tow RENAULT TWINGO 2009 2.G Chasiss Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 132 of 281

33A-34

REAR AXLE COMPONENTS

Rear stub axle carrier: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the rear wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .aUnclip the parking brake cable from the calliper at

(1) .

aRemove:

-the brake calliper mounting bolts (2) ,

-the "brake calliper mounting - brake calliper" as-

sembly.

aAttach the "brake calliper mounting - brake calliper"

assembly to the suspension spring.

aRemove the rear brake disc (see 33A, Rear axle

components, Rear brake disc: Removal - Refit-

ting, page 33A-11) . Equipment required

component jack

Tightening torquesm

new bolts of the rear

stub axle carrier53 N.m

lower bolt of the rear

shock absorber105 N.m

new bolts of the brake

calliper mounting105 Nm

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

Page 135 of 281

33A-37

REAR AXLE COMPONENTS

Complete rear axle system: Removal - Refitting

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRelease the parking brake.

aFit the pedal press on the brake pedal to limit the

amount of brake fluid running out.

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

1 - Removal

aRemove:

-the heat shield clips (1) ,

-the heat shield.

aUndo the adjusting screw (2) of the parking brake

compensator.

aRemove the parking brake compensator brake ca-

bles. Special tooling required

Mot. 1390Suppor t for removal - refitting

of engine - gearbox assembly

Equipment required

pedal press

safety strap(s)

Tightening torquesm

rear axle bearing bolts62 Nm

brake hose lower unions17 Nm

119435

119436

Page 141 of 281

35A-1

WHEELS AND TYRES

Wheel: Removal - Refitting

35A

The removal - refitting procedure is the same for all

wheels.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove the trim.

aPosition the wheel so that the valve is at the top.

aMark the position of the wheel on the hub.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen the wheel bolts with the wheel on the

ground.

aRaise the lift.

aRemove:

-the wheel bolts,

-the wheel.

If the wheel cannot be removed after the bolt has

been undone:

aPosition all the wheel bolts.

aTighten the wheel bolts to bring all the bolt heads

into contact with the wheel.

aUndo the wheel bolts by one turn.aStrike around the edge of the tyre walls (1) several

times using a mallet on the inner and outer surfaces

of the wheel to detach the wheel.

aRemove:

-the wheel bolts,

-the wheel. Note:

This mark is required in order to:

-Note the original position of the wheel on the

hub,

-perform the balancing operation.

Note:

Use sockets with protective sheaths in order to

avoid scratching the alloy wheel rims.

100682

Page 144 of 281

35A-4

WHEELS AND TYRES

Wheel: Balancing

35A

I - PREREQUISITES FOR WHEEL BALANCING

aWheel balancing is a measurement operation.

Several conditions must be met to achieve a reliable

result in a single operation.

The wheel balancer must be installed in accordance

with the manufacturer's instructions.

It is essential to calibrate the balancer according to

the frequency recommended by the manufacturer.

Do not grease the threaded shaft.

Check the condition of the supports, centring com-

ponents and mountings.

Replace any faulty parts (see manufacturer's in-

structions).

The wheel and the wheel balancer must be clean.

Driver's perception

aIf the wheels are not correctly balanced this causes

the steering wheel and/or the vehicle floor to vibrate.

These vibrations appear between 54 mph (90 km/h)

and 90 mph (150 km/h).

II - BALANCING PREPARATION OPERATION

aAdjust the tyre pressure (see 35A, Wheels and ty-

res, Tyre pressure: Identification, page 35A-10) .

aAlways carry out a road test for a minimum distance

of 1 mile (2 km) before balancing the wheels, in or-

der to remove any flat spots on the tread caused by

the vehicle being immobilised.

aActions to be carried out immediately after the test

drive:

