ESP RENAULT TWINGO 2009 2.G Chasiss Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 20 of 281

30A-16

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

a

aShape the pipe using a bender, curve after curve,

while respecting the original shape of the pipe.

128814

WARNING

To avoid weakening the pipe, either bend once or

bend progressively by increasing the bend (that

is, by continually decreasing the curve radius).

Do not install a rigid pipe on a vehicle that may

have been bended and then unbended alterna-

tively to reach the correct curve radius.

Note:

During the bending operation, the required angle

should be passed slightly in order to compensate

for material elasticity.

Page 21 of 281

30A-17

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

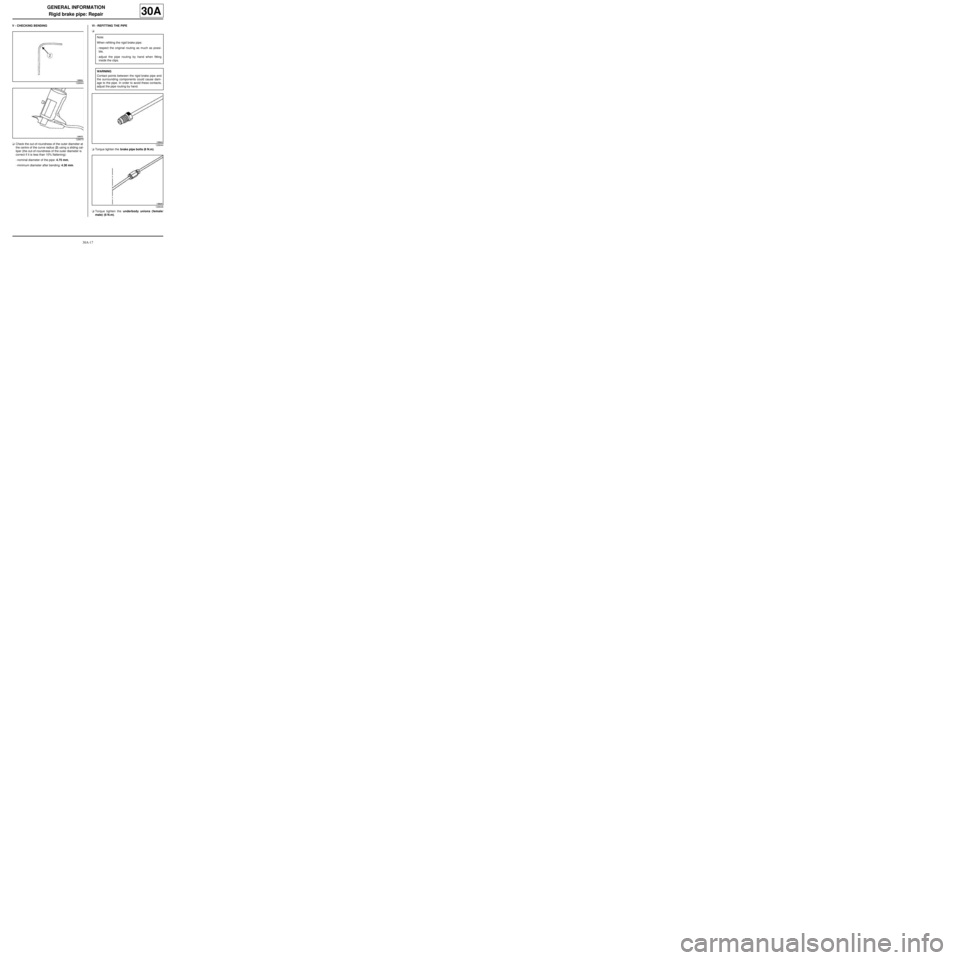

V - CHECKING BENDING

aCheck the out-of-roundness of the outer diameter at

the centre of the curve radius (2) using a sliding cal-

liper (the out-of-roundness of the outer diameter is

correct if it is less than 10% flattening):

-nominal diameter of the pipe: 4.75 mm,

-minimum diameter after bending: 4.30 mm.VI - REFITTING THE PIPE

a

aTorque tighten the brake pipe bolts (8 N.m).

aTorque tighten the underbody unions (female/

male) (6 N.m).

128664

128670

Note:

When refitting the rigid brake pipe:

-respect the original routing as much as possi-

ble,

-adjust the pipe routing by hand when fitting

inside the clips.

WARNING

Contact points between the rigid brake pipe and

the surrounding components could cause dam-

age to the pipe. In order to avoid these contacts,

adjust the pipe routing by hand.

128644

128646

Page 22 of 281

30A-18

GENERAL INFORMATION

Brake fluid: Specifications

30A

BRAKE FLUID REPLACEMENT INTERVAL

Our braking technology, and in particular the disc

brakes (hollow pistons which conduct little heat, have a

low volume of fluid in the cylinder, sliding callipers

avoiding the need for a fluid reserve in the least cooled

area of the wheel), has allowed us to prevent the risk of

« vapour lock » as far as possible, even with heavy

braking (mountainous area). However, current brake

fluids are subject to minor deterioration during the first

months of use due to slight humidity intake. This is why

it is recommended that you change the brake fluid: see

maintenance booklet for the vehicle.

