engine RENAULT TWINGO 2009 2.G Chasiss User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 196 of 281

37A-17

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

JB1 or JH1 or JH3 or JR5, and LEFT-HAND DRIVE

37A

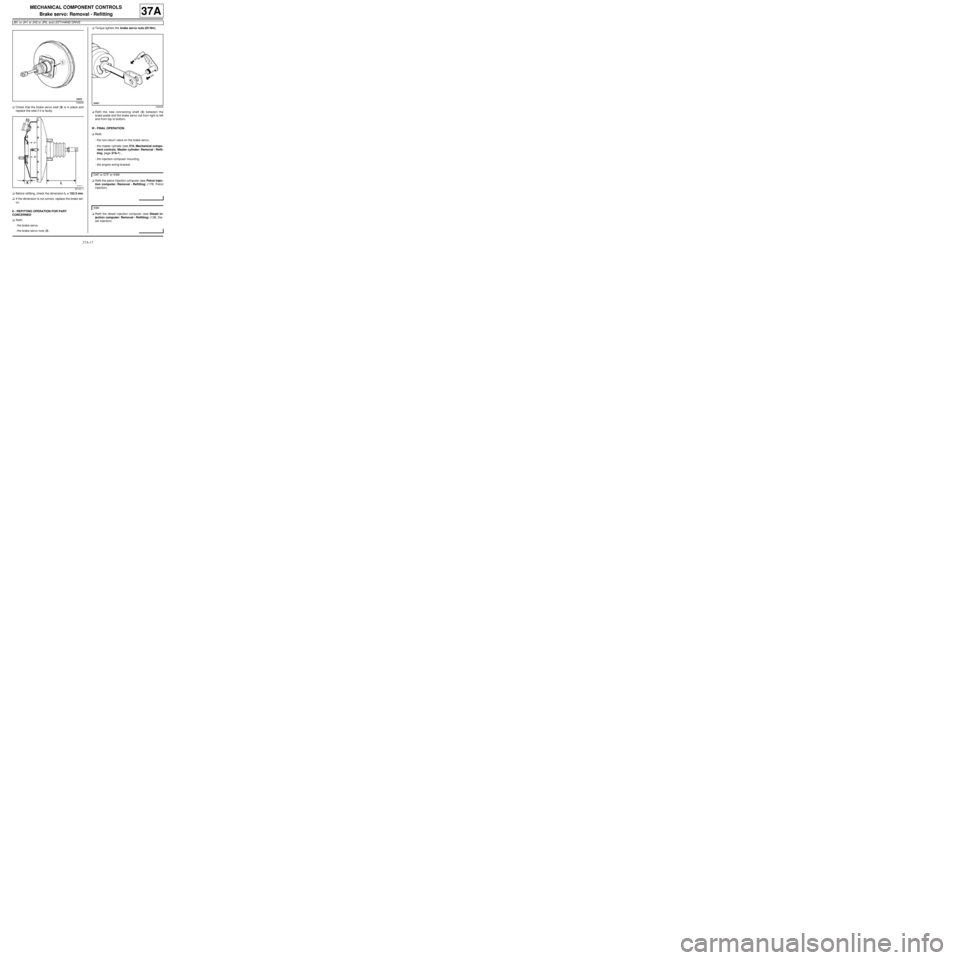

aCheck that the brake servo seal (5) is in place and

replace the seal if it is faulty.

aBefore refitting, check the dimension L = 153.3 mm.

aIf the dimension is not correct, replace the brake ser-

vo.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the brake servo,

-the brake servo nuts (3) .aTorque tighten the brake servo nuts (25 Nm).

aRefit the new connecting shaft (3) between the

brake pedal and the brake servo rod from right to left

and from top to bottom.

