towing RENAULT TWINGO 2009 2.G Engine And Peripherals Manual PDF

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 376 of 652

13B-15

DIESEL INJECTION

Crankshaft position sensor: Removal - Refitting

C44, and K9K

13B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the crankshaft position sensor connector

(1) from underneath the vehicle.

aRemove:

-the crankshaft position sensor bolt (2) ,

-the crankshaft position sensor.

REFITTING

REFITTING OPERATION FOR PART CONCERNED

aRefit:

-the crankshaft position sensor,

-the crankshaft position sensor bolt.

aTighten the crankshaft position sensor bolt.

aConnect the crankshaft position sensor electrical

connector from underneath the vehicle.

120327

Page 377 of 652

13B-16

DIESEL INJECTION

High pressure pump: Removal - Refitting

K9K

13B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front engine cover.

aDisconnect the battery (see ) (80A, Battery).

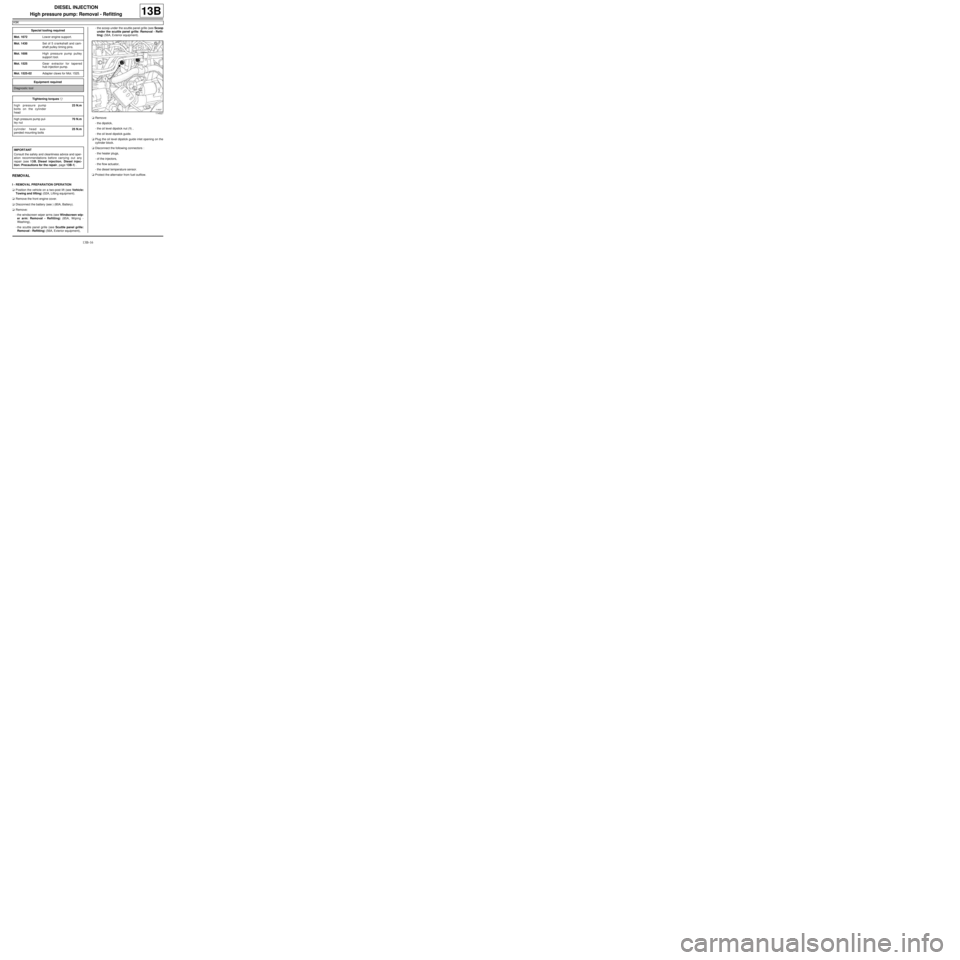

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aRemove:

-the dipstick,

-the oil level dipstick nut (1) ,

-the oil level dipstick guide.

aPlug the oil level dipstick guide inlet opening on the

cylinder block.

aDisconnect the following connectors :

-the heater plugs,

-of the injectors,

-the flow actuator,

-the diesel temperature sensor.

aProtect the alternator from fuel outflow. Special tooling required

Mot. 1672Low er engine support.

