light RENAULT TWINGO 2009 2.G Chasiss ESP Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 101

Page 2 of 101

38C -2V3 MR-413-X44-38C050$010.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

1. APPLICABILITY OF THE DOCUMENT

Th is d ocument p resents the fault finding procedure applica ble to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING:

Documentation type

Fault finding procedures (this document):

–Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu-Schéma (CD-ROM), paper.

Type of diagnostic tools

–CLIP

Special tooling required

3. REMINDERS

Procedure

To run fault finding on the vehicle computers, switch on the ignition.

Depending on the type of vehicle equipment, proceed as follows:

To cut off + after ignition feed, proceed as follows:Vehicle: New TwingoComputer name: Bosch 8.1 ESP

Function concerned: Bosch ESPVdiag No.: 05

Special tooling required

Multimeter

Elé. 1681Universal bornier

For vehicles with key/radio frequency remote control, use the key to switch on the ignition.

For vehicles with a Renault card,

–with the vehicle card in the card reader,

–press and hold the start button (longer than 5 seconds) with start-up conditions not fulfilled,

connect the diagnostic tool and perform the required operations.

For vehicles with key/radio frequency remote control, use the key to switch off the ignition.

For vehicles with a Renault card,

press the Start button twice briefly (less than 3 seconds),

ensure that the + after ignition feed has been cut off by checking that the computer indicator lights on the instrument

panel have gone out.

ESP_V05_PRELI

ANTI-LOCK BRAKING SYSTEM

Fault finding – Introduction

Page 5 of 101

38C -5V3 MR-413-X44-38C050$010.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Introduction

Bosch 8.1 ESP

Vdiag No.: 05

38C

4. FAULT FINDING PROCEDURE (CONTINUED)

4.1 Wiring check

Fault finding problems

Disconnecting the connectors and/or manipulating the wiring may temporarily clear the cause of a fault.

Visual inspection

Look for damage under the bonnet and in the passenger compartment.

Carefully check the protectors, insulation, and routing of the wiring, as well as the mountings.

Physical inspection

When manipulating the wiring, either use the diagnostic tool to detect a change in status, from "stored" to "present",

or the multimeter to view the status changes.

Make sure that the connectors are firmly secured.

Apply light pressure to the connectors.

Twist the wiring harness.

Checking earth insulation

This check is carried out by measuring the voltage (multimeter in voltmeter mode) between the suspect connection

and the 12 V or 5 V. The correct measured value is 0 V.

Checking insulation against + 12 V or + 5 V

This check is carried out by measuring the voltage (multimeter in voltmeter mode) between the suspect connection

and the earth. In the first instance, the earth may be taken on the chassis. The correct measured value should be 0 V

Continuity check

A continuity check is carried out by measuring the resistance (multimeter in ohmmeter mode), with the connectors

disconnected at both ends. The expected result is 1

± 1 for every connection. The line must be fully checked, and the

intermediate connections are only included in the method if this saves time during the fault finding procedure. The

continuity check on the multiplex lines must be carried out on both wires. The measured value should be 1 ± 1.

Checking the supply

This check may be carried out using a test light (21 W or 5 W depending on the maximum authorised load).

Page 6 of 101

38C -6V3 MR-413-X44-38C050$010.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Introduction

Bosch 8.1 ESP

Vdiag No.: 05

38C

4.2 Checking the connectors

Visual inspection of the connection:

–Check that the connector is connected correctly and that the male and female parts of the connection are correctly

coupled.

Visual inspection of the area around the connection:

–Check the condition of the mounting (pin, strap, adhesive tape, etc.) if the connectors are attached to the vehicle.

–Check that there is no damage to the wiring trim (sheath, foam, adhesive tape, etc.) near the wiring.

–Check that there is no damage to the electrical wires at the connector outputs, in particular on the insulating material

(wear, cuts, burns, etc.).

Disconnect the connector to continue the checks.

Visual inspection of the plastic casing:

–Check that there is no mechanical damage (casing crushed, cracked, broken, etc.), in particular to the fragile

components (lever, lock, openings, etc.).

–Check that there is no heat damage (casing melted, darker, deformed, etc.).

–Check that there are no stains (grease, mud, liquid, etc.).

Visual inspection of the metal contacts:

(The female contact is called CLIP. The male contact is called TAB.)

