check oil RENAULT TWINGO 2009 2.G Engine And Peripherals Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 245 of 652

11A-128

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

D7F – D4F, and 772

11A

aTighten to torque and in order the cylinder head

bolts (initial torque) (20 N.m).

aCheck that all the cylinder head bolts are pretight-

ened to 20 Nm.

aAngle tighten in order the cylinder head bolts (230˚

±± ± ±

6).

III - FINAL OPERATION

aRefit the exhaust bracket bolts.

aTighten the exhaust bracket bolts.

aConnect the water chamber hoses.

aFit the water chamber hose clips using the tool (Mot.

1448) or (Mot. 1202-01) or (Mot. 1202-02).

aConnect the coolant temperature sensor connector.

aRefit:

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the ignition coil.

aRefit:

-the inlet manifold (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) .

aRefit:

-the air filter unit,

-the air filter box retaining belts,

-the intake distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) .

aRefit:

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment).

aRefit:

-a new oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting,

page 10A-29) ,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aPerform the following operations:

-top up the engine oil (see 10A, Engine and cylin-

der block assembly, Engine oil: Draining - Re-

filling, page 10A-22) ,

18641

D4F

D7F

D4F

Page 250 of 652

11A-133

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

D4F, and 780 or 782

11A

2 - Checking the gasket face

aCheck the flatness of the cylinder head gasket face

(see Cylinder head: Check) .

3 - Optional additional operations

aWhen replacing the cylinder head, strip the cylinder

head (see Cylinder head: Stripping - Rebuilding) .

aIf necessary, carry out a complete check of the cylin-

der head (see Cylinder head: Check) .

II - REFITTING OPERATION FOR PART

CONCERNED

aBring the pistons to mid-stroke position to prevent

them from coming into contact with the valves during

the tightening of the cylinder head.

aCheck for the cylinder head centring dowels on the

cylinder block.

