warning light RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 8 of 652

10A-2

ENGINE AND CYLINDER BLOCK ASSEMBLY

Crankshaft seal on timing end: Removal - Refitting

K4M

10A

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the mating face of the crankshaft seal at the timing

end,

-the crankshaft seal housing at the timing end of the

cylinder block.

II - REFITTING OPERATION

aRefit a new crankshaft seal at the timing end, using

the tool (Mot. 1385) (2) .

III - FINAL OPERATION

aRefit:

-the camshaft dephaser (see 11A, Top and front of

engine, Camshaft dephaser: Removal - Refit-

ting, page 11A-135) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the throttle valve (see 12A, Fuel mixture, Throttle

valve: Removal - Refitting, page 12A-20) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray.

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery). WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

14523

Page 38 of 652

10A-32

ENGINE AND CYLINDER BLOCK ASSEMBLY

Oil filter: Removal - Refitting

K4M

10A

aWipe any oil run-off with a cloth.

aTop up the engine oil with oil recommended by the

manufacturer (see Engine oil: Specifications)

(Technical Note 6013A, 04A, Lubricants).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aStart the engine and wait until the oil pressure warn-

ing light goes out on the instrument panel.

aCheck for leaks from the oil filter.

aRefit the engine undertray.

aWait at least 10 minutes.

aCheck the oil level using the dipstick.

aAdjust the engine oil level if necessary.WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

delivering the vehicle to the customer.

Page 50 of 652

10A-44

ENGINE AND CYLINDER BLOCK ASSEMBLY

Conrod bearing shell: Removal - Refitting

K9K

10A

aTilt the engine oil sump forwards in order to access

the oil pump bolts.

aTorque tighten the oil pump bolts (25 N.m) using

the torque wrench PROSTEEL, part number 77 11

226 888 starting with the 13 mm bolt.

a

aRefit the engine oil sump bolts.

aTorque tighten in order the engine oil sump bolts

(see 10A, Engine and cylinder block assembly,

Lower cover: Removal - Refitting, page 10A-6) .

aRefit the catalytic converter upstream stay (see 19B,

Exhaust, Catalytic converter: Removal - Refit-

ting, page 19B-12) .

aConnect the connector to the oil level sensor.

aRefit the relay bearing of the front right-hand wheel

driveshaft (see Front right-hand driveshaft: Re-

moval - Refitting) .

aRefit the front axle subframe (see Front axle sub-

frame: Removal - Refitting) (31A, Front axle com-

ponents).

aRemove the safety strap(s) from the radiator.

aRefit the lower engine tie-bar (see 19D, Engine

mounting, Lower engine tie-bar: Removal - Refit-

ting, page 19D-18) .aDisconnect the crankshaft position sensor (4) to pre-

vent the engine from starting.

aRefit the oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting,

page 10A-29)

aFill up the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22) .

aStart the engine using the starter until the engine oil

warning light goes out.

aConnect the crankshaft position sensor.

aRefit the engine undertray.

aClear the present faults using the Diagnostic tool.

140918

Note:

Check that the engine oil sump seal is definitely

in place before tightening the engine oil sump

bolts.