-Position the vehicle on a two-post vehicle lift (see

Vehicle: Towing and lifting) ,

-raise the vehicle,

-leave the four wheels hanging free,

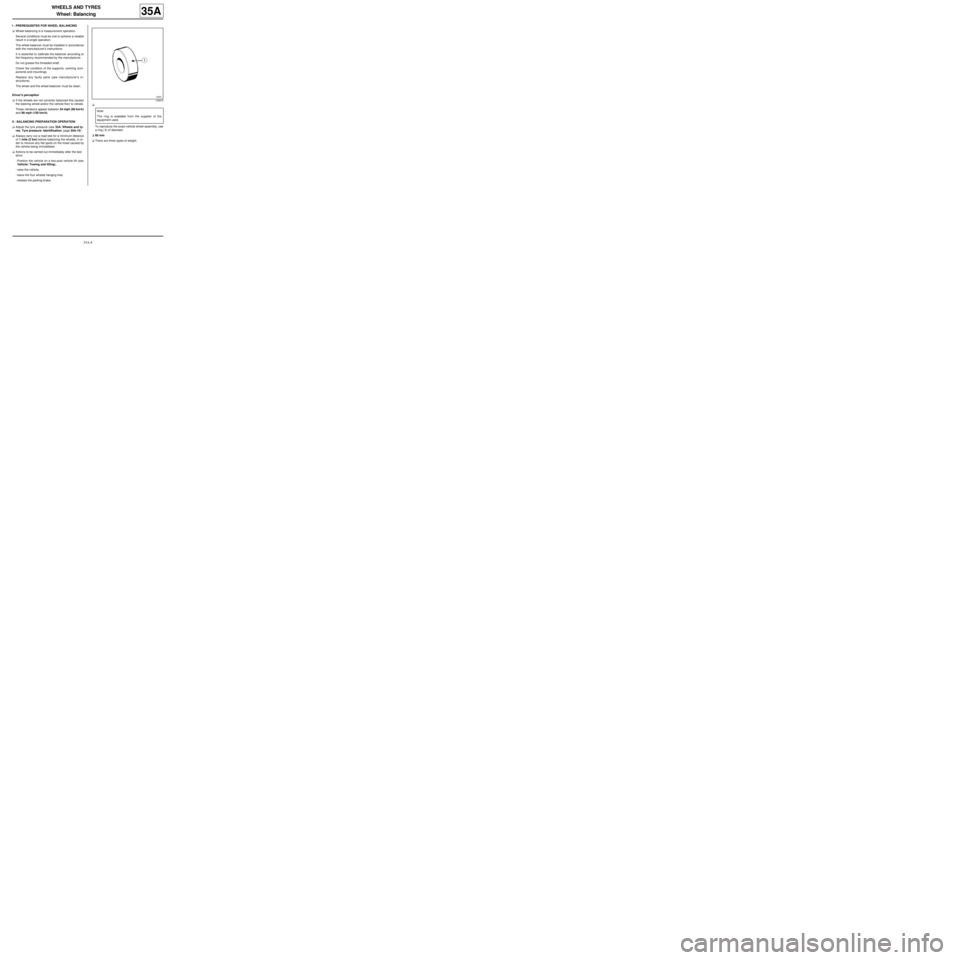

-release the parking brake.a

To reproduce the exact vehicle wheel assembly, use

a ring (1) of diameter:

a60 mm

aThere are three types of weight:

105870

Note:

The ring is available from the supplier of the

equipment used.

Page 148 of 281

35A-8

WHEELS AND TYRES

Tyres: Removal - Refitting

35A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the wheel in question (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the balance weights,

-the valve mechanism.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDetach:

-the bead from the outside of the tyre, starting with

the side opposite the valve,

-the bead from the inside of the tyre.aPosition the tyre lever approximately 15 cm from the

valve on the outside of the wheel rim in order to re-

move the exterior bead from the tyre.

aRemove the exterior bead of the tyre, finishing at the

valve.

aPosition the tyre lever approximately 15 cm from the

valve on the outside of the wheel rim in order to re-

move the bead from inside the tyre.

aRemove the interior bead of the tyre, finishing at the

valve.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Tyre valve

aLubricate the two tyre beads correctly using the

TYRE PASTE (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts).

