tow RENAULT TWINGO 2009 2.G Chasiss Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 6 of 281

30A-2

GENERAL INFORMATION

Brake circuit: Precautions for the repair

30A

I - SAFETY

1 - Advice to be followed before any operation

For an operation requiring the use of a lift, follow the

safety advice (see Vehicle: Towing and lifting) (02A,

Lifting equipment).

The brake regulation circuit must be free of all hydrau-

lic and electrical faults.

In case of incorrect handling, the brake fluid can cause

serious injury and damage. Follow the manufacturer's

instructions for brake fluid.

To prevent dust from entering the master cylinder res-

ervoir and the brake circuit, the plug must be removed

just before filling and closed immediately afterwards,

2 - Instructions to be followed during the operation

Do not press on the brake pedal during work on the

brake system.

If, during work on the brake system, any damage on

any part is observed, it must be repaired before driving

the vehicle again.

Brake fluid is highly corrosive. Ensure any brake fluid

spilt on parts of the vehicle is cleaned off.

Use brake fluids that comply with the Renault standard

(see Vehicle: Parts and consumables for the repair)

.

Check the brake fluid levels in the braking circuit and

the bleeding device.

Check that the pressure of the bleeding device is be-

tween 1.5 bar and 2 bar.

II - CLEANLINESS

1 - Advice to be followed before any operation

Protect any bodywork components that risk being dam-

aged by brake fluid with a cover.

2 - Instructions to be followed during the operation

Fit blanking plugs recommended for the Siemens K9K

injection system at the end of each pipe and in all the

openings of the disconnected components of the brake

circuit.

Clean around the braking system with BRAKE

CLEANER (see Vehicle: Parts and consumables

for the repair) (04B, Consumables - Products).Do not allow friction materials to come into contact with

grease, oil or other lubricants and cleaning products

which are mineral oil based.

III - GENERAL RECOMMENDATIONS

When replacing brake pads, always replace the pads

on the other side as well.

When replacing a disc, always replace the disc on the

opposite side.

When replacing brake discs, you must replace the

brake pads.

Always replace the rigid brake pipe clips.

Reminder:

-The pipes between the master cylinder, callipers and

the hydraulic assembly are connected using threaded

unions with a metric thread.

-Therefore, only parts specified in the Parts Catalogue

for this vehicle should be used. WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the surrounding

components, regardless of the position of the

wheels.

IMPORTANT

To avoid any accident, br ing the pistons, brake pads

and brake discs into contact by depressing the

brake pad several times.

Page 8 of 281

30A-4

GENERAL INFORMATION

Braking circuit: Bleed

30A

This procedure must be applied after one of the fol-

lowing components has been removed or replaced:

-the master cylinder,

-the brake fluid,

-the hydraulic unit,

-a rigid pipe,

-a hose,

-the reservoir,

-a calliper.aUse locally produced containers to collect the used

brake fluid.

Front and rear callipers:

-2 washer fluid containers (1) (1 litre),

-4 mm diameter transparent pipes (2) ,

-4 pipettes (3) ,

-2 T-unions (4) .

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aSwitch off the vehicle ignition. Equipment required

pedal press

brake circuit bleeding device

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair (see 30A, General information, Brake cir-

cuit: Precautions for the repair, page 30A-2) .

WARNING

Switch off the vehicle ignition so as not to activate

the hydraulic unit solenoid valves when bleeding the

brake circuit.

WARNING

The level must be between the « MIN » and

« MAX » markings on the reservoir.

115993

Note:

The new hydraulic unit is pre-filled.

When working on one of the following compo-

nents , position a pedal press to limit the outflow

of brake fluid and prevent any air from entering

the master cylinder and the circuits downstream

of the master cylinder:

-hydraulic unit,

-pipes between the hydraulic unit and brake cal-

lipers,

-brake hoses,

-brake calliper.

Remove the pedal press before carrying out the

braking system bleeding procedure.