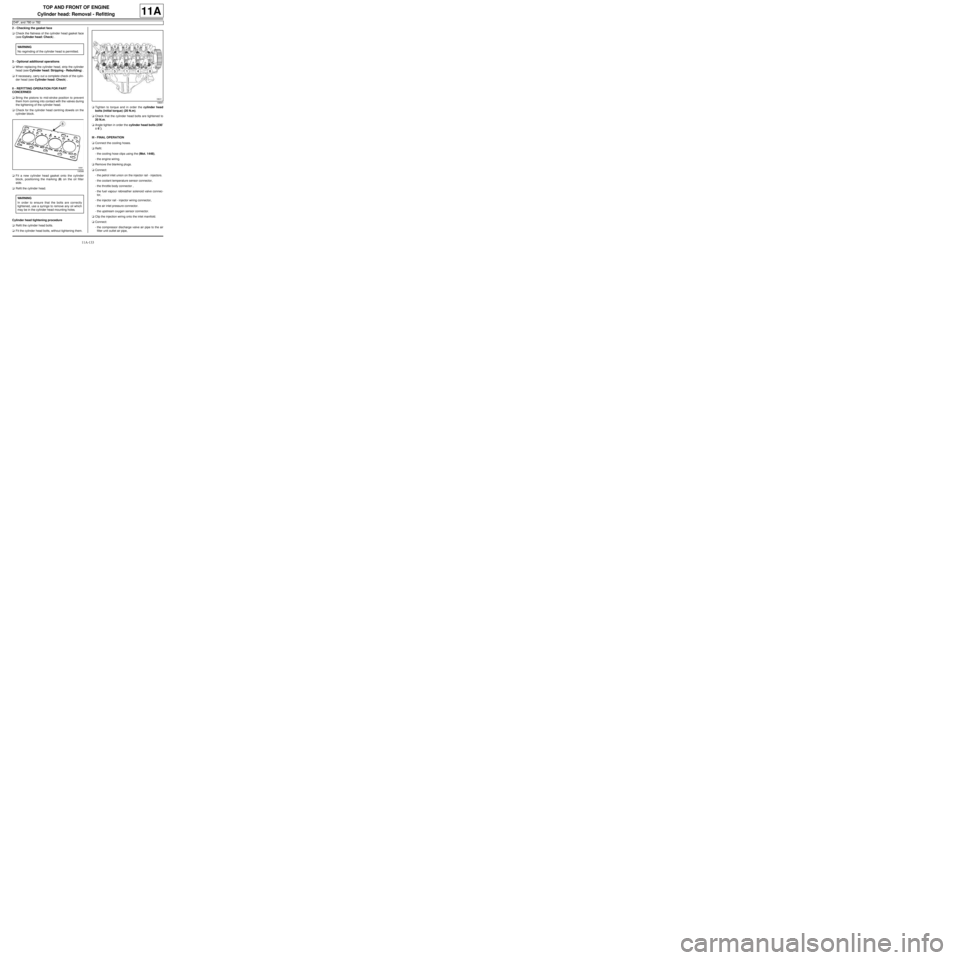

aFit a new cylinder head gasket onto the cylinder

block, positioning the marking (8) on the oil filter

side.

aRefit the cylinder head.

Cylinder head tightening procedure

aRefit the cylinder head bolts.

aFit the cylinder head bolts, without tightening them.aTighten to torque and in order the cylinder head

bolts (initial torque) (20 N.m).

aCheck that the cylinder head bolts are tightened to

20 N.m.

aAngle tighten in order the cylinder head bolts (230˚

±± ± ±

6˚).

III - FINAL OPERATION

aConnect the cooling hoses.

aRefit:

-the cooling hose clips using the (Mot. 1448),

-the engine wiring.

aRemove the blanking plugs.

aConnect:

-the petrol inlet union on the injector rail - injectors.

-the coolant temperature sensor connector,

-the throttle body connector ,

-the fuel vapour rebreather solenoid valve connec-

tor,

-the injector rail - injector wiring connector,

-the air inlet pressure connector.

-the upstream oxygen sensor connector.

aClip the injection wiring onto the inlet manifold.

aConnect:

-the compressor discharge valve air pipe to the air

filter unit outlet air pipe, WARNING

No regrinding of the cylinder head is permitted.

19598

WARNING

In order to ensure that the bolts are correctly

tightened, use a syringe to remove any oil which

may be in the cylinder head mounting holes.

18641

Page 326 of 652

12B-1

TURBOCHARGING

Turbocharging: Precautions for the repair

D4F or K9K

12B

I - TURBOCHARGER: GENERAL INSTRUCTIONS

For the turbocharging pressure regulator check (see

Fault finding - Tests) (Technical Note 3419A, 12B,

Turbocharging).