Mot. 1430Set of 5 crankshaft and cam-

shaft pulley timing pins.

Mot. 1606High pressure pump pulley

support tool.

Mot. 1525Gear extractor for tapered

hub injection pump.

Mot. 1525-02Adapter claws for Mot. 1525.

Equipment required

Diagnostic tool

Tightening torquesm

high pressure pump

bolts on the cylinder

head23 N.m

high pressure pump pul-

ley nut70 N.m

cylinder head sus-

pended mounting bolts25 N.m

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 13B, Diesel injection, Diesel injec-

tion: Precautions for the repair, page 13B-1) .

114527

Page 404 of 652

13B-43

DIESEL INJECTION

Injector rail: Removal - Refitting

K9K

13B

REMOVAL

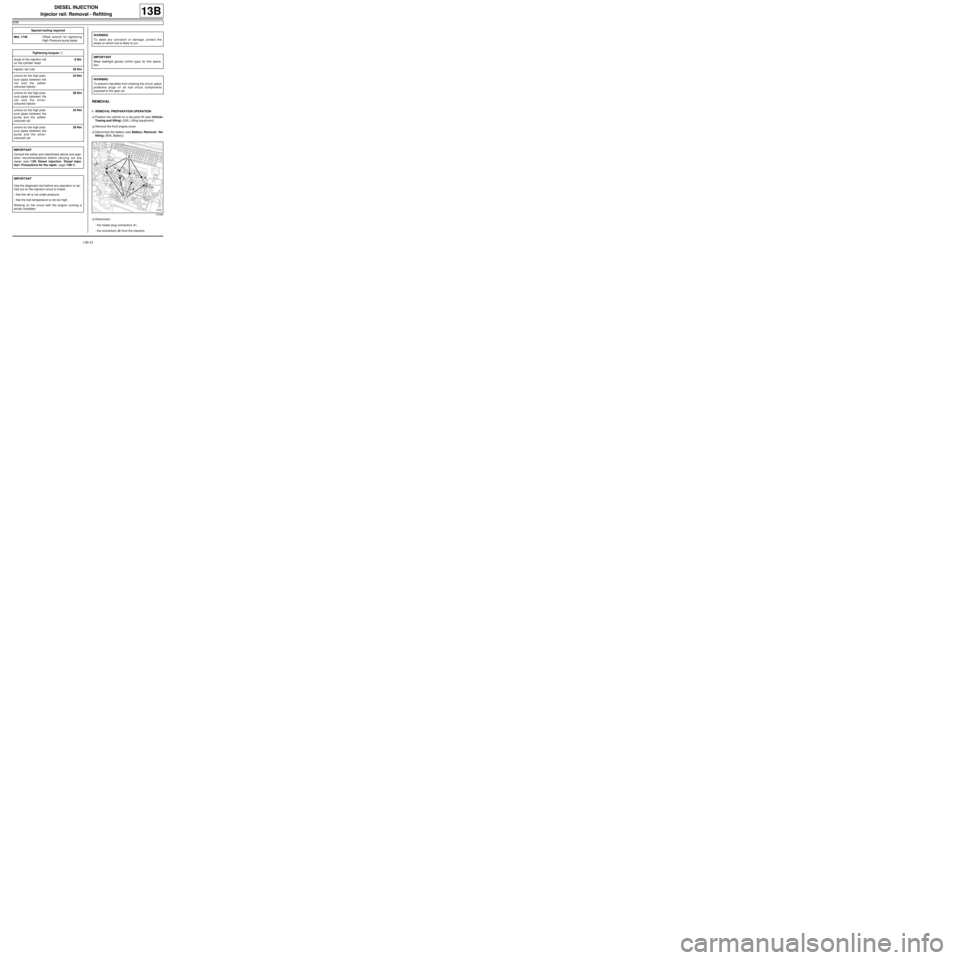

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment)

aRemove the front engine cover.

