engine RENAULT TWINGO 2009 2.G Chasiss Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 30 of 281

30A-26

GENERAL INFORMATION

Underbody heights: Adjustment value

30A

W1 = 158 mm ±± ± ±

8 mm

W2 = 270.7 mm ±± ± ±

12 mm

W1 = 163.5 mm ±± ± ±

8 mm

W2 = 275.1 mm ±± ± ±

12 mm

W1 = 157.7 mm ±± ± ±

8 mm

W2 = 270.3 mm ±± ± ±

12 mm EQUIPMENT LEVEL SPORT, and 16" ALUMIN-

IUM WHEELS

EQUIPMENT LEVEL SPORT, and 17" ALUMIN-

IUM WHEELS, and WITHOUT ADDITIONAL

SPORT PACK

EQUIPMENT LEVEL SPORT, and 17" ALUMIN-

IUM WHEELS, and ADDITIONAL EXTREME PACK

Note:

The position of the vehicle varies according to:

-the weight of the engine,

-the springs and shock absorbers,

-the tyres,

-the amount of fuel in the tank.

Page 86 of 281

31A-43

FRONT AXLE COMPONENTS

Front axle subframe: Removal - Refitting

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the universal joint cover (1) (do not keep).

aSet the wheels straight ahead.

aFit a flywheel immobiliser.

aRemove the bolt (2) from the universal joint (do not

keep).

aTilt the universal joint on the steering box to detach it

from the pinion. Special tooling required

Tav. 476Ball joint extractor.

Mot. 1390Suppor t for removal - refitting

of engine - gearbox assembly

Equipment required

flywheel immobiliser

Tightening torquesm

rear subframe bolts105 Nm

front subframe bolts62 Nm

front end cross member

bolts21 Nm

acoustic tie-rod bolts21 Nm

acoustic tie-rod bolts90 Nm

subframe tie-rod bolts21 Nm

subframe tie-rod nuts62 Nm

gear lever arm nut28 Nm

nuts of the lower arm

ball joints62 N.m

bolts of the lower ball

joints62 N.m

nuts of the track rod

ends37 N.m

universal joint bolt24 Nm

119544

Note:

Do not pull the intermediate shaft out.

