RENAULT TWINGO 2009 2.G Chasiss ABS Repair Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 76

Page 51 of 76

38C-51

MR-413-X44-38C000$564_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

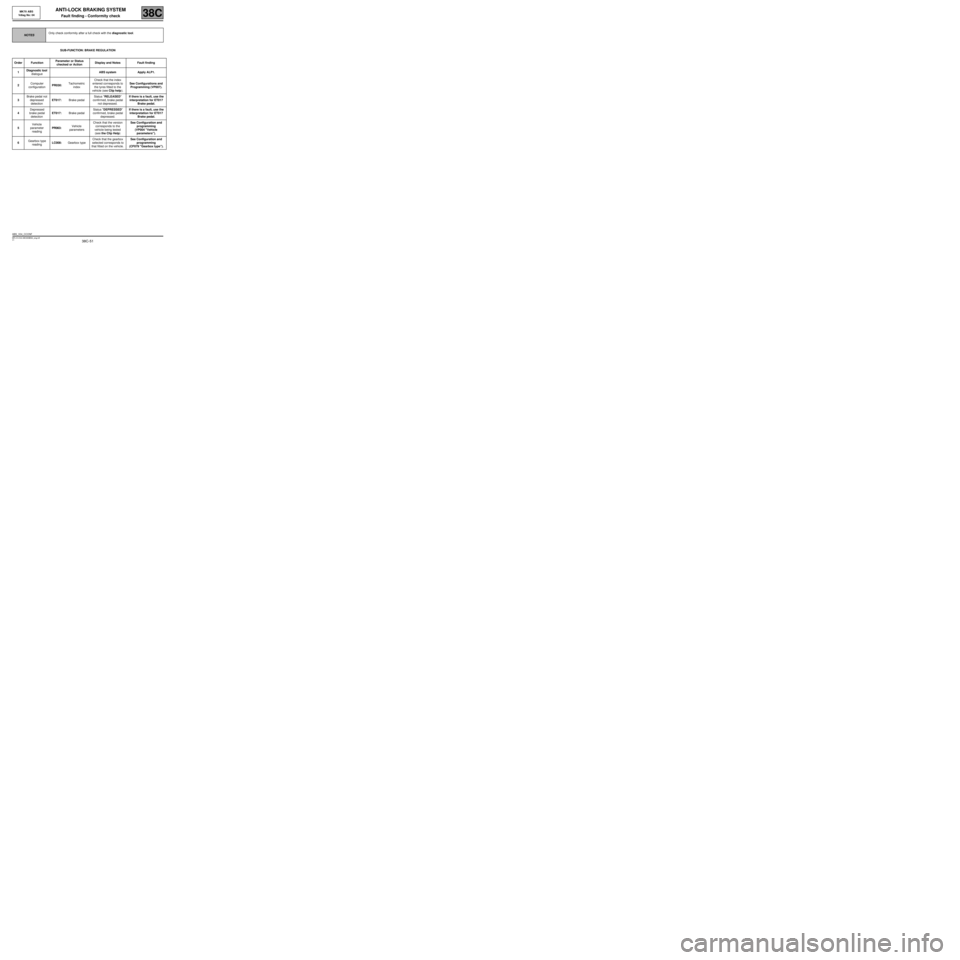

Fault finding - Conformity check

SUB-FUNCTION: BRAKE REGULATION

NOTESOnly check conformity after a full check with the diagnostic tool.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Diagnostic tool

dialogueABS system Apply ALP1.

2Computer

configurationPR030:Tachometric

indexCheck that the index

entered corresponds to

the tyres fitted to the

vehicle (see Clip help).See Configurations and

Programming (VP007).

3Brake pedal not

depressed

detectionET017:Brake pedalStatus "RELEASED"

confirmed, brake pedal

not depressed.If there is a fault, use the

interpretation for ET017

Brake pedal.

4Depressed

brake pedal

detectionET017:Brake pedalStatus "DEPRESSED"

confirmed, brake pedal

depressed.If there is a fault, use the

interpretation for ET017

Brake pedal.