III - FINAL OPERATION.

aRefit:

-the non-return valve on the brake servo,

-the master cylinder (see 37A, Mechanical compo-

nent controls, Master cylinder: Removal - Refit-

ting, page 37A-1) ,

-the injection computer mounting,

-the engine wiring bracket.

aRefit the petrol injection computer (see Petrol injec-

tion computer: Removal - Refitting) (17B, Petrol

injection).

aRefit the diesel injection computer (see Diesel in-

jection computer: Removal - Refitting) (13B, Die-

sel injection).

109206

91101-1

109205

D4F or D7F or K4M

K9K

Page 198 of 281

37A-19

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

RIGHT-HAND DRIVE

37A

REMOVAL

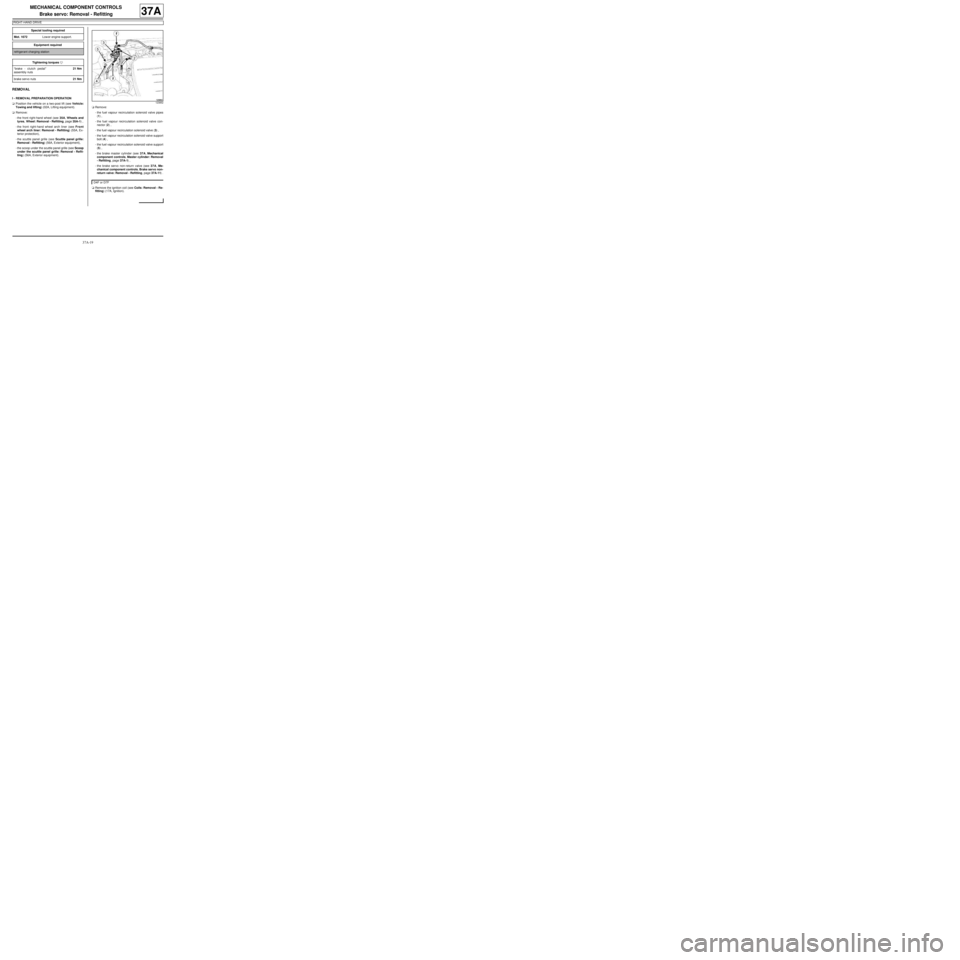

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front right-hand wheel (see 35A, Wheels and

tyres, Wheel: Removal - Refitting, page 35A-1) ,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).aRemove:

-the fuel vapour recirculation solenoid valve pipes

(1) ,

-the fuel vapour recirculation solenoid valve con-

nector (2) ,

-the fuel vapour recirculation solenoid valve (3) ,

-the fuel vapour recirculation solenoid valve support

bolt (4) ,

-the fuel vapour recirculation solenoid valve support

(5) ,

-the brake master cylinder (see 37A, Mechanical

component controls, Master cylinder: Removal

- Refitting, page 37A-1) ,

-the brake servo non-return valve (see 37A, Me-

chanical component controls, Brake servo non-

return valve: Removal - Refitting, page 37A-11) .

aRemove the ignition coil (see Coils: Removal - Re-

fitting) (17A, Ignition). Special tooling required

Mot. 1672Low er engine support.

