tow RENAULT TWINGO 2009 2.G Chasiss Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 86 of 281

31A-43

FRONT AXLE COMPONENTS

Front axle subframe: Removal - Refitting

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

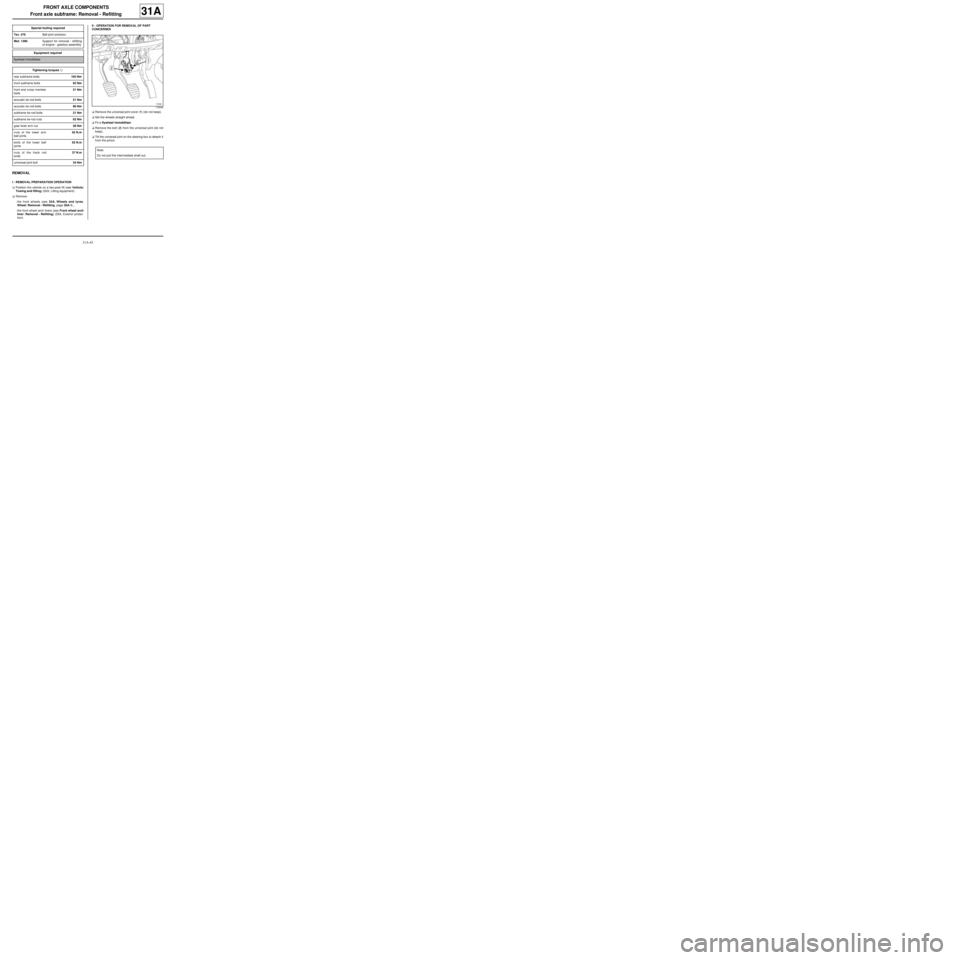

tion).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the universal joint cover (1) (do not keep).

aSet the wheels straight ahead.

aFit a flywheel immobiliser.

aRemove the bolt (2) from the universal joint (do not

keep).

aTilt the universal joint on the steering box to detach it

from the pinion. Special tooling required

Tav. 476Ball joint extractor.