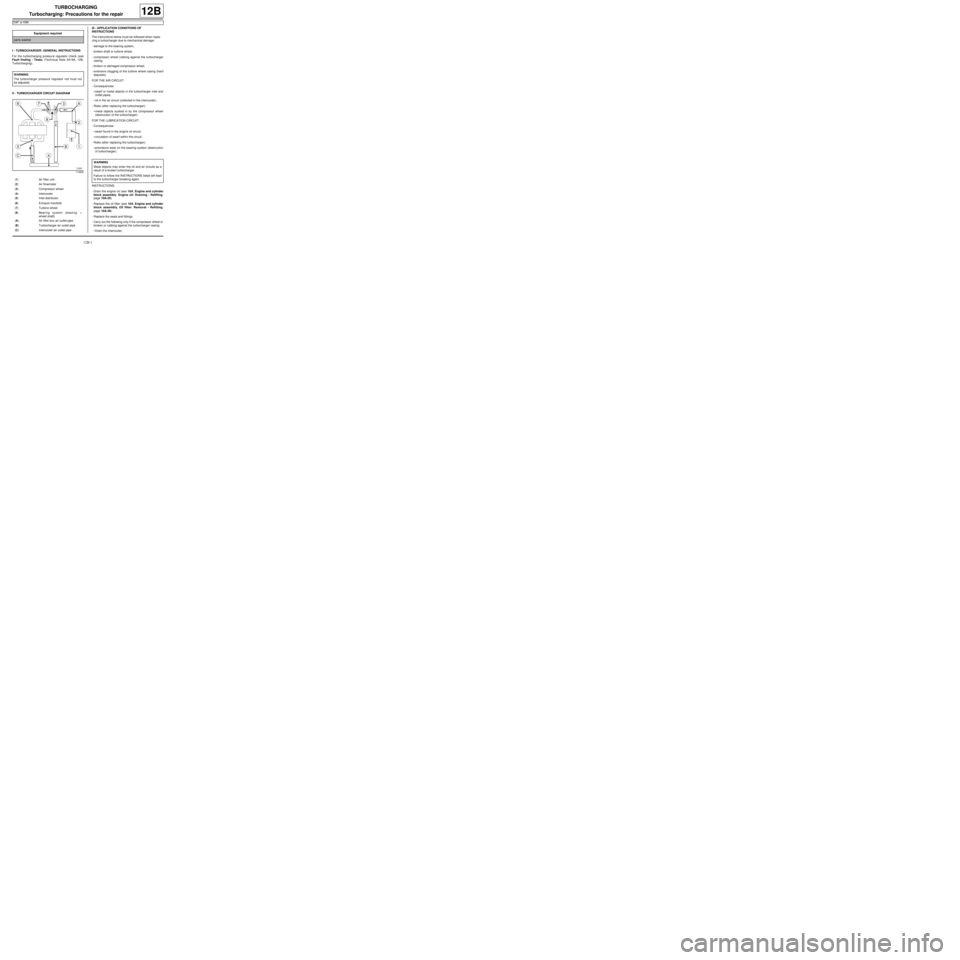

II - TURBOCHARGER CIRCUIT DIAGRAMIII - APPLICATION CONDITIONS OF

INSTRUCTIONS

The instructions below must be followed when repla-

cing a turbocharger due to mechanical damage:

-damage to the bearing system,

-broken shaft or turbine wheel,

-compressor wheel rubbing against the turbocharger

casing,

-broken or damaged compressor wheel,

-extensive clogging of the turbine wheel casing (hard

deposits).

FOR THE AIR CIRCUIT:

-Consequences:

•swarf or metal objects in the turbocharger inlet and

outlet pipes,

•oil in the air circuit (collected in the intercooler).

-Risks (after replacing the turbocharger):

•metal objects sucked in by the compressor wheel

(destruction of the turbocharger).

FOR THE LUBRICATION CIRCUIT:

-Consequences:

•swarf found in the engine oil circuit,

•circulation of swarf within the circuit.

-Risks (after replacing the turbocharger):

•premature wear on the bearing system (destruction

of turbocharger).

INSTRUCTIONS:

-Drain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22)

-Replace the oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting,

page 10A-29) .

-Replace the seals and fittings,

-Carry out the following only if the compressor wheel is

broken or rubbing against the turbocharger casing:

•Drain the intercooler, Equipment required

par ts washer

WARNING

The turbocharger pressure regulator rod must not

be adjusted.

112666

(1) Air filter unit

(2) Air flowmeter

(3) Compressor wheel

(4) Intercooler

(5) Inlet distributor

(6) Exhaust manifold

(7) Turbine wheel

(8) Bearing system (bearing +

wheel shaft)

(A) Air filter box air outlet pipe

(B) Turbocharger air outlet pipe

(C) Intercooler air outlet pipe

WARNING

Metal objects may enter the oil and air circuits as a

result of a broken turbocharger.

Failure to follow the INSTRUCTIONS listed will lead

to the turbocharger breaking again.

Page 327 of 652

12B-2

TURBOCHARGING

Turbocharging: Precautions for the repair

D4F or K9K

12B

•Clean the turbocharger air pipes.