Equipment required

refrigerant charging station

Tightening torquesm

“brake - clutch pedal”

assembly nuts21 Nm

brake servo nuts21 Nm

123852

D4F or D7F

Page 199 of 281

37A-20

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

RIGHT-HAND DRIVE

37A

aDrain the refrigerant circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove the "dehydrator reservoir - expansion

valve" connecting pipe (see Dehydrator reservoir -

expansion valve connecting pipe: Removal - Re-

fitting) (62A, Air conditioning).

aRemove:

-the air filter (see Air filter: Removal - Refitting)

(12A, Fuel mixture),

-the bolts (6) of the air filter unit heat-resistant pro-

tector,

-the air filter unit heat-resistant protector (7) .

aRemove:

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (19D, En-

gine mounting),-the right-hand suspended engine mounting (see

Right-hand suspended engine mounting: Re-

moval - Refitting) (19D, Engine mounting).

aRemove the catalytic converter (see Catalytic con-

verter: Removal - Refitting) (19B, Exhaust).

aRemove the exhaust manifold (see Exhaust mani-

fold: Removal - Refitting) (12A, Fuel mixture). AIR CONDITIONING or CLIMATE CONTROL

D7F

123868

D4F

D4F, and 780

K4M

Page 201 of 281

37A-22

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

RIGHT-HAND DRIVE

37A

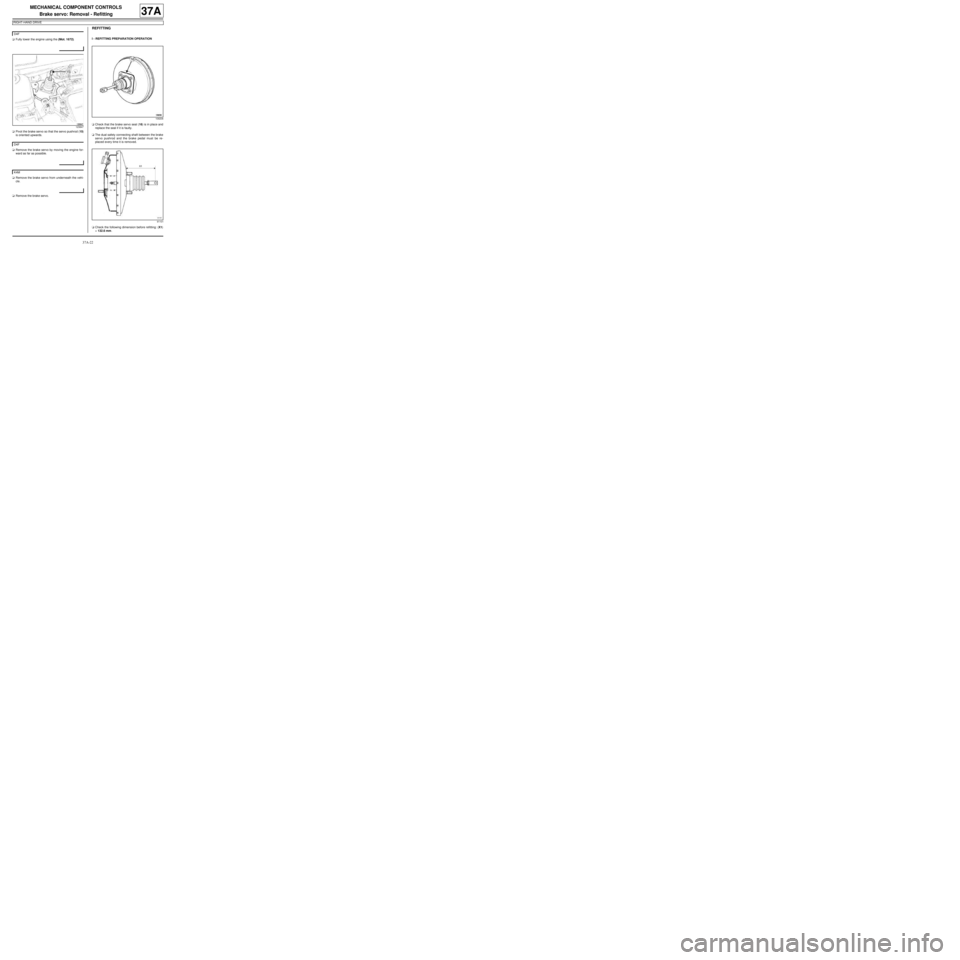

aFully lower the engine using the (Mot. 1672).

aPivot the brake servo so that the servo pushrod (15)

is oriented upwards.

aRemove the brake servo by moving the engine for-

ward as far as possible.

aRemove the brake servo from underneath the vehi-

cle.

aRemove the brake servo.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck that the brake servo seal (16) is in place and

replace the seal if it is faulty.

aThe dual safety connecting shaft between the brake

servo pushrod and the brake pedal must be re-

placed every time it is removed.

aCheck the following dimension before refitting: (X1)

= 132.6 mm. D4F

123847

D4F

K4M

109206

91101

Page 202 of 281

37A-23

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