5Vehicle

parameter

readingPR063: Vehicle

parametersCheck that the version

corresponds to the

vehicle being tested

(see the Clip Help)See Configuration and

programming

(VP004 "Vehicle

parameters").

6Gearbox type

readingLC008:Gearbox typeCheck that the gearbox

selected corresponds to

that fitted on the vehicle.See Configuration and

programming

(CF079 "Gearbox type").

ABS_V04_CCONF

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$564_eng.mif

Page 52 of 76

38C-52

MR-413-X44-38C000$611_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

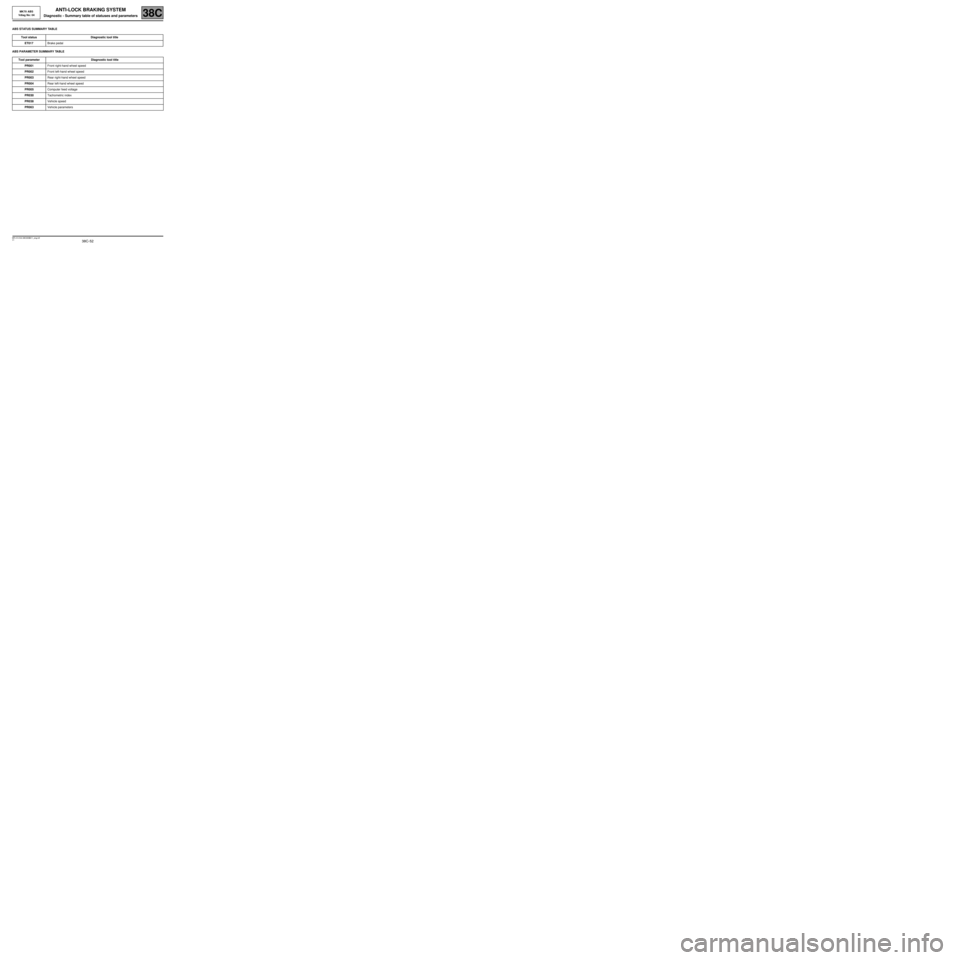

Diagnostic - Summary table of statuses and parameters

ABS STATUS SUMMARY TABLE

ABS PARAMETER SUMMARY TABLETool status Diagnostic tool title

ET017Brake pedal

Tool parameter Diagnostic tool title

PR001Front right-hand wheel speed

PR002Front left-hand wheel speed

PR003Rear right-hand wheel speed

PR004Rear left-hand wheel speed

PR005Computer feed voltage

PR030Tachometric index

PR038Vehicle speed

PR063Vehicle parameters

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$611_eng.mif

