LPG cylinder 2

combustion misfire1.DEF/2.DEF

DF6371303LPG cylinder 3

combustion misfire1.DEF/2.DEF

DF6381304LPG cylinder 4

combustion misfire1.DEF/2.DEF

DF6391300Combustion misfire in

LPG mode1.DEF/2.DEF/

3.DEF

JSAA741.0

Page 37 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-37V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

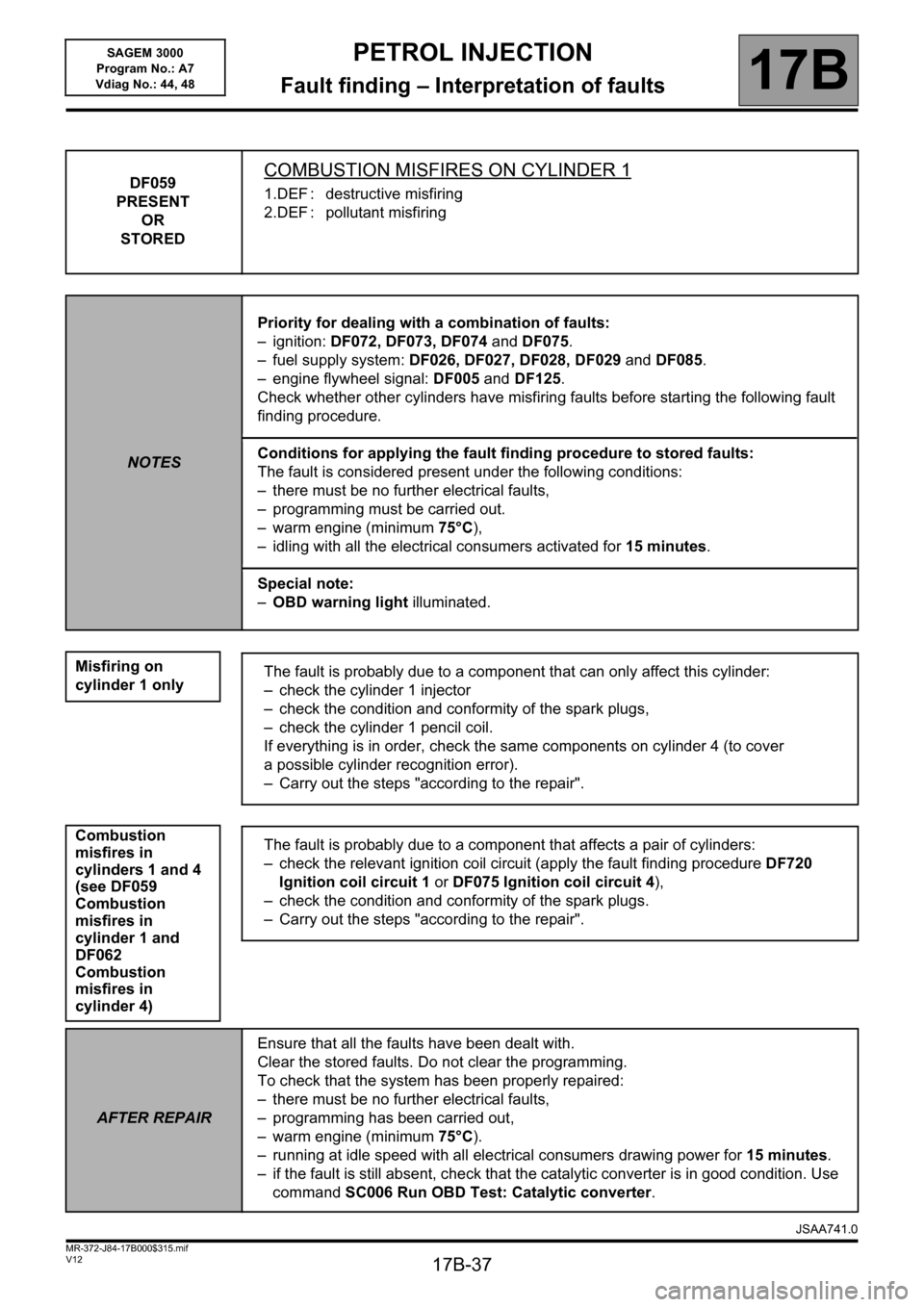

DF059

PRESENT

OR

STOREDCOMBUSTION MISFIRES ON CYLINDER 1

1.DEF : destructive misfiring

2.DEF : pollutant misfiring

NOTESPriority for dealing with a combination of faults:

– ignition: DF072, DF073, DF074 and DF075.