RIGHT-HAND DRIVE

37A

II - REFITTING OPERATION FOR PART

CONCERNED

aPosition the brake servo by moving the engine for-

ward as far as possible and tilting the pushrod up-

wards.

aRefit the brake servo from underneath the vehicle.

aRefit the brake servo.

aPosition the “brake - clutch pedal” assembly on the

bulkhead.

aTorque tighten the “brake - clutch pedal” assem-

bly nuts (21 Nm).

aRefit:

-the new dual safety connecting shaft between the

brake servo pushrod and the brake pedal from right

to left and from top to bottom,

-the brake servo nuts.

aTorque tighten the brake servo nuts (21 Nm).

III - FINAL OPERATION.

aRefit:

-the clutch master cylinder support,

-the clutch master cylinder support bolts,

-the clutch master cylinder rod on the clutch pedal.

aRefit the exhaust manifold (see Exhaust manifold:

Removal - Refitting) (12A, Fuel mixture).aRefit the catalytic converter (see Catalytic convert-

er: Removal - Refitting) (19B, Exhaust).

aRefit:

-the right-hand suspended engine mounting (see

Right-hand suspended engine mounting: Re-

moval - Refitting) (19D, Engine mounting),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (19D, En-

gine mounting).

aRefit:

-the air filter box heat-resistant protector,

-the air filter box heat-resistant protector bolts,

-the air filter (see Air filter: Removal - Refitting)

(12A, Fuel mixture).

aRefit the "dehydrator reservoir - expansion valve"

connection (see Dehydrator reservoir - expansion

valve connecting pipe: Removal - Refitting) (62A,

Air conditioning).

aFill the refrigerant circuit using a refrigerant charg-

ing station (see Refrigerant circuit: Draining -

Filling) (62A, Air conditioning).

aRefit the ignition coil (see Coils: Removal - Refit-

ting) (17A, Ignition). D4F

K4M

JH3 or JR5

K4M

D4F, and 780

D4F

D7F

AIR CONDITIONING or CLIMATE CONTROL

D4F or D7F

Page 204 of 281

37A-25

MECHANICAL COMPONENT CONTROLS

Vacuum pump: Removal - Refitting

K9K

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove:

-the engine cover,

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture).

