sensor RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 576 of 652

19A-66

COOLING

Coolant temperature sensor: Removal - Refitting

D4F or D7F

19A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced :

-coolant temperature sensor seal.

aConsumable (see Vehicle: Parts and consuma-

bles for the repair) :

-COOLANT.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

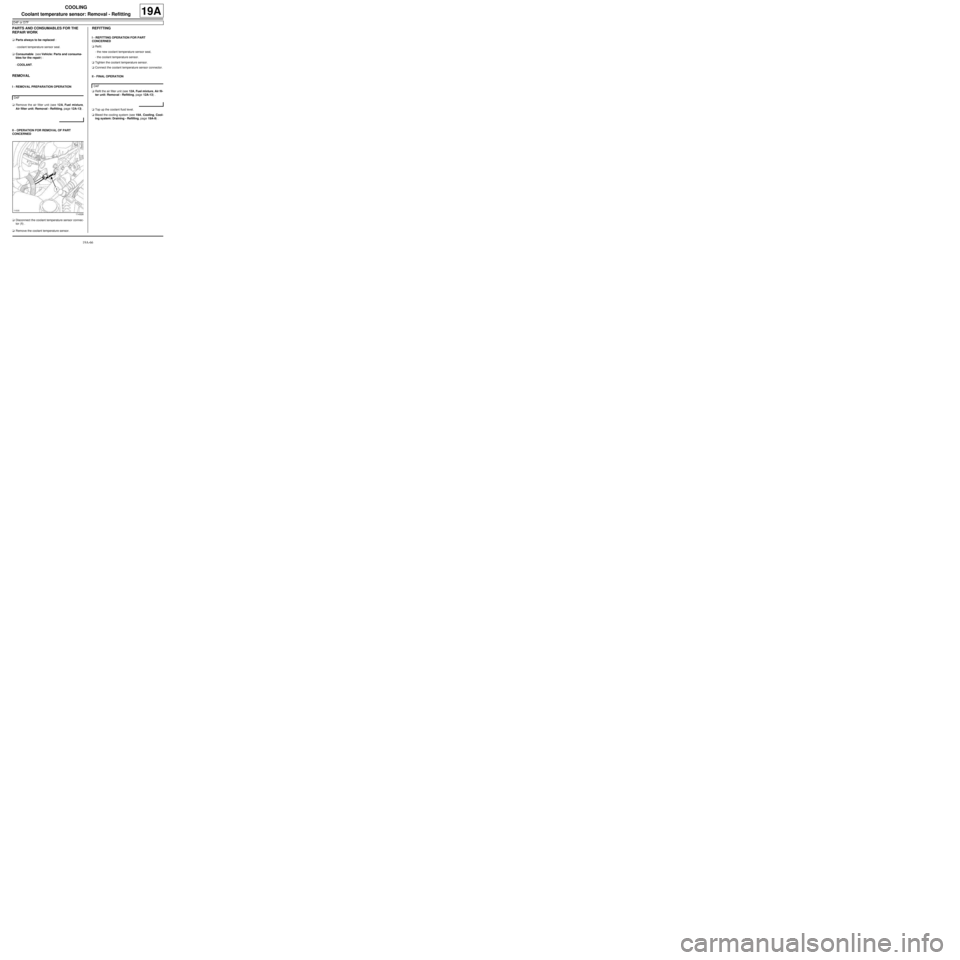

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the coolant temperature sensor connec-

tor (1) .

aRemove the coolant temperature sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the new coolant temperature sensor seal,

-the coolant temperature sensor.

aTighten the coolant temperature sensor.

aConnect the coolant temperature sensor connector.

II - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aTop up the coolant fluid level.

aBleed the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) . D4F

114326

D4F

Page 577 of 652

19A-67

COOLING

Coolant temperature sensor: Removal - Refitting

K9K

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

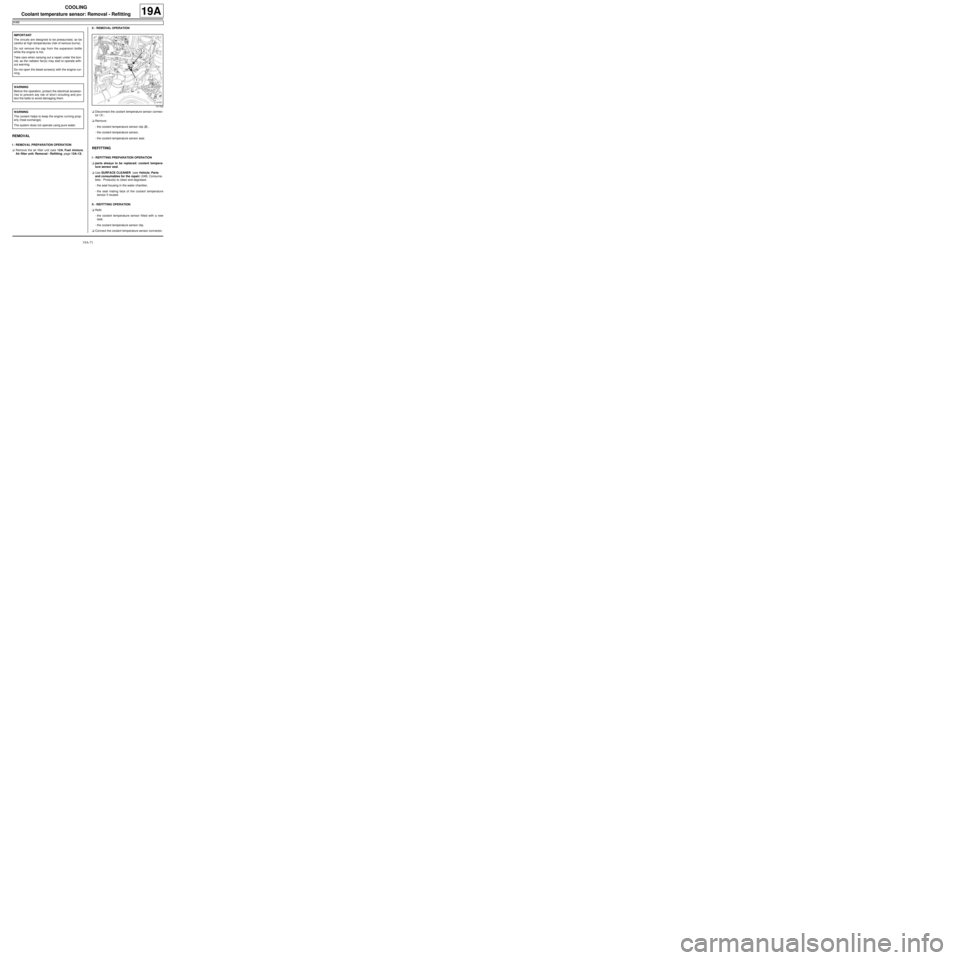

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove the front engine cover.

aUnclip the neck on the gearbox.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the coolant temperature sensor connec-

tor.

aRemove:

-the coolant temperature sensor clip,

-the coolant temperature sensor,

-the coolant temperature sensor seal.

REFITTING

I - REFITTING PREPARATIONS OPERATION

a

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the new seal on the coolant temperature sensor,

-the coolant temperature sensor,

-the coolant temperature sensor clip.

aConnect the coolant temperature sensor connector.

III - FINAL OPERATION.

aClip the channel to the gearbox.

aFill the cooling system (see 19A, Cooling, Cooling

system: Draining - Refilling, page 19A-9) .

aRefit the engine cover. IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system does not operate using pure water.

WARNING

The seals m ust always be replaced.