Page 53 of 76

38C-53

MR-413-X44-38C000$658_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

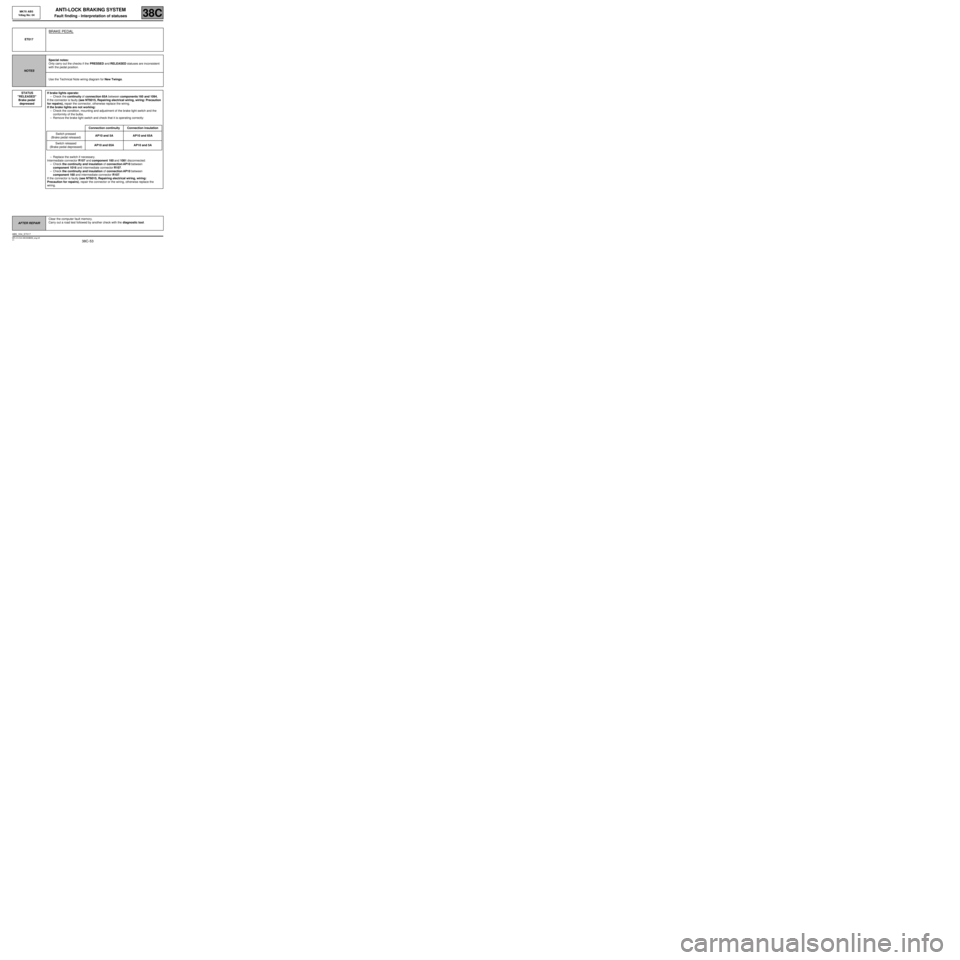

Fault finding - Interpretation of statuses

ET017

BRAKE PEDAL

NOTESSpecial notes:

Only carry out the checks if the PRESSED and RELEASED statuses are inconsistent

with the pedal position.

Use the Technical Note wiring diagram for New Twingo.

STATUS

"RELEASED"

Brake pedal

depressed

If brake lights operate:

–Check the continuity of connection 65A between components 160 and 1094.

If the connector is faulty (see NT6015, Repairing electrical wiring, wiring: Precaution

for repairs), repair the connector, otherwise replace the wiring.

If the brake lights are not working:

–Check the condition, mounting and adjustment of the brake light switch and the

conformity of the bulbs.

–Remove the brake light switch and check that it is operating correctly:

Connection continuity Connection insulation

Switch pressed

(Brake pedal released)AP10 and 5A AP10 and 65A

Switch released

(Brake pedal depressed)AP10 and 65A AP10 and 5A

–Replace the switch if necessary.