Page 89 of 281

31A-46

FRONT AXLE COMPONENTS

Front axle subframe: Removal - Refitting

31A

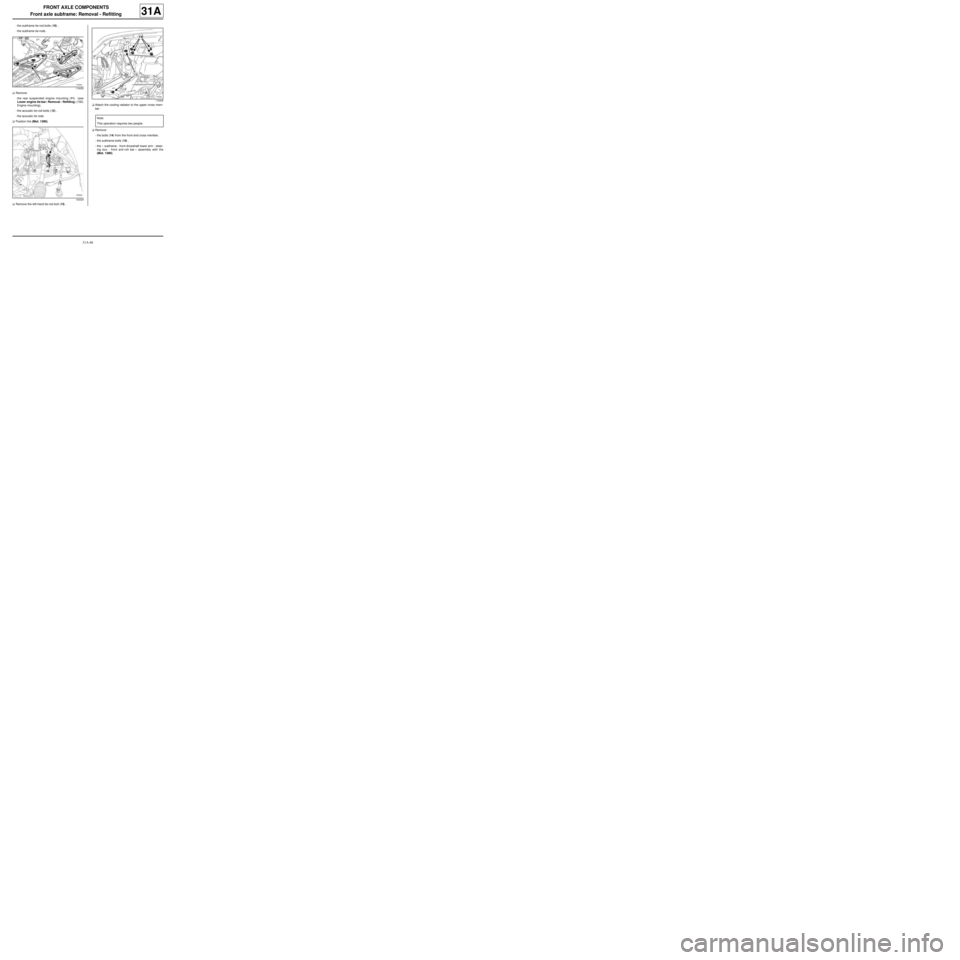

-the subframe tie-rod bolts (10) ,

-the subframe tie-rods.

aRemove:

-the rear suspended engine mounting (11) (see

Lower engine tie-bar: Removal - Refitting) (19D,

Engine mounting),

-the acoustic tie-rod bolts (12) ,

-the acoustic tie rods.

aPosition the (Mot. 1390).

aRemove the left-hand tie-rod bolt (13) .aAttach the cooling radiator to the upper cross mem-

ber.

aRemove:

-the bolts (14) from the front end cross member,

-the subframe bolts (15) ,

-the « subframe - front driveshaft lower arm - steer-

ing box - front anti-roll bar » assembly with the

(Mot. 1390).

119335

132029

119336

Note:

This operation requires two people.

Page 91 of 281

31A-48

FRONT AXLE COMPONENTS

Front axle subframe: Removal - Refitting

31A

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the speed selection cable guide on the sub-

frame.

aRefit:

-the front driveshaft lower arms (see 31A, Front

axle components, Front driveshaft lower arm:

Removal - Refitting, page 31A-33) ,

-the front anti-roll bar (see 31A, Front axle compo-

nents, Front anti-roll bar: Removal - Refitting,

page 31A-52) ,

-the steering box (see 36A, Steering assembly,

Steering box: Removal - Refitting, page 36A-1) .