1 - Topping up the level

Wear of the brake pads will result in a gradual drop in

the fluid level in the reservoir.

Do not top up the fluid, as the level will rise again when

the pads are next changed. The brake fluid level must

not fall below the minimum mark.

2 - Approved brake fluid

Mixing two incompatible brake fluids in the brake circuit

may lead to:

-serious risk of leakage due mainly to deterioration of

the cups,

-deterioration in the operation of the ESP system.

To prevent such risks, it is essential to use only brake

fluids that comply with the RENAULT standard (see

Vehicle: Parts and consumables for the repair) .

Page 74 of 281

31A-31

FRONT AXLE COMPONENTS

Front shock absorber and spring: Removal - Refitting31A

a

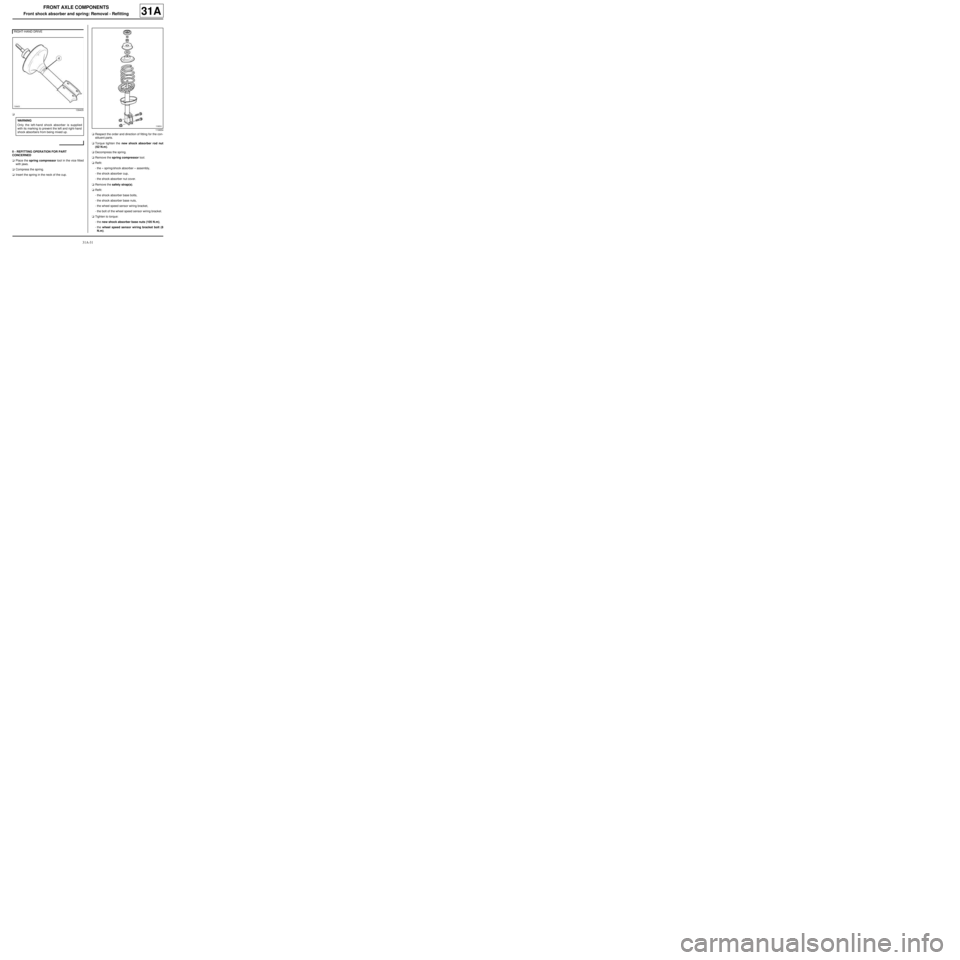

II - REFITTING OPERATION FOR PART

CONCERNED

aPlace the spring compressor tool in the vice fitted

with jaws.

aCompress the spring.

aInsert the spring in the neck of the cup.aRespect the order and direction of fitting for the con-

stituent parts.

aTorque tighten the new shock absorber rod nut

(62 N.m).

aDecompress the spring.

aRemove the spring compressor tool.

aRefit:

-the « spring/shock absorber » assembly,

-the shock absorber cup,

-the shock absorber nut cover.

aRemove the safety strap(s).

aRefit:

-the shock absorber base bolts,

-the shock absorber base nuts,

-the wheel speed sensor wiring bracket,

-the bolt of the wheel speed sensor wiring bracket.

aTighten to torque:

-the new shock absorber base nuts (105 N.m),

-the wheel speed sensor wiring bracket bolt (8

N.m). RIGHT-HAND DRIVE

139405

WARNING

Only the left-hand shock absorber is supplied

with its marking to prevent the left and right-hand

shock absorbers from being mixed up.