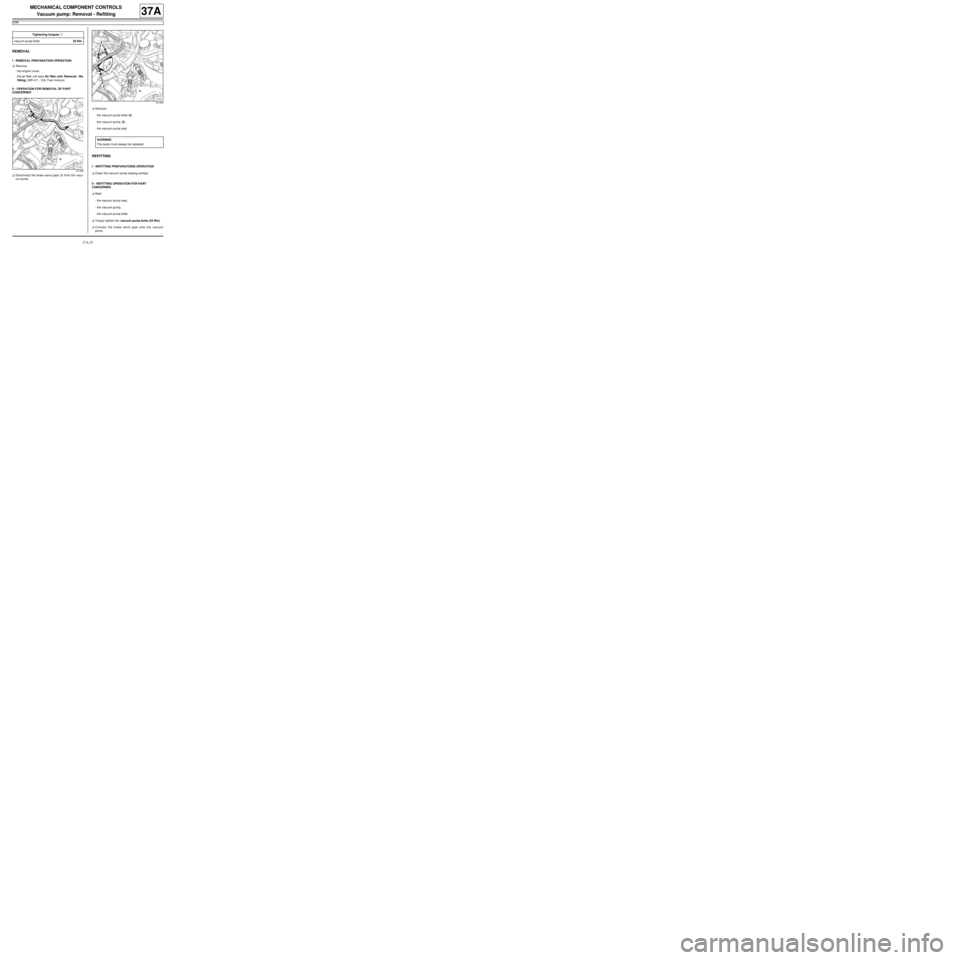

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the brake servo pipe (1) from the vacu-

um pump.aRemove:

-the vacuum pump bolts (2) ,

-the vacuum pump (3) ,

-the vacuum pump seal.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aClean the vacuum pump sealing surface.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the vacuum pump seal,

-the vacuum pump,

-the vacuum pump bolts.

aTorque tighten the vacuum pump bolts (25 Nm).

aConnect the brake servo pipe onto the vacuum

pump. Tightening torquesm

vacuum pump bolts25 Nm

121356

121355

WARNING

The seals m ust always be replaced.

Page 205 of 281

37A-26

MECHANICAL COMPONENT CONTROLS

Vacuum pump: Removal - Refitting

K9K

37A

III - FINAL OPERATION.

aRefit:

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture),

-the engine cover.