– fuel supply system: DF026, DF027, DF028, DF029 and DF085.

– engine flywheel signal: DF005 and DF125.

Check whether other cylinders have misfiring faults before starting the following fault

finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– warm engine (minimum 75°C),

– idling with all the electrical consumers activated for 15 minutes.

Special note:

–OBD warning light illuminated.

Misfiring on

cylinder 1 only

Combustion

misfires in

cylinders 1 and 4

(see DF059

Combustion

misfires in

cylinder 1 and

DF062

Combustion

misfires in

cylinder 4)

The fault is probably due to a component that can only affect this cylinder:

– check the cylinder 1 injector

– check the condition and conformity of the spark plugs,

– check the cylinder 1 pencil coil.

If everything is in order, check the same components on cylinder 4 (to cover

a possible cylinder recognition error).

– Carry out the steps "according to the repair".

The fault is probably due to a component that affects a pair of cylinders:

– check the relevant ignition coil circuit (apply the fault finding procedure DF720

Ignition coil circuit 1 or DF075 Ignition coil circuit 4),

– check the condition and conformity of the spark plugs.

– Carry out the steps "according to the repair".

AFTER REPAIREnsure that all the faults have been dealt with.

Clear the stored faults. Do not clear the programming.

To check that the system has been properly repaired:

– there must be no further electrical faults,

– programming has been carried out,

– warm engine (minimum 75°C).

– running at idle speed with all electrical consumers drawing power for 15 minutes.

– if the fault is still absent, check that the catalytic converter is in good condition. Use

command SC006 Run OBD Test: Catalytic converter.

JSAA741.0

Page 38 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-38V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