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aDisconnect:

-the heater plug connectors (1) ,

-the connectors (2) from the injectors. Special tooling required

Mot. 1746Offset wrench for tightening

High Pressure pump pipes.

Tightening torquesm

studs of the injection rail

on the cylinder head8 Nm

injector rail nuts28 Nm

unions for the high pres-

sure pipes between the

rail and the yellow-

coloured injector24 Nm

unions for the high pres-

sure pipes between the

rail and the silver-

coloured injector28 Nm

unions for the high pres-

sure pipes between the

pump and the yellow-

coloured r ail24 Nm

unions for the high pres-

sure pipes between the

pump and the silver-

coloured r ail28 Nm

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 13B, Diesel injection, Diesel injec-

tion: Precautions for the repair, page 13B-1) .

IMPORTANT

Use the diagnostic tool before any operation is car-

ried out on the injection circuit to check:

-that the rail is not under pressure,

-that the fuel temperature is not too high.

Working on the circuit with the engine running is

strictly forbidden.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

IMPORTANT

Wear leaktight gloves (nitrile type) for this opera-

tion.

WARNING

To prevent impurities from entering the circuit, place

protective plugs on all fuel circuit components

exposed to the open air.

127895

Page 416 of 652

13C-1

PREHEATING

Pre-postheating unit: Removal - Refitting

K9K

13C

REMOVAL

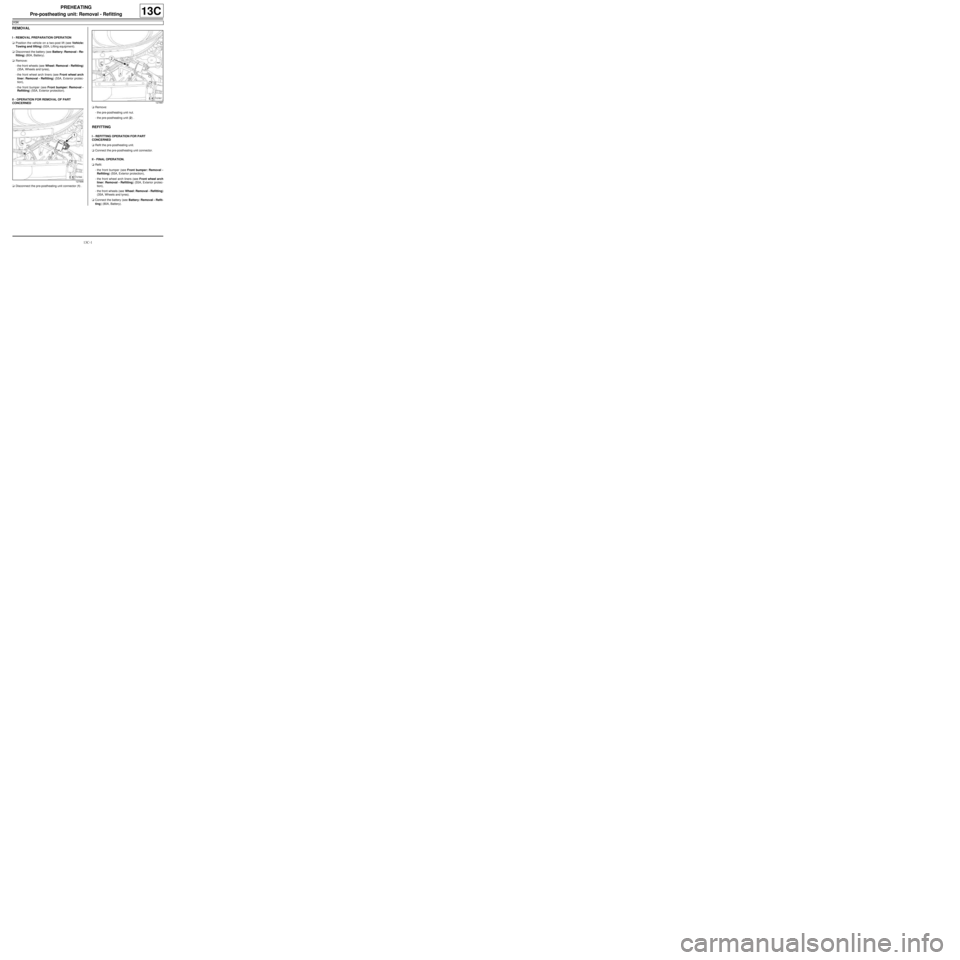

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the pre-postheating unit connector (1) .aRemove:

-the pre-postheating unit nut.