Mot. 1390Suppor t for removal - refitting

of engine - gearbox assembly

Equipment required

flywheel immobiliser

Tightening torquesm

rear subframe bolts105 Nm

front subframe bolts62 Nm

front end cross member

bolts21 Nm

acoustic tie-rod bolts21 Nm

acoustic tie-rod bolts90 Nm

subframe tie-rod bolts21 Nm

subframe tie-rod nuts62 Nm

gear lever arm nut28 Nm

nuts of the lower arm

ball joints62 N.m

bolts of the lower ball

joints62 N.m

nuts of the track rod

ends37 N.m

universal joint bolt24 Nm

119544

Note:

Do not pull the intermediate shaft out.

Page 95 of 281

31A-52

FRONT AXLE COMPONENTS

Front anti-roll bar: Removal - Refitting

EQ UIPMENT LEVEL EA0 or EQUIPMENT LEVEL EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT LEVEL EA5

or EQUIPMENT LEVEL EAG or EQUIPMENT LEVEL EZ2 or EQUIPMENT LEVEL EZ4

31A

Anti-roll bar specifications:

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front axle subframe (see 31A, Front

axle components, Front axle subframe: Removal

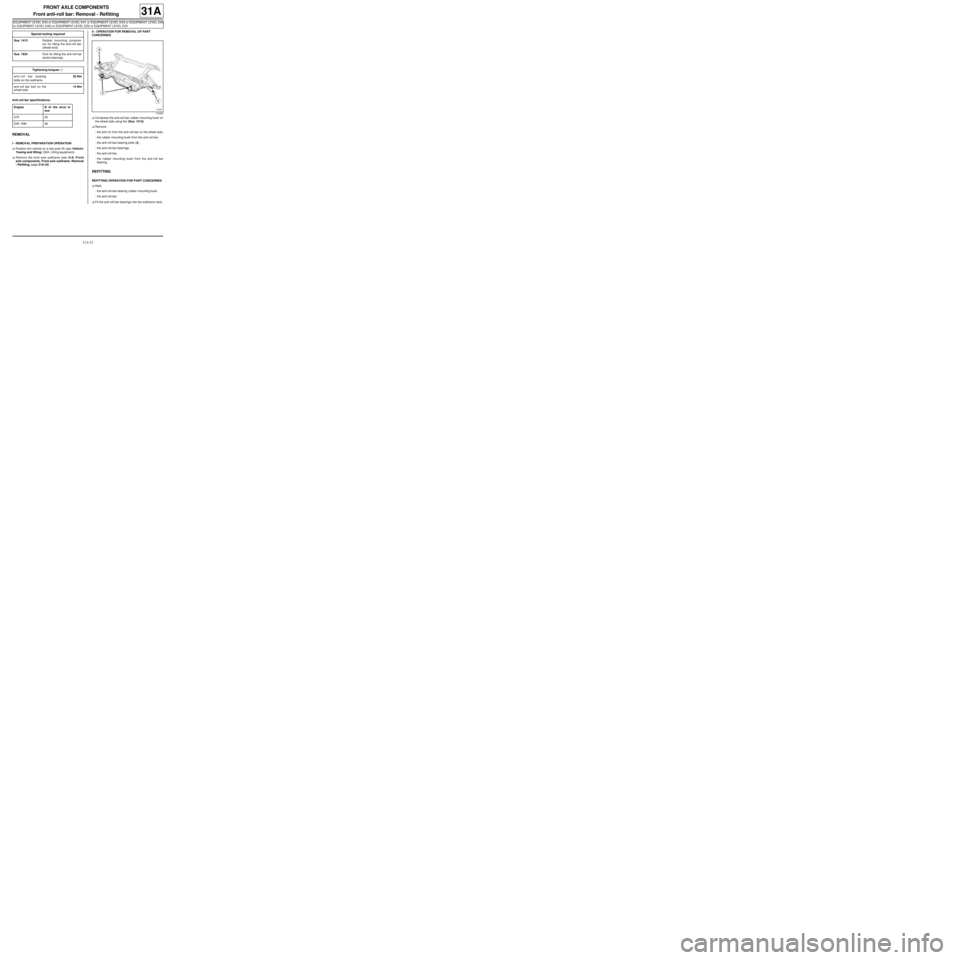

- Refitting, page 31A-43) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aCompress the anti-roll bar rubber mounting bush on

the wheel side using the (Sus. 1413).

aRemove:

-the bolt (1) from the anti-roll bar on the wheel side,

-the rubber mounting bush from the anti-roll bar,

-the anti-roll bar bearing bolts (2) ,

-the anti-roll bar bearings,

-the anti-roll bar,

-the rubber mounting bush from the anti-roll bar

bearing.