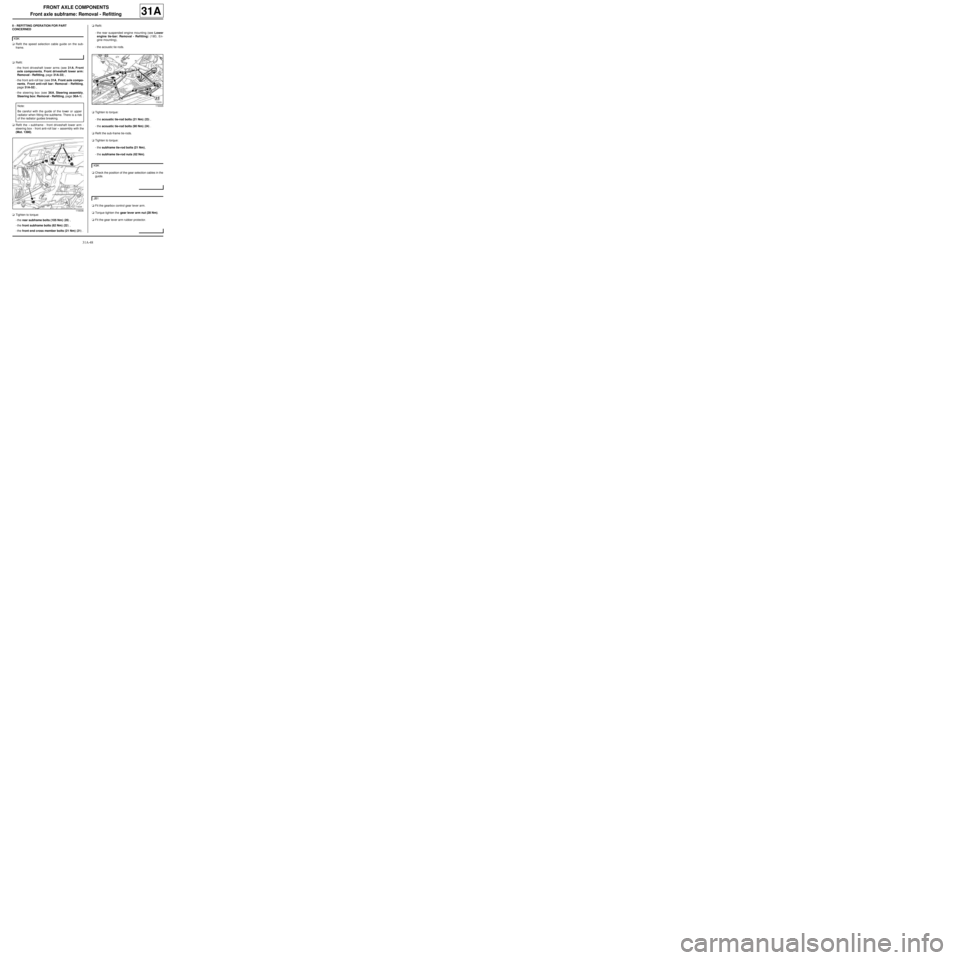

aRefit the « subframe - front driveshaft lower arm -

steering box - front anti-roll bar » assembly with the

(Mot. 1390).

aTighten to torque:

-the rear subframe bolts (105 Nm) (20) ,

-the front subframe bolts (62 Nm) (22) ,

-the front end cross member bolts (21 Nm) (21) .aRefit:

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (19D, En-

gine mounting),

-the acoustic tie rods.

aTighten to torque:

-the acoustic tie-rod bolts (21 Nm) (23) ,

-the acoustic tie-rod bolts (90 Nm) (24) .

aRefit the sub-frame tie-rods.

aTighten to torque:

-the subframe tie-rod bolts (21 Nm),

-the subframe tie-rod nuts (62 Nm).

aCheck the position of the gear selection cables in the

guide.

aFit the gearbox control gear lever arm.

aTorque tighten the gear lever arm nut (28 Nm).

aFit the gear lever arm rubber protector. K9K

Note:

Be careful with the guide of the lower or upper

radiator when fitting the subframe. There is a risk

of the radiator guides breaking.