-the pre-postheating unit (2) .

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the pre-postheating unit.

aConnect the pre-postheating unit connector.

II - FINAL OPERATION.

aRefit:

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

127896

127897

Page 422 of 652

14A-4

ANTIPOLLUTION

Fuel vapour absorber: Removal - Refitting

D4F or D7F or K4M, and TECHNICAL REG: GERMANY or TECHNICAL REG: AUSTRIA or TECHNICAL REG:

BALKANS or TECHNICAL-LEGISLATIVE BELGIUM or TECHNICAL REG: BOSNIA or TECHNICAL REG:

CYPRUS-MALTA or CZECH REP AND SLOVAKIA or TECHNICAL REG: DENMARK or TECHNICAL REG: DOM

(FRENCH OVERSEAS SUBDIVISION) or TECHNICAL REG: SPAIN or TECHNICAL REG: FINLAND or

TECHNICAL REG: FRANCE or TECHNICAL REG: GREAT BRITAIN or TECHNICAL REG: GREECE or

TECHNICAL-LEGISLATIVE HOLLAND or TECHNICAL REG: HUNGARY or TECHNICAL REG: IRELAND or

TECHNICAL REG: ICELAND or TECHNICAL REG: ISRAEL or TECHNICAL REG: ITALY or TECHNICAL REG:

JAPAN or TECHNICAL REG: NORTH or TECHNICAL REG: NORWAY or TECHNICAL REG: POLAND or

TECHNICAL REG: PORTUGAL or TECHNICAL REG: SLOVENIA or TECHNICAL REG: SWEDEN or TECHNICAL

REG: SWITZERLAND or TECHNICAL REG: TOM (FRENCH OVERSEAS TERRITORIES)

14A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

II - REMOVAL OPERATION

aUnclip:

-the fuel filter on the fuel vapour absorber in the di-

rection of the arrow (1) ,

-the fuel vapour absorber in the direction of the ar-

row (2) . IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

Keep the pipe unions away from contaminated

areas.

WARNING

To prevent impurities from entering the circuit, place

protective plugs on all fuel circuit components

exposed to the open air.

