ECU RENAULT SCENIC 2015 J95 / 3.G User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2015, Model line: SCENIC, Model: RENAULT SCENIC 2015 J95 / 3.GPages: 270, PDF Size: 6.08 MB

Page 208 of 270

5.8

TYRE INFLATION KIT (5/5)

Precautions when using the kit

The kit should not be operated for more

than 15 consecutive minutes.

Nothing should be placed

around the driver’s feet

as such objects may slide

under the pedals during

sudden braking manoeuvres and

obstruct their use.

Please be aware that a

poorly tightened or miss-

ing valve cap can make the

tyres less airtight and lead

to pressure loss.

Always use valve caps identical to

those fitted originally and tighten

them fully.

Following repair with the kit,

do not travel further than

120 miles (200 km). In addi-

tion, reduce your speed and

under no circumstances exceed

48 mph (80 km/h). The sticker,

which you must affix in a prominent

position on the dashboard, reminds

you of this.

Depending on the country or local

legislation, a tyre repaired with the

inflation kit may need to be replaced.

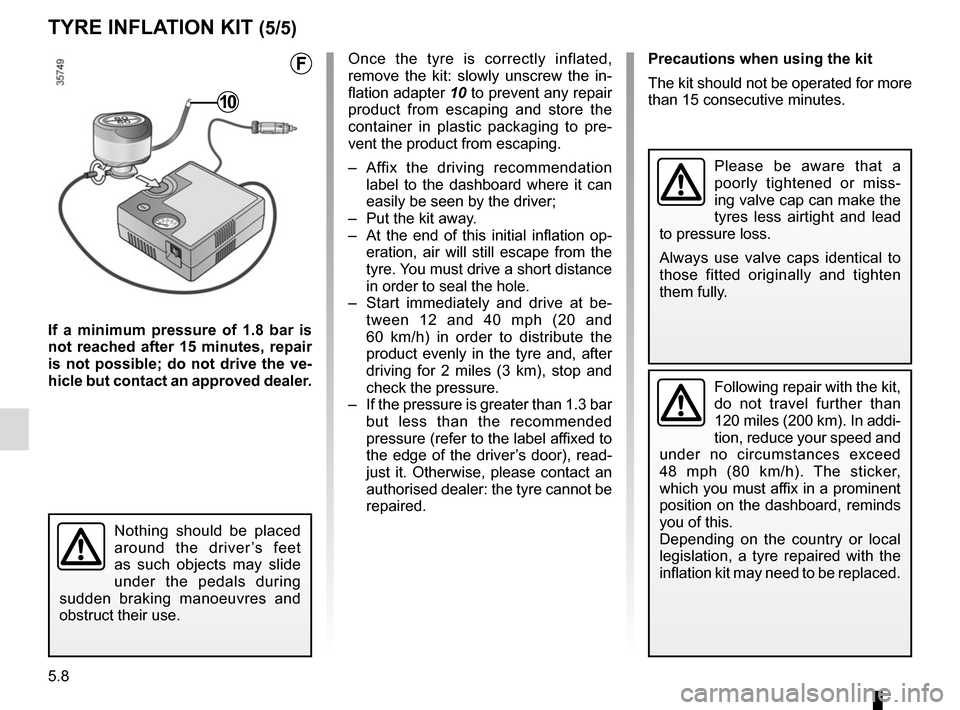

10

If a minimum pressure of 1.8 bar is

not reached after 15 minutes, repair

is not possible; do not drive the ve-

hicle but contact an approved dealer. Once the tyre is correctly inflated,

remove the kit: slowly unscrew the in-

flation adapter

10 to prevent any repair

product from escaping and store the

container in plastic packaging to pre-

vent the product from escaping.

– Affix the driving recommendation label to the dashboard where it can

easily be seen by the driver;

– Put the kit away.

– At the end of this initial inflation op- eration, air will still escape from the

tyre. You must drive a short distance

in order to seal the hole.

– Start immediately and drive at be- tween 12 and 40 mph (20 and

60 km/h) in order to distribute the

product evenly in the tyre and, after

driving for 2 miles (3 km), stop and

check the pressure.

– If the pressure is greater than 1.3 bar but less than the recommended

pressure (refer to the label affixed to

the edge of the driver’s door), read-

just it. Otherwise, please contact an

authorised dealer: the tyre cannot be

repaired.