–Check that there are no bent contacts (the contact is not inserted correctly and can come out of the back of the

connector). The spring contact of the connector when the wire is pulled slightly.

–Check that there is no damage (folded tabs, clips open too wide, blackened or melted contact, etc.).

–Check that there is no oxidation on the metal contacts. Note:

Carry out each requested check visually.

Do not remove a connector if it is not required.

Note:

Repeated connections and disconnections alter the functionality of the connectors and increase the risk of

poor electrical contact. Limit the number of connections/disconnections as much as possible.

Note:

The check is carried out on the 2 parts of the connection. There may be 2 types of connections:

–Connector/Connector.

–Connector/Device.

Page 9 of 101

38C -9V3 MR-413-X44-38C050$020.mif

Bosch 8.1 ESP

Vdiag No.: 05

38C

The computer/hydraulic unit assembly:

–Located to the left of the bulkhead in the engine compartment.

Front wheel sensors:

–Screwed into the stub-axle, each front sensor has an intermediate connector located behind the plastic wheel arch

liner.

Rear wheel sensor intermediate connectors:

–Located in a sealed unit under the vehicle.

Rear wheel sensors:

–Screwed into the rear brake drum flange (For vehicles equipped with drum brakes).

–Clipped onto the sensor mounting (For vehicles equipped with disc brakes).

Brake light switch:

–Located on the pedal assembly.

Lateral acceleration and yaw speed sensor:

–Located under the passenger seat

ANTI-LOCK BRAKING SYSTEM

Fault finding – List and location of components

Page 11 of 101

38C-11V3 MR-413-X44-38C050$030.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

Number Description

1Computer/hydraulic unit assembly

2Steering wheel angle

3Torque setpoint on the engine management computer

4Sequential gearbox operating phase (if fitted)

5Instrument panel

6Diagnostic socket

7 UCH

8Vehicle speed wire

9Brake light control relay

10Combined sensor: lateral acceleration and yaw speed

11Brake disc with instrumented bearing target

12Wheel speed sensor

13Battery

14Traction control deactivation button (Only on RS version)

15Brake switch

Electric circuit

Hydraulic circuit

Private multiplex line

Vehicle multiplex line

ANTI-LOCK BRAKING SYSTEM

Fault finding – Functional diagram

Page 12 of 101

38C-12V3 MR-413-X44-38C050$040.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

EBD (electronic braking distribution):

The electronic braking distribution unit optimises the brakeforce distribution between the front and rear axles.

This function ensures vehicle stability under braking.

ABS (anti-lock braking system):

The ABS prevents the wheels from locking when braking. This function allows the vehicle to be steered under

braking and ensures vehicle stability under braking.

MSR (engine torque control):

This is a function that enhances the ABS function. Its purpose is to prevent the drive wheels from spinning

excessively when lifting off the accelerator or changing down a gear on a low grip surface, by requesting the engine

management to regulate the driving torque of the engine (resisting torque compensation) to "relaunch" the wheels.

ASR (wheel traction control):

This function keeps the drive wheels from slipping during starting or acceleration.

The system brakes the wheel in a slippage situation to maintain full traction.

ESP: Electronic stability program:

The ESP guarantees within physical limits the dynamic stability of the vehicle by checking and correcting oversteer.

In any case, the ESP system does not intervene in place of the driver. Using data from the steering wheel, it merely

makes vehicle handling truer to the driver's intention.

CDC (Dynamic Driving Control):

The Dynamic Driving Control guarantees vehicle steerability within physical limits by checking and correcting

understeer.

The Dynamic Driving Control is an advancement of the ESP system and has same objective: to maintain vehicle

control in all operating situations.

The ESP computer supplies the other computers with information on the vehicle speed via a wire connection for the

radio, the power-assisted steering and the electric sunroof, and via the multiplex network for the other computers.

The ESP computer also supplies the multiplex network with the odometry for the instrument panel and navigation

system.

If heavy braking produces very rapid deceleration, the ESP computer issues a request to the UCH (passenger

compartment connection unit) via the multiplex network asking it to switch on the hazard warning lights (depending

on the law in the relevant country).

ANTI-LOCK BRAKING SYSTEM

Fault finding – Features

Page 13 of 101

38C-13V3 MR-413-X44-38C050$050.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

Wheel speed sensors:

Give the speed of each of the vehicle's wheels. The analysis of the sensors allows the calculation of the vehicle

speed.