REFITTING

REFITTING OPERATION FOR PART CONCERNED

aRefit:

-the anti-roll bar bearing rubber mounting bush,

-the anti-roll bar.

aFit the anti-roll bar bearings into the subframe neck. Special tooling required

Sus. 1413Rubber mounting compres-

sor for fitting the anti-roll bar.

(wheel end).

Sus. 1824Fork for fitting the anti-roll bar

centre bearings.

Tightening torquesm

anti-roll bar bearing

bolts on the subframe35 Nm

anti-roll bar bolt on the

wheel side14 Nm

Engine Ø of the strut in

mm

D7F 25

D4F, K9K 26

119406

Page 97 of 281

31A-54

FRONT AXLE COMPONENTS

Front anti-roll bar: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

Anti-roll bar specifications:

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the wheel arch liners (see Front wheel arch liner:

Removal - Refitting) (55A, Exterior protection),

-the front axle subframe (see 31A, Front axle com-

ponents, Front axle subframe: Removal - Refit-

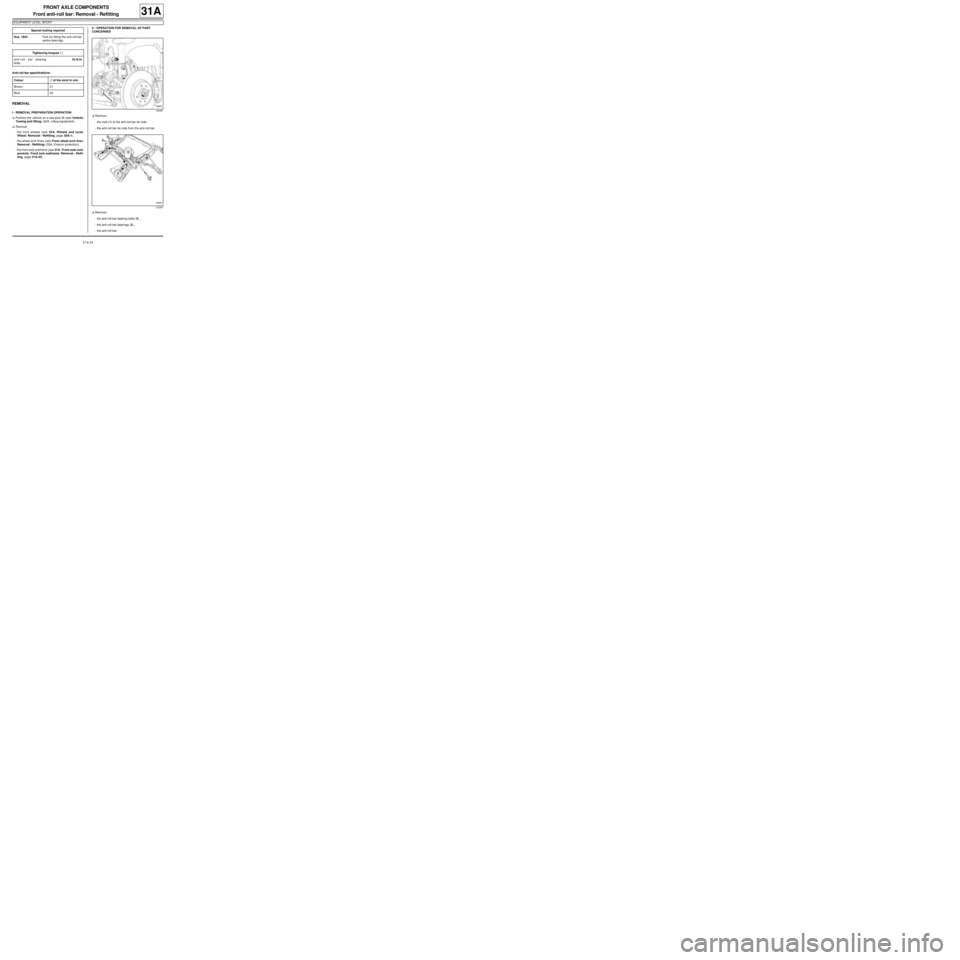

ting, page 31A-43) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the nuts (1) of the anti-roll bar tie rods,

-the anti-roll bar tie rods from the anti-roll bar.

aRemove:

-the anti-roll bar bearing bolts (2) ,

-the anti-roll bar bearings (3) ,

-the anti-roll bar, Special tooling required

Sus. 1824Fork for fitting the anti-roll bar

centre bearings.

Tightening torquesm

anti-roll bar bearing

bolts35 N.m

Colour∅ of the strut in mm

Brown 21

Blue 20132461

132457

Page 99 of 281

33A-1

REAR AXLE COMPONENTS

Rear brake pads: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

When replacing brake pads, be sure to replace the

pads on the opposite side.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove the rear wheels (see 35A, Wheels and ty-