II - REFITTING OPERATION FOR PART

CONCERNED

aEngage the lower tyre bead approximately 15 cm af-

ter the valve.

aFinish fitting the tyre at the valve.

aFit the exterior bead approximately 15 cm after the

valve using the tyre lever.

aInflate the tyre to 3.5 bar to press the tyre beads

against the wheel rim.

18884

18885

Page 152 of 281

36A-1

STEERING ASSEMBLY

Steering box: Removal - Refitting

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRemove:

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the « subframe - front driveshaft lower arm - power-

assisted steering box - front anti-roll bar » assem-

bly (see 31A, Front axle components, Front axle

subframe: Removal - Refitting, page 31A-43) .

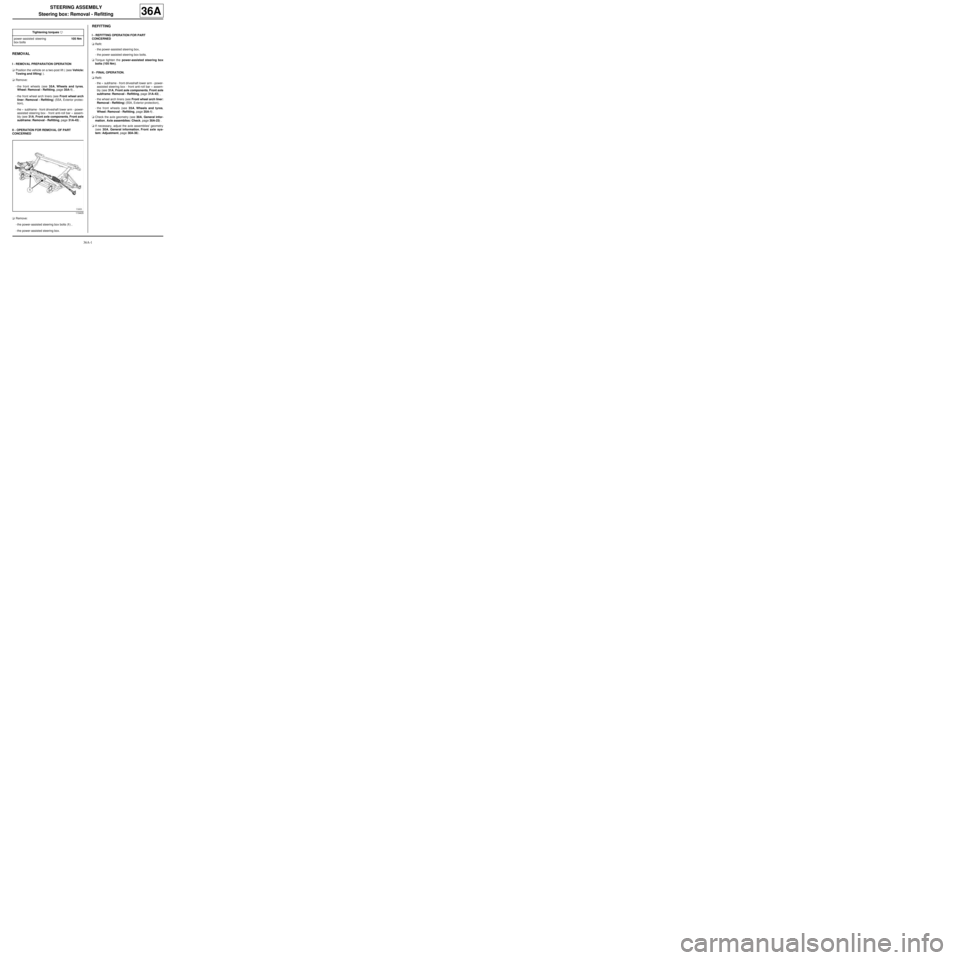

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the power-assisted steering box bolts (1) ,

-the power-assisted steering box.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the power-assisted steering box,

-the power-assisted steering box bolts.

aTorque tighten the power-assisted steering box

bolts (105 Nm).