Brake lights switch:

Signals the position of the brake pedal (pressed or released).

Combined sensor (Dual sensor):

Indicates the lateral acceleration and the yaw speed of the vehicle. The analysis of these data combined with the

data from the other sensors allows the determination of the vehicle's path.

Steering wheel angle sensor:

Angular indication of the desired path of the vehicle.

ANTI-LOCK BRAKING SYSTEM

Fault finding – Role of components

Page 14 of 101

38C-14V3 MR-413-X44-38C050$060.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

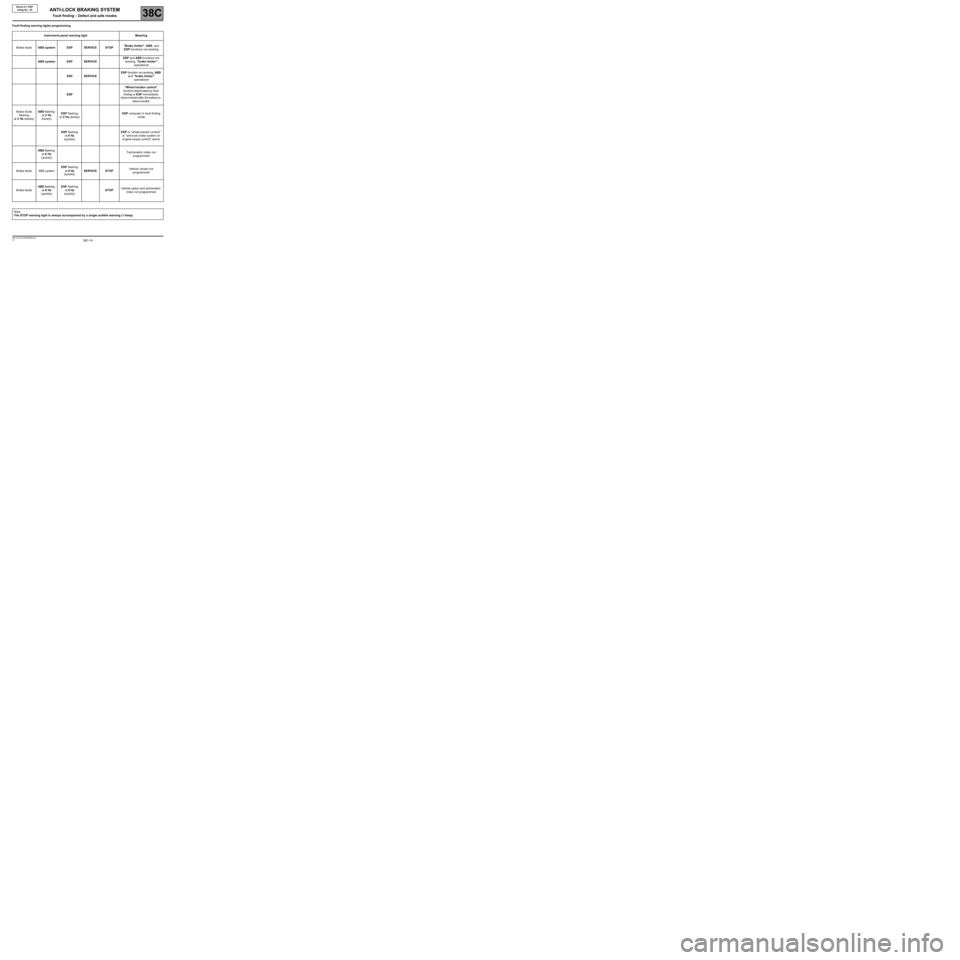

Fault finding warning lights programming

Instrument panel warning light Meaning

Brake faultsABS system ESP SERVICE STOP"Brake limiter", ABS, and

ESP functions not working

ABS system ESP SERVICEESP and ABS functions not

working, "brake limiter"

operational

ESP SERVICEESP function not working, ABS

and "brake limiter"

operational

ESP

"Wheel traction control"

function deactivated by fault

finding orESPmomentarily

disco nnected a fter the battery is

disconnected

Brake faults

flashing

at 2 H z (slowly)ABS flashing

at 2 Hz

(slowly)ESP flashing

at 2 Hz (slowly)ESP computer in fault finding

mode

ESP flashing

at 8 Hz

(quickly)ESP or "wheel traction control"

or "anti-lock brake system on

engine torque control" active

ABS flashing

at 8 Hz

(quickly)Tachometric index not

programmed

Brake faults ABS systemESP flashing

at 8 Hz

(quickly)SERVICE STOPVehicle variant not

programmed

Brake faultsABS flashing

at 8 Hz

(quickly)ESP flashing

at 8 Hz

(quickly)STOPVehicle option and tachometric

index not programmed

Note:

The STOP warning light is always accompanied by a single audible warning (1 beep).

