torque RENAULT TWINGO 2009 2.G Engine And Peripherals Owners Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 217 of 652

11A-100

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

D4F, and 780 or 782

11A

aTighten the collar nut until the cover comes into con-

tact with the cylinder head.aRemove:

-the nut,

-the cover,

-the guard,

-the threaded rod.

aRefit:

-the camshaft pulley,

-the new camshaft pulley bolt (13) .

aTorque and angle tighten the camshaft pulley bolt

(30 N.m + 45˚ ±± ± ±

6˚) using the (Mot. 799-01).

19592-3

19592-419592-5

18722

Page 219 of 652

11A-102

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

D7F

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aPerform the following operations:

-drain the engine oil (see 10A, Engine and cylin-

der block assembly, Engine oil: Draining - Re-

filling, page 10A-22) ,

-drain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the ignition coil (see 17A, Ignition, Coils: Remov-

al - Refitting, page 17A-1) ,

-the air filter box (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the intake distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) .

aRemove:

-the bolt (1) from the camshaft sprocket using the

(Mot. 799-01),

-the camshaft sprocket,

-the cylinder head (see ) . Special tooling required

Mot. 799-01Timing gear wheel immobil-

iser.

Mot. 1381Camshaft seal extractor tool

30 x 42 x 7.

Mot. 1587Tool for fitting camshaft

"PTFE" seal.