119336

119335

K9K

JB1

Page 95 of 281

31A-52

FRONT AXLE COMPONENTS

Front anti-roll bar: Removal - Refitting

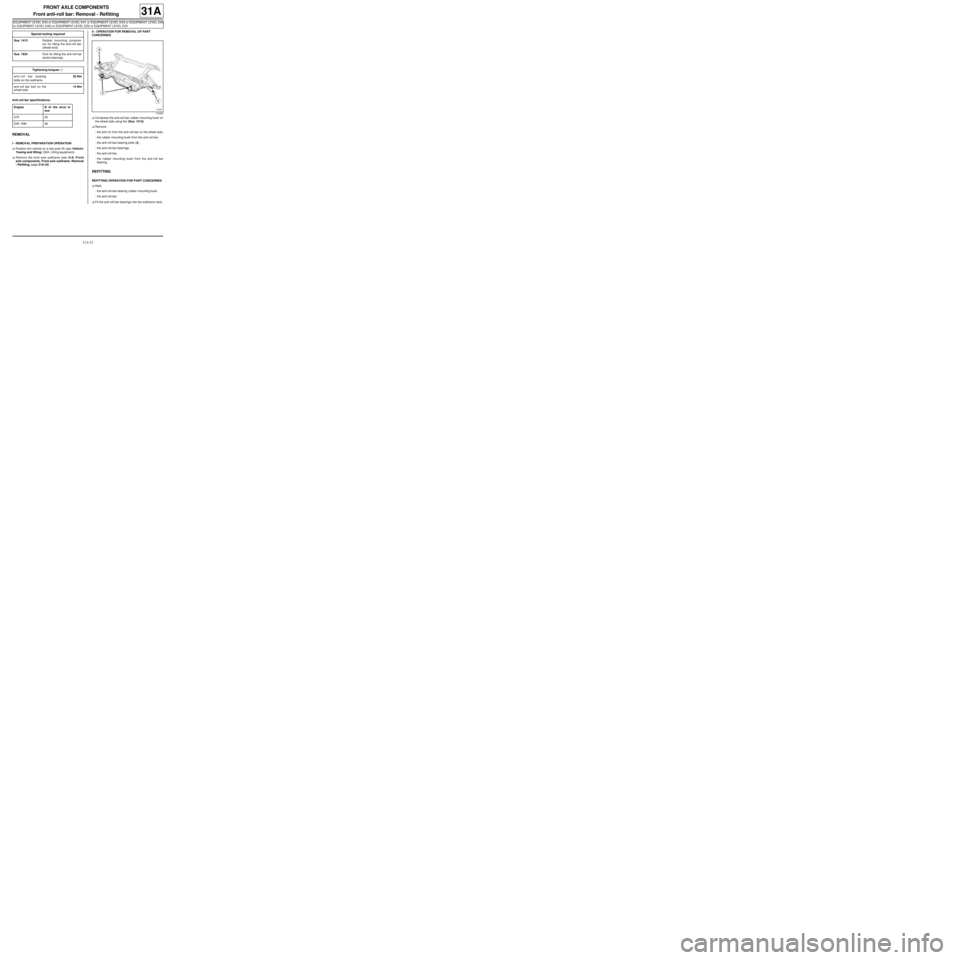

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

Anti-roll bar specifications:

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front axle subframe (see 31A, Front

axle components, Front axle subframe: Removal

- Refitting, page 31A-43) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aCompress the anti-roll bar rubber mounting bush on

the wheel side using the (Sus. 1413).

aRemove:

-the bolt (1) from the anti-roll bar on the wheel side,

-the rubber mounting bush from the anti-roll bar,

-the anti-roll bar bearing bolts (2) ,

-the anti-roll bar bearings,

-the anti-roll bar,

-the rubber mounting bush from the anti-roll bar

bearing.

REFITTING

REFITTING OPERATION FOR PART CONCERNED

aRefit:

-the anti-roll bar bearing rubber mounting bush,

-the anti-roll bar.

aFit the anti-roll bar bearings into the subframe neck. Special tooling required

Sus. 1413Rubber mounting compres-

sor for fitting the anti-roll bar.

(wheel end).

Sus. 1824Fork for fitting the anti-roll bar

centre bearings.