ANTI-LOCK BRAKING SYSTEM

Fault finding – Defect and safe modes

Page 15 of 101

38C-15V3 MR-413-X44-38C050$070.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

REPLACING THE COMPUTER:

When replacing the computer (see MR 411, Mechanical, 38C, Anti-lock braking system, Braking computer:

Removal - Refitting), use the following procedure:

–Switch off the ignition.

–Replace the computer.

–Enter the VIN number using command VP001 Enter VIN (see Configurations and Programming).

–Configure the tachometric index using command VP007 Tachometric index (see Configurations and

programming).

–Configure the vehicle parameters using command VP004 Vehicle parameters (see Configurations and

programming).

–Inhibit or authorise illumination of the automatic brake lights (depending on the country's legislation) using

command VP021 Inhibit automatic brake lights or VP022 Authorise automatic brake lights.

–Clear the ESP sensor offsets using command RZ011 Sensors offsets (see Configurations and programming).

–Enter the After-Sales date using command VP006 Enter last APV* operation date.

–Perform a road test followed by a fault reading to confirm that the system is operating correctly.

REPLACING THE STEERING WHEEL ANGLE SENSOR:

–Calibrate the steering wheel angle sensor using command VP003 Steering wheel angle sensor (see

Configurations and programming).

–Clear the ESP sensor offsets using command RZ011 Sensor offsets.

REPLACING THE COMBINED SENSOR:

–Clear the ESP sensor offsets using command RZ011 Sensor offsets.

* APV: After-Sales

ANTI-LOCK BRAKING SYSTEM

Fault finding – Replacement of components

Page 16 of 101

38C-16V3 MR-413-X44-38C050$080.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

Parameters:

VP001: Enter VIN

This command allows the vehicle identification number to be entered into the computer.

Use this command each time the computer is replaced. The VIN (VF...) is engraved on the manufacturer's plate on

the front right-hand door pillar and stamped on the body under the windscreen on the left-hand side.

VP003: Steering wheel angle sensor

This command is used to calibrate the steering wheel angle.

With the steering wheel horizontal and the front wheels set straight ahead, calibrate the steering wheel angle sensor

using command VP003 on the diagnostic tool.

VP004: Vehicle parameters

This command configures the engine type configuration, the braking definition and the body type. Select the

command VP004 on the diagnostic tool.

VP006: Enter last After-Sales operation date

Whenever the ABS system is worked on in the shop, the date must be entered.

Select command VP006 on the diagnostic tool.

Enter the service date using the diagnostic tool keypad.

VP007: Tachometric index

This command is used to program the computer memory with the index required to calculate the vehicle speed

according to the tyre size.

The BOSCH 8.1 ESP computer supplies the vehicle speed signal to all areas where this information is needed

(instrument panel, engine management, etc.). This vehicle speed signal replaces the one supplied by the speed

sensor located on the gearbox.

The ESP computer calculates the vehicle speed from the wheel speed and the tyre circumference.

The tyre circumference must be programmed into the memory of a new computer. This consists of entering an index

"X" using the command VP007 "Tachometric index" on the diagnostic tool.

Once the number has been entered using the VP007 command, delete the fault in the computer memory and then

switch off the ignition. Use parameter PR030 "Tachometric index" to check that the index entered has been

recognised by the system.

VP021: Inhibit automatic brake lights

This command deactivates the automatic brake lights.

Select command VP021 on the diagnostic tool.

VP022: Automatic brake lights authorisation

This command authorises the automatic brake lights.

Select command VP022 on the diagnostic tool.

* APV: After-SalesNote:

The vehicle speed is supplied by a wire (connection 47F) to the radio, to the electric power-assisted

steering, to the electric sunroof and by the multiplex network for the other computers.

ANTI-LOCK BRAKING SYSTEM

Fault finding – Configurations and programming