Tightening torquesm

camshaft flange bolts12Nm

bolts of the cylinder

head23 N.m + 36˚

bolt of the camshaft

sprocket bolt45 Nm

124822

Page 221 of 652

11A-104

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

D7F

11A

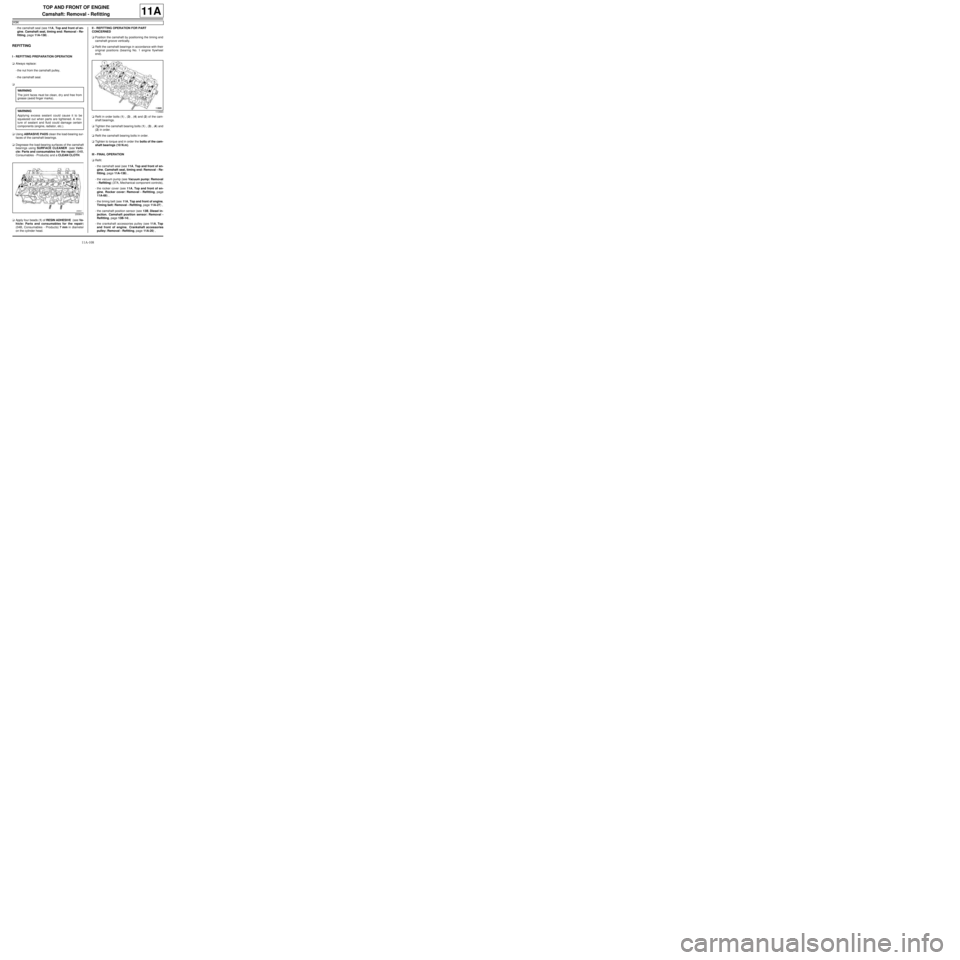

II - REFITTING OPERATION FOR PART

CONCERNED

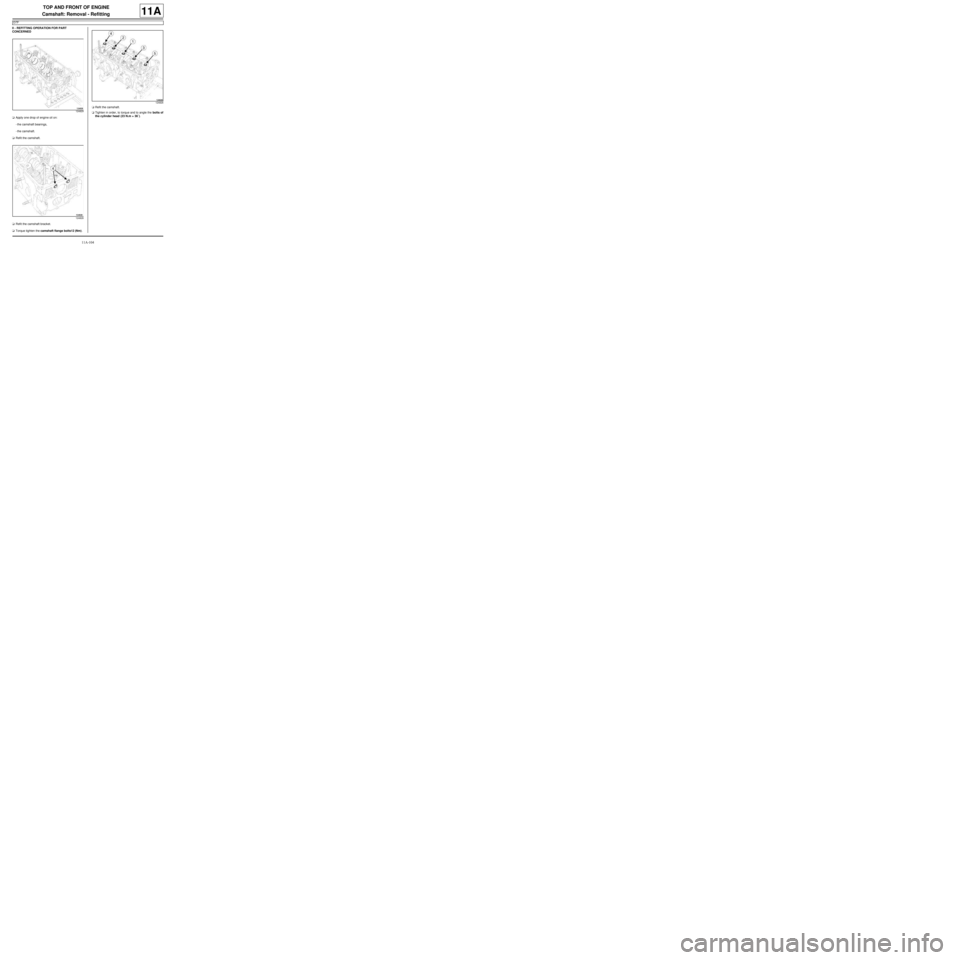

aApply one drop of engine oil on:

-the camshaft bearings,

-the camshaft.

aRefit the camshaft.

aRefit the camshaft bracket.

aTorque tighten the camshaft flange bolts12 (Nm).aRefit the camshaft.

aTighten in order, to torque and to angle the bolts of

the cylinder head (23 N.m + 36˚).