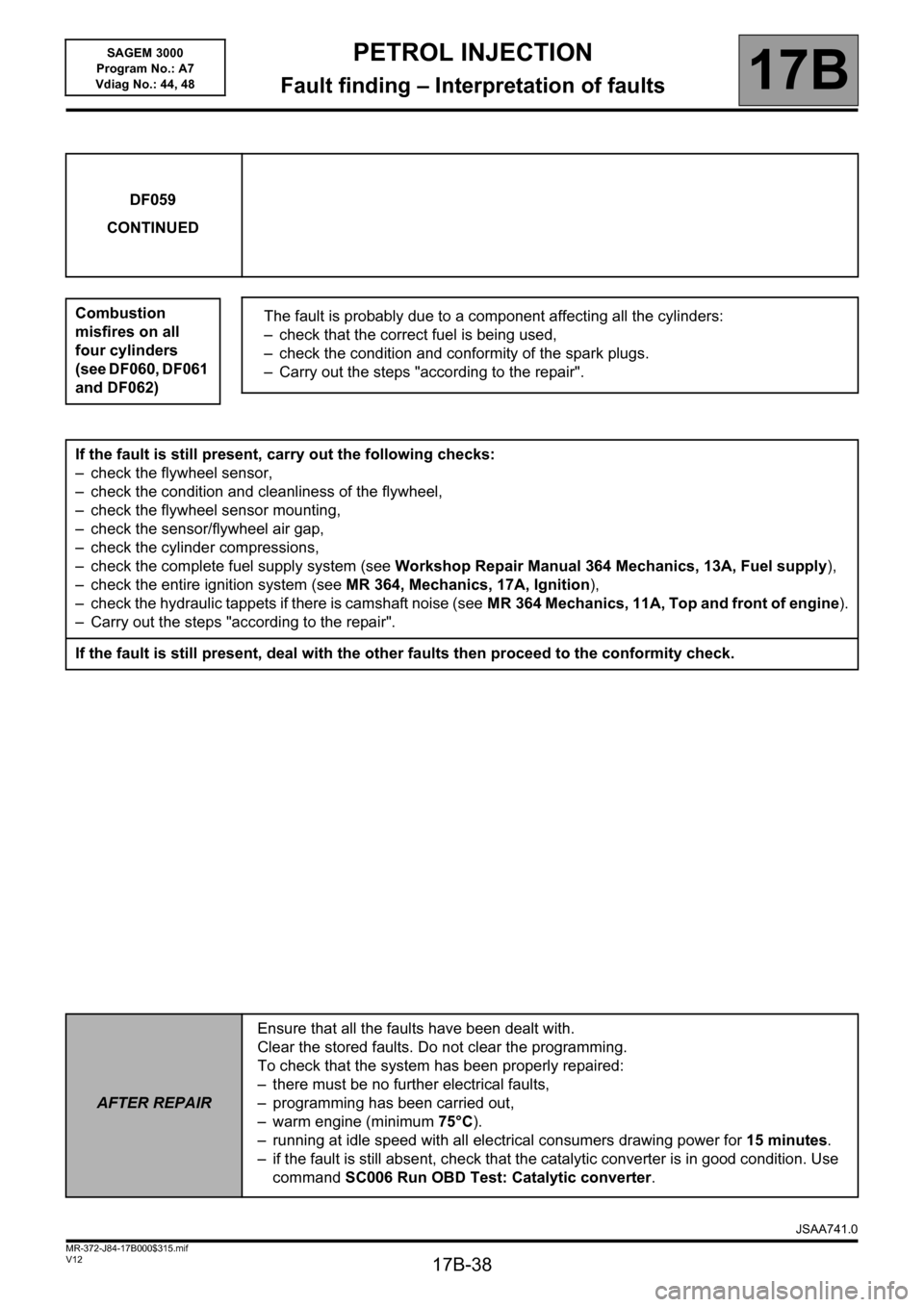

DF059

CONTINUED

Combustion

misfires on all

four cylinders

(see DF060, DF061

and DF062)

The fault is probably due to a component affecting all the cylinders:

– check that the correct fuel is being used,

– check the condition and conformity of the spark plugs.

– Carry out the steps "according to the repair".

If the fault is still present, carry out the following checks:

– check the flywheel sensor,

– check the condition and cleanliness of the flywheel,

– check the flywheel sensor mounting,

– check the sensor/flywheel air gap,

– check the cylinder compressions,

– check the complete fuel supply system (see Workshop Repair Manual 364 Mechanics, 13A, Fuel supply),

– check the entire ignition system (see MR 364, Mechanics, 17A, Ignition),

– check the hydraulic tappets if there is camshaft noise (seeMR 364 Mechanics, 11A, Top and front of engine).

– Carry out the steps "according to the repair".

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIREnsure that all the faults have been dealt with.

Clear the stored faults. Do not clear the programming.

To check that the system has been properly repaired:

– there must be no further electrical faults,

– programming has been carried out,

– warm engine (minimum 75°C).

– running at idle speed with all electrical consumers drawing power for 15 minutes.

– if the fault is still absent, check that the catalytic converter is in good condition. Use

command SC006 Run OBD Test: Catalytic converter.

JSAA741.0

Page 39 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-39V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