Page 233 of 281

37A-54

MECHANICAL COMPONENT CONTROLS

Clutch circuit: Bleed

JH3 or JR5

37A

Bleed in the event of:

-dead travel,

-pedal at mid-travel,

-pedal to the floor,

-poor gear changing.

I - PRECAUTIONS DURING REPAIR

Risks relating to contamination.

aThe hydraulic clutch system is very sensitive to con-

tamination. The risks caused by contamination are:

-impossible to change gears,

-damage to or destruction of the clutch system,

-leaks on the hydraulic circuit.

All the operations on the hydraulic clutch circuit sys-

tem must be carried out under excellent cleanliness

conditions. This ensures that no impurities enter the

hydraulic circuit during the operation.

The cleanliness principles apply to all components

of the hydraulic clutch circuit.

Items causing contamination are:

-metal or plastic swarf,

-fibres:

•cardboard,

•brushes,

•paper,

•clothing,

•cloth,

•dust and particles in the air,

•etc.

Cleaning cloths.

aUse lint-free cleaning cloths (see Products recom-

mended for the repair) (04B, Consumables - Prod-

ucts).

Each cloth must only be used once.There are two types of equipment used to bleed the

clutch circuit:

aARC50 via the brake fluid reservoir.

aSyringe via the bleed hole located on the clutch

slave cylinder.

There are two procedures used to bleed the clutch

circuit:

aIf no parts of the hydraulic clutch circuit are remo-

ved:

-Carry out the bleed operation using the ARC50 via

the brake fluid reservoir or using a new syringe via

the bleed hole located on the clutch slave cylinder.

aIf no parts of the hydraulic clutch circuit are remo-

ved:

-Only carry out the bleed operation using a new sy-

ringe by injecting the brake fluid via the bleed hole

on the clutch slave cylinder.

Consumables required for the repair:

aBleed the clutch circuit using approved (see Vehi-

cle: Parts and consumables for the repair) brake

fluid (04B, consumables - products).

II - PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the engine undertray. Equipment required

brake circuit bleeding device

hydraulic circuit bleed syringe

Note:

-Even the tiniest air bubble in the circuit can

cause faulty operation (pedal failing to return

properly, crunching sound when changing gear,

etc.).

-Incorrect bleeding can lead to incorrect detec-

tion of faults and unnecessary part replace-

ments.

Page 239 of 281

37A-60

MECHANICAL COMPONENT CONTROLS

Clutch circuit: Bleed

JH3 or JR5

37A

VI - FINAL OPERATION

aRefit the engine undertray.

aRemove the vehicle from the two-post lift (see Vehi-

cle: Towing and lifting) (02A, Lifting equipment).

Page 259 of 281

37A-80

MECHANICAL COMPONENT CONTROLS

Brake servo: Check

RIGHT-HAND DRIVE

37A

aConnect a vacuum pump to the end of the non-re-

turn valve.

aActivate the vacuum pump to obtain a vacuum of

500 mbar.

aCheck that the vacuum pressure does not drop. If it

does, the non-return valve is pierced; replace the

valve (see 37A, Mechanical component controls,

Brake servo non-return valve: Removal - Refit-

ting, page 37A-11) .

aRefit the non-return valve pipe on the intake distribu-

tor.V - CHECKING THE VACUUM PUMP

aConnect the external vacuum pump to the engine

vacuum pump.

aStart the engine.

aCheck the following values:

-550 mbar in 5 seconds for an engine speed of 700

rpm,

-700 mbar in 3 seconds and 900 mbar in 5 sec-

onds for an engine speed of 4050 rpm.

aReplace the vacuum pump if the values are different

(see 37A, Mechanical component controls, Vacu-

um pump: Removal - Refitting, page 37A-25) .

aRefit the non-return valve pipe onto the vacuum

pump.

VI - FINAL OPERATION.

aRefit:

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the front right-hand wheel (see 35A, Wheels and

tyres, Wheel: Removal - Refitting, page 35A-1) .

123907

D4F or D7F

K9K

106889