Tightening torquesm

anti-roll bar bearing

bolts on the subframe35 Nm

anti-roll bar bolt on the

wheel side14 Nm

Engine Ø of the strut in

mm

D7F 25

D4F, K9K 26

119406

Page 135 of 281

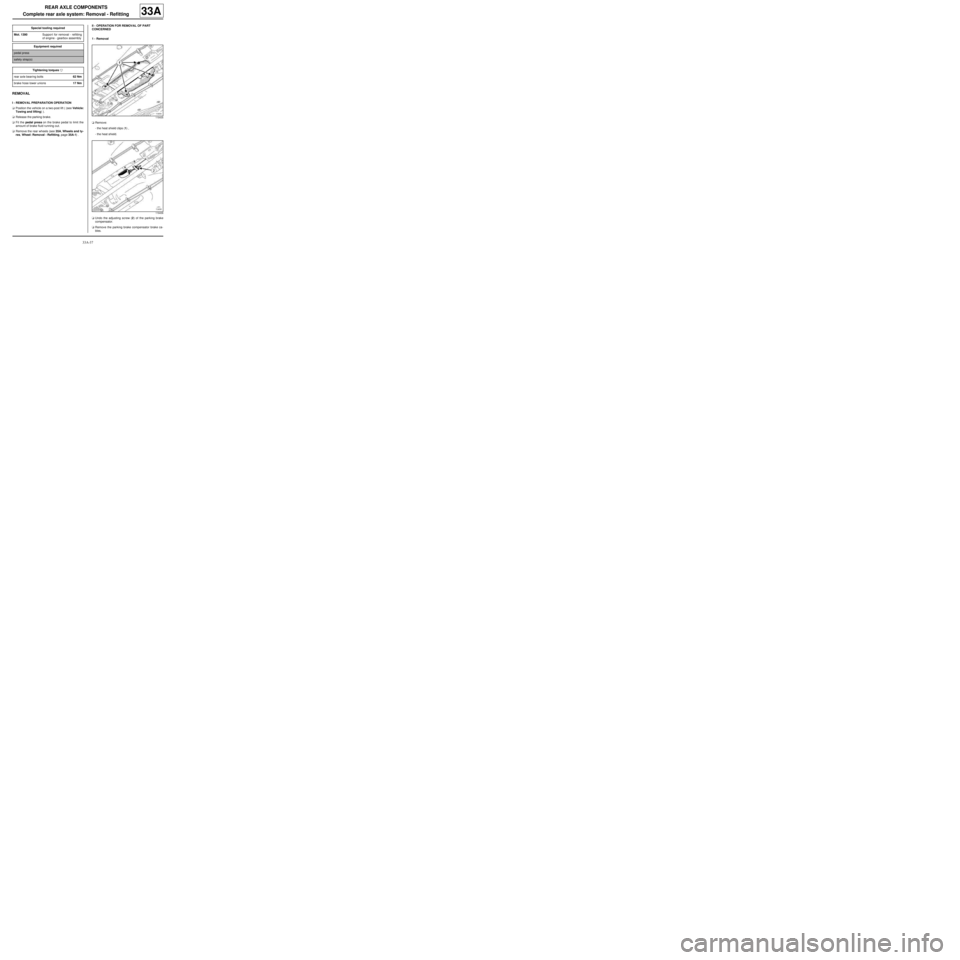

33A-37

REAR AXLE COMPONENTS

Complete rear axle system: Removal - Refitting

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRelease the parking brake.

aFit the pedal press on the brake pedal to limit the

amount of brake fluid running out.

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

1 - Removal

aRemove:

-the heat shield clips (1) ,

-the heat shield.

aUndo the adjusting screw (2) of the parking brake

compensator.

aRemove the parking brake compensator brake ca-

bles. Special tooling required

Mot. 1390Suppor t for removal - refitting

of engine - gearbox assembly

Equipment required

pedal press

safety strap(s)