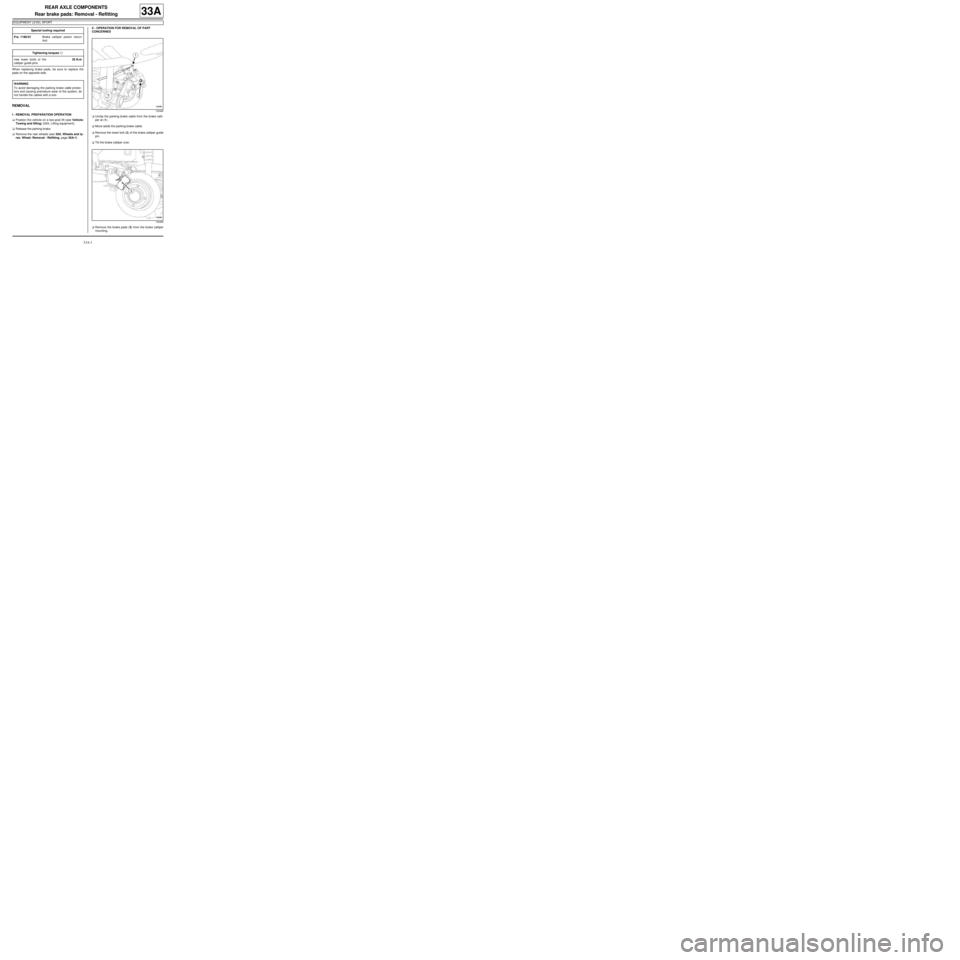

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip the parking brake cable from the brake calli-

per at (1) .

aMove aside the parking brake cable.

aRemove the lower bolt (2) of the brake calliper guide

pin.

aTilt the brake calliper over.

aRemove the brake pads (3) from the brake calliper

mounting. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Tightening torquesm

new lower bolts of the

calliper guide pins35 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

132466

Page 102 of 281

33A-4

REAR AXLE COMPONENTS

Rear brake hose: Removal - Refitting

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aFit the pedal press to the brake pedal to limit the

outflow of brake fluid.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUndo the rigid pipe unions (1) on the rear brake hose

concerned.

aRemove the rear brake hose concerned.

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the rear brake hose concerned,

-the rigid brake pipe unions on the rear brake hose

concerned.

aScrew on the rigid brake pipe unions on the rear

brake hose concerned without tightening them.

aTorque tighten the rigid pipe unions on the rear

brake hose concerned ( 17 Nm).

III - FINAL OPERATION.

aRemove the pedal press from the brake pedal to

limit the outflow of brake fluid.

aBleed the brake circuit (see 30A, General informa-

tion, Braking circuit: Bleed, page 30A-4) . Equipment requiredpedal press

Tightening torquesm

rigid pipe unions on the

rear brake hose con-

cerned17 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

119339

WARNING

In order to not damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

Page 103 of 281

33A-5

REAR AXLE COMPONENTS

Rear brake hose: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aPosition a pedal press on the brake pedal to limit

the outflow of brake fluid.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUndo the brake pipe unions (1) .

aRemove:

-the brake hose clips (2) ,

-the brake hoses.

REFITTING

I - REFITTING PREPARATION OPERATION

a

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the brake hose,

-the brake hose clip.

aTighten to torque:

-the brake hose union on the master cylinder

side (13 N.m), Equipment required

pedal press

Tightening torquesm

brake hose union on the

master cylinder side13 N.m

brake hose union on the

brake calliper side13 N.m

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

119339

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

Page 105 of 281

33A-7

REAR AXLE COMPONENTS

Rear brake calliper: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

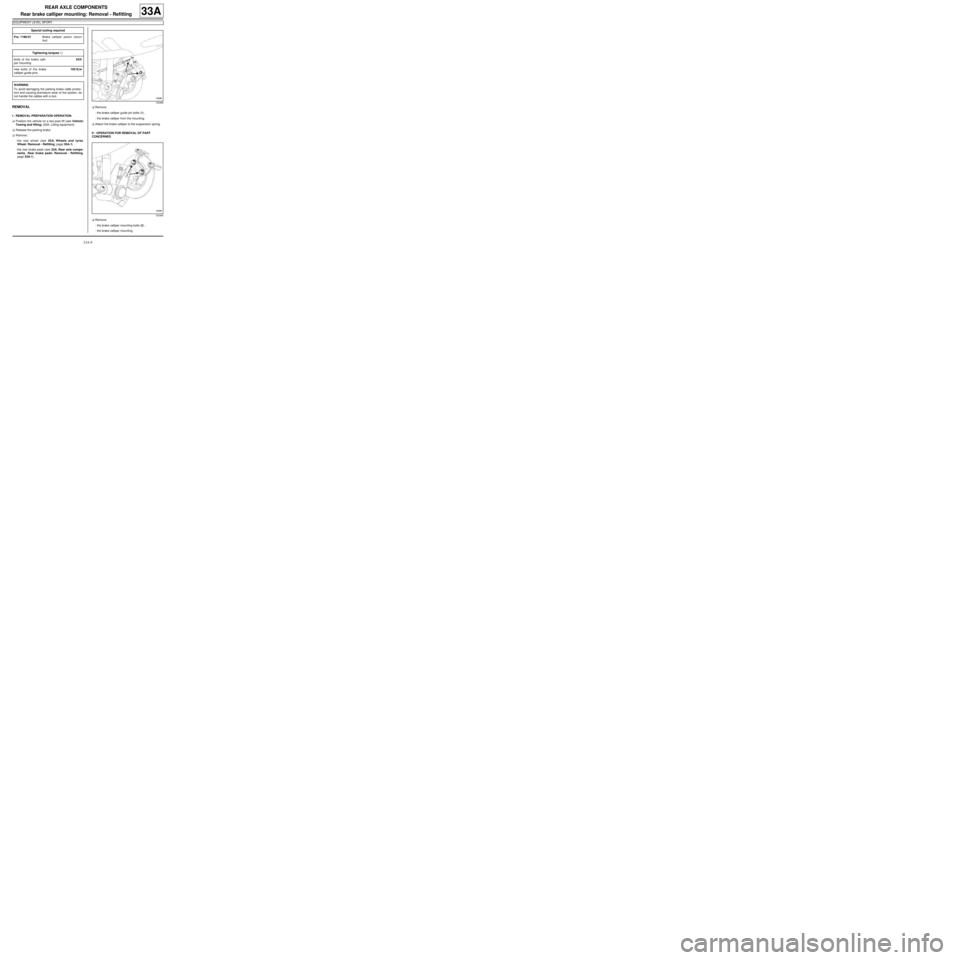

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aPosition a pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove the rear wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip the parking brake cable from the brake calli-

per at (1) .

aMove aside the parking brake cable.

aLoosen the calliper brake pipe union (2) .

aRemove:

-the brake calliper guide pin bolts (3) ,

-the brake calliper from the mounting,

-the union between the brake pipe and the calliper,

-the brake calliper.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper supports,

-the callipers.

aAlways replace the brake calliper guide pin bolts. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

pedal press

Tightening torquesm

new bolts on the brake

calliper guide pins35 N.m

brake pipe union on the

calliper13 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

Page 107 of 281

33A-9

REAR AXLE COMPONENTS

Rear brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove:

-the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake pads: Removal - Refitting,

page 33A-1) .aRemove:

-the brake calliper guide pin bolts (1) ,

-the brake calliper from the mounting.

aAttach the brake calliper to the suspension spring.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the brake calliper mounting bolts (2) ,

-the brake calliper mounting. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Tightening torquesm

bolts of the brake calli-

per mountingXXX

new bolts of the brake

calliper guide pins105 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

132465

Page 109 of 281

33A-11

REAR AXLE COMPONENTS

Rear brake disc: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

Brake discs cannot be reground. If there is excessive

scoring or wear, they will need to be replaced (see

30A, General information, Brake: Specifications,

page 30A-19) .

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake pads: Removal - Refitting,

page 33A-1) .aRemove:

-the brake calliper mounting bolts (1) ,

-the "brake calliper mounting - brake calliper" as-

sembly.