Intermediate connector R107 and component 160 and 1081 disconnected:

–Check the continuity and insulation of connection AP10 between

component 1016 and intermediate connector R107.

–Check the continuity and insulation of connection AP10 between

component 160 and intermediate connector R107.

If the connector is faulty (see NT6015, Repairing electrical wiring, wiring:

Precaution for repairs), repair the connector or the wiring, otherwise replace the

wiring.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_ET017

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$658_eng.mif

Page 54 of 76

38C-54

MR-413-X44-38C000$658_eng.mif

V1

MK70 ABS

Vdiag No: 04ANTI-LOCK BRAKING SYSTEM

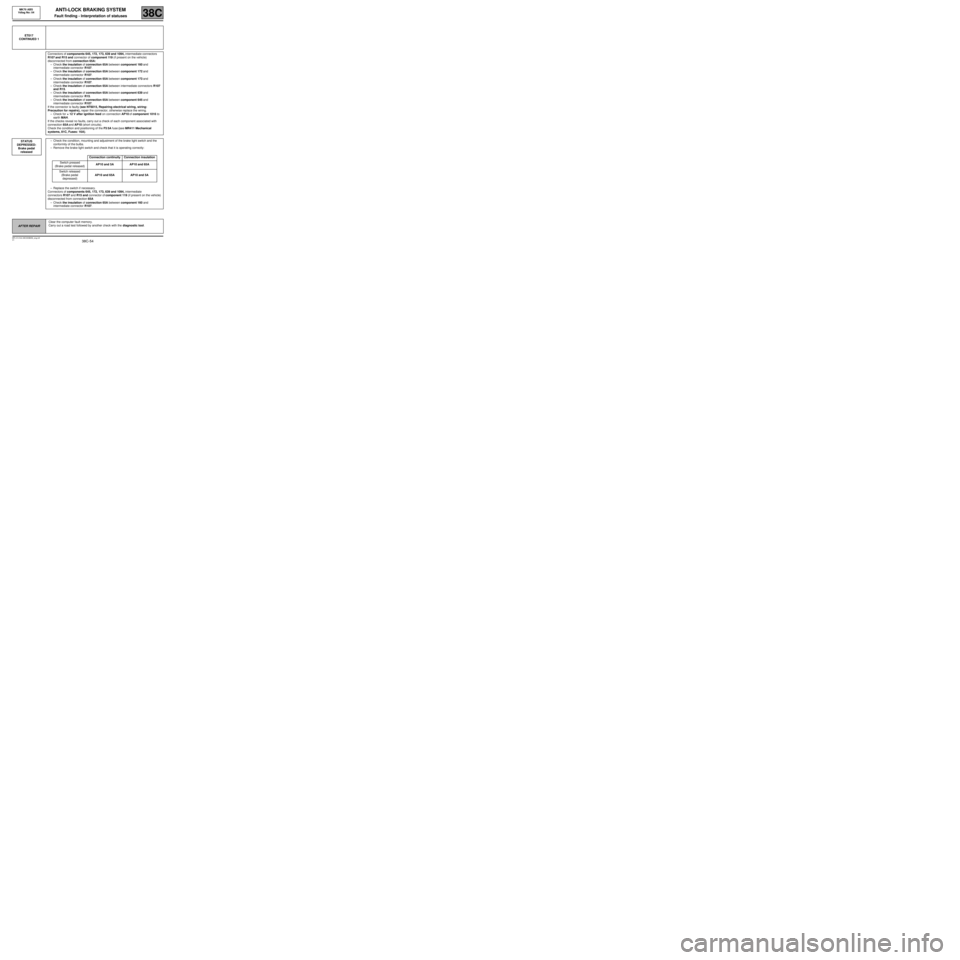

Fault finding - Interpretation of statuses38C

ET017

CONTINUED 1

Connectors of components 645, 172, 173, 639 and 1094, intermediate connectors

R107 and R15 and connector of component 119 (if present on the vehicle)

disconnected from connection 65A:

–Check the insulation of connection 65A between component 160 and

intermediate connector R107.