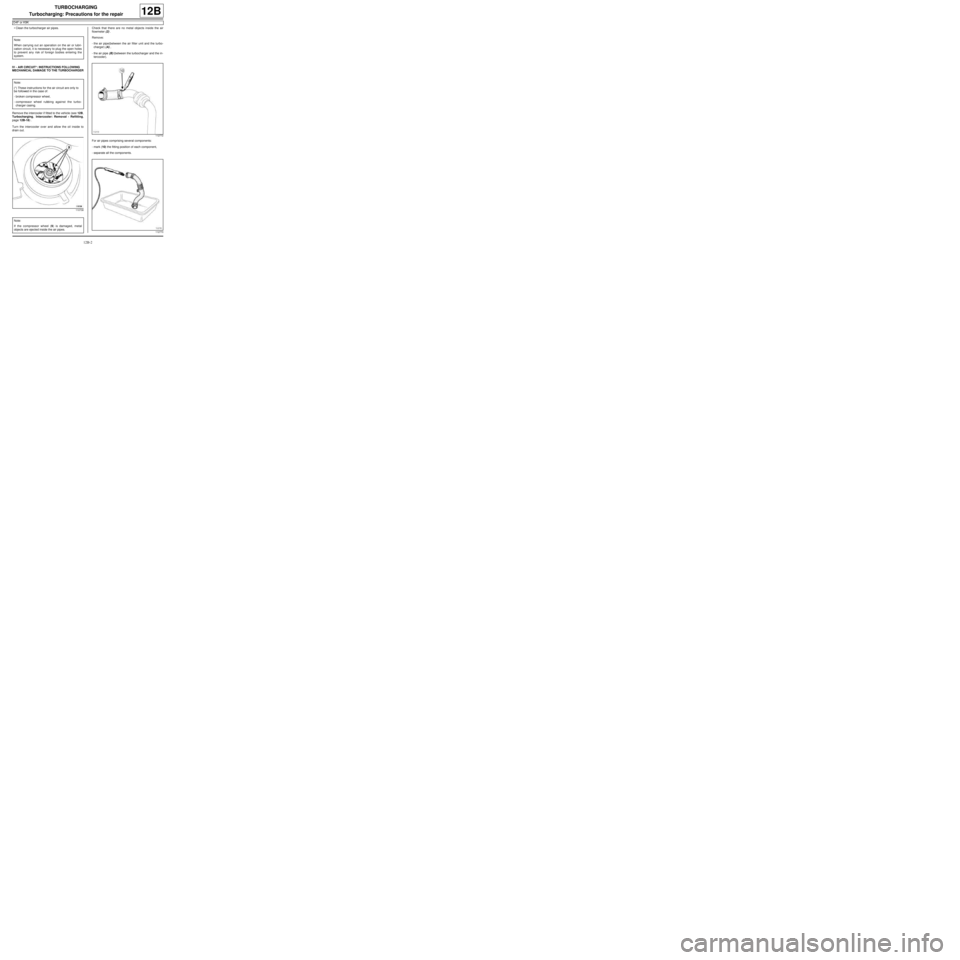

IV - AIR CIRCUIT*: INSTRUCTIONS FOLLOWING

MECHANICAL DAMAGE TO THE TURBOCHARGER

Remove the intercooler if fitted to the vehicle (see 12B,

Turbocharging, Intercooler: Removal - Refitting,

page 12B-18) .

Turn the intercooler over and allow the oil inside to

drain out.Check that there are no metal objects inside the air

flowmeter (2) .

Remove:

-the air pipe(between the air filter unit and the turbo-

charger) (A) ,

-the air pipe (B) (between the turbocharger and the in-

tercooler).

For air pipes comprising several components:

-mark (10) the fitting position of each component,

-separate all the components. Note:

When carrying out an oper ation on the air or lubri-

cation circuit, it is necessary to plug the open holes

to prevent any risk of foreign bodies entering the

system.

Note:

(*) These instructions for the air circuit are only to

be followed in the case of:

-broken compressor wheel,

-compressor wheel rubbing against the turbo-

charger casing.