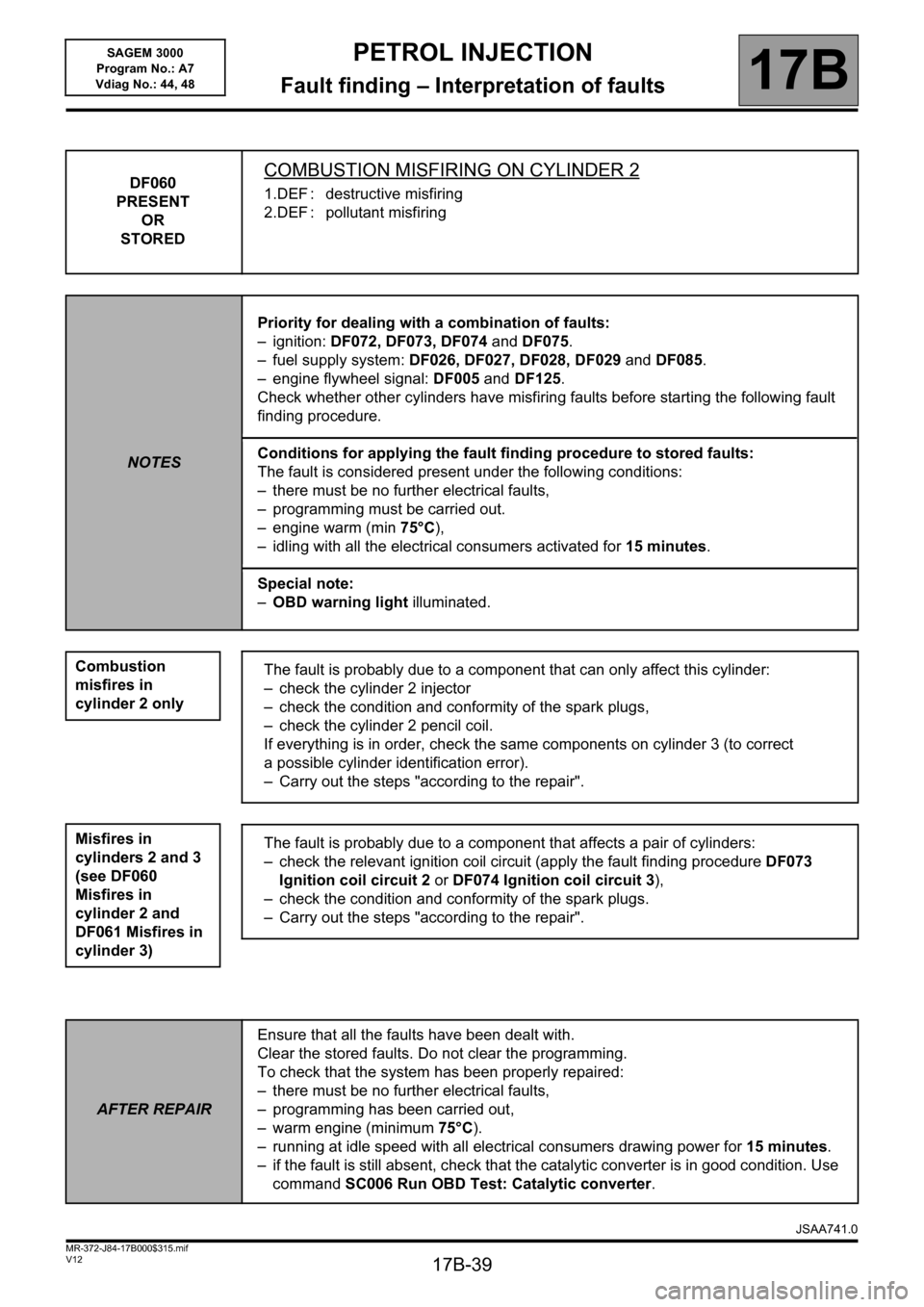

DF060

PRESENT

OR

STOREDCOMBUSTION MISFIRING ON CYLINDER 2

1.DEF : destructive misfiring

2.DEF : pollutant misfiring

NOTESPriority for dealing with a combination of faults:

– ignition: DF072, DF073, DF074 and DF075.

– fuel supply system: DF026, DF027, DF028, DF029 and DF085.

– engine flywheel signal: DF005 and DF125.

Check whether other cylinders have misfiring faults before starting the following fault

finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– engine warm (min 75°C),

– idling with all the electrical consumers activated for 15 minutes.

Special note:

–OBD warning light illuminated.

Combustion

misfires in

cylinder 2 only

Misfires in

cylinders 2 and 3

(see DF060

Misfires in

cylinder 2 and

DF061 Misfires in

cylinder 3)

The fault is probably due to a component that can only affect this cylinder:

– check the cylinder 2 injector

– check the condition and conformity of the spark plugs,

– check the cylinder 2 pencil coil.