123824

Page 134 of 652

11A-17

TOP AND FRONT OF ENGINE

Accessories belt: Removal - Refitting

K4M

11A

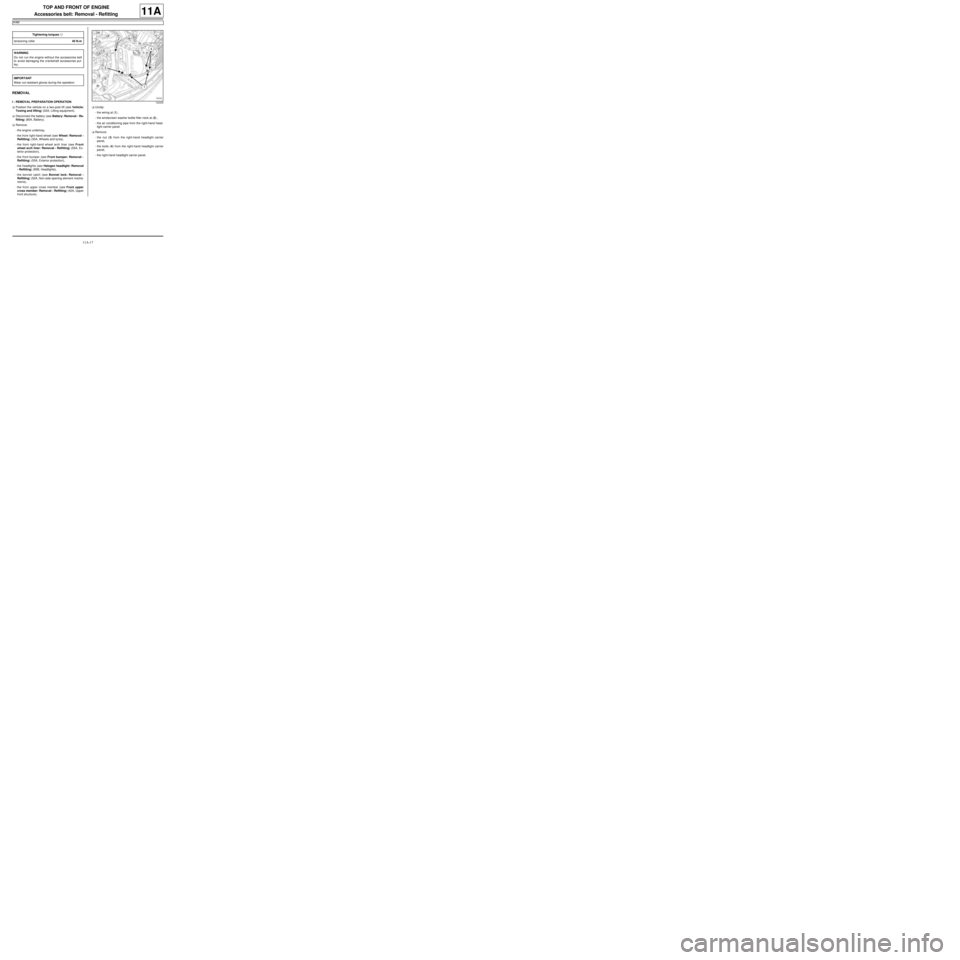

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure).aUnclip:

-the wiring at (1) ,

-the windscreen washer bottle filler neck at (2) ,

-the air conditioning pipe from the right-hand head-

light carrier panel.

aRemove:

-the nut (3) from the right-hand headlight carrier

panel,

-the bolts (4) from the right-hand headlight carrier

panel,

-the right-hand headlight carrier panel. Tightening torquesm

tensioning roller40 N.m

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

IMPORTANT

Wear cut-resistant gloves during the operation.132339

Page 142 of 652

11A-25

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

K4M

11A

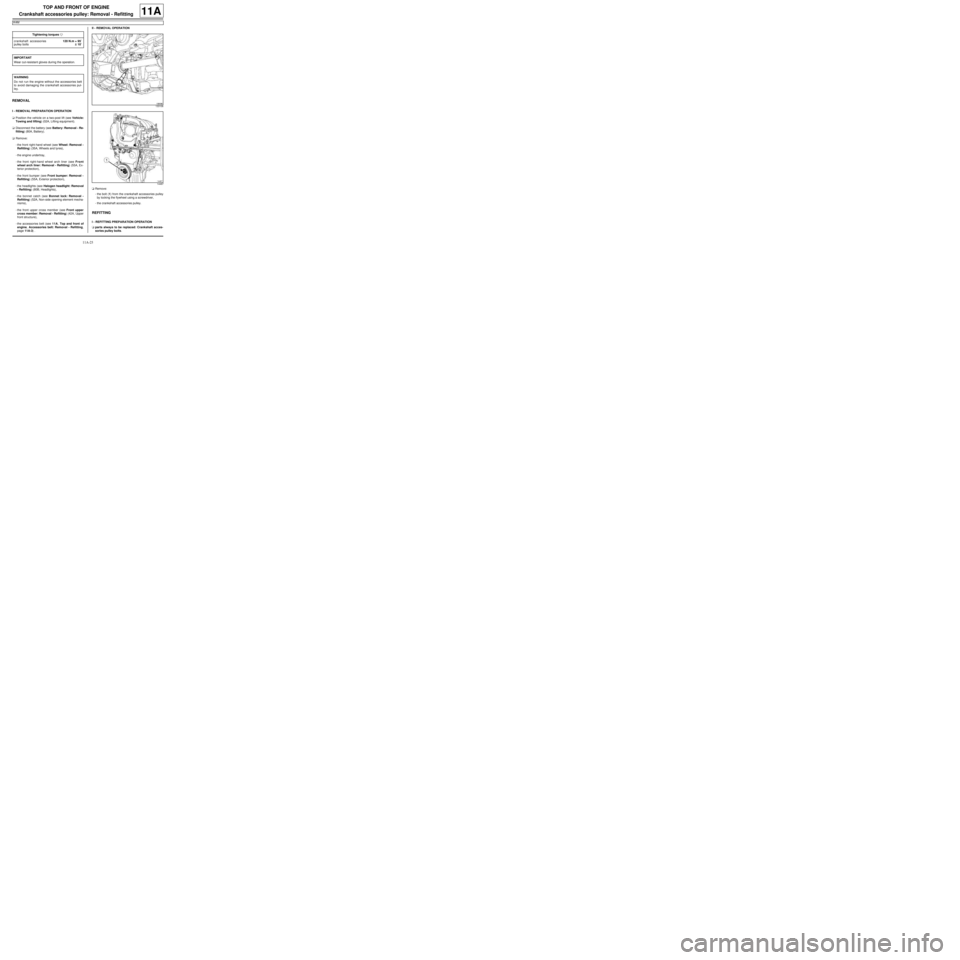

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .II - REMOVAL OPERATION

aRemove:

-the bolt (1) from the crankshaft accessories pulley

by locking the flywheel using a screwdriver,

-the crankshaft accessories pulley.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Crankshaft acces-

sories pulley bolts. Tightening torquesm

crankshaft accessories

pulley bolts120 N.m + 95˚

±± ± ±

10˚

IMPORTANT

Wear cut-resistant gloves during the operation.

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

133106

14487

Page 155 of 652

11A-38

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (80B, Headlights),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) . Special tooling required

Mot. 1672Low er engine support.

Mot. 1489TDC locating pin.

Mot. 1430Set of 5 crankshaft and cam-

shaft pulley timing pins.

Tightening torquesm

tensioning roller bolt27 N.m

camshaft pulley wheel

bolts14 N.m

TDC setting pin plug25 N.m

cylinder head sus-

pended mounting bolts25 Nm

IMPORTANT

Wear protective gloves during the operation.

WARNING

The belt must be replaced with a new one if it has

been removed.

WARNING

When replacing the belt, always replace the tension

wheels and idler pulleys.

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

Page 231 of 652

11A-114

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K9K

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front engine cover.

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (80B, Headlights),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) .

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRemove:

-the nut from the dipstick guide,

-the dipstick guide.

aDisconnect:

-the injector connectors,

-the heater plug connectors ,

-the connectors to the high pressure pump,

-injector rail pressure sensor connector,

-the accelerometer connector.

aRemove the nut from the engine wiring channel.

aMove aside the engine wiring.

aDisconnect the fuel inlet and return pipes from the

high pressure pump. Special tooling required

Mot. 1202-01Clip pliers for hose clips

(large size).

Mot. 1202-02Clip pliers for hose clips

(small size)

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

cylinder head bolt tightening gauge (angular mea-

suring type)

Tightening torquesm

cylinder head bolts (ini-

tial torque)25 N.m

cylinder head bolts270˚ ±± ± ±

10˚

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to r un.