aAttach the "calliper mounting - brake calliper" to the

shock absorber spring.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the hub's nut cover (2) . Equipment required

par ts washer

Tightening torquesm

new hub nut175 N.m

brake calliper mounting

bolts105 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132467

132456

Page 111 of 281

33A-13

REAR AXLE COMPONENTS

Rear brake disc: Description

EQ UIPMENT LEVEL SPORT

33A

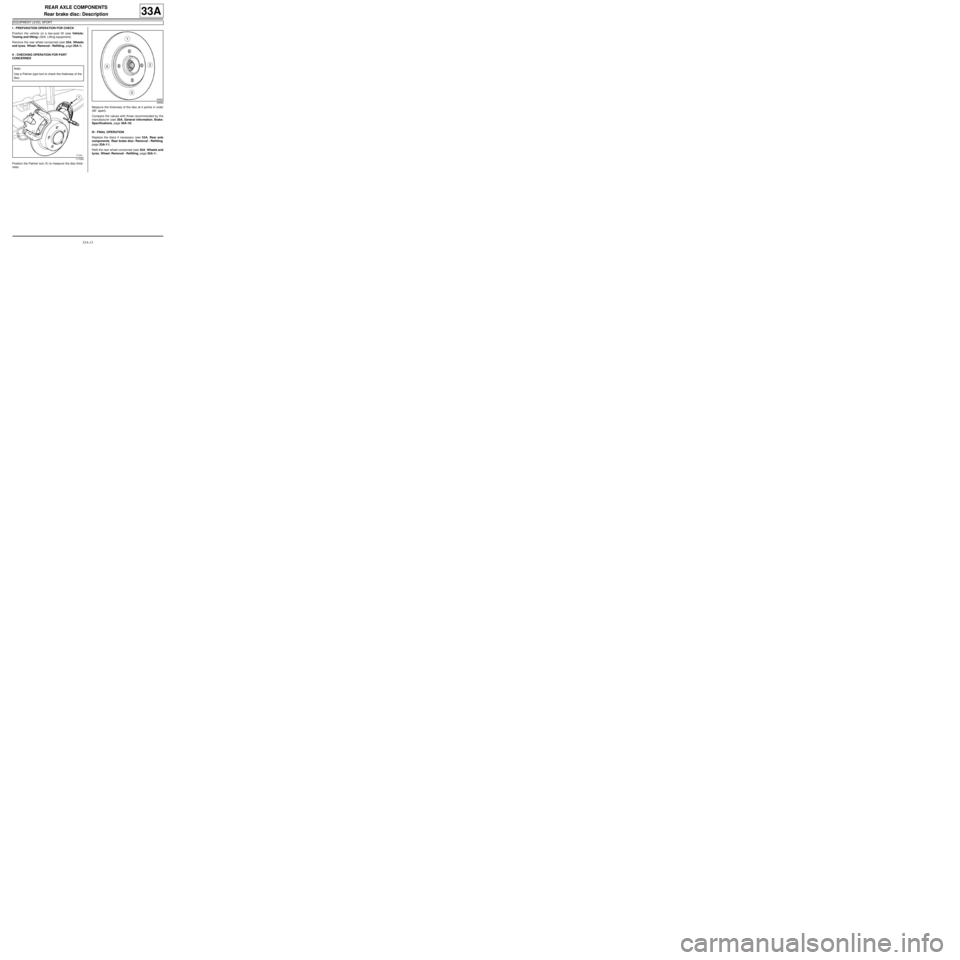

I - PREPARATION OPERATION FOR CHECK

Position the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

Remove the rear wheel concerned (see 35A, Wheels

and tyres, Wheel: Removal - Refitting, page 35A-1) .

II - CHECKING OPERATION FOR PART

CONCERNED

Position the Palmer tool (1) to measure the disc thick-

ness.Measure the thickness of the disc at 4 points in order

(90˚ apart).

Compare the values with those recommended by the

manufacturer (see 30A, General information, Brake:

Specifications, page 30A-19) .

III - FINAL OPERATION

Replace the discs if necessary (see 33A, Rear axle

components, Rear brake disc: Removal - Refitting,

page 33A-11) .

Refit the rear wheel concerned (see 35A, Wheels and

tyres, Wheel: Removal - Refitting, page 35A-1) . Note:

Use a Palmer type tool to check the thickness of the

disc.

117058

99582