II - FINAL OPERATION.

aRefit:

-the « subframe - front driveshaft lower arm - power-

assisted steering box - front anti-roll bar » assem-

bly (see 31A, Front axle components, Front axle

subframe: Removal - Refitting, page 31A-43) ,

-the wheel arch liners (see Front wheel arch liner:

Removal - Refitting) (55A, Exterior protection),

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aCheck the axle geometry (see 30A, General infor-

mation, Axle assemblies: Check, page 30A-23) .

aIf necessary, adjust the axle assemblies' geometry

(see 30A, General information, Front axle sys-

tem: Adjustment, page 30A-36) . Tightening torquesm

power-assisted steering

box bolts105 Nm

119405

Page 153 of 281

36A-2

STEERING ASSEMBLY

Track rod: Removal - Refitting

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

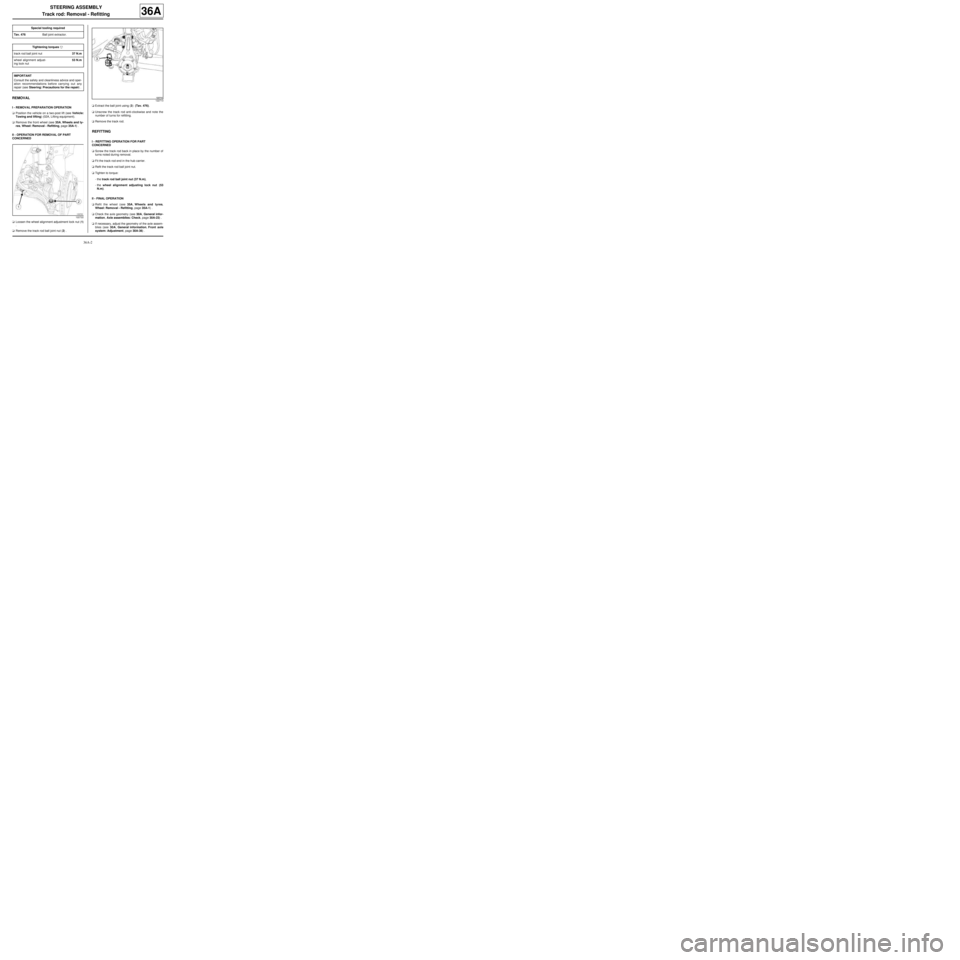

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLoosen the wheel alignment adjustment lock nut (1)

.

aRemove the track rod ball joint nut (2) .aExtract the ball joint using (3) (Tav. 476).

aUnscrew the track rod anti-clockwise and note the

number of turns for refitting.

aRemove the track rod.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aScrew the track rod back in place by the number of

turns noted during removal.

aFit the track rod end in the hub carrier.

aRefit the track rod ball joint nut.

aTighten to torque:

-the track rod ball joint nut (37 N.m),

-the wheel alignment adjusting lock nut (53

N.m).