–Check the insulation of connection 65A between component 172 and

intermediate connector R107.

–Check the insulation of connection 65A between component 173 and

intermediate connector R107.

–Check the insulation of connection 65A between intermediate connectors R107

and R15.

–Check the insulation of connection 65A between component 639 and

intermediate connector R15.

–Check the insulation of connection 65A between component 645 and

intermediate connector R107.

If the connector is faulty (see NT6015, Repairing electrical wiring, wiring:

Precaution for repairs), repair the connector, otherwise replace the wiring.

–Check for + 12 V after ignition feed on connection AP10 of component 1016 to

earth MAH.

If the checks reveal no faults, carry out a check of each component associated with

connection 65A and AP10 (short circuits).

Check the condition and positioning of the F5 5A fuse (see MR411 Mechanical

systems, 81C, Fuses: 16A).

–Check the condition, mounting and adjustment of the brake light switch and the

conformity of the bulbs.

–Remove the brake light switch and check that it is operating correctly:

Connection continuity Connection insulation

Switch pressed

(Brake pedal released)AP10 and 5A AP10 and 65A

Switch released

(Brake pedal

depressed)AP10 and 65A AP10 and 5A

–Replace the switch if necessary.

Connectors of components 645, 172, 173, 639 and 1094, intermediate

connectors R107 and R15 and connector of component 119 (if present on the vehicle)

disconnected from connection 65A

–Check the insulation of connection 65A between component 160 and

intermediate connector R107.

STATUS

DEPRESSED:

Brake pedal

released

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 55 of 76

38C-55

MR-413-X44-38C000$658_eng.mif

V1

ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of statuses

MK70 ABS

Vdiag No: 04

38C

ET017

CONTINUED 2

–Check the insulation of connection 65A between component 172 and intermediate connector R107.

–Check the insulation of connection 65A between component 173 and intermediate connector R107.

–Check the insulation of connection 65A between intermediate connectors R107 and R15.

–Check the insulation of connection 65A between component 639 and intermediate connector R15.

–Check the insulation of connection 65A between component 645 and intermediate connector R107.

If the connector is faulty (see NT6015, Repairing electrical wiring, wiring: Precaution for repairs),

repair the connector, otherwise replace the wiring.

If the checks reveal no faults, carry out a check of each component associated with connection 65A

(internal component faults).