Page 27 of 281

30A-23

GENERAL INFORMATION

Axle assemblies: Check

30A

aLock the slip plates of the lift.

aPosition the vehicle on a lift (see Vehicle: Towing

and lifting) .

aCheck the condition of the following components:

-track rods,

-axial ball joint linkages,

-subframe,

-lower arm rubber bushes,

-lower arm ball joints (see Front driveshaft lower

arm ball joint: Check) ,

-shock absorbers,

-tyres,

aCheck:

-the tyre size (see 35A, Wheels and tyres, Tyres:

Identification, page 35A-7) ,

-the tyre inflation pressure (see 35A, Wheels and

tyres, Tyre pressure: Identification, page 35A-

10) .

aPut the vehicle in the VODM position (vehicle in run-

ning order) (see 30A, General information, Under-

body heights: Adjustment value, page 30A-24) :

-tank full,

-vehicle empty (without luggage, etc.).

aConsult:

-the front axle geometry values (see 30A, General

information, Front axle assembly: Adjustment

values, page 30A-31) ,

-the rear axle geometry values (see 30A, General

information, Rear axle assembly: Adjustment

values, page 30A-38) .

aRefer to the user manual for the geometry tester.

aCheck the geometry using the geometry tester.

aIf there is an inconsistency between the manufactur-

er's values and the measured values:

aAdjust the front axle (see 30A, General informa-

tion, Front axle system: Adjustment, page 30A-

36)

Page 44 of 281

31A-1

FRONT AXLE COMPONENTS

Front brake pads: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

When replacing brake pads, be sure to replace the

pads on the opposite side.

REMOVAL

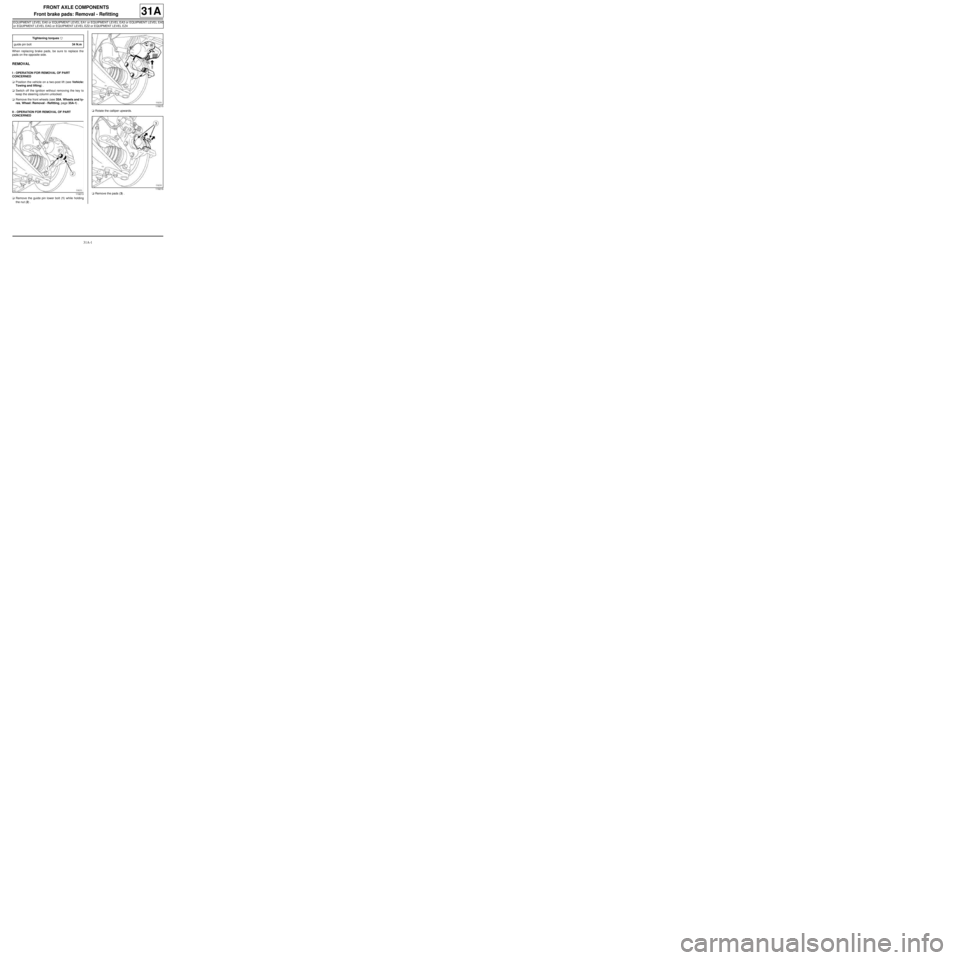

I - OPERATION FOR REMOVAL OF PART

CONCERNED

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) .

aSwitch off the ignition without removing the key to

keep the steering column unlocked.