Tightening torquesm

rear axle bearing bolts62 Nm

brake hose lower unions17 Nm

119435

119436

Page 150 of 281

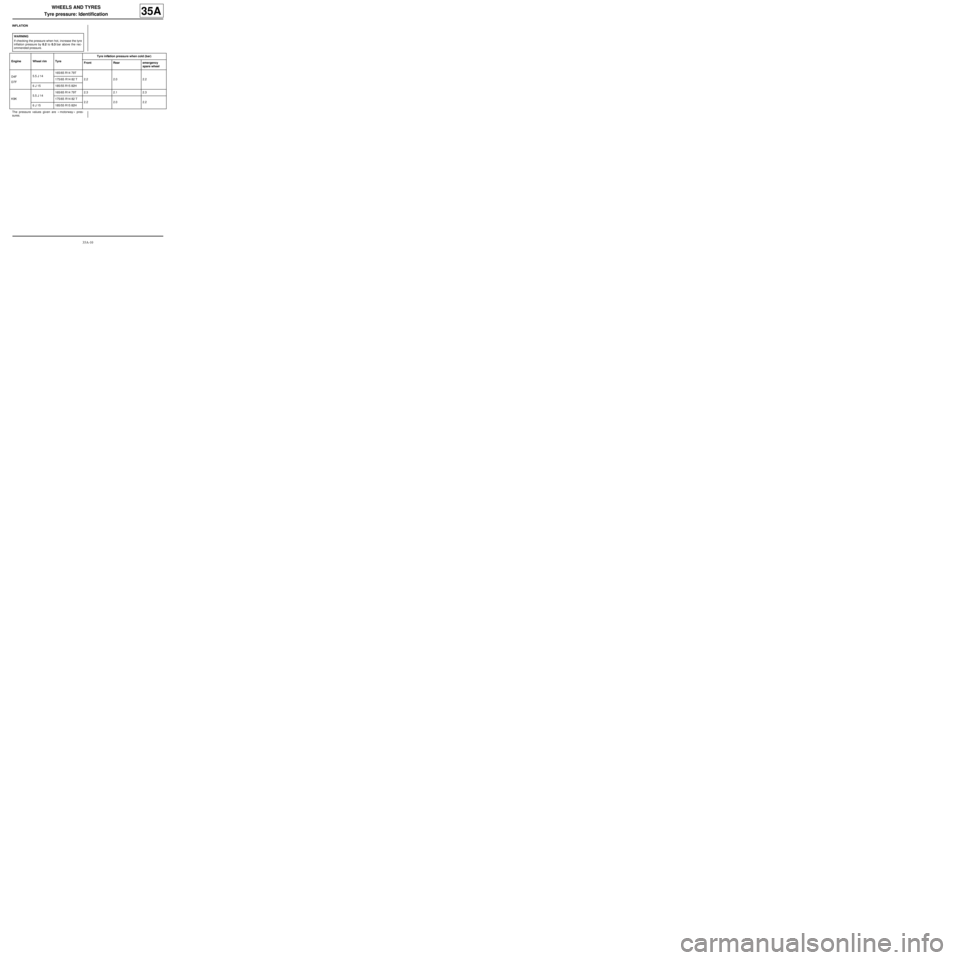

35A-10

WHEELS AND TYRES

Tyre pressure: Identification

35A

INFLATION

The pressure values given are « motorway » pres-

sures.WARNING

If checking the pressure when hot, increase the tyre

inflation pressure by 0.2 to 0.3 bar above the rec-

ommended pressure.

Engine Wheel rim TyreTyre inflation pressure when cold (bar)