D4F or D7F

120513

Page 424 of 652

14A-6

ANTIPOLLUTION

Fuel vapour absorber: Removal - Refitting

D4F, and SOUTH AFRICA

14A

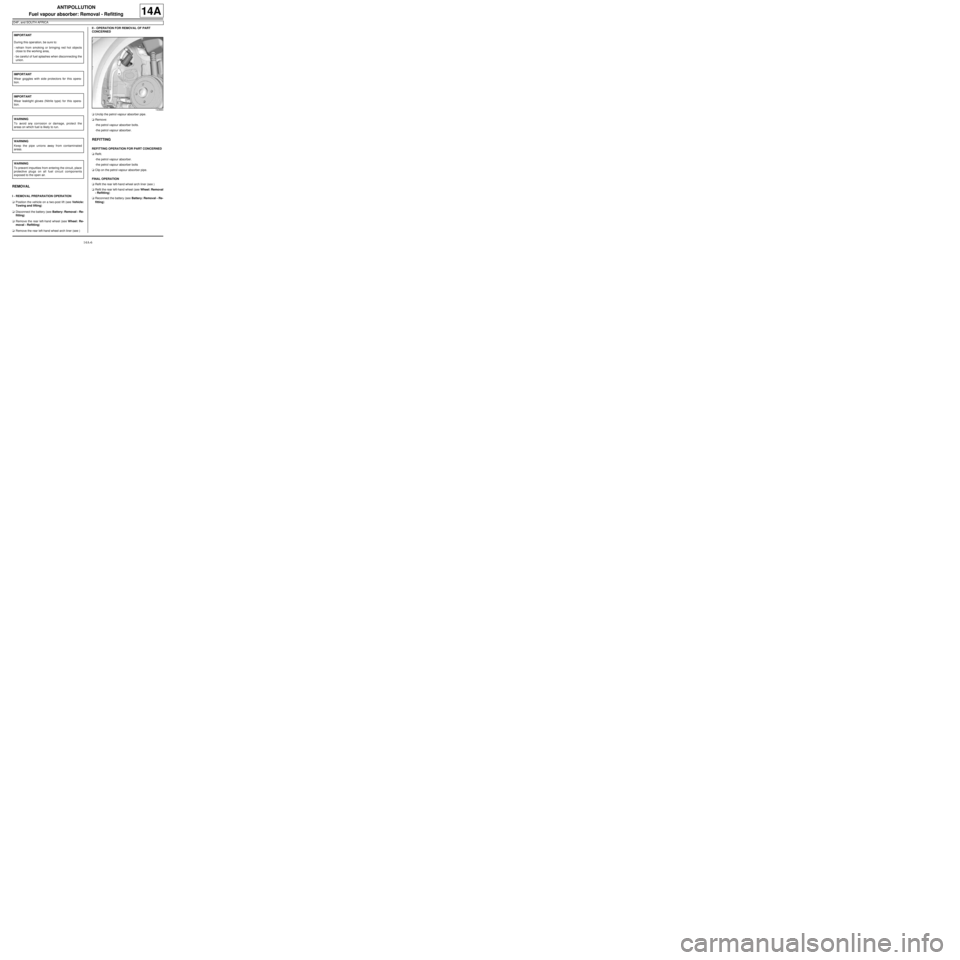

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting)

aDisconnect the battery (see Battery: Removal - Re-

fitting)

aRemove the rear left-hand wheel (see Wheel: Re-

moval - Refitting)

aRemove the rear left-hand wheel arch liner (see ) II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip the petrol vapour absorber pipe.

aRemove:

-the petrol vapour absorber bolts.

-the petrol vapour absorber.

REFITTING

REFITTING OPERATION FOR PART CONCERNED

aRefit.

-the petrol vapour absorber.

-the petrol vapour absorber bolts

aClip on the petrol vapour absorber pipe.

FINAL OPERATION

aRefit the rear left-hand wheel arch liner (see )

aRefit the rear left-hand wheel (see Wheel: Removal

- Refitting)

aReconnect the battery (see Battery: Removal - Re-

fitting) IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

Keep the pipe unions away from contaminated

areas.

WARNING

To prevent impurities from entering the circuit, place

protective plugs on all fuel circuit components

exposed to the open air.

143884

Page 429 of 652

14A-11

ANTIPOLLUTION

Exhaust gas cooler: Removal - Refitting

K9K

14A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the EGR solenoid valve (see 14A, Antipollution,

Exhaust gas recirculation solenoid valve: Re-

moval - Refitting, page 14A-10) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,-the exhaust gas recirculation rigid pipe (see 14A,

Antipollution, Exhaust gas recirculation rigid

pipe: Removal - Refitting, page 14A-19) ,

-the exhaust gas recirculation assembly (see 14A,

Antipollution, Exhaust gas recirculation as-

sembly: Removal - Refitting, page 14A-15) .