aRemove the front wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the guide pin lower bolt (1) while holding

the nut (2) .aRotate the calliper upwards.

aRemove the pads (3) . Tightening torquesm

guide pin bolt34 N.m

119213

119215

119216

Page 46 of 281

31A-3

FRONT AXLE COMPONENTS

Front brake pads: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aSet the wheels straight ahead.

aRemove the front wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - REMOVAL OPERATION

aRemove the retaining spring (1) using a wide, flat-

blade screwdriver.

aMark the position of the cap on the base of the shock

absorber using a indelible pencil.

aUnclip the cap from the base of the shock absorber. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

indelible pencil

Tightening torquesm

guide pin bolts28 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see Front axle components: Precautions for

the repair) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the surrounding

components.

145122

Page 49 of 281

31A-6

FRONT AXLE COMPONENTS

Front brake hose: Removal - Refitting

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) .

aSet the wheels straight ahead.

aPosition a pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen the hose union (1) on the rigid pipe union.

aRemove the retaining (2) fork from the hose.

aTo avoid the premature damage of the brake hose

by friction, observe the following procedure before

unclipping the hose:

aSet the wheels straight ahead.

aMark the position of the cap on the base of the shock

absorber using a permanent marker.

aUnclip the brake hose cap (3) from the shock ab-

sorber base.

aLoosen the hose union on the brake calliper.

aRemove the brake hose.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

a Equipment required

pedal press

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see Front axle components: Precautions

for the repair) .

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

135304

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

Page 51 of 281

31A-8

FRONT AXLE COMPONENTS

Front brake calliper: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) .

aFit the pedal press to the brake pedal to limit the

outflow of brake fluid.

aUnlock the steering column.

aRemove the front wheel on the side concerned (see

35A, Wheels and tyres, Wheel: Removal - Refit-

ting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnlock the brake hose (1) on the brake calliper.

aRemove the brake pads (see 31A, Front axle com-

ponents, Front brake pads: Removal - Refitting,

page 31A-1) . Equipment required

pedal press

Tightening torquesm

guide pin bolts34 N.m

brake hose17 N.m

Note:

The callipers supplied as spare par ts are pre-filled

with br ake fluid.

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

119214

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

Page 53 of 281

31A-10

FRONT AXLE COMPONENTS

Front brake calliper: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

aFit a pedal press on the brake pedal to limit the out-

flow of brake fluid.II - REMOVAL OPERATION

aSlightly loosen the brake hose union (1) of the calli-

per.

aRemove:

-the brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) ,

-the brake hose union on the brake calliper.

aFit blanking plugs on the ends of the openings.

aRemove the brake calliper.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck:

-the condition of the calliper gaiter,

-the condition of the calliper piston; replace it if there

are deep scratches or cracks.

aReplace any faulty parts (see 31A, Front axle com-

ponents, Front brake calliper: Repair, page 31A-

12) .

aClean using a wire brush and BRAKE CLEANER

(see ) (04B, Consumables - Products):

-the calliper mounting,

-the calliper. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

pedal press

Tightening torquesm

brake hose union13 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see Front axle components: Precautions for

the repair) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

146248

Page 55 of 281

31A-12

FRONT AXLE COMPONENTS

Front brake calliper: Repair

31A

REPAIR

I - REPAIR PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aPosition the pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove:

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front brake calliper (see 31A, Front axle com-

ponents, Front brake calliper: Removal - Refit-

ting, page 31A-8) .II - REPAIR OPERATION FOR PART CONCERNED

aRemove the piston using compressed air, making

sure to insert a wooden block between the calliper

and the piston to avoid damaging it. Any trace of im-

pact on the end panel will render the piston unfit for

use.

aRemove the dust seal.

aRemove the rectangular section seal from the calli-

per groove with a round edged spring blade (feeler

gauge).

aClean the parts using methylated spirit. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

pedal press

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see Front axle components: Precautions

for the repair) .

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

81546

81545

WARNING

The whole calliper must systematically be

replaced if there are any scratches in the calliper

bore.

Page 57 of 281

31A-14

FRONT AXLE COMPONENTS

Front brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) .aRemove the guide pin upper bolt (1) while holding

the nut (2) .

aHang the brake calliper on the shock absorber

spring using a safety strap(s). Equipment required

safety strap(s)

Tightening torquesm

brake calliper mounting

bolts100 N.m

guide pin upper bolt29 N.m

119218

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.