124829

124828

124826

Page 222 of 652

11A-105

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

D7F

11A

a

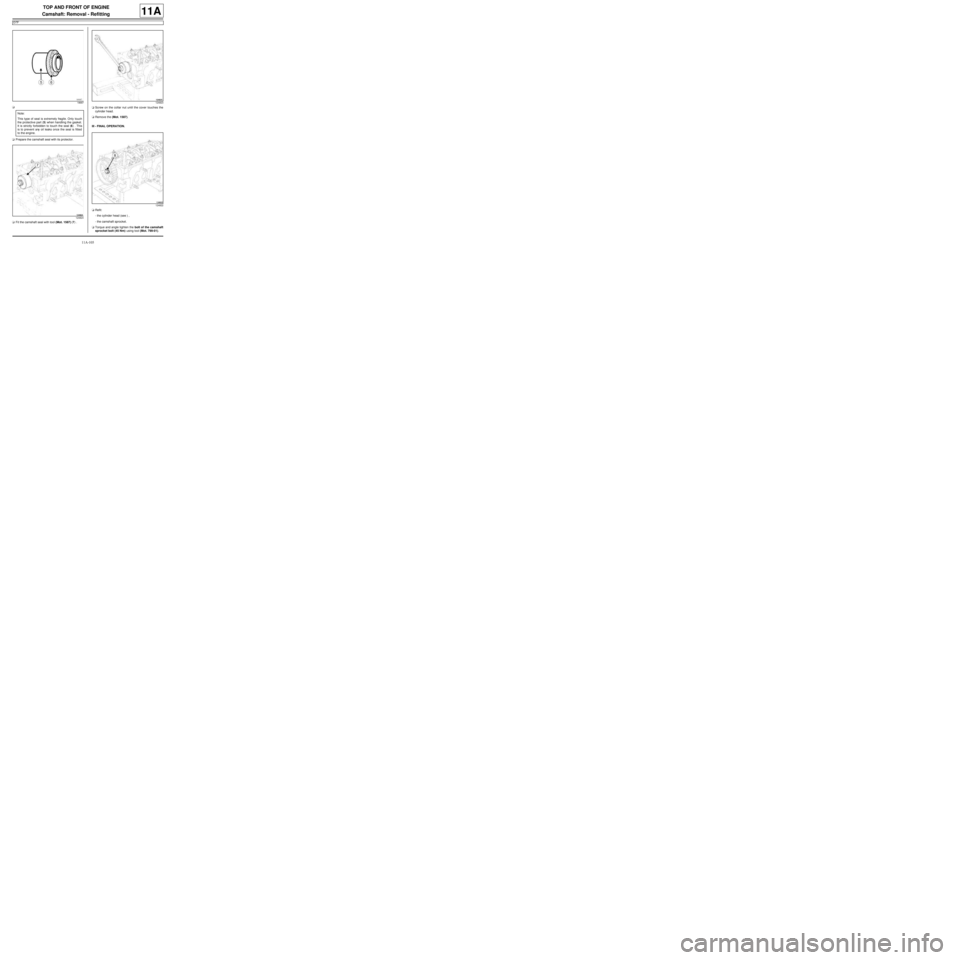

aPrepare the camshaft seal with its protector.

aFit the camshaft seal with tool (Mot. 1587) (7) .aScrew on the collar nut until the cover touches the

cylinder head.

aRemove the (Mot. 1587).

III - FINAL OPERATION.

aRefit:

-the cylinder head (see ) ,

-the camshaft sprocket.

aTorque and angle tighten the bolt of the camshaft

sprocket bolt (45 Nm) using tool (Mot. 799-01).

18687

Note:

This type of seal is extremely fragile. Only touch

the protective part (5) when handling the gasket.

It is strictly forbidden to touch the seal (6) . This

is to prevent any oil leaks once the seal is fitted

to the engine.

124824

124823

124822

Page 224 of 652

11A-107

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

K9K

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front engine cover.