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 56 of 76

38C-56

MR-413-X44-38C000$705_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

Fault finding - Dealing with computer statuses and parameters

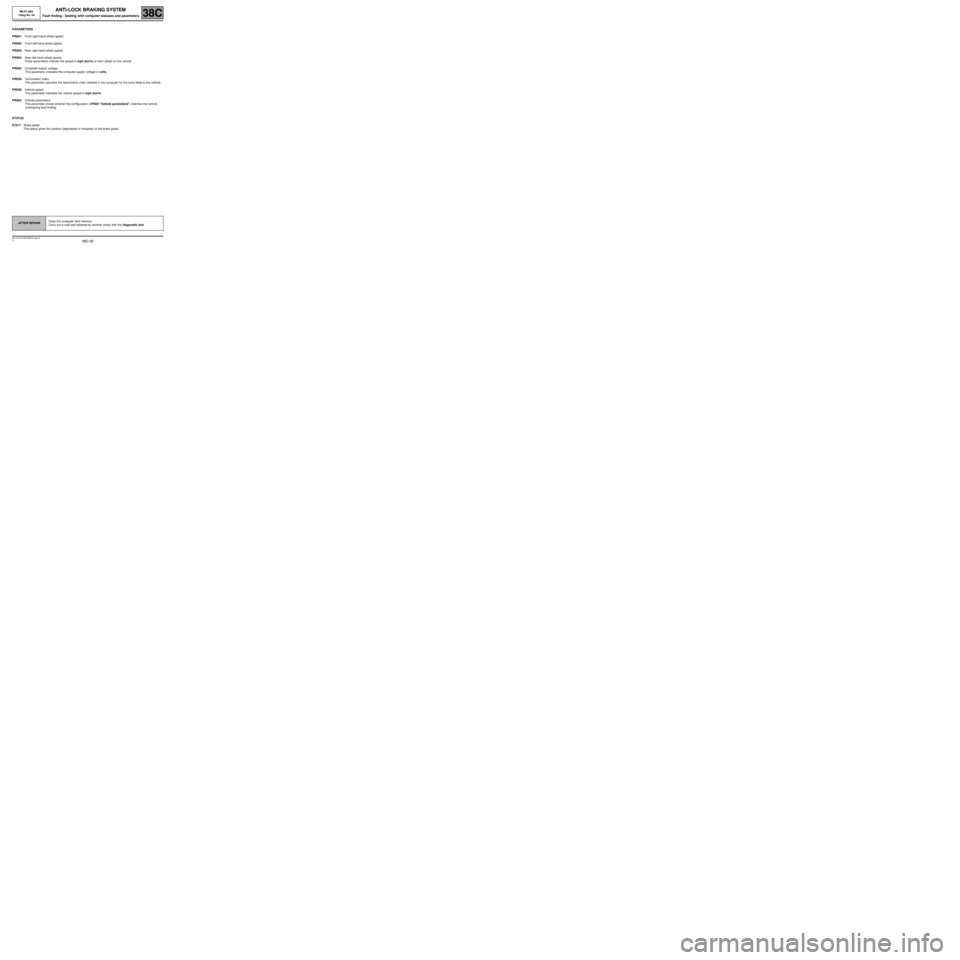

PARAMETERS

PR001: Front right-hand wheel speed.

PR002: Front left-hand wheel speed.

PR003: Rear right-hand wheel speed.

PR004: Rear left-hand wheel speed.

These parameters indicate the speed in mph (km/h) of each wheel on the vehicle.

PR005: Computer supply voltage.

This parameter indicates the computer supply voltage in volts.

PR030: Tachometric index.

This parameter specifies the tachometric index entered in the computer for the tyres fitted to the vehicle.

PR038: Vehicle speed.

This parameter indicates the vehicle speed in mph (km/h).

PR063: Vehicle parameters.

This parameter shows whether the configuration (VP004 "Vehicle parameters") matches the vehicle

undergoing fault finding.

STATUS

ET017: Brake pedal

This status gives the position (depressed or released) of the brake pedal

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$705_eng.mif

Page 57 of 76

38C-57

MR-413-X44-38C000$752_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

Fault finding - Dealing with command modes

CLEARING

RZ001: Fault memory.

This command is used for clearing the computer's stored faults.

SPECIAL COMMANDS

SC001: Check target teeth.

This command tests the condition of the teeth on each wheel.

Select command SC001 "Check target teeth" and follow the instructions.

The test result should indicate 48 sprockets.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$752_eng.mif