IMPORTANT

Dur ing this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

Page 328 of 652

12B-3

TURBOCHARGING

Turbocharging: Precautions for the repair

D4F or K9K

12B

One by one, clean the pipes removed with the parts

washer :

-brush as much of the inside of the pipe as possible

(only use brushes with plastic bristles),

-wash plenty of cleaning product from the cleaning sta-

tion through the pipe,

-allow the cleaned pipe to drain by standing it upright,

-ensure the cleaning product has drained out com-

pletely (check areas where liquid may be retained,

e.g. gaiters, resonators etc.).

Dry the pipes one by one using a compressed air spray

gun.

For pipes comprising several components:

-assemble the components, taking note of their correct

fitting position (10) .

Refit:

-the air pipe(between the air filter unit and the turbo-

charger) (A) ,

-the air pipe (B) (between the turbocharger and the in-

tercooler).

Refit the intercooler, if fitted to the vehicle (see 12B,

Turbocharging, Intercooler: Removal - Refitting,

page 12B-18) .V - LUBRICATION CIRCUIT**: INSTRUCTIONS

FOLLOWING MECHANICAL DAMAGE TO THE

TURBOCHARGER

Drain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22) .

Replace the oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting, page

10A-29) .

Only fill the engine with a suitable oil type (see Engine

oil: Specifications) (Technical Note 6013A, 04A, Lu-

bricants).

VI - GENERAL INSTRUCTIONS TO BE FOLLOWED

WHEN REMOVING A TURBOCHARGER

Always replace:

-the oil supply pipe:

•if the pipe is blocked, even partially (due to scale,

carbonised oil etc.),

•if the pipe is fitted with self-retaining seals.

-the oil return pipe:

•if the pipe is blocked, even partially (due to scale,

carbonised oil etc.),

•if the pipe is fitted with self-retaining seals.

-all seals that have been removed,

-all fittings that have been removed.

When starting the engine:

-do not accelerate,

-allow the engine to run for 1 minute,the time taken for

the oil circuit pressure to increase (until the oil pres-

sure warning light on the instrument panel goes out),

-accelerate several times at no load,

-check the air circuit and the oil circuit for leaks.

112771

Note:

(**) These instructions relating to the lubrication cir-

cuit must always be followed in all cases of

mechanical damage as listed above.

WARNING

Failure to observe the following procedure may lead

to destr uction of the turbocharger.