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (80B, Headlights),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the vacuum pump (see Vacuum pump: Removal

- Refitting) (37A, Mechanical component controls).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

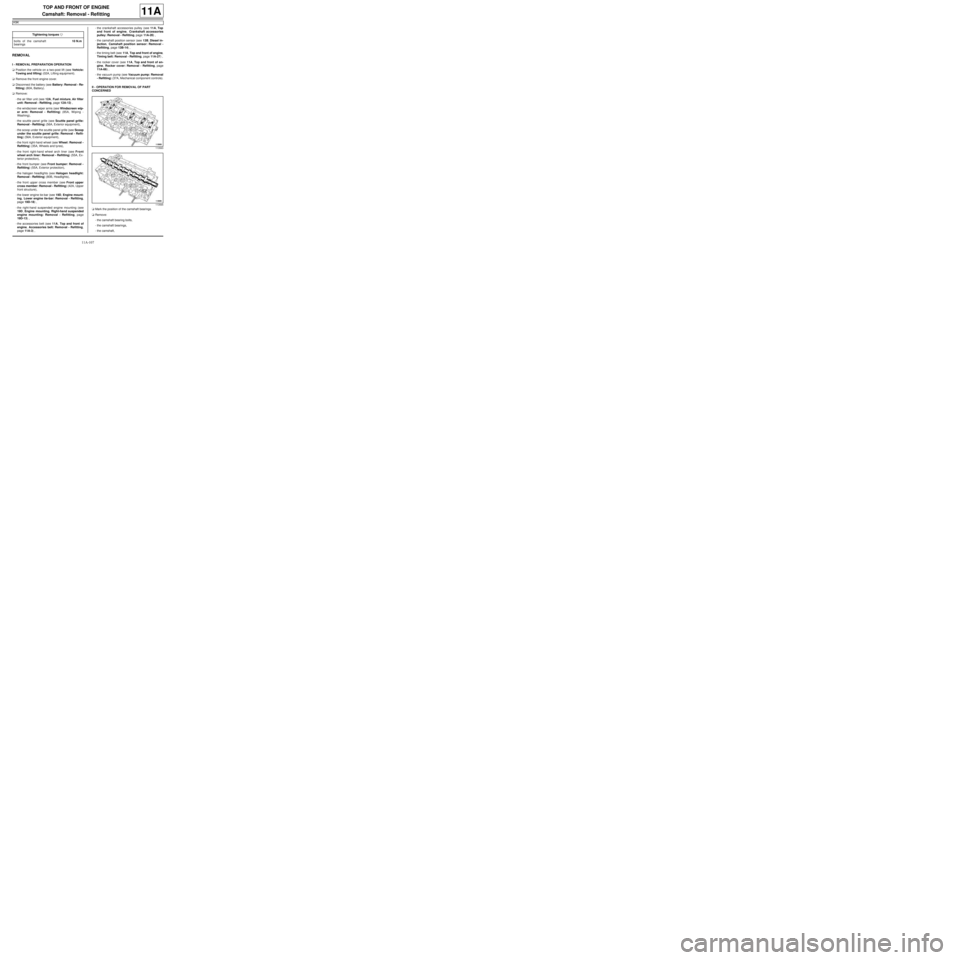

aMark the position of the camshaft bearings.

aRemove:

-the camshaft bearing bolts,

-the camshaft bearings,

-the camshaft, Tightening torquesm

bolts of the camshaft

bearings10 N.m

113563

113565

Page 225 of 652

11A-108

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

K9K

11A

-the camshaft seal (see 11A, Top and front of en-

gine, Camshaft seal, timing end: Removal - Re-

fitting, page 11A-138) .