110738

Note:

If the compressor wheel (9) is damaged, metal

objects are ejected inside the air pipes.

112772

112770

Page 328 of 652

12B-3

TURBOCHARGING

Turbocharging: Precautions for the repair

D4F or K9K

12B

One by one, clean the pipes removed with the parts

washer :

-brush as much of the inside of the pipe as possible

(only use brushes with plastic bristles),

-wash plenty of cleaning product from the cleaning sta-

tion through the pipe,

-allow the cleaned pipe to drain by standing it upright,

-ensure the cleaning product has drained out com-

pletely (check areas where liquid may be retained,

e.g. gaiters, resonators etc.).

Dry the pipes one by one using a compressed air spray

gun.

For pipes comprising several components:

-assemble the components, taking note of their correct

fitting position (10) .

Refit:

-the air pipe(between the air filter unit and the turbo-

charger) (A) ,

-the air pipe (B) (between the turbocharger and the in-

tercooler).

Refit the intercooler, if fitted to the vehicle (see 12B,

Turbocharging, Intercooler: Removal - Refitting,

page 12B-18) .V - LUBRICATION CIRCUIT**: INSTRUCTIONS

FOLLOWING MECHANICAL DAMAGE TO THE

TURBOCHARGER

Drain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22) .

Replace the oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting, page

10A-29) .

Only fill the engine with a suitable oil type (see Engine

oil: Specifications) (Technical Note 6013A, 04A, Lu-

bricants).

VI - GENERAL INSTRUCTIONS TO BE FOLLOWED

WHEN REMOVING A TURBOCHARGER

Always replace:

-the oil supply pipe:

•if the pipe is blocked, even partially (due to scale,

carbonised oil etc.),

•if the pipe is fitted with self-retaining seals.

-the oil return pipe:

•if the pipe is blocked, even partially (due to scale,

carbonised oil etc.),

•if the pipe is fitted with self-retaining seals.

-all seals that have been removed,

-all fittings that have been removed.

When starting the engine:

-do not accelerate,

-allow the engine to run for 1 minute,the time taken for

the oil circuit pressure to increase (until the oil pres-

sure warning light on the instrument panel goes out),

-accelerate several times at no load,

-check the air circuit and the oil circuit for leaks.

112771

Note:

(**) These instructions relating to the lubrication cir-

cuit must always be followed in all cases of

mechanical damage as listed above.

WARNING

Failure to observe the following procedure may lead

to destr uction of the turbocharger.

Page 331 of 652

12B-6

TURBOCHARGING

Turbocharger: Removal - Refitting

K9K

12B

aRemove:

-the turbocharger nuts (8) ,

-the turbocharger,

-the turbocharger seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: seal between ex-

haust manifold and turbocharger.

aIf there has been a fault in the turbocharger, check

that the inlet circuit assembly is not full of oil. If it is,

remove the components to be cleaned, and clean

them using a cleaning trough or a parts washer

then dry them using a compressed air nozzle.

aIf the turbocharger is being reused, clean it using a

cleaning trough or a parts washer then dry it using

a compressed air nozzle.

aUse ABRASIVE PADS (see Vehicle: Parts and

consumables for the repair) (04B, Consumables -

Products) to clean the bearing faces:

-the exhaust manifold - turbocharger,

-the turbocharger - catalytic converter,

-the turbocharger - oil return pipe.aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) and clean cloths to degrease the

mating faces:

-of the exhaust manifold on the turbocharger side,

-of the turbocharger on the exhaust manifold side,

-of the turbocharger on the catalytic converter side,

-of the turbocharger on the oil return pipe side,

-of the catalytic converter on the turbocharger side.

aIn the event of replacement, torque tighten the

studs on the turbocharger (9 N.m).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the turbocharger fitted with a new seal.

aTorque tighten the turbocharger nuts (28 N.m).

aConnect:

-the turbocharging pressure regulator pipe,

-the intercooler air inlet pipe on the turbocharger

side.

aClip the intercooler air inlet pipe on the turbocharger

side.

aConnect the turbocharger air outlet pipe to the turbo-

charger.

aTighten the clip of the turbocharger air outlet pipe on

the turbocharger.

aRefit the turbocharger oil pipes (see 12B, Turbo-

charging, Turbocharger oil pipe: Removal - Re-

fitting, page 12B-12) .

aRefit the air outlet pipe onto the air filter unit.