Front Rear emergency

spare wheel

D4F

D7F5.5 J 14165/65 R14 79T

2.2 2.0 2.2 175/65 R14 82 T

6 J 15 185/55 R15 82H

K9K5.5 J 14165/65 R14 79T 2.3 2.1 2.3

175/65 R14 82 T

2.2 2.0 2.2

6 J 15 185/55 R15 82H

Page 162 of 281

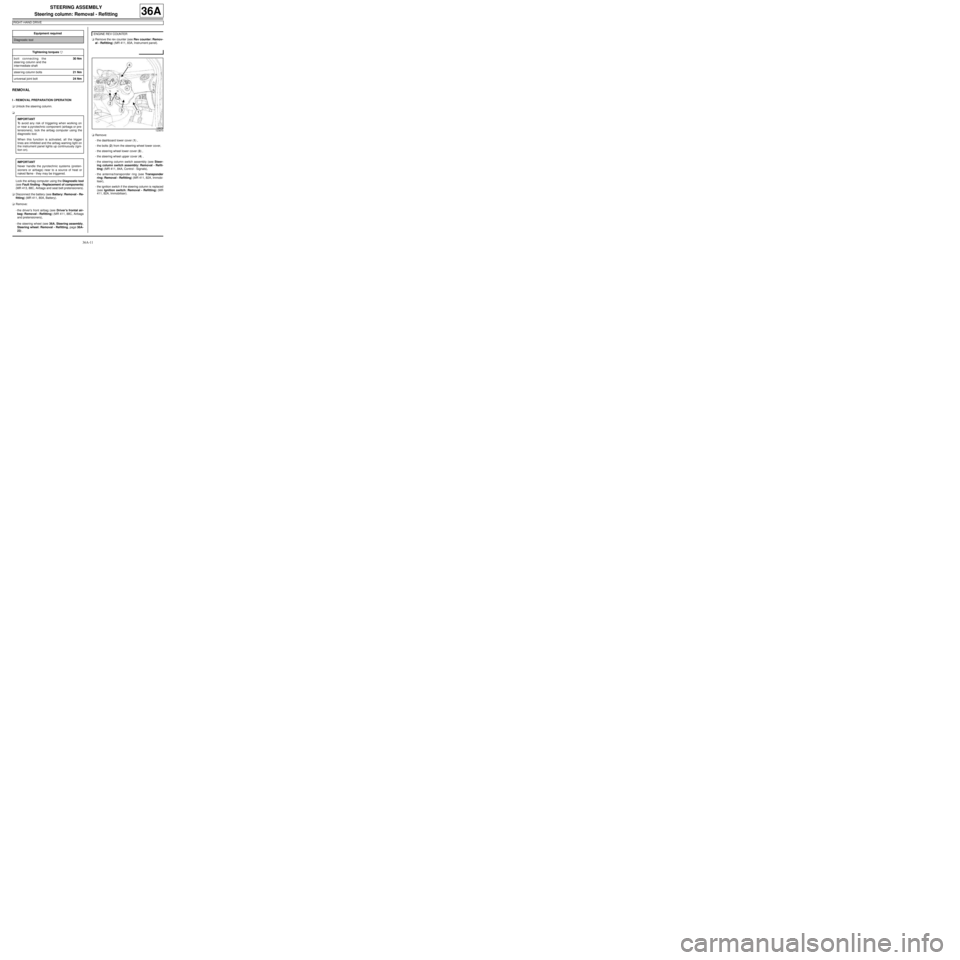

36A-11

STEERING ASSEMBLY

Steering column: Removal - Refitting

RIGHT-HAND DRIVE

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aUnlock the steering column.

a

Lock the airbag computer using the Diagnostic tool

(see Fault finding - Replacement of components)

(MR 413, 88C, Airbags and seat belt pretensioners).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove:

-the driver's front airbag (see Driver's frontal air-

bag: Removal - Refitting) (MR 411, 88C, Airbags

and pretensioners),

-the steering wheel (see 36A, Steering assembly,

Steering wheel: Removal - Refitting, page 36A-

23) .aRemove the rev counter (see Rev counter: Remov-

al - Refitting) (MR 411, 83A, Instrument panel).

aRemove:

-the dashboard lower cover (1) ,

-the bolts (2) from the steering wheel lower cover,

-the steering wheel lower cover (3) ,

-the steering wheel upper cover (4) ,

-the steering column switch assembly (see Steer-

ing column switch assembly: Removal - Refit-

ting) (MR 411, 84A, Control - Signals),

-the antenna/transponder ring (see Transponder

ring: Removal - Refitting) (MR 411, 82A, Immobi-

liser),

-the ignition switch if the steering column is replaced

(see Ignition switch: Removal - Refitting) (MR

411, 82A, Immobiliser). Equipment required

Diagnostic tool

Tightening torquesm

bolt connecting the

steer ing column and the

inter mediate shaft30 Nm

steer ing column bolts21 Nm

universal joint bolt24 Nm

IMPORTANT

To avoid any risk of triggering when working on

or near a pyrotechnic component (airbags or pre-

tensioners), lock the airbag computer using the

diagnostic tool.

When this function is activated, all the trigger

lines are inhibited and the airbag warning light on

the instrument panel lights up continuously (igni-

tion on).

IMPORTANT

Never handle the pyrotechnic systems (preten-

sioners or airbags) near to a source of heat or

naked flame - they may be triggered.

ENGINE REV COUNTER

123870

Page 166 of 281

36A-15

STEERING ASSEMBLY

Steering column: Removal - Refitting

RIGHT-HAND DRIVE

36A

-the steering wheel lower cover,

-the steering wheel lower cover bolts,

-the dashboard lower cover.

aRefit the rev counter (see Rev counter: Removal -

Refitting) (MR 411, 83A, Instrument panel).

aRefit:

-the steering wheel (see 36A, Steering assembly,

Steering wheel: Removal - Refitting, page 36A-

23) ,

-the driver's front airbag (see Driver's frontal air-

bag: Removal - Refitting) (MR 411, 88C, Airbags

and pretensioners).

aConnect the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

a

Unlock the airbag computer using the Diagnostic

tool (see Fault finding - Replacement of compo-

nents) (MR 413, 88C, Airbags and pretensioners). ENGINE REV COUNTER

IMPORTANT

To avoid a fault with or even triggering of pyro-

technic components (airbags or pretensioners),

check the airbag computer using the diagnostic

tool.