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace:

-the nut from the camshaft pulley,

-the camshaft seal.

a

aUsing ABRASIVE PADS clean the load-bearing sur-

faces of the camshaft bearings.

aDegrease the load-bearing surfaces of the camshaft

bearings using SURFACE CLEANER (see Vehi-

cle: Parts and consumables for the repair) (04B,

Consumables - Products) and a CLEAN CLOTH.

aApply four beads (1) of RESIN ADHESIVE (see Ve-

hicle: Parts and consumables for the repair)

(04B, Consumables - Products) 7 mm in diameter

on the cylinder head.II - REFITTING OPERATION FOR PART

CONCERNED

aPosition the camshaft by positioning the timing end

camshaft groove vertically.

aRefit the camshaft bearings in accordance with their

original positions (bearing No. 1 engine flywheel

end).

aRefit in order bolts (1) , (3) , (4) and (2) of the cam-

shaft bearings.

aTighten the camshaft bearing bolts (1) , (3) , (4) and

(2) in order.

aRefit the camshaft bearing bolts in order.

aTighten to torque and in order the bolts of the cam-

shaft bearings (10 N.m).

III - FINAL OPERATION

aRefit:

-the camshaft seal (see 11A, Top and front of en-

gine, Camshaft seal, timing end: Removal - Re-

fitting, page 11A-138) ,

-the vacuum pump (see Vacuum pump: Removal

- Refitting) (37A, Mechanical component controls),

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) , WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

WARNING

Applying excess sealant could cause it to be

squeezed out when parts are tightened. A mix-

ture of sealant and fluid could damage certain

components (engine, radiator, etc.).

20064-1

113563

Page 227 of 652

11A-110

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

K4M

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the coils (see 17A, Ignition, Coils: Removal - Re-

fitting, page 17A-1) ,

-the throttle valve (see 12A, Fuel mixture, Throttle

valve: Removal - Refitting, page 12A-20) ,

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the oil decanter (see 11A, Top and front of en-

gine, Oil decanter: Removal - Refitting, page

11A-147) ,

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the camshaft dephaser (see 11A, Top and front of

engine, Camshaft dephaser: Removal - Refit-

ting, page 11A-135) ,

-the camshaft seals on the timing end (see 11A,

Top and front of engine, Camshaft seal, timing

end: Removal - Refitting, page 11A-138) ,

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) .