112327

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

K9K, and 718

K9K, and 740

Page 335 of 652

12B-10

TURBOCHARGING

Turbocharger: Removal - Refitting

D4F, and 780 or 782

12B

aLoosen the clip of the air filter unit air outlet pipe.

aRemove:

-the air outlet pipe of the air filter unit,

-the turbocharger cooling pipe bracket bolt,

-the turbocharger cooling hollow pipe bolts,

-the turbocharger cooling pipes.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Turbocharger nut.

aparts always to be replaced: seal between ex-

haust manifold and turbocharger.

aparts always to be replaced: Turbocharger cool-

ant pipe if replacing the turbocharger.

aUse a SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease the sealing

surfaces:

-of the turbocharger (if being reused),

-of the exhaust manifold.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new turbocharger seal,

-the turbocharger,

-new turbocharger nuts.

aTorque tighten the turbocharger nuts (21 N.m).

1 - If replacing the turbocharger

aRefit:

-the turbocharger cooling pipes,

-the turbocharger cooling hollow pipe bolts,

-the turbocharger cooling pipe bracket bolts,-the air outlet pipe of the air filter unit.

aTighten the clip of the air outlet pipe on the air filter

unit.

aTorque tighten:

-the turbocharger cooling pipe hollow bolts (30

N.m),

-the turbocharger cooling pipe bracket bolts (10

N.m).

a

aConnect the turbocharging pressure regulation

pipes.

aClip on the clips of the turbocharging pressure regu-

lation pipes.

2 - If the turbocharger is not being replaced

aClip the wiring onto the turbocharger coolant rigid

pipe strut.

aConnect:

-the turbocharger discharge air pipe,

-the oil vapour recirculation pipe on the air filter unit

air outlet pipe,

-the petrol vapour recirculation pipe on the air filter

unit air outlet pipe,

-the turbocharging regulation solenoid valve con-

nector from the turbocharger,

-the ignition coil connector.

aTighten the turbocharger discharge air pipe clip.

aRefit the turbocharger oil supply pipe (see 12B, Tur-

bocharging, Turbocharger oil pipe: Removal -

Refitting, page 12B-12) .

aRefit the turbocharger cooling pipe strut bolt.

aConnect the turbocharger cooling hoses.

aFit the turbocharger cooling hose clips using the tool

(Mot. 1448).

aRemove the tools (Ms. 583).

aRefit the turbocharger oil return pipe (see 12B, Tur-

bocharging, Turbocharger oil pipe: Removal -

Refitting, page 12B-12) . WARNING

Ensure that no foreign bodies enter the turbine or

compressor during the refitting operation.

Check that the turbocharger oil return pipe is not

partially or completely blocked by scale. Check

that there are no leaks. If there are, replace the

part.Note:

Dur ing this operation, use a set of feeler gauges

to ensure that there is a minimum clearance of 3

mm between the turbocharger water outlet pipe

and the turbocharger heat shield.