Page 58 of 76

38C-58

MR-413-X44-38C000$799_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

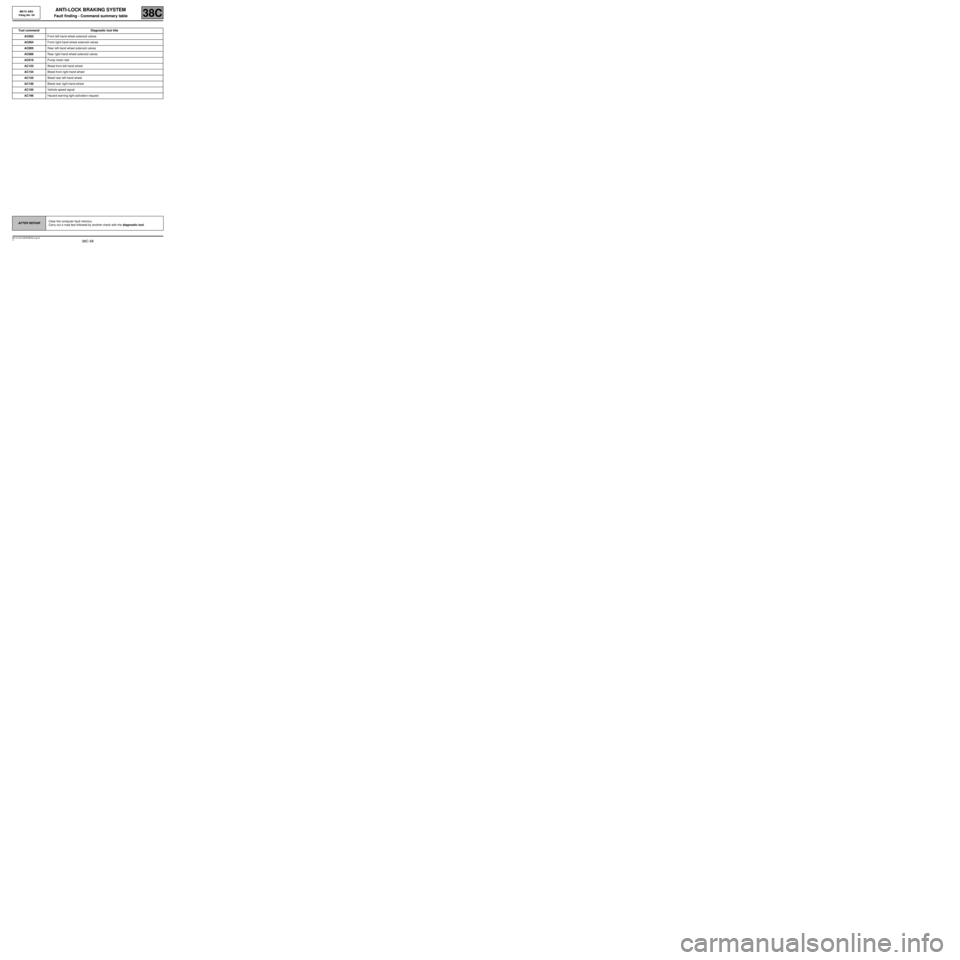

Fault finding - Command summary table

Tool command Diagnostic tool title

AC003Front left-hand wheel solenoid valves

AC004Front right-hand wheel solenoid valves

AC005Rear left-hand wheel solenoid valves

AC006Rear right-hand wheel solenoid valves

AC016Pump motor test

AC153Bleed front left-hand wheel

AC154Bleed front right-hand wheel

AC155Bleed rear left-hand wheel

AC156Bleed rear right-hand wheel

AC195Vehicle speed signal

AC196Hazard warning light activation request

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$799_eng.mif

Page 59 of 76

38C-59

MR-413-X44-38C000$846_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

Fault finding - Dealing with command modes

AC003

AC004

AC005

AC006FRONT LEFT-HAND WHEEL SOLENOID VALVES

FRONT RIGHT-HAND WHEEL SOLENOID VALVES

REAR LEFT-HAND WHEEL SOLENOID VALVES

REAR RIGHT-HAND WHEEL SOLENOID VALVES

NOTESConditions of use of the command.

Ignition on, engine stopped and vehicle speed zero.

Before using the commands, check that the battery is fully charged.

The previous 4 commands allow the hydraulic check of each wheel.

Raise the vehicle in order to be able to rotate the wheels, and check that they rotate freely.

Keep the brake pedal depressed to prevent the wheel being tested from being turned by hand (do not brake so

firmly that full braking power is reached).

Select and confirm the command of the wheel being examined (e.g. Front left-hand wheel solenoid valves, etc.)

Turn the wheel concerned by hand; 5 locking/unlocking cycles should be noted on the wheel.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_AC003 / ABS_V04_AC004

ABS_V04_AC005 / ABS_V04_AC006

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$846_eng.mif

Page 60 of 76

38C-60

MR-413-X44-38C000$846_eng.mif

V1

ANTI-LOCK BRAKING SYSTEM

Fault finding - Dealing with command modes

MK70 ABS

Vdiag No: 04

38C

AC016

PUMP MOTOR TEST

NOTESConditions of use of the command.

Ignition on, engine stopped and vehicle speed zero.

Before using the command, check that the battery is fully charged.

This command is used to test the pump motor control circuit.

Select command AC016 Pump Motor Test.

The motor must run for 5 seconds.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_AC016