119654

Page 146 of 281

35A-6

WHEELS AND TYRES

Wheel: Balancing

35A

aEnter the specific wheel parameters when starting

the wheel balancer.

aStart the wheel balancer and check the wheel bal-

ance, which should be 0 g on each plane of the

wheel.

aIf this is not the case, remove the old wheel balanc-

ing weights and repeat the wheel balancing proce-

dure, checking that the wheel balance equals 0 on

each wheel plane.

IV - FINAL OPERATION

aRefit the wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) . WARNING

To avoid detachment of the balance weights, use

only weights which correspond to the vehicle

wheel rims.

Page 209 of 281

37A-30

MECHANICAL COMPONENT CONTROLS

Accelerator pedal: Removal - Refitting

37A

aBond the pedal pad (3) to the pedal (4) by pressing

on the right-hand side.

Press the pad to ensure bonding.

III - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the accelerator pedal,

-the accelerator pedal nuts.

aTorque tighten the accelerator pedal nuts (8 N.m ).

aConnect the accelerator pedal potentiometer con-

nector.

135017

Note:

Respect the range of motion when fitting.

Page 215 of 281

37A-36

MECHANICAL COMPONENT CONTROLS

Brake pedal: Removal - Refitting

RIGHT-HAND DRIVE, and 5-SPEED MANUAL GEARBOX

37A

aBond the pedal pad (19) to the pedal (20) by press-

ing on the right-hand side.

Press the pad to ensure bonding.

IV - FINAL OPERATION

aFit the dashboard.

aRefit the dashboard bolts.

aConnect the airbag inhibition switch connector.

aRefit the dashboard side panel.

aRefit:

-the clutch master cylinder,

-the connecting clip between the outlet pipe and the

clutch master cylinder,

-the clutch master cylinder support,

-the clutch support bolts,

-the clutch master cylinder rod.aRefit the clutch pedal switch (see ) .

aRefit the accelerator pedal (see 37A, Mechanical

component controls, Accelerator pedal: Remov-

al - Refitting, page 37A-29) .

aRefit:

-the brake pedal switch (see 37A, Mechanical

component controls, Brake pedal switch: Re-

moval - Refitting, page 37A-42) ,

-the dashboard lower trim.

135017

Note:

Respect the range of motion when fitting.

JH3 or JR5

CRUISE CONTROL

JB1

Page 220 of 281

37A-41

MECHANICAL COMPONENT CONTROLS

Brake pedal: Removal - Refitting

LEFT-HAND DRIVE, and 5-SPEED MANUAL GEARBOX

37A

III - REFITTING OPERATION FOR THE ALUMINIUM

PEDAL PADS

aCheck that the pedal is at ambient temperature.

aCheck that the surface of the pedal is clean.

aActivate the pedal bonding surface with some paper

soaked in HEPTANE.

Wipe immediately with a clean and dry cloth.

Remove the protection around the pad.aBond the pedal pad (8) to the pedal (9) by pressing

on the right-hand side.

Press the pad to ensure bonding.

IV - FINAL OPERATION

aRefit the clutch pedal switch (see 37A, Mechanical

component controls, Clutch pedal switch: Re-

moval - Refitting, page 37A-52) .

aRefit the brake pedal switch (see 37A, Mechanical

component controls, Brake pedal switch: Re-

moval - Refitting, page 37A-42)

aRefit the switch wiring on the pedals in the position

marked during the removal operation. EQ UIPMENT LEVEL SPORT

Note:

If only the pad is being replaced, allow the pedal

to cool.

Note:

The bonding area must be clean, and free from

finger marks and fabric deposits.

Note:

It is essential to activate the surface and to wipe

in the same direction: there is a risk of contami-

nating the bonding surface when wiping.

Note:

Do not use the same paper to activate the sur-

face and to wipe the surface.

Throw the paper away after each use.

135017

Note:

Respect the r ange of motion when fitting.

CRUISE CONTROL

Page 280 of 281

38C-21

ANTI-LOCK BRAKING SYSTEM

Braking computer: Removal - Refitting

38C

This repair method only relates to vehicles without

ESP, equipped with TEVES brand hydraulic unit.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove the entire hydraulic unit (see 38C, Anti-

lock braking system, Hydraulic brake unit: Re-

moval - Refitting, page 38C-2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the braking computer bolts (1) on the hydraulic unit,

-the braking computer (2) .

REFITTING

I - REFITTING PREPARATION OPERATION

aDo not clean the pressure modulation unit (3) . Special tooling required

Mot. 1608Torque screwdriver 1 to 6.6

N.m.

Equipment required

Diagnostic tool

Tightening torquesm

braking computer bolts3 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

121457

19113