F

Page 209 of 270

5.9

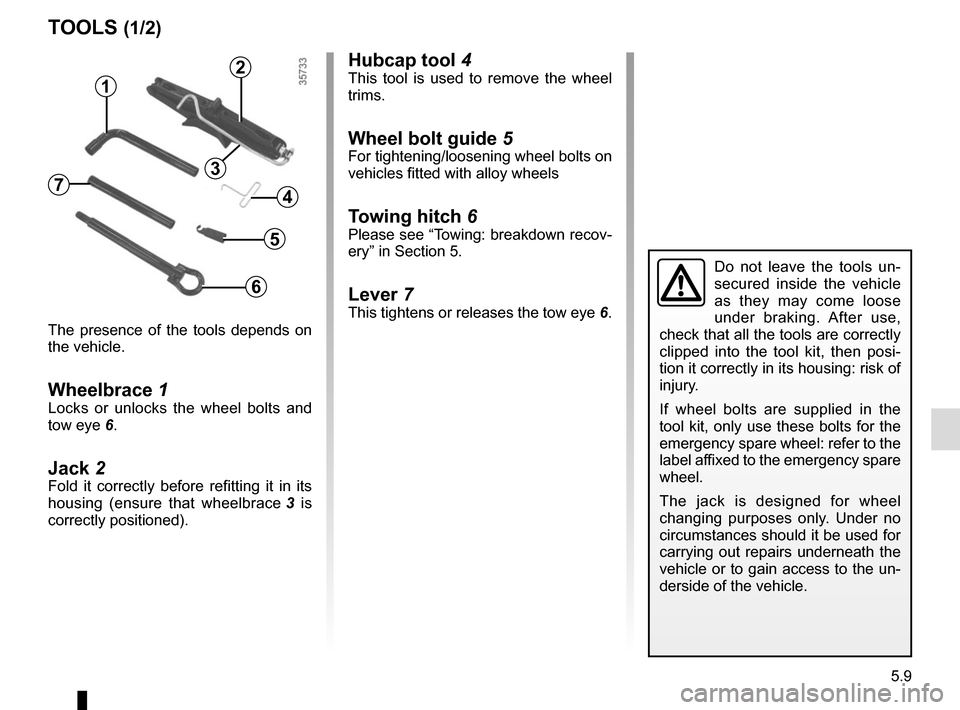

Hubcap tool 4This tool is used to remove the wheel

trims.

Wheel bolt guide 5For tightening/loosening wheel bolts on

vehicles fitted with alloy wheels

Towing hitch 6Please see “Towing: breakdown recov-

ery” in Section 5.

Lever 7This tightens or releases the tow eye 6.

The presence of the tools depends on

the vehicle.

Wheelbrace 1Locks or unlocks the wheel bolts and

tow eye 6.

Jack 2Fold it correctly before refitting it in its

housing (ensure that wheelbrace 3 is

correctly positioned).

TOOLS (1/2)

Do not leave the tools un-

secured inside the vehicle

as they may come loose

under braking. After use,

check that all the tools are correctly

clipped into the tool kit, then posi-

tion it correctly in its housing: risk of

injury.

If wheel bolts are supplied in the

tool kit, only use these bolts for the

emergency spare wheel: refer to the

label affixed to the emergency spare

wheel.

The jack is designed for wheel

changing purposes only. Under no

circumstances should it be used for

carrying out repairs underneath the

vehicle or to gain access to the un-

derside of the vehicle.

2

1

4

6

5

73

Page 210 of 270

5.10

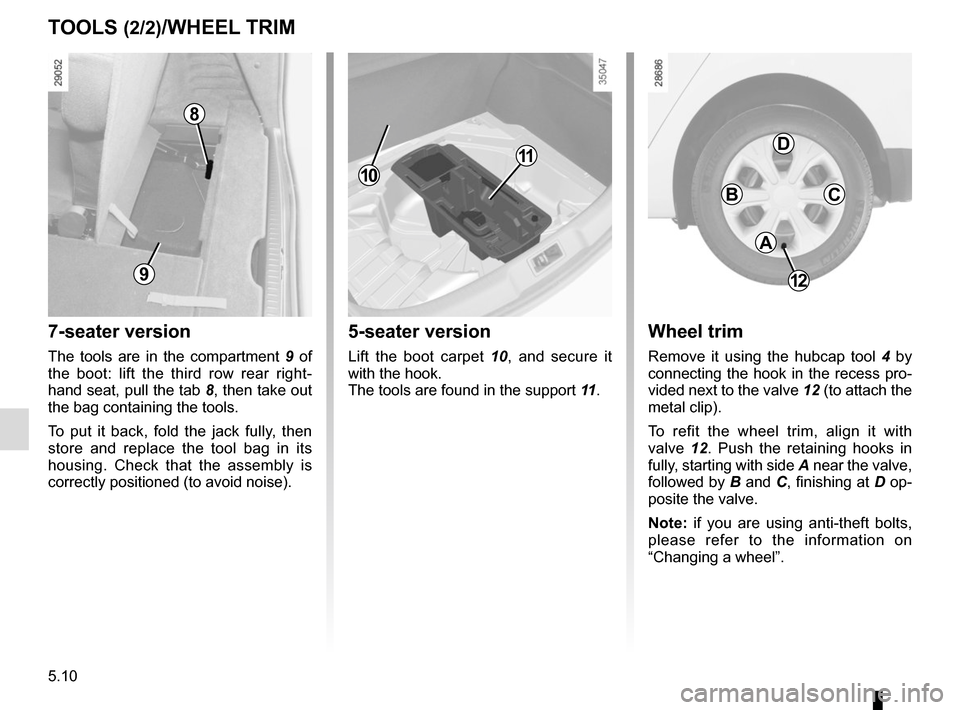

TOOLS (2/2)/WHEEL TRIM

12

A

BC

D

Wheel trim

Remove it using the hubcap tool 4 by

connecting the hook in the recess pro-

vided next to the valve 12 (to attach the

metal clip).

To refit the wheel trim, align it with

valve 12. Push the retaining hooks in

fully, starting with side A near the valve,

followed by B and C, finishing at D op-

posite the valve.

Note: if you are using anti-theft bolts,

please refer to the information on

“Changing a wheel”.

5-seater version

Lift the boot carpet 10, and secure it

with the hook.

The tools are found in the support 11.

7-seater version

The tools are in the compartment 9 of

the boot: lift the third row rear right-

hand seat, pull the tab 8, then take out

the bag containing the tools.

To put it back, fold the jack fully, then

store and replace the tool bag in its

housing. Check that the assembly is

correctly positioned (to avoid noise).

9

8

10

11