30A-23

GENERAL INFORMATION

Axle assemblies: Check

30A

aLock the slip plates of the lift.

aPosition the vehicle on a lift (see Vehicle: Towing

and lifting) .

aCheck the condition of the following components:

-track rods,

-axial ball joint linkages,

-subframe,

-lower arm rubber bushes,

-lower arm ball joints (see Front driveshaft lower

arm ball joint: Check) ,

-shock absorbers,

-tyres,

aCheck:

-the tyre size (see 35A, Wheels and tyres, Tyres:

Identification, page 35A-7) ,

-the tyre inflation pressure (see 35A, Wheels and

tyres, Tyre pressure: Identification, page 35A-

10) .

aPut the vehicle in the VODM position (vehicle in run-

ning order) (see 30A, General information, Under-

body heights: Adjustment value, page 30A-24) :

-tank full,

-vehicle empty (without luggage, etc.).

aConsult:

-the front axle geometry values (see 30A, General

information, Front axle assembly: Adjustment

values, page 30A-31) ,

-the rear axle geometry values (see 30A, General

information, Rear axle assembly: Adjustment

values, page 30A-38) .

aRefer to the user manual for the geometry tester.

aCheck the geometry using the geometry tester.

aIf there is an inconsistency between the manufactur-

er's values and the measured values:

aAdjust the front axle (see 30A, General informa-

tion, Front axle system: Adjustment, page 30A-

36)

35A-11

WHEELS AND TYRES

Wheel rim: Identification

35A

IDENTIFICATION

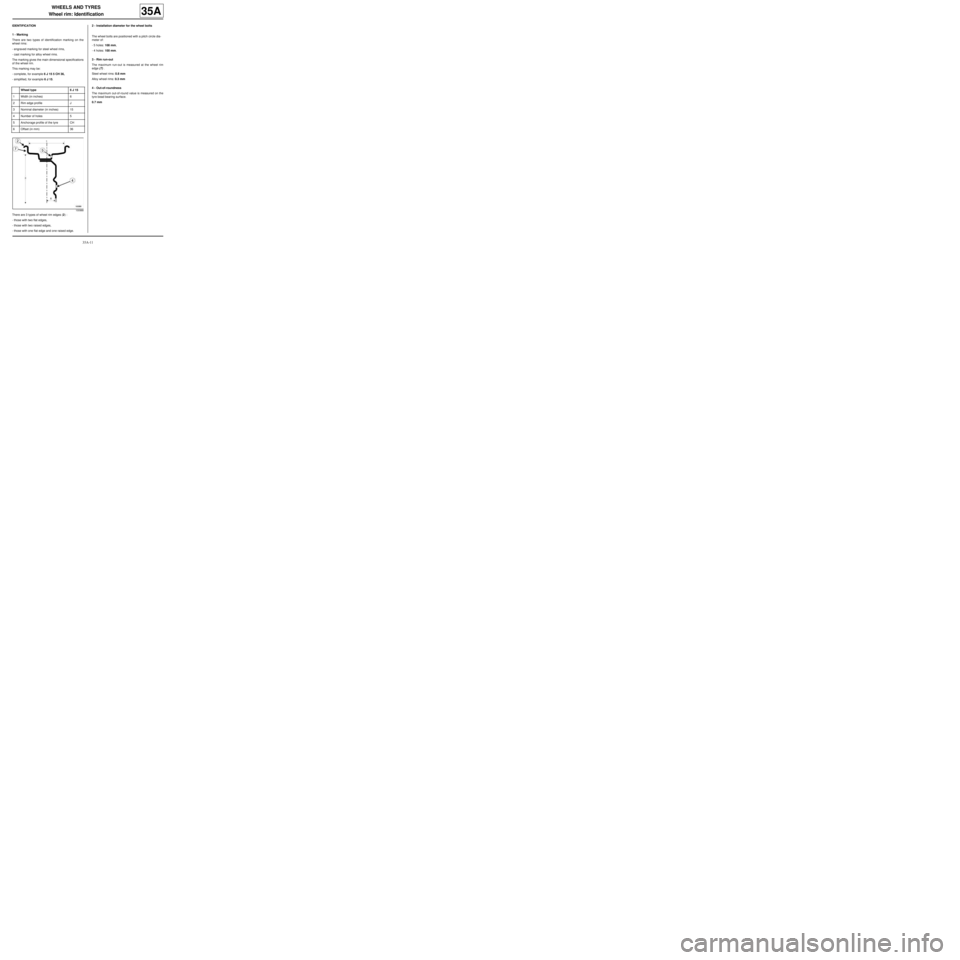

1 - Marking

There are two types of identification marking on the

wheel rims:

-engraved marking for steel wheel rims,

-cast marking for alloy wheel rims.

The marking gives the main dimensional specifications

of the wheel rim.

This marking may be:

-complete, for example 6 J 15 5 CH 36,

-simplified, for example 6 J 15.

There are 3 types of wheel rim edges (2) :

-those with two flat edges,

-those with two raised edges,

-those with one flat edge and one raised edge.2 - Installation diameter for the wheel bolts

The wheel bolts are positioned with a pitch circle dia-

meter of:

-5 holes: 108 mm,

-4 holes: 100 mm.

3 - Rim run-out

The maximum run-out is measured at the wheel rim

edge (7) .

Steel wheel rims: 0.8 mm

Alloy wheel rims: 0.3 mm

4 - Out-of-roundness

The maximum out-of-round value is measured on the

tyre bead bearing surface.

0.7 mm Wheel type 6 J 15

1Width (in inches) 6

2Rim edge profile J

3Nominal diameter (in inches) 15

4Number of holes 5

5Anchorage profile of the tyre CH

6Offset (in mm) 36

100988