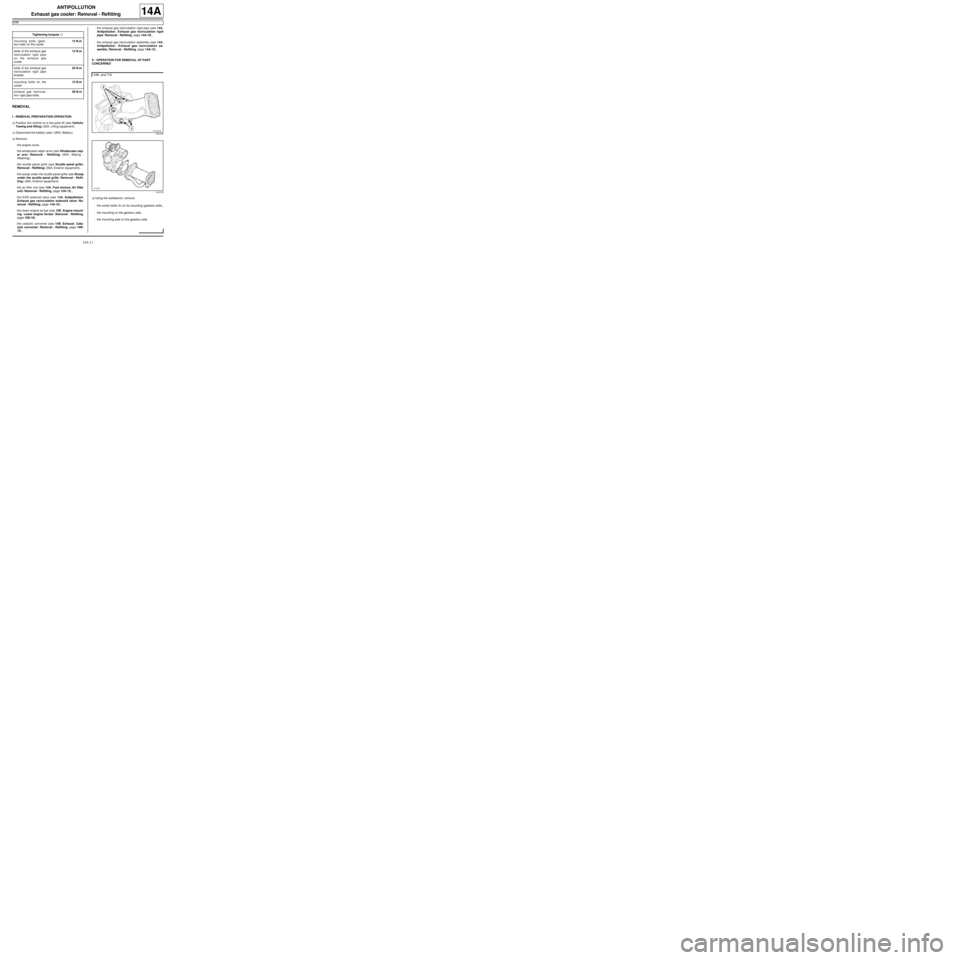

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUsing the workbench, remove:

-the cooler bolts (1) on its mounting (gearbox side),

-the mounting on the gearbox side,

-the mounting seal on the gearbox side. Tightening torquesm

mounting bolts (gear-

box side) on the cooler12 N.m

bolts of the exhaust gas

recirculation rigid pipe

on the exhaust gas

cooler12 N.m

bolts of the exhaust gas

recirculation rigid pipe

bracket25 N.m

mounting bolts on the

cooler12 N.m

exhaust gas recircula-

tion r igid pipe bolts36 N.m

K9K, and 718

141215

141216

Page 433 of 652

14A-15

ANTIPOLLUTION

Exhaust gas recirculation assembly: Removal - Refitting

K9K

14A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing)

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the EGR solenoid valve (see 14A, Antipollution,

Exhaust gas recirculation solenoid valve: Re-

moval - Refitting, page 14A-10) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the rigid exhaust gas recirculation pipe (see 14A,