Page 578 of 652

19A-68

COOLING

Coolant temperature sensor: Removal - Refitting

D4F, and 780

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).Tightening torquesm

coolant temperature

sensor23 Nm

Page 579 of 652

19A-69

COOLING

Coolant temperature sensor: Removal - Refitting

D4F, and 780

19A

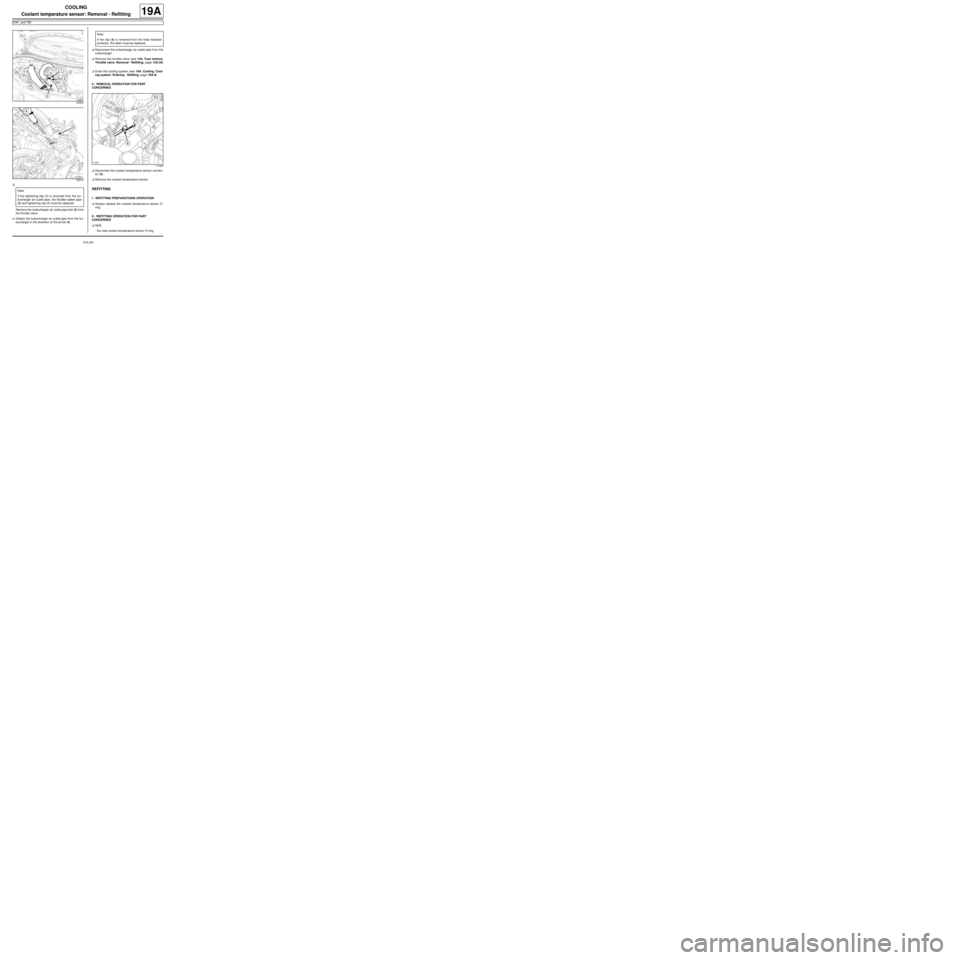

a

Remove the turbocharger air outlet pipe bolt (3) from

the throttle valve.

aDetach the turbocharger air outlet pipe from the tur-

bocharger in the direction of the arrow (4) .aDisconnect the turbocharger air outlet pipe from the

turbocharger.

aRemove the throttle valve (see 12A, Fuel mixture,

Throttle valve: Removal - Refitting, page 12A-20)

.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

II - REMOVAL OPERATION FOR PART

CONCERNED

aDisconnect the coolant temperature sensor connec-

tor (6) .

aRemove the coolant temperature sensor.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aAlways replace the coolant temperature sensor O-

ring.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the new coolant temperature sensor O-ring,

122833

122673

Note:

If the tightening clip (1) is removed from the tur-

bocharger air outlet pipe, the flexible rubber pipe

(2) and tightening clip (1) must be replaced.