If everything is in order, check the same components on cylinder 3 (to correct

a possible cylinder identification error).

– Carry out the steps "according to the repair".

The fault is probably due to a component that affects a pair of cylinders:

– check the relevant ignition coil circuit (apply the fault finding procedure DF073

Ignition coil circuit 2 or DF074 Ignition coil circuit 3),

– check the condition and conformity of the spark plugs.

– Carry out the steps "according to the repair".

AFTER REPAIREnsure that all the faults have been dealt with.

Clear the stored faults. Do not clear the programming.

To check that the system has been properly repaired:

– there must be no further electrical faults,

– programming has been carried out,

– warm engine (minimum 75°C).

– running at idle speed with all electrical consumers drawing power for 15 minutes.

– if the fault is still absent, check that the catalytic converter is in good condition. Use

command SC006 Run OBD Test: Catalytic converter.

JSAA741.0

Page 40 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-40V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

DF060

CONTINUED

Combustion

misfires on all

four cylinders

(see DF060, DF061

and DF062)

The fault is probably due to a component affecting all the cylinders:

– check that the correct fuel is being used,

– check the condition and conformity of the spark plugs.

– Carry out the steps "according to the repair".

If the fault is still present, carry out the following checks:

– check the flywheel sensor,

– check the condition and cleanliness of the flywheel,

– check the flywheel sensor mounting,

– check the flywheel/sensor air gap

– check the cylinder compressions,

– check the complete fuel supply system (see Workshop Repair Manual 364 Mechanics, 13A, Fuel supply),

– check the entire ignition system (see MR 364, Mechanics, 17A, Ignition),

– check the hydraulic tappets if there is camshaft noise (seeMR 364 Mechanics, 11A, Top and front of engine).

– Carry out the steps "according to the repair".

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIREnsure that all the faults have been dealt with.

Clear the stored faults. Do not clear the programming.

To check that the system has been properly repaired:

– there must be no further electrical faults,

– programming has been carried out,

– warm engine (minimum 75°C).

– running at idle speed with all electrical consumers drawing power for 15 minutes.

– if the fault is still absent, check that the catalytic converter is in good condition. Use

command SC006 Run OBD Test: Catalytic converter.

JSAA741.0

Page 41 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-41V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

DF061

PRESENT

OR

STOREDCOMBUSTION MISFIRING ON CYLINDER 3

1.DEF : destructive misfiring

2.DEF : pollutant misfiring

NOTESPriority for dealing with a combination of faults:

– ignition: DF072, DF073, DF074 and DF075.

– fuel supply system: DF026, DF027, DF028, DF029 and DF085.

– engine flywheel signal: DF005 and DF125.

Check whether other cylinders have misfiring faults before starting the following fault

finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– engine warm (min 75°C),

– idling with all the electrical consumers activated for 15 minutes.

Special note:

–OBD warning light illuminated.

Combustion

misfires in

cylinder 3 only

Misfires in

cylinders 2 and 3

(see DF060

Misfires in

cylinder 2 and

DF061 Misfires in

cylinder 3)

The fault is probably due to a component that can only affect this cylinder:

– check the cylinder 3 injector,

– check the condition and conformity of the spark plugs,

– check the cylinder 3 pencil coil.

If everything is in order, check the same components on cylinder 2 (to correct a

possible cylinder identification error).

– Carry out the steps "according to the repair".

The fault is probably due to a component that affects a pair of cylinders:

– check the relevant ignition coil circuit (apply the fault finding procedure DF073

Ignition coil circuit 2 or DF074 Ignition coil circuit 3),

– check the condition and conformity of the spark plugs.

– Carry out the steps "according to the repair".

AFTER REPAIREnsure that all the faults have been dealt with.

Clear the stored faults. Do not clear the programming.

To check that the system has been properly repaired:

– there must be no further electrical faults,

– programming has been carried out,

– warm engine (minimum 75°C).

– running at idle speed with all electrical consumers drawing power for 15 minutes.

– if the fault is still absent, check that the catalytic converter is in good condition. Use

command SC006 Run OBD Test: Catalytic converter.

JSAA741.0