Antipollution, Exhaust gas recirculation rigid

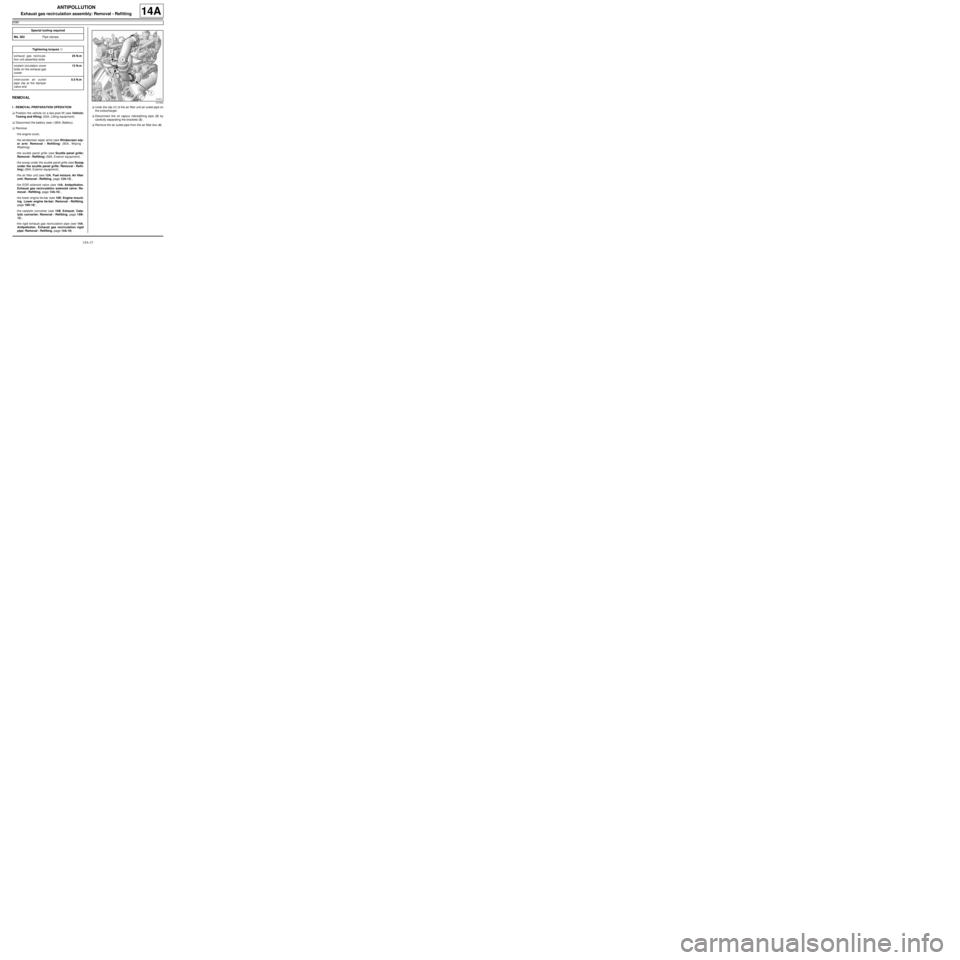

pipe: Removal - Refitting, page 14A-19) .aUndo the clip (1) of the air filter unit air outlet pipe on

the turbocharger.

aDisconnect the oil vapour rebreathing pipe (2) by

carefully separating the brackets (3) .

aRemove the air outlet pipe from the air filter box (4) . Special tooling required

Ms. 583Pipe clamps .

Tightening torquesm

exhaust gas recircula-

tion unit assembly bolts25 N.m

coolant circulation cover

bolts on the exhaust gas

cooler12 N.m

intercooler air outlet

pipe clip at the damper

valve end5.5 N.m

121633

Page 437 of 652

14A-19

ANTIPOLLUTION

Exhaust gas recirculation rigid pipe: Removal - Refitting

K9K

14A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the bolts (1) from the exhaust gas recirculation rigid

pipe on the exhaust manifold,

-the bolts (2) of the exhaust gas recirculation rigid

pipe on the exhaust gas cooler,

-the bolts (3) of the exhaust gas recirculation rigid

pipe bracket,

-the EGR rigid pipe. Tightening torquesm

bolts of the exhaust gas

recirculation rigid pipe

on the exhaust manifold36 N.m

bolts of the exhaust gas

recirculation rigid pipe

on the exhaust gas

cooler12 N.m

bolts of the exhaust gas

recirculation rigid pipe

bracket25 N.m

rigid exhaust gas recir-

culation pipe clip5 N.m

bolts of the exhaust gas

recirculation rigid pipe

on the exhaust manifold36 N.m

K9K, and 718

141224

Page 443 of 652

16A-4

STARTING - CHARGING

Alternator: Removal - Refitting

D4F or D7F, and AIR CONDITIONING

16A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aRemove the inlet distributor (see 12A, Fuel mixture,

Inlet distributor: Removal - Refitting, page 12A-

29) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the alternator connector.

aRemove the alternator positive terminal nut.

aRemove:

-the alternator bolts,

-the alternator. Tightening torquesm

alter nator bolts25 N.m

D4F

120519