Note:

If the clip (5) is removed from the heat resistant

protector, the latter must be replaced.

114326

Page 580 of 652

19A-70

COOLING

Coolant temperature sensor: Removal - Refitting

D4F, and 780

19A

-the coolant temperature sensor.

aTorque tighten the coolant temperature sensor

(23 Nm).

aConnect the coolant temperature sensor connector.

III - FINAL OPERATION

aRefit the throttle valve (see 12A, Fuel mixture,

Throttle valve: Removal - Refitting, page 12A-20)

.

aPush the turbocharger air outlet pipe clip in the di-

rection of the arrow (7) .

aConnect the turbocharger air outlet pipe onto the tur-

bocharger.

aRefit the turbocharger air outlet pipe bolt on the

throttle valve.

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

122666

Page 581 of 652

19A-71

COOLING

Coolant temperature sensor: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .II - REMOVAL OPERATION

aDisconnect the coolant temperature sensor connec-

tor (1) .

aRemove:

-the coolant temperature sensor clip (2) ,

-the coolant temperature sensor,

-the coolant temperature sensor seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: coolant tempera-

ture sensor seal.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the seal housing in the water chamber,

-the seal mating face of the coolant temperature

sensor if reused.

II - REFITTING OPERATION

aRefit:

-the coolant temperature sensor fitted with a new

seal,

-the coolant temperature sensor clip.

aConnect the coolant temperature sensor connector. IMPORTANT

The circuits are designed to be pressurised, so be

careful at high temperatures (risk of serious burns).

Do not remove the cap from the expansion bottle

while the engine is hot.

Take care when carrying out a repair under the bon-

net, as the radiator fan(s) may start to operate with-

out warning.

Do not open the bleed screw(s) with the engine run-

ning.

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system does not operate using pure water.

131762

Page 582 of 652

19A-72

COOLING

Coolant temperature sensor: Removal - Refitting

K4M

19A

III - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aPerform the following operations:

-top up the coolant level,

-bleed the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

Page 597 of 652

19B-15

EXHAUST

Catalytic converter: Removal - Refitting

D4F, and 772 – D7F

19B

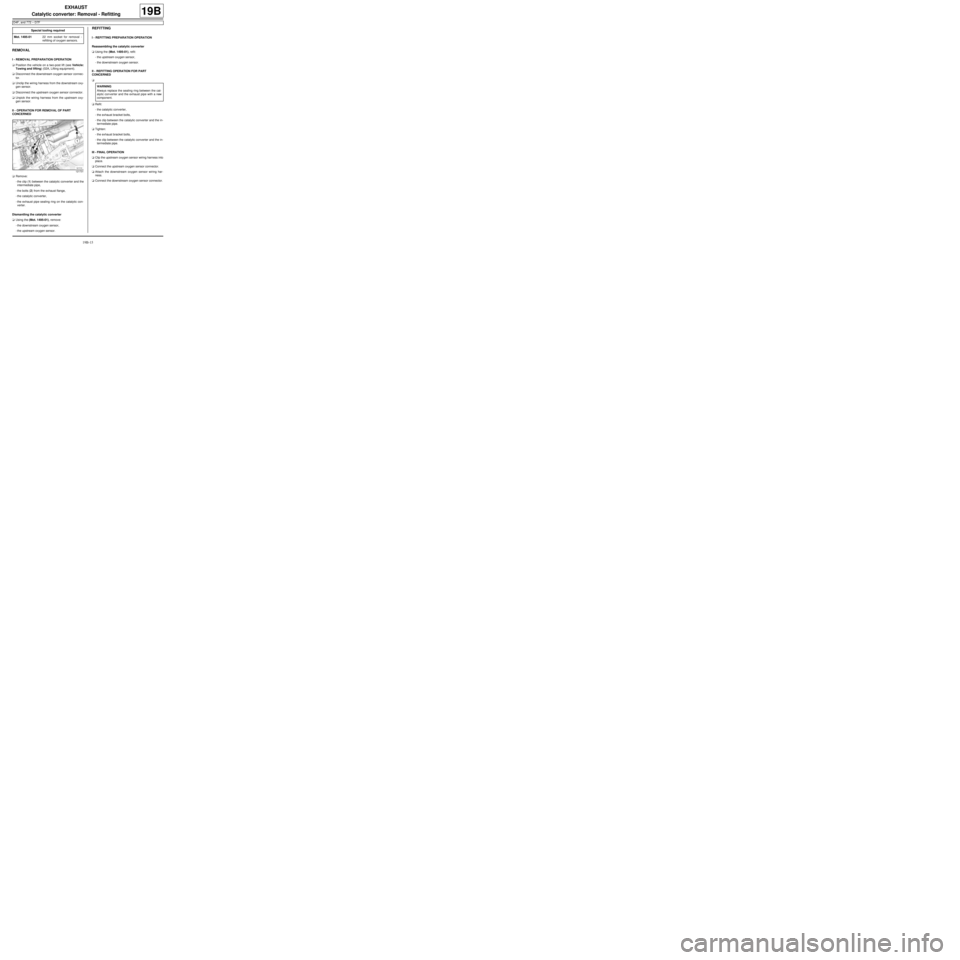

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the downstream oxygen sensor connec-

tor.

aUnclip the wiring harness from the downstream oxy-

gen sensor.

aDisconnect the upstream oxygen sensor connector.

aUnpick the wiring harness from the upstream oxy-

gen sensor.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the clip (1) between the catalytic converter and the

intermediate pipe,

-the bolts (2) from the exhaust flange,

-the catalytic converter,

-the exhaust pipe sealing ring on the catalytic con-

verter.

Dismantling the catalytic converter

aUsing the (Mot. 1495-01), remove:

-the downstream oxygen sensor,

-the upstream oxygen sensor.

REFITTING

I - REFITTING PREPARATION OPERATION

Reassembling the catalytic converter

aUsing the (Mot. 1495-01), refit:

-the upstream oxygen sensor,

-the downstream oxygen sensor.

II - REFITTING OPERATION FOR PART

CONCERNED

a

aRefit:

-the catalytic converter,

-the exhaust bracket bolts,

-the clip between the catalytic converter and the in-

termediate pipe.

aTighten:

-the exhaust bracket bolts,

-the clip between the catalytic converter and the in-

termediate pipe.

III - FINAL OPERATION

aClip the upstream oxygen sensor wiring harness into

place.

aConnect the upstream oxygen sensor connector.

aAttach the downstream oxygen sensor wiring har-

ness.

aConnect the downstream oxygen sensor connector. Special tooling required

Mot. 1495-0122 mm socket for removal -

refitting of oxygen sensors.

121731

WARNING

Always replace the sealing ring between the cat-

alytic con verter and the exhaust pipe with a new

component.

Page 598 of 652

19B-16

EXHAUST

Catalytic converter: Removal - Refitting

D4F, and 780 or 782

19B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the air filter box strut bolt,-the air filter box strut,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) . Tightening torquesm