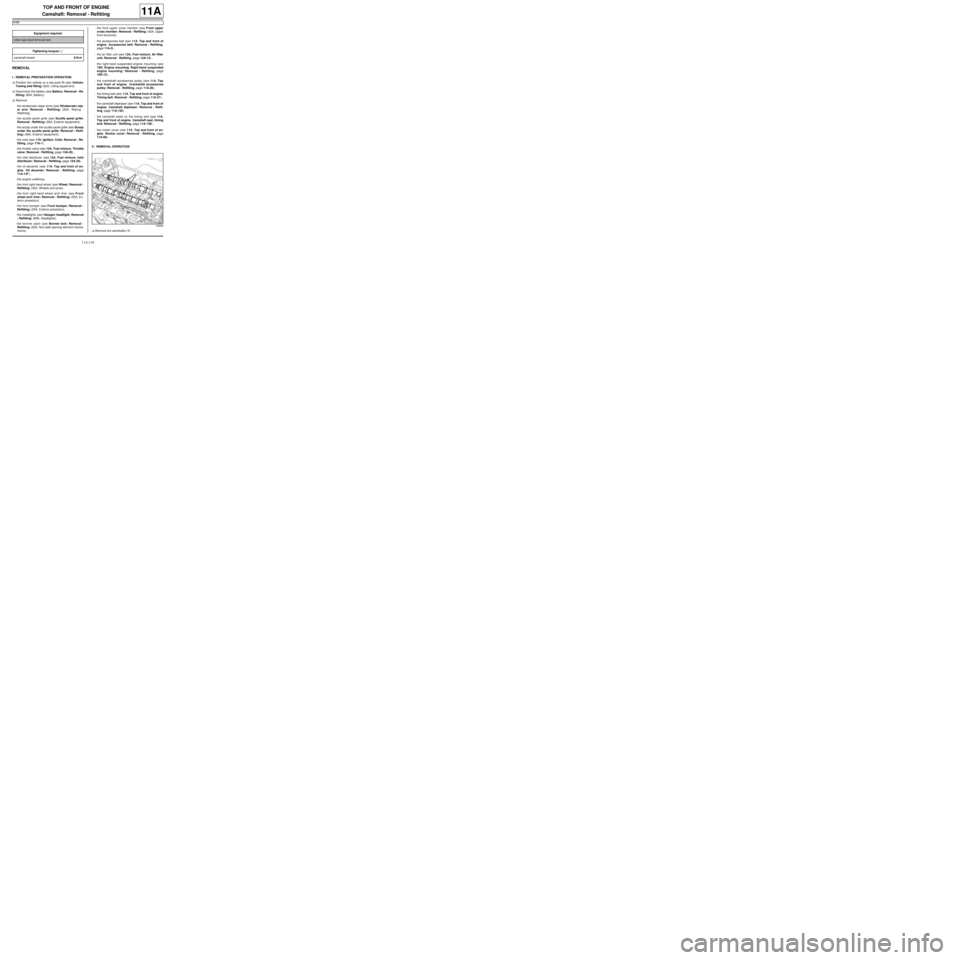

II - REMOVAL OPERATION

aRemove the camshafts (1) . Equipment required

roller-type stud removal tool

Tightening torquesm

camshaft dowel8 N.m

128685

Page 229 of 652

11A-112

TOP AND FRONT OF ENGINE

Camshaft: Removal - Refitting

K4M

11A

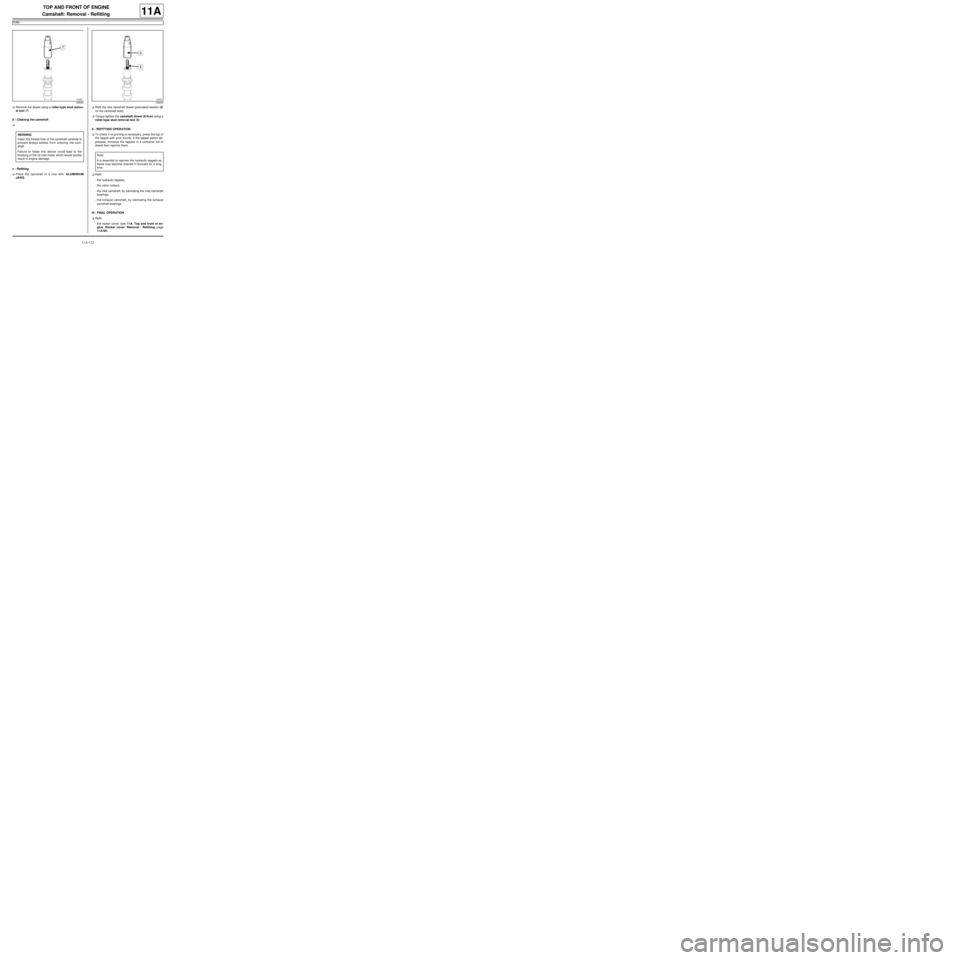

aRemove the dowel using a roller-type stud remov-

al tool (7) .