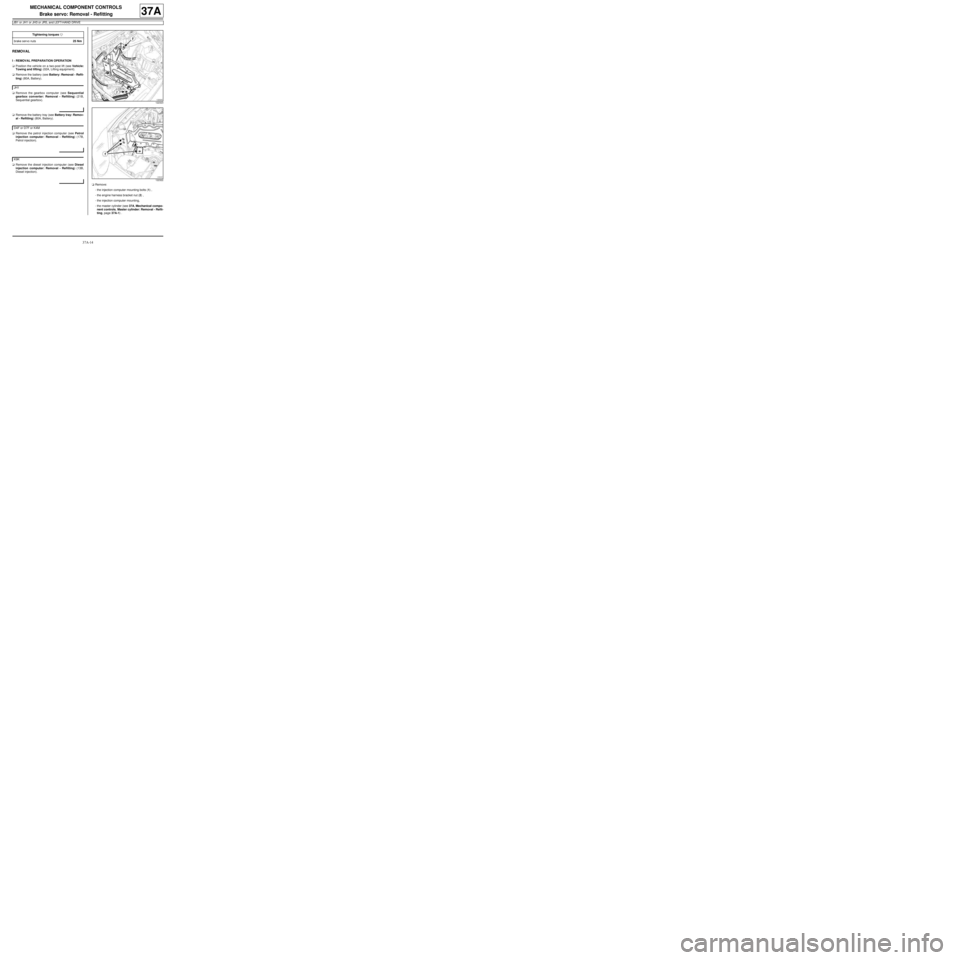

Page 193 of 281

37A-14

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

JB1 or JH1 or JH3 or JR5, and LEFT-HAND DRIVE

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aRemove the gearbox computer (see Sequential

gearbox converter: Removal - Refitting) (21B,

Sequential gearbox).

aRemove the battery tray (see Battery tray: Remov-

al - Refitting) (80A, Battery).

aRemove the petrol injection computer (see Petrol

injection computer: Removal - Refitting) (17B,

Petrol injection).

aRemove the diesel injection computer (see Diesel

injection computer: Removal - Refitting) (13B,

Diesel injection).

aRemove:

-the injection computer mounting bolts (1) ,

-the engine harness bracket nut (2) ,

-the injection computer mounting,

-the master cylinder (see 37A, Mechanical compo-

nent controls, Master cylinder: Removal - Refit-

ting, page 37A-1) . Tightening torquesm

brake servo nuts25 Nm

JH1

D4F or D7F or K4M

K9K

122323

122322