catalytic converter lower

bracket bolt on the gear-

box44 N.m

bolts of the catalytic

converter lower bracket

on the engine25 N.m

side bracket bolts on the

catalytic converter21 N.m

side bracket bolts on the

engine21 N.m

catalytic converter nuts

on the turbocharger (ini-

tial torque)20 N.m

catalytic converter nuts

on the turbocharger30 N.m

bolts of the catalytic

converter lower bracket

on the catalytic con-

verter (initial torque)20 N.m

bolts of the catalytic

converter lower bracket

on the catalytic con-

verter30 N.m

exhaust downpipe bolts21 N.m

catalytic converter strut

nut21 N.m

catalytic converter strut

bolt on the rocker cover21 N.m

Page 601 of 652

19B-19

EXHAUST

Catalytic converter: Removal - Refitting

D4F, and 780 or 782

19B

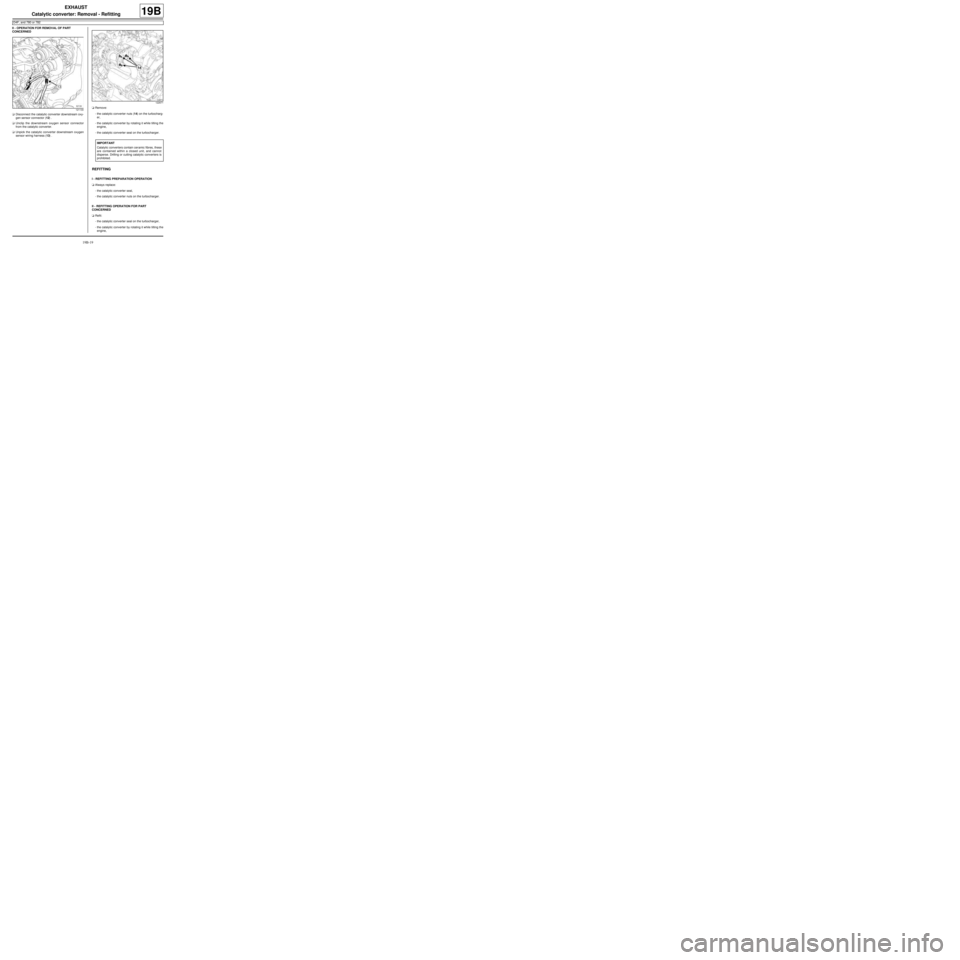

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the catalytic converter downstream oxy-

gen sensor connector (12) .

aUnclip the downstream oxygen sensor connector

from the catalytic converter.

aUnpick the catalytic converter downstream oxygen

sensor wiring harness (13) .aRemove:

-the catalytic converter nuts (14) on the turbocharg-

er,

-the catalytic converter by rotating it while tilting the

engine,

-the catalytic converter seal on the turbocharger.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace:

-the catalytic converter seal,

-the catalytic converter nuts on the turbocharger.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the catalytic converter seal on the turbocharger,

-the catalytic converter by rotating it while tilting the

engine,

121130

122671

IMPORTANT

Catalytic converters contain cer amic fibres, these

are contained within a closed unit, and cannot

disperse. Drilling or cutting catalytic converters is

prohibited.