b - Cleaning the camshaft

a

c - Refitting

aPlace the camshaft in a vice with ALUMINIUM

JAWS.aRefit the new camshaft dowel (precoated section (8)

on the camshaft side).

aTorque tighten the camshaft dowel (8 N.m) using a

roller-type stud removal tool (9) .

II - REFITTING OPERATION

aTo check if re-priming is necessary, press the top of

the tappet with your thumb. If the tappet piston de-

presses, immerse the tappets in a container full of

diesel then reprime them.

aRefit:

-the hydraulic tappets,

-the valve rockers,

-the inlet camshaft, by lubricating the inlet camshaft

bearings,

-the exhaust camshaft, by lubricating the exhaust

camshaft bearings.

III - FINAL OPERATION

aRefit:

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

109050

WARNING

Clean the thread hole of the camshaft carefully to

prevent foreign bodies from entering the cam-

shaft.

Failure to follow this advice could lead to the

blocking of the oil inlet holes, which would quickly

result in engine damage.

109050

Note:

It is essential to repr ime the hydraulic tappets as

these may become drained if removed for a long

time.

Page 231 of 652

11A-114

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K9K

11A

REMOVAL

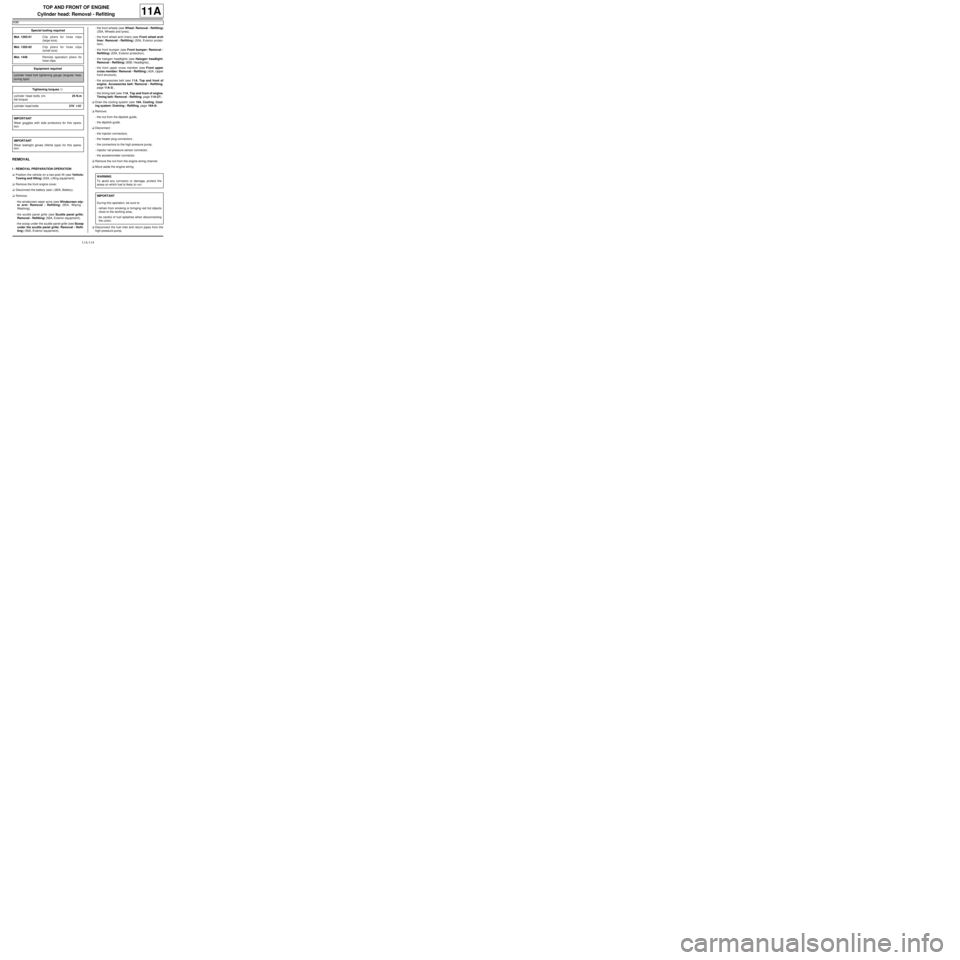

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front engine cover.