II - FINAL OPERATION

aRefit the wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aCheck the axle geometry (see 30A, General infor-

mation, Axle assemblies: Check, page 30A-23) .

aIf necessary, adjust the geometry of the axle assem-

blies (see 30A, General information, Front axle

system: Adjustment, page 30A-36) . Special tooling required

Tav. 476Ball joint extractor.

Tightening torquesm

track rod ball joint nut37 N.m

wheel alignment adjust-

ing lock nut53 N.m

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see Steering: Precautions for the repair) .

122722

122713

Page 155 of 281

36A-4

STEERING ASSEMBLY

Axial ball joint linkage: Removal - Refitting

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

a

aApply the before repair procedure using the dia-

gnostic tool:

-connect the diagnostic tool,

-select the airbag computer,

-go to repair mode,

-apply the "before repair procedure".

aRemove:

-the front wheel on the side in question (see 35A,

Wheels and tyres, Wheel: Removal - Refitting,

page 35A-1) ,

-the track rod (see 36A, Steering assembly, Track

rod: Removal - Refitting, page 36A-2) ,

-the steering box gaiter (see 36A, Steering assem-

bly, Steering box gaiter: Removal - Refitting,

page 36A-16) .

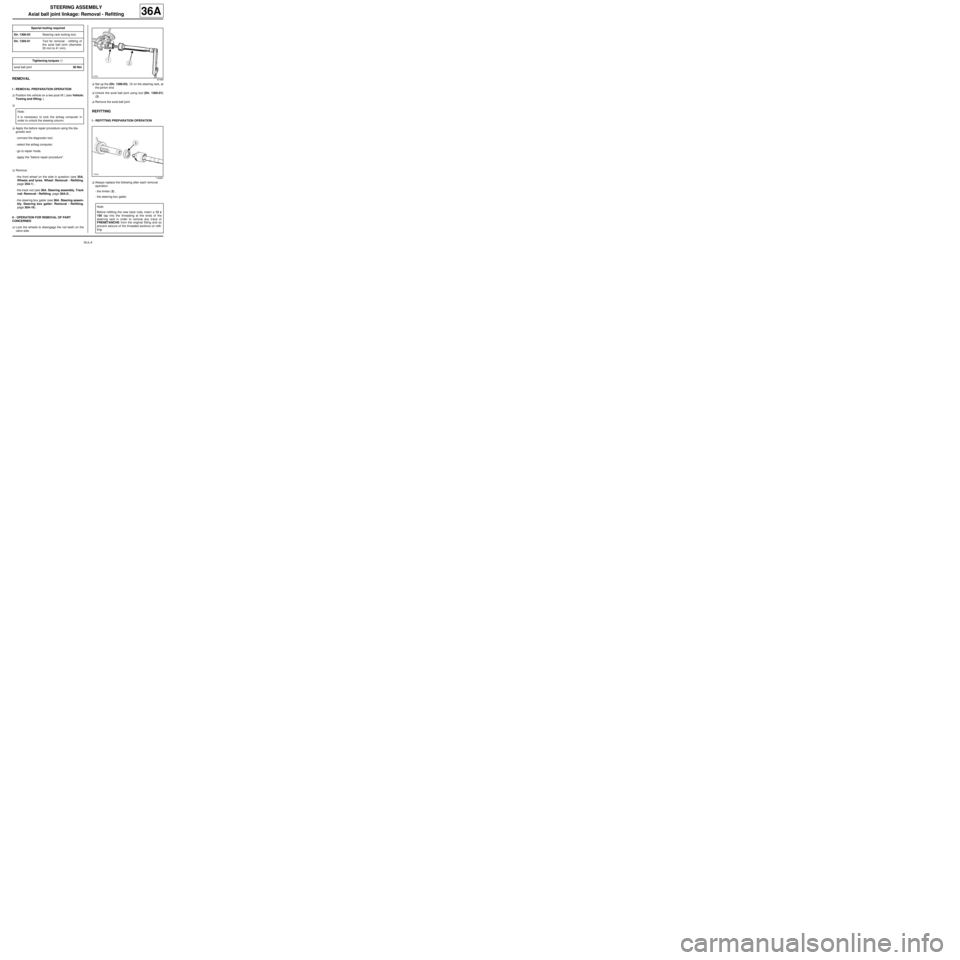

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLock the wheels to disengage the rod teeth on the

valve side.aSet up the (Dir. 1306-03) (1) on the steering rack, at

the pinion end.