Page 390 of 652

13B-29

DIESEL INJECTION

Flow actuator: Removal - Refitting

K9K

13B

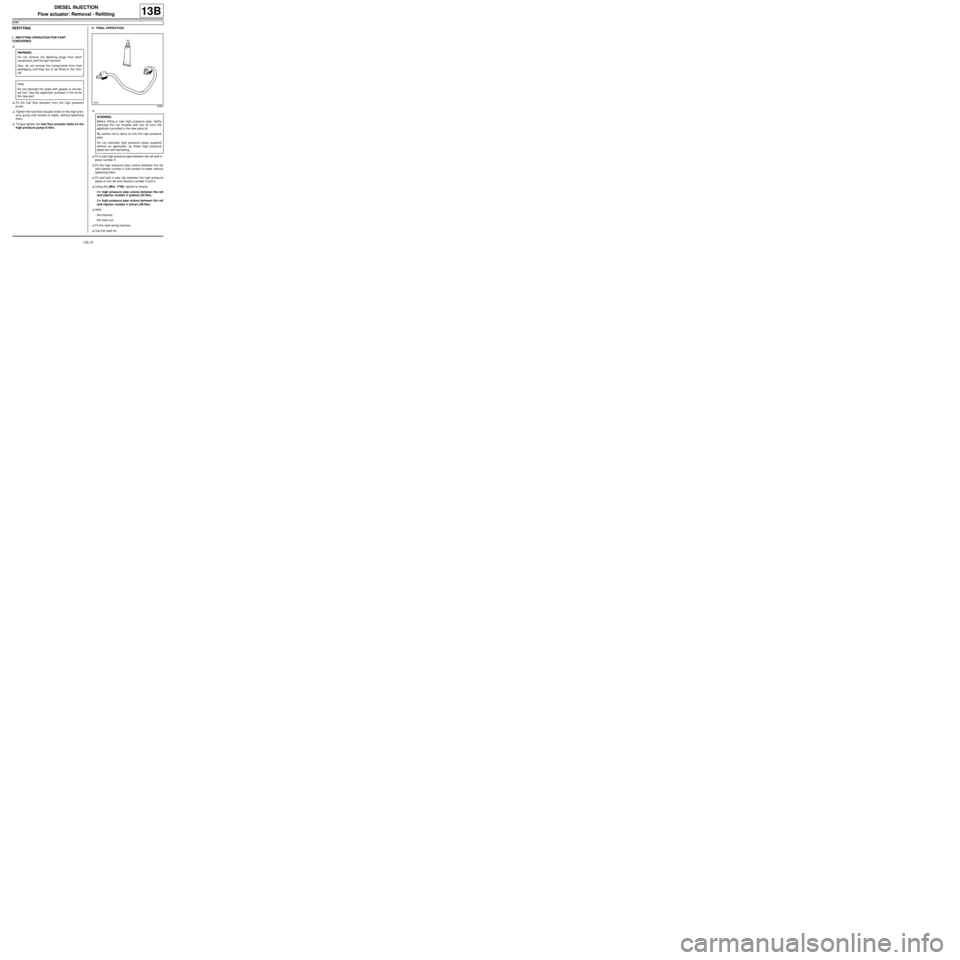

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

a

aFit the fuel flow actuator onto the high pressure

pump.

aTighten the fuel flow actuator bolts on the high pres-

sure pump until contact is made, without tightening

them.

aTorque tighten the fuel flow actuator bolts on the

high pressure pump (6 Nm).II - FINAL OPERATION.

a

aFit a new high pressure pipe between the rail and in-

jector number 4.

aFit the high pressure pipe unions between the rail

and injector number 4 until contact is made, without

tightening them.

aFit and lock a new clip between the high pressure

pipes on the rail and injectors number 3 and 4.

aUsing the (Mot. 1746), tighten to torque:

-the high pressure pipe unions between the rail

and injector number 4 (yellow) (24 Nm),

-the high pressure pipe unions between the rail

and injector number 4 (silver) (28 Nm).

aRefit:

-the channel,

-the neck nut.

aFit the neck wiring harness.

aClip the neck on. WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

Note:

Do not lubricate the seals with grease or old die-

sel fuel. Use the applicator provided in the kit for

the new part.

20960

WARNING

Before fitting a new high pressure pipe, lightly

lubricate the nut threads with the oil from the

applicator provided in the new parts kit.

Be careful not to allow oil into the high pressure

pipe.

Do not lubricate high pressure pipes supplied

without an applicator, as these high pressure

pipes are self-lubr icating.

Page 398 of 652

13B-37

DIESEL INJECTION

High pressure pipe between pump and rail: Removal - Refitting

K9K

13B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aClean the high pressure pipe unions (6) between the

pump and the rail (see 13B, Diesel injection, Die-

sel injection: Precautions for the repair, page

13B-1) .

aRemove the high pressure pipe (6) between the

pump and the rail and discard it.

aFit suitable blanking plugs on:

-the high pressure pump,

-the injector rail.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aII - REFITTING OPERATION FOR PART

CONCERNED

a

aFit a new high pressure pipe between the pump and

the rail.

aScrew on the high pressure pipe unions between the

pump and the rail without tightening them until con-

tact is made.

aUsing the (Mot. 1746), tighten to torque:

-the high pressure pipe unions between the

pump and the yellow rail (24 Nm),

-the high pressure pipe unions between the

pump and the silver rail (28 Nm).

III - FINAL OPERATION.

aRefit:

-the channel,

-the neck nut.

aFit the neck wiring harness.

121419

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

Only remove the blanking plugs from the pro-

tected components at the last possible moment.

Also, do not remove the components from their

packaging until just before fitting them to the

vehicle.

20960

WARNING

Before fitting a new high pressure pipe, lightly

lubricate the nut threads with oil from the applica-

tor provided in the new par t.

Be careful not to allow oil into the high pressure

pipe.

Do not lubricate high pressure pipes supplied

without an applicator; these pipes are self-lubri-

cating.