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (80B, Headlights),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) .

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRemove:

-the nut from the dipstick guide,

-the dipstick guide.

aDisconnect:

-the injector connectors,

-the heater plug connectors ,

-the connectors to the high pressure pump,

-injector rail pressure sensor connector,

-the accelerometer connector.

aRemove the nut from the engine wiring channel.

aMove aside the engine wiring.

aDisconnect the fuel inlet and return pipes from the

high pressure pump. Special tooling required

Mot. 1202-01Clip pliers for hose clips

(large size).

Mot. 1202-02Clip pliers for hose clips

(small size)

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

cylinder head bolt tightening gauge (angular mea-

suring type)

Tightening torquesm

cylinder head bolts (ini-

tial torque)25 N.m

cylinder head bolts270˚ ±± ± ±

10˚

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to r un.

IMPORTANT

Dur ing this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

Page 234 of 652

11A-117

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K9K

11A

aIf necessary, carry out a complete check of the cylin-

der head (see Cylinder head: Check) .

II - REFITTING OPERATION FOR PART

CONCERNED

aBring the pistons to mid-stroke position to prevent

them from coming into contact with the valves during

the tightening of the cylinder head.

aRefit:

-a new cylinder head gasket,

-the cylinder head.

Cylinder head tightening procedure

aRefit the cylinder head bolts.

aFit the cylinder head bolts, without tightening them.

aTighten to torque and in order the cylinder head

bolts (initial torque) (25 N.m).

aCheck that the cylinder head bolts are tightened to

25 Nm.

aAngle tighten the cylinder head bolts (270˚ ±± ± ±

10˚) in

order using a cylinder head bolt tightening gauge

(angular measuring type).

III - FINAL OPERATION

aRefit:

-the timing end bracket on the air filter box.

-the timing end bracket bolt on the air filter box,-the two high pressure pipes between the rail and

injector at the timing end (see 13B, Diesel injec-

tion, High pressure pipe between rail and injec-

tor: Removal - Refitting, page 13B-39) ,

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the oil return pipe fitted with new seals, fitting it into

the cylinder block (see 12B, Turbocharging, Tur-

bocharger oil pipe: Removal - Refitting, page

12B-12) .

aRefit the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) .

aConnect:

-the coolant temperature sensor connector,

-the heater matrix cooling hose to the water cham-

ber.

aFit the clip on the heater matrix cooling hose onto

the water chamber using the (Mot. 1202-01) or

(Mot. 1202-02) or (Mot. 1448).

aConnect the coolant pump inlet pipe cooling hose.

aFit the cooling hose clip at the coolant pump inlet

pipe end using the (Mot. 1202-01) or (Mot. 1202-02)

or (Mot. 1448).

aConnect the EGR cooler cooling hose.

aFit the cooling hose clip at the EGR cooler end using

the (Mot. 1202-01) or (Mot. 1202-02) or (Mot.

1448).

aConnect the brake servo pipe onto the vacuum

pump.

aFit the engine wiring.

aClip:

-the breather pipe onto the gearbox,

-the wiring on the engine lifting eye on the gearbox

side.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aRemove the blanking plugs from the fuel pipes and

high pressure pump.

aConnect the fuel inlet and return pipes to the high

pressure pump.

aFit the engine wiring.

aConnect:

-the accelerometer connector,

-injector rail pressure sensor connector, WARNING

In order to ensure that the bolts are correctly

tightened, use a syringe to remove any oil which

may be in the cylinder head mounting holes.

19712