Page 343 of 652

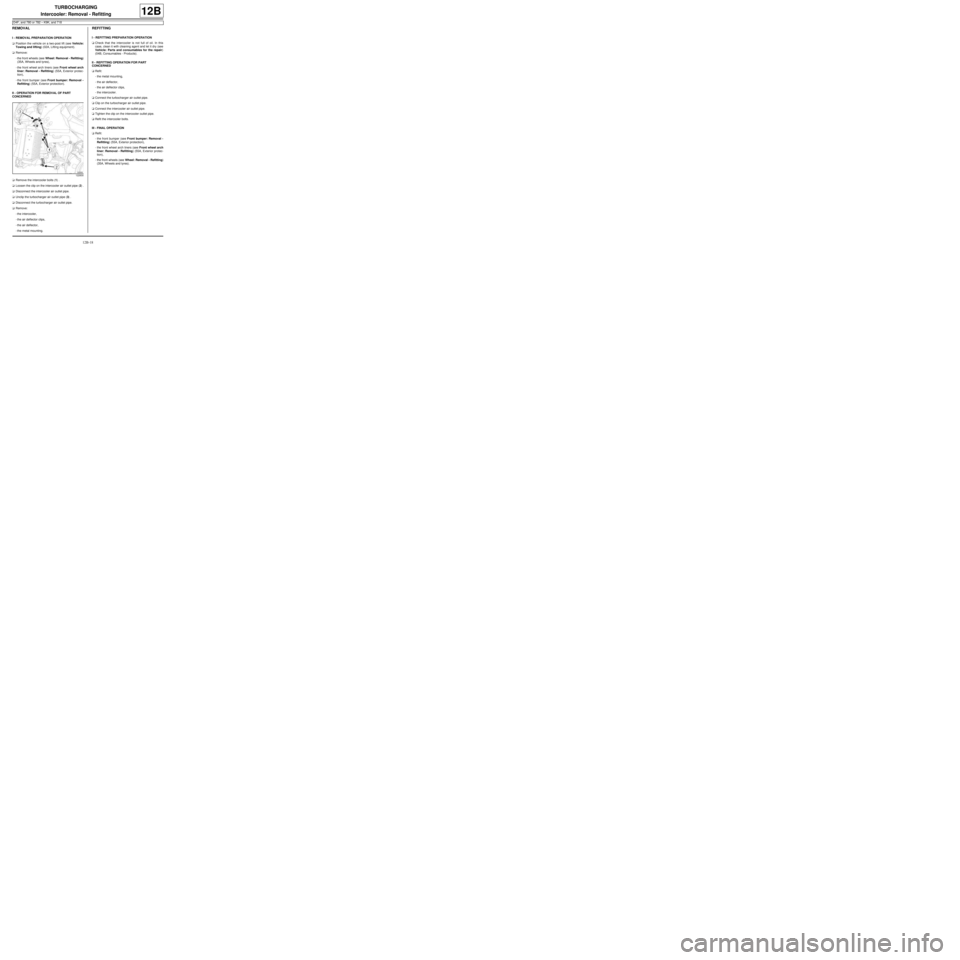

12B-18

TURBOCHARGING

Intercooler: Removal - Refitting

D4F, and 780 or 782 – K9K, and 718

12B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the intercooler bolts (1) .

aLoosen the clip on the intercooler air outlet pipe (2) .

aDisconnect the intercooler air outlet pipe.

aUnclip the turbocharger air outlet pipe (3) .

aDisconnect the turbocharger air outlet pipe.

aRemove:

-the intercooler,

-the air deflector clips,

-the air deflector,

-the metal mounting.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck that the intercooler is not full of oil. In this

case, clean it with cleaning agent and let it dry (see

Vehicle: Parts and consumables for the repair)

(04B, Consumables - Products).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the metal mounting,

-the air deflector,

-the air deflector clips,

-the intercooler.

aConnect the turbocharger air outlet pipe.

aClip on the turbocharger air outlet pipe.

aConnect the intercooler air outlet pipe.

aTighten the clip on the intercooler outlet pipe.

aRefit the intercooler bolts.

III - FINAL OPERATION

aRefit:

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres).

122830

Page 352 of 652

13A-9

FUEL SUPPLY

Fuel pressure: Check

D4F or D7F

13A

CHECK

aI - PREPARATION OPERATION FOR CHECK

aEnsure you have a checking tool (Mot. 1311-01) and

a “T” union (Mot. 1311-08).

aRemove the oil filler neck.