aUnlock the axial ball joint using tool (Dir. 1305-01)

(2) .

aRemove the axial ball joint.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the following after each removal

operation:

-the limiter (3) ,

-the steering box gaiter. Special tooling required

Dir. 1306-03Steering r ack locking tool.

Dir. 1305-01Tool for removal - refitting of

the axial ball joint (diameter

35 mm to 41 mm).

Tightening torquesm

axial ball joint50 Nm

Note:

It is necessary to lock the airbag computer in

order to unlock the steering column.

97469

116991

Note:

Before refitting the new track rods, inser t a 12 x

100 tap into the threading at the ends of the

steer ing rack in order to remove any trace of

FRENETANCHE from the original fitting and so

pre vent seizure of the threaded sections on refit-

ting.

Page 167 of 281

36A-16

STEERING ASSEMBLY

Steering box gaiter: Removal - Refitting

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the track rod, (see 36A, Steering assembly,

Track rod: Removal - Refitting, page 36A-2)

-the wheel alignment adjusting lock nut.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

aRemove the gaiter retaining clip (1)

aCut the gaiter retaining clip (2) .

aRemove the gaiter (3) .

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace:

-the steering box gaiter,

-the retaining clips.

aClean the contact surfaces between the steering box

and the gaiter using SURFACE CLEANER (see Ve-

hicle: Parts and consumables for the repair) .

aCoat the gaiter bearing face on the axial ball joint

with SILICONE LUBRICANT (see Vehicle: Parts

and consumables for the repair) to prevent the

gaiter from twisting.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new steering box gaiter,

-new retaining clips.

III - FINAL OPERATION.

aRefit:

-the wheel alignment adjustment lock nut,

-the track rod, (see 36A, Steering assembly,

Track rod: Removal - Refitting, page 36A-2)

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aCheck the axle geometry (see 30A, General infor-

mation, Axle assemblies: Check, page 30A-23) .

aIf necessary, adjust the axle assemblies' geometry

(see 30A, General information, Front axle sys-

tem: Adjustment, page 30A-36) .

105678

Note:

When removing the steering gaiter, blast the gai-

ter surfaces with compressed air to eliminate any

impurities that could enter the steering box.

Note:

Be sure to centre the steer ing to ensure the air in

the gaiters is equalised.

Note:

Be careful not to damage the gaiters: risk of irre-

versible damage.

Page 168 of 281

36A-17

STEERING ASSEMBLY

Bulkhead seal: Removal - Refitting

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRemove:

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front wheel arch liners ( (see Front wheel arch

liner: Removal - Refitting) ),

-the « subframe - front driveshaft lower arm - power-

assisted steering box - front anti-roll bar » assem-

bly (see 31A, Front axle components, Front axle

subframe: Removal - Refitting, page 31A-43) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDetach the steering box bulkhead seal (1) .

REFITTING

I - REFITTING PREPARATIONS OPERATION

aDegrease the surface in contact with the bulkhead

seal using SURFACE CLEANER.

II - REFITTING OPERATION FOR PART

CONCERNED

aRemove the safety film from the adhesive section of

the new bulkhead seal.

aBond the new bulkhead seal on the steering box.III - FINAL OPERATION.

aRefit:

-the « subframe - front driveshaft lower arm - power-

assisted steering box - front anti-roll bar » assem-

bly (see 31A, Front axle components, Front axle

subframe: Removal - Refitting, page 31A-43) ,

-the front wheel arch liners ( (see Front wheel arch

liner: Removal - Refitting) ),

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

119653