II - TEST OPERATION

aDisconnect the petrol inlet pipe from the injector rail. Special tooling required

Mot. 1311-01Pressure gauges and petrol

pressure measur ing unions.

Mot. 1311-08Union for taking fuel pres-

sure measurements .

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

116887

D4F

Page 353 of 652

13A-10

FUEL SUPPLY

Fuel pressure: Check

D4F or D7F

13A

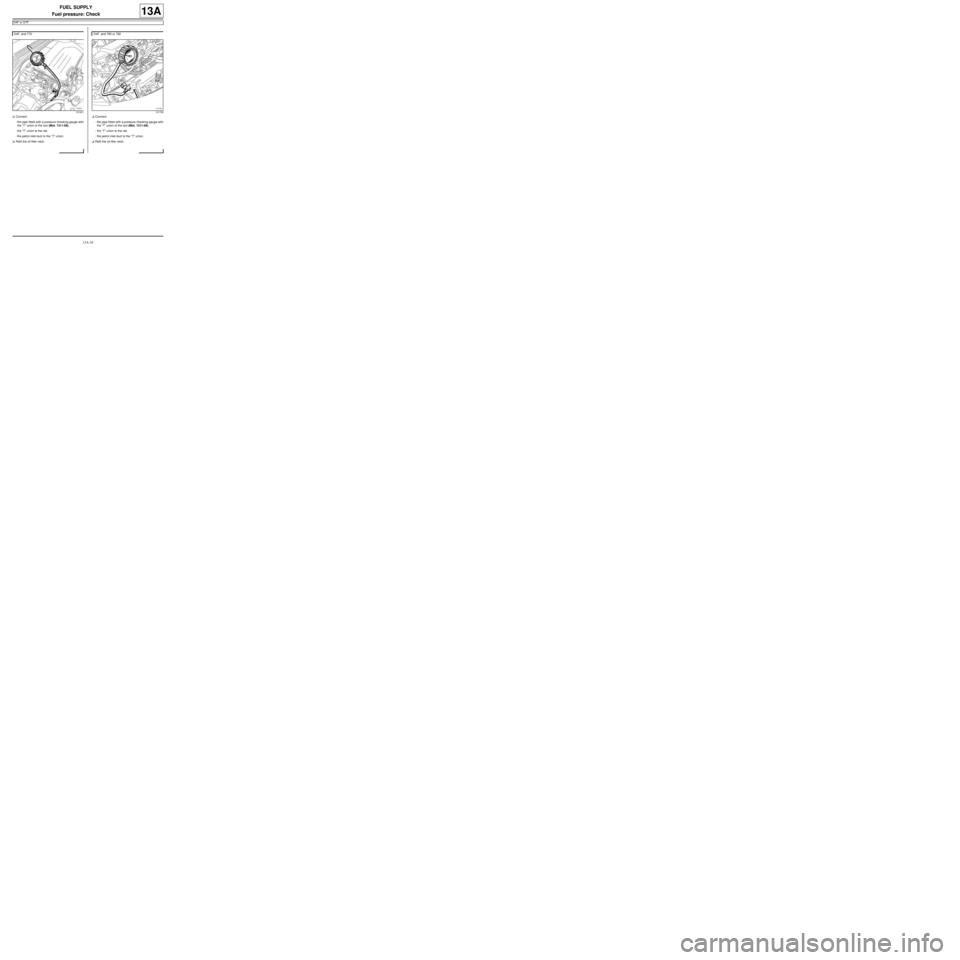

aConnect:

-the pipe fitted with a pressure checking gauge with

the “T” union of the tool (Mot. 1311-08),

-the “T” union to the rail,

-the petrol inlet duct to the “T” union.

aRefit the oil filler neck.aConnect:

-the pipe fitted with a pressure checking gauge with

the “T” union of the tool (Mot. 1311-08),

-the “T” union to the rail,

-the petrol inlet duct to the “T” union.

aRefit the oil filler neck. D4F, and 772

121821

